Professional Documents

Culture Documents

Asme CCase 1996-2

Uploaded by

ADAMJSRAOOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme CCase 1996-2

Uploaded by

ADAMJSRAOCopyright:

Available Formats

85

Asme BPVC Code Cases 1998 Edition CCASE11996 06-15-98 12:59:09

CASE

1996-2

CASES OF ASME BOILER AND PRESSURE VESSEL CODE

Approval Date: December 10, 1989

See Numeric Index for expiration

and any reafrmation dates.

Case 1996-2

Electric Resistance Welded Low Alloy Steel Boiler

and Superheater Tubes

Section I

Inquiry: May electric resistance welded low alloy

steel tubes with the chemical analysis shown in Table

1, and minimum mechanical properties as shown in

Table 2, that otherwise conform to SA-250, be used

in Section I construction?

Reply: It is the opinion of the Committee that electric

resistance welded low alloy steel tubes having the

chemical requirements shown in Table 1 and room

temperature mechanical property requirements as shown

in Table 2 may be used in Section I construction,

provided that:

(a) the material shall meet the chemical analysis and

minimum tensile requirements described in the Inquiry

and shall otherwise meet the requirements of SA-250

except as shown in (b) and (c) below;

(b) the tubing shall be furnished in the full annealed,

isothermal annealed, or normalized and tempered condi-

tion. If furnished in the normalized and tempered

condition, the minimum tempering temperature shall

be 1200F;

(c) the hardness shall not exceed 163 HB (85 HRB);

(e) each tube shall be subjected to one of the nonde-

structive electric tests per SA-450;

(d) the maximum allowable stress values for the

material shall be those given in Table 3 or 4;

(e) this material shall be considered P-No. 3, Group

No. 1;

(f) a manufacturers test report meeting the require-

ments of SA-450 shall be provided;

(g) this Case number shall be shown in the material

certication and marking of the material.

This is Electrontic File Page # 85

TABLE 1

GENERAL REQUIREMENTS

Element Composition, %

Carbon 0.100.20

Manganese 0.300.61

Phosphorus, max. 0.030

Sulfur, max. 0.020

Silicon 0.100.30

Chromium 0.500.81

Molybdenum 0.440.65

TABLE 2

MECHANICAL PROPERTY REQUIREMENTS

Tensile strength, min., ksi 60

Yield strength, min., ksi 30

Elongation in 2 in., min., % 30 [Note (1)]

GENERAL NOTE: For longitudinal strip tests, a deduction of 1.50%

for each

1

32

in. decrease in wall thickness below

5

16

in. from the basic

minimum elongation shall be made.

NOTE:

(1) The following table gives the computed minimum values:

Elongation in 2 in.,

Wall Thickness, in. min., %

5

16

(0.312) 30.00

9

32

(0.281) 28.50

1

4

(0.250) 27.00

7

32

(0.219) 25.50

3

16

(0.188) 24.00

5

32

(0.156) 22.50

1

8

(0.125) 21.00

3

32

(0.094) 19.50

1

16

(0.062) 18.00

GENERAL NOTE: The above table gives the computed minimum

elongation values for each

1

32

in. decrease in wall thickness. Where

the wall thickness lies between two values shown above, the minimum

elongation value shall be determined by the following equation:

E p 48t + 15.00

where

E p elongation in 2 in., %

t p actual thickness for specimen, in.

86

Asme BPVC Code Cases 1998 Edition CCASE11996 06-15-98 12:59:09

CASE (continued)

1996-2

CASES OF ASME BOILER AND PRESSURE VESSEL CODE

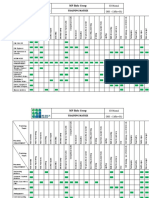

TABLE 3

Maximum Allowable

For Metal Temperature Stress Values, ksi

Not Exceeding, F [Note (1)]

20 to 400 12.8

500 12.8

600 12.8

650 12.8

700 12.8

750 12.6

800 12.2

850 11.9

900 11.6

950 7.8

1000 5.0

NOTE:

(1) These values include a joint efciency factor of 0.85.

TABLE 4

Maximum Allowable

For Metal Temperature Stress Values, ksi

Not Exceeding, F [Notes (1) through (5)]

20 to 400 15.0

500 15.0

600 15.0

650 15.0

700 15.0

750 14.8

800 14.4

850 14.0

900 13.7

950 9.2

1000 5.9

NOTES:

(1) The tubing shall be used for boiler, waterwall, superheater, and

economizer tubes that are enclosed within the setting.

(2) The maximum outside diameter shall be 3

1

2

in.

(3) The weld seam of each tube shall be subjected to an angle-beam

ultrasonic inspection per SA-450.

(4) Each tube shall be subjected to a nondestructive electric test per

SA-450 over its entire length.

(5) This Case number shall be shown in the Manufacturers Data

Report.

This is Electrontic File Page # 86

You might also like

- Asme Ccase - 2059Document2 pagesAsme Ccase - 2059ADAMJSRAONo ratings yet

- Case 2179-3Document2 pagesCase 2179-3Aiyappa DevrajNo ratings yet

- 1876 3Document4 pages1876 3hogoyoNo ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- Asme CCase 2063-3Document2 pagesAsme CCase 2063-3ADAMJSRAONo ratings yet

- Asme CCase 2029-2Document2 pagesAsme CCase 2029-2ADAMJSRAONo ratings yet

- Iiw 1693 05Document19 pagesIiw 1693 05Pradip Goswami100% (1)

- Astm A618Document4 pagesAstm A618Mohamed Farouk100% (1)

- A 632 - 02 Qtyzmi0wmkeDocument4 pagesA 632 - 02 Qtyzmi0wmkeLUISALBERTO06011985No ratings yet

- Specification For Seamless Copper Alloy Pipe and TubeDocument11 pagesSpecification For Seamless Copper Alloy Pipe and Tubeomsingh1988No ratings yet

- Astm A333Document7 pagesAstm A333Luis Evangelista Moura Pacheco100% (3)

- Asme 2153Document1 pageAsme 2153Varma DantuluriNo ratings yet

- A210-A210m - 02Document3 pagesA210-A210m - 02vmonrroy7450No ratings yet

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForJuan Pablo BautistaNo ratings yet

- Asme Section II A Sa-209 Sa-209mDocument6 pagesAsme Section II A Sa-209 Sa-209mAnonymous GhPzn1xNo ratings yet

- Asme CCase 2038-4Document2 pagesAsme CCase 2038-4ADAMJSRAONo ratings yet

- Fundamentos Del Codigo ASME, Secciones I y VIII Div. 1Document50 pagesFundamentos Del Codigo ASME, Secciones I y VIII Div. 1white9013No ratings yet

- A 822 - 90 r00 Qtgymi9bodiyts1sruqDocument5 pagesA 822 - 90 r00 Qtgymi9bodiyts1sruqsachinguptachdNo ratings yet

- ASTM A537 Standard SpecificationDocument4 pagesASTM A537 Standard SpecificationLeon SanchezNo ratings yet

- WS-302 Ab 11302021Document7 pagesWS-302 Ab 11302021quality cncNo ratings yet

- 1750 22Document4 pages1750 22hogoyoNo ratings yet

- 2488 2Document2 pages2488 2hogoyoNo ratings yet

- Asme Questions and Answers Part - IvDocument4 pagesAsme Questions and Answers Part - IvAshwani Dogra100% (1)

- QTIWOS9BMJA5TQDocument3 pagesQTIWOS9BMJA5TQquiensabe0077No ratings yet

- Asme Section II A Sa-358 Sa-358mDocument10 pagesAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xNo ratings yet

- Asme Ccase - 2058Document2 pagesAsme Ccase - 2058ADAMJSRAONo ratings yet

- A 789 - A 789M - 04 Qtc4os9bnzg5tqDocument4 pagesA 789 - A 789M - 04 Qtc4os9bnzg5tqAhmad HajeerNo ratings yet

- A334Document6 pagesA334Aleksei AvilaNo ratings yet

- Gray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)Document4 pagesGray Iron Castings For Pressure-Containing Parts For Temperatures Up To 650°F (350°C)quiensabe0077No ratings yet

- Seamless and Welded Ferritic/Austenitic Stainless Steel PipeDocument6 pagesSeamless and Welded Ferritic/Austenitic Stainless Steel PipeJosé Ramón GutierrezNo ratings yet

- Sa 203Document4 pagesSa 203gst ajahNo ratings yet

- Code Case 2304-2 - Alloy Uns35045Document2 pagesCode Case 2304-2 - Alloy Uns35045uvarajmecheriNo ratings yet

- TDC PP742 F2Document3 pagesTDC PP742 F2Arjun PrajapatiNo ratings yet

- API 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsDocument13 pagesAPI 570 Authorized Piping Inspector Preparatory Program Mock Exam QuestionsShanawas Abdul Razak80% (5)

- Asme B31.3Document69 pagesAsme B31.39440864459100% (4)

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocument4 pagesASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaNo ratings yet

- IGS-M-PL-02-1 (3) Jul. 2010: ApprovedDocument18 pagesIGS-M-PL-02-1 (3) Jul. 2010: ApprovedMehdi orojluNo ratings yet

- Seamless Pipes - API 5L Grade X65 PSL 2Document2 pagesSeamless Pipes - API 5L Grade X65 PSL 2shiv kr dubeyNo ratings yet

- Sa 537Document6 pagesSa 537Mauricio Carestia100% (1)

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDocument5 pagesTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalNo ratings yet

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDocument6 pagesTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalNo ratings yet

- Technical Notes - B31.3Document36 pagesTechnical Notes - B31.3Amit Pandey100% (1)

- Asme CCase 2067-2Document2 pagesAsme CCase 2067-2ADAMJSRAONo ratings yet

- Astm A387 A387m 1992Document6 pagesAstm A387 A387m 1992Alberto Alexander RodriguezNo ratings yet

- Seamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForDocument3 pagesSeamless Medium-Carbon Steel Boiler and Superheater Tubes: Standard Specification ForJoshua SteigerwaldNo ratings yet

- ASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceDocument4 pagesASTM A426 Centrifugally Cast Ferritic Alloy Steel Pipe For High - Temperature ServiceSumedh ParadkarNo ratings yet

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocument4 pagesA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98No ratings yet

- Seamless and Welded Carbon and Alloy-Steel Tubes For Low-Temperature ServiceDocument6 pagesSeamless and Welded Carbon and Alloy-Steel Tubes For Low-Temperature ServiceAlphaEcc EngineeringTeamNo ratings yet

- Asme Section II A Sa-395Document12 pagesAsme Section II A Sa-395Anonymous GhPzn1xNo ratings yet

- A 789 - A 789M - 02 Qtc4os0wmkeDocument4 pagesA 789 - A 789M - 02 Qtc4os0wmkeAhmad HajeerNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Rechargeable Batteries Applications HandbookFrom EverandRechargeable Batteries Applications HandbookRating: 2 out of 5 stars2/5 (1)

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- API exam set 10Document26 pagesAPI exam set 10ADAMJSRAONo ratings yet

- API exam set 11Document11 pagesAPI exam set 11ADAMJSRAONo ratings yet

- Asme CCase 2016-1Document2 pagesAsme CCase 2016-1ADAMJSRAONo ratings yet

- Asme Ccase - 2083Document2 pagesAsme Ccase - 2083ADAMJSRAONo ratings yet

- Asme Ccase - 2053Document2 pagesAsme Ccase - 2053ADAMJSRAONo ratings yet

- Asme CCase 2067-2Document2 pagesAsme CCase 2067-2ADAMJSRAONo ratings yet

- Asme CCase 2091-2Document2 pagesAsme CCase 2091-2ADAMJSRAONo ratings yet

- Asme CCase 2016-1Document2 pagesAsme CCase 2016-1ADAMJSRAONo ratings yet

- Asme CCase 2079-1Document2 pagesAsme CCase 2079-1ADAMJSRAONo ratings yet

- Asme Ccase - 2058Document2 pagesAsme Ccase - 2058ADAMJSRAONo ratings yet

- Asme Ccase - 2073Document2 pagesAsme Ccase - 2073ADAMJSRAONo ratings yet

- Asme CCase 2067-2Document2 pagesAsme CCase 2067-2ADAMJSRAONo ratings yet

- Asme Ccase - 2069Document2 pagesAsme Ccase - 2069ADAMJSRAONo ratings yet

- Asme CCase 2055-1Document2 pagesAsme CCase 2055-1ADAMJSRAONo ratings yet

- Asme Ccase - 2046Document2 pagesAsme Ccase - 2046ADAMJSRAONo ratings yet

- Asme Ccase - 2056Document2 pagesAsme Ccase - 2056ADAMJSRAONo ratings yet

- Asme Ccase - 2053Document2 pagesAsme Ccase - 2053ADAMJSRAONo ratings yet

- Asme CCase 2033-2Document2 pagesAsme CCase 2033-2ADAMJSRAONo ratings yet

- Asme Ccase - 2034Document2 pagesAsme Ccase - 2034ADAMJSRAONo ratings yet

- Asme CCase 2043-2Document2 pagesAsme CCase 2043-2ADAMJSRAONo ratings yet

- Asme CCase 2029-2Document2 pagesAsme CCase 2029-2ADAMJSRAONo ratings yet

- Asme CCase 2038-4Document2 pagesAsme CCase 2038-4ADAMJSRAONo ratings yet

- Asme CCase 2016-1Document2 pagesAsme CCase 2016-1ADAMJSRAONo ratings yet

- Asme CCase 2018-2Document2 pagesAsme CCase 2018-2ADAMJSRAONo ratings yet

- Asme CCase 2016-1Document2 pagesAsme CCase 2016-1ADAMJSRAONo ratings yet

- Asme Ccase - 2056Document2 pagesAsme Ccase - 2056ADAMJSRAONo ratings yet

- Asme Ccase - 1998Document2 pagesAsme Ccase - 1998ADAMJSRAONo ratings yet

- Asme CCase 2010-3Document2 pagesAsme CCase 2010-3ADAMJSRAONo ratings yet

- IMG - 0092 PSME Code 2012 90Document1 pageIMG - 0092 PSME Code 2012 90Bugoy2023No ratings yet

- Mtech Geotechnical Engineering 2016Document48 pagesMtech Geotechnical Engineering 2016Venkatesh ThumatiNo ratings yet

- Alimak AustraliancontractminingDocument5 pagesAlimak AustraliancontractminingmanudemNo ratings yet

- MP Birla Group: Training MatrixDocument3 pagesMP Birla Group: Training MatrixAprilia kusumaNo ratings yet

- 72 Names of God in HasidimDocument16 pages72 Names of God in HasidimFrancesco VinciguerraNo ratings yet

- Anatomy Mckinley PPT Chapter 1Document65 pagesAnatomy Mckinley PPT Chapter 1Rosa AlcantarNo ratings yet

- The War Archives - Machinery of Conflict. British Military Trucks of WWIIDocument84 pagesThe War Archives - Machinery of Conflict. British Military Trucks of WWIISebastijan Kerše100% (10)

- English Idea BookDocument2 pagesEnglish Idea Bookapi-551731988No ratings yet

- CP I-O Modules PDFDocument91 pagesCP I-O Modules PDFVlad ChioreanNo ratings yet

- Minicap FTC260, FTC262: Technical InformationDocument20 pagesMinicap FTC260, FTC262: Technical InformationAmanda PorterNo ratings yet

- AWWA Bacterial Regrowth in Distr Sys PDFDocument368 pagesAWWA Bacterial Regrowth in Distr Sys PDFsaishankarlNo ratings yet

- Compression Molding of Gypsum Blocks Using Ecological Brick MachinesDocument11 pagesCompression Molding of Gypsum Blocks Using Ecological Brick Machinessami fanuaelNo ratings yet

- 21734Document67 pages21734Jeef100% (4)

- Portland Traffic Crash Report 2021Document11 pagesPortland Traffic Crash Report 2021KGW NewsNo ratings yet

- VMA 2520 eDocument7 pagesVMA 2520 eVijaya SimhaNo ratings yet

- 02 - AFT - Know Your Pump & System Curves - Part 2ADocument8 pages02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNo ratings yet

- DD Cen TR 10347-2006Document14 pagesDD Cen TR 10347-2006prabagaran88% (8)

- A Community School: Research Aspect 2 ReportDocument13 pagesA Community School: Research Aspect 2 ReportMarsha MianNo ratings yet

- Pic24fj256ga705 Family Data Sheet Ds30010118eDocument424 pagesPic24fj256ga705 Family Data Sheet Ds30010118eD GzHzNo ratings yet

- Mahamrityunjaya MantraDocument8 pagesMahamrityunjaya MantraBalakrishnan KannanNo ratings yet

- Case CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFDocument701 pagesCase CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFJorge Martinez100% (3)

- Intelligence, Reasoning, Creativity, and WisdomDocument3 pagesIntelligence, Reasoning, Creativity, and WisdomSammy DeeNo ratings yet

- John 16 33 Sweet Peace For Tried Believers - Charles SpurgeonDocument15 pagesJohn 16 33 Sweet Peace For Tried Believers - Charles Spurgeonstevel75No ratings yet

- SRWM M.PDocument34 pagesSRWM M.PAmare BayeNo ratings yet

- Price List Grand I10 Nios DT 01.05.2022Document1 pagePrice List Grand I10 Nios DT 01.05.2022VijayNo ratings yet

- CHM4943 Wastewater TreatmentDocument7 pagesCHM4943 Wastewater TreatmentUsman GhaniNo ratings yet

- Sri Lanka's Mineral Resources Can Enrich Country's CoffersDocument139 pagesSri Lanka's Mineral Resources Can Enrich Country's CoffersPrashan Francis100% (3)

- Papaya Burger - Chapter 1 6Document129 pagesPapaya Burger - Chapter 1 6Nicole Velasco NuquiNo ratings yet

- Diversification in Flavoured Milk: A ReviewDocument6 pagesDiversification in Flavoured Milk: A ReviewInternational Journal of Clinical and Biomedical Research (IJCBR)No ratings yet

- 1 5109354204116287644 PDFDocument336 pages1 5109354204116287644 PDFGerardoNo ratings yet