Professional Documents

Culture Documents

Pneumatic Slide Gate

Uploaded by

emad sabriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pneumatic Slide Gate

Uploaded by

emad sabriCopyright:

Available Formats

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.

doc Page 1 of 7

A N I SO 9 0 0 1 COMP AN Y

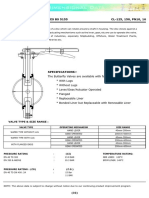

PNEUMATIC SLIDE GATE

INSTALLATION

&

OPERATION MANUAL

HYQUIP SYSTEMS LTD,

Rotolok Division,

HYQUIP HOUSE

1-1-564/1/A, GANDHINAGAR,

HYDERABAD 500 020 (A.P.)

Ph. # . 761 3222, 760 7907, 760 7908.

Fax # . ++91 40 761 1468.

E mail : hrpl@hyquip.org

URL : www.hyquiprotolok.com

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.doc Page 2 of 7

A N I SO 9 0 0 1 COMP AN Y

TABLE OF CONTENTS

FOR

SLIDE GATES

SECTION DESCRIPTION PAGE NO.

I GENERAL INFORMATION 2

II OPERATION 3

III INSTALLATION 4

III MAINTENANCE 5

III RECOMMENDED LUBRICANTS 6

III TECHNICAL SPECIFICATIONS 7

IV G.A. DRAWING 8

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.doc Page 3 of 7

A N I SO 9 0 0 1 COMP AN Y

S L I D E G A T E S

G E N E R A L I N F O R M A T I O N

These instructions have been prepared in an effort to acquaint you with the fundamentals of this Slide Gates. It is

important that these instructions be read carefully and that the procedure outlined be understood and followed.

It has been our experience that in most instances Slide Gates can be properly erected and operated by field personnel if

care is taken initially to the steps covered in this booklet.

This Slide Gates has been designed for your requirements, but proper attention is necessary to ensure peak operating

efficiency.

It is strongly suggested that if you encounter unexplainable difficulties during initial start up of operation, you contact

HYQUIP ROTOLOK PVT. LTD., 1-1-564/1/A, Gandhinagar, Hyderabad 500 020, Ph: 27613222, 27607907, 27607908.

Fax No. ++91 40 2761 1468, E-mail : hrpl@hyquip.org. Our field personnel are usually available for supervisory

assistance.

A Slide Gates is often only one of many pieces of equipment in a material handling system and its proper operation is

contingent upon the correct operation of the other pieces of equipment.

These Slide Gates will give you many years of satisfactory service, but in order to do so, maintenance is of vital

importance. There are number of normal wearing parts in this Slide Gates which will require periodic replacement.

Experience with your own installation will indicate the frequency of such replacement. It is our effort to have available

from stock as many replacement parts as possible but there are cases where this is not feasible. For that reason we

have included a section covering recommended spare parts. We urge you to give serious consideration to the early

purchase of these items to avoid lengthy and costly shutdowns due to not having these on hand when needed.

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.doc Page 4 of 7

A N I SO 9 0 0 1 COMP AN Y

O P E R A T I O N

Once the Slide Gates are put in operation, observe for wear and tear of the Flap.

The Operation and Maintenance Manual for the same is enclosed herewith for your ready reference.

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.doc Page 5 of 7

A N I SO 9 0 0 1 COMP AN Y

I N S T A L L A T I O N

1. Prior to installation the following are to be checked :

a) Check for receipt of all the materials as per Part List.

b) Check for any damage of Body / Arms if any, to be rectified before installation.

c) Check matching Flanges are as per our Drawing.

d) Inspection covers to be removed before assembly / installation.

2. All the loose parts to be put in position as per the match markings and assembled.

3. The Valve should be aligned and levelled completely and the assembly bolts to be tightened.

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.doc Page 6 of 7

A N I SO 9 0 0 1 COMP AN Y

M A I N T E N A N C E

1. Lubrication of the bearings with lubricant as specified in Section IV.

2. The frequency of the lubrication depends on the application and hours of operation.

3. Replace the bearing before it is fully worn out.

4. Check periodically for any wear of Flap / Liner and repair / replace accordingly.

\\Rotolok1\h r p l\DATA\O & M Manuals\Pneumatic Slide Gate.doc Page 7 of 7

A N I SO 9 0 0 1 COMP AN Y

R E C O M M E N D E D L U B R I C A N T S

Recommended grade of lubricants for bearing :

Recommended Grease :

10C BP

Bearings SERUOGEN 2 BP-ENERGREASE RBB-2

The grease should be pumped through the grease nipples provided on the bearing housings. Over greasing

will result in some grease leakage eventually finding its way into bearing race and this will increase the

viscocity of lubricant resulting in over heating of the bearing.

The lubricants given are put forward in association with the manufacturers and commission of any equivalent

make does not mean that it cannot be used. The particular supplier must however accept full responsibility

that grade outside this list are fully equivalent.

You might also like

- Chapter 1 Oil Seal IntroductionDocument0 pagesChapter 1 Oil Seal IntroductionZMCONTROLNo ratings yet

- SSP421 Body BasicsDocument76 pagesSSP421 Body Basicsmamuko100% (3)

- Symptoms Causes Remedies: Rolling Bearing DamageDocument1 pageSymptoms Causes Remedies: Rolling Bearing Damageemad sabriNo ratings yet

- RF Return Line FilterDocument8 pagesRF Return Line Filterboobalan_shriNo ratings yet

- Oil Expeller Shaft Analysis JournalDocument11 pagesOil Expeller Shaft Analysis JournalRemartin MaglantayNo ratings yet

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDocument5 pagesMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNo ratings yet

- Orbinox VG08 Knife Gate ValveDocument8 pagesOrbinox VG08 Knife Gate ValveYorkistNo ratings yet

- Maintain Submersible Pumps Oil Check DiagnosisDocument36 pagesMaintain Submersible Pumps Oil Check DiagnosiskaritocorredorpeaNo ratings yet

- Shell InspectionDocument23 pagesShell Inspectionemad sabri100% (1)

- Alignment StandardsDocument6 pagesAlignment StandardsFidelFornolles100% (2)

- 3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingDocument4 pages3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingPhamLeDanNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Design DocumentDocument10 pagesDesign DocumentLiza WoodsNo ratings yet

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedDocument47 pagesInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasNo ratings yet

- Effective MaintenanceDocument19 pagesEffective Maintenanceemad sabri100% (1)

- Effective MaintenanceDocument19 pagesEffective Maintenanceemad sabri100% (1)

- Brosur REVCO WPA GEAR REDUCER PDFDocument52 pagesBrosur REVCO WPA GEAR REDUCER PDFtisna drafterNo ratings yet

- Cert KONDO HoistDocument1 pageCert KONDO HoistSuparerk SirivedinNo ratings yet

- Replacement of Seawater Condenser MOVsDocument6 pagesReplacement of Seawater Condenser MOVsBilel MahjoubNo ratings yet

- RDSO - Vendor Directory July 16 FinalDocument233 pagesRDSO - Vendor Directory July 16 Finalabhics6750% (2)

- Shurjoint 2017 Installation InstructionsDocument241 pagesShurjoint 2017 Installation InstructionsbalotNo ratings yet

- Chinese Centrifuge LW450x1000 Centrifuge ManualDocument34 pagesChinese Centrifuge LW450x1000 Centrifuge ManualNurlan Valiyev100% (1)

- Closure Data PEDocument2 pagesClosure Data PEjowarNo ratings yet

- The Most Important Books of The Cement IndustryDocument3 pagesThe Most Important Books of The Cement Industryemad sabriNo ratings yet

- The Most Important Books of The Cement IndustryDocument3 pagesThe Most Important Books of The Cement Industryemad sabriNo ratings yet

- Alternative fuels optimize cement production costs and reduce emissionsDocument25 pagesAlternative fuels optimize cement production costs and reduce emissionsemad sabri100% (1)

- Alternative fuels optimize cement production costs and reduce emissionsDocument25 pagesAlternative fuels optimize cement production costs and reduce emissionsemad sabri100% (1)

- Alternative fuels optimize cement production costs and reduce emissionsDocument25 pagesAlternative fuels optimize cement production costs and reduce emissionsemad sabri100% (1)

- CementDocument24 pagesCementanshuldoc9100% (1)

- Slide Gate Manual 2014 11Document25 pagesSlide Gate Manual 2014 11Mouayed ZeadanNo ratings yet

- ITB-spc For Tape Coating For UG Piping PDFDocument15 pagesITB-spc For Tape Coating For UG Piping PDFShyam Sundar GayenNo ratings yet

- Gatevalve (Wedge Vs Parallel Slide - Flowserve)Document5 pagesGatevalve (Wedge Vs Parallel Slide - Flowserve)Shameer MajeedNo ratings yet

- Static Pressure Calculation SheetDocument24 pagesStatic Pressure Calculation SheetMuhammad ZubairNo ratings yet

- KB Coupling CatalogueDocument2 pagesKB Coupling CatalogueGaurav BedseNo ratings yet

- Katalog Hydraulic Jack Merek SunrunDocument4 pagesKatalog Hydraulic Jack Merek SunrunFebri SartikaNo ratings yet

- Enhanced PLC-5 Programmable Controllers: Purpose of This DocumentDocument24 pagesEnhanced PLC-5 Programmable Controllers: Purpose of This Documenthunter73No ratings yet

- Pipe Wall ThicknessDocument1 pagePipe Wall ThicknessFurkan Burak MuhammedNo ratings yet

- Bangladesh MGI 300TD Continuous Polyester Production Line Bottle FlakeDocument44 pagesBangladesh MGI 300TD Continuous Polyester Production Line Bottle Flakeswapon kumar shillNo ratings yet

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocument7 pagesResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesNo ratings yet

- Minimum Length and Spacing For Welded Nozzles PDFDocument7 pagesMinimum Length and Spacing For Welded Nozzles PDFSoniNo ratings yet

- Stainless Steel Upn Channels SectionsDocument4 pagesStainless Steel Upn Channels SectionsKriengsak RuangdechNo ratings yet

- Work Method StatementDocument9 pagesWork Method StatementdjvhNo ratings yet

- Fabrication ProcessDocument6 pagesFabrication ProcessSounak ChakrabortyNo ratings yet

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherNo ratings yet

- Fat GensetDocument5 pagesFat GensetYoga AsmaraNo ratings yet

- Butterfly Valve Cycle TestDocument4 pagesButterfly Valve Cycle TestParthiban MechanicalNo ratings yet

- Installation and Maintenance Manual for Jyoti Vertical Turbine PumpsDocument55 pagesInstallation and Maintenance Manual for Jyoti Vertical Turbine PumpsGary Estay MonasteriosNo ratings yet

- C C CCCCCCCCCCCC C CDocument62 pagesC C CCCCCCCCCCCC C CGaurav VashishtNo ratings yet

- BA-1 5 EcoFlex EN SC 11052012 PDFDocument78 pagesBA-1 5 EcoFlex EN SC 11052012 PDFSumayyia QamarNo ratings yet

- SAPP Series PumpsDocument2 pagesSAPP Series Pumpssahildhingra100% (1)

- VV 450/150 Compressor Spare Parts CatalogDocument55 pagesVV 450/150 Compressor Spare Parts CatalogRoy F Bastari100% (1)

- Victaulic DimensionsDocument2 pagesVictaulic DimensionsSH1961No ratings yet

- Butterfly ValveDocument4 pagesButterfly ValveghjtyuNo ratings yet

- Victaulic 2D BlocksDocument8 pagesVictaulic 2D BlocksdemdiinNo ratings yet

- Air Lock Relay: MIL Controls LimitedDocument2 pagesAir Lock Relay: MIL Controls Limitedsumit kumarNo ratings yet

- Fisher 3661Document36 pagesFisher 3661HYDRAULICGURU100% (1)

- Mineral oil centrifuge instruction manualDocument216 pagesMineral oil centrifuge instruction manualVladimirNo ratings yet

- KWT 860R Operating ManualDocument33 pagesKWT 860R Operating ManualElite Cleaning ProductsNo ratings yet

- 02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Document38 pages02 - Ab-Pf1a-C000-B13-Spec-0007 - 02C2.1Walid BdeirNo ratings yet

- HVAC Catalogue 2016Document233 pagesHVAC Catalogue 2016Vincent GabrielNo ratings yet

- Denso Petrolatum TapeDocument1 pageDenso Petrolatum TapeAnonymous 4IpmN7OnNo ratings yet

- Operating Manual MIXDocument28 pagesOperating Manual MIXDorin DragosNo ratings yet

- Dx800 s5 Specification Sheet EnglishDocument3 pagesDx800 s5 Specification Sheet EnglishAntónio Pedro TavaresNo ratings yet

- Internal pressure thickness calculation as per ASME B31.3Document1 pageInternal pressure thickness calculation as per ASME B31.3DikaAnindyajati100% (1)

- Horizontal Boring MachineDocument15 pagesHorizontal Boring MachineMushfik123No ratings yet

- Installation and Operating Manual For Pneumatic Control ValvesDocument1 pageInstallation and Operating Manual For Pneumatic Control ValvesFairos ZakariahNo ratings yet

- Air Compressor ASK-27TDocument5 pagesAir Compressor ASK-27TJonson CaoNo ratings yet

- High HDT Superior Vinyl Ester Resin - Crest731Document3 pagesHigh HDT Superior Vinyl Ester Resin - Crest731GautamNo ratings yet

- Thyssenkrupp Industries India: Polysius Cement DivisionDocument23 pagesThyssenkrupp Industries India: Polysius Cement DivisionunimarinesNo ratings yet

- Multitec RO - 1777.82-10 Instruciones de OperaciónDocument20 pagesMultitec RO - 1777.82-10 Instruciones de OperaciónAlvialvarezNo ratings yet

- 5'' 19.5 - G105 NC50 6.625-3.25Document1 page5'' 19.5 - G105 NC50 6.625-3.25Hamza LahbibenNo ratings yet

- Lovol 1004Document2 pagesLovol 1004Dhee DoodzNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Crankshaft Front Seal InstallSMCS - 1160 - 012Document4 pagesCrankshaft Front Seal InstallSMCS - 1160 - 012Tawanda Tradyboy MorgansNo ratings yet

- Glossary of Conveyor Belt TermsDocument8 pagesGlossary of Conveyor Belt Termsemad sabriNo ratings yet

- UtilitiesDocument17 pagesUtilitiesnkw123No ratings yet

- Growing HerbsDocument10 pagesGrowing Herbsemad sabriNo ratings yet

- Glossary of Conveyor Belt TermsDocument8 pagesGlossary of Conveyor Belt Termsemad sabriNo ratings yet

- UtilitiesDocument17 pagesUtilitiesnkw123No ratings yet

- 2013 Plant Info Summary Sample PDFDocument38 pages2013 Plant Info Summary Sample PDFemad sabriNo ratings yet

- Econ 2Document16 pagesEcon 2ediabcNo ratings yet

- Maximizing Maintenance Effectiveness Through AuditsDocument4 pagesMaximizing Maintenance Effectiveness Through Auditsemad sabriNo ratings yet

- Maximizing Maintenance Effectiveness Through AuditsDocument4 pagesMaximizing Maintenance Effectiveness Through Auditsemad sabriNo ratings yet

- Hammercrusher1 PDFDocument4 pagesHammercrusher1 PDFemad sabriNo ratings yet

- Basic Organic Gardening InformationDocument13 pagesBasic Organic Gardening Informationemad sabriNo ratings yet

- IEEE IASPCA 2012 Conference Plant Tours at TXI Hunter Cement PlantDocument2 pagesIEEE IASPCA 2012 Conference Plant Tours at TXI Hunter Cement Plantemad sabriNo ratings yet

- The Role of Tribology in Engineering Materials: Friction, Lubrication and WearDocument40 pagesThe Role of Tribology in Engineering Materials: Friction, Lubrication and Wearemad sabri100% (1)

- 1Document20 pages1Kelly EstradaNo ratings yet

- Ni HardMaterialDataandApplications 11017 PDFDocument28 pagesNi HardMaterialDataandApplications 11017 PDFhesamalaNo ratings yet

- Operations: The PlantDocument4 pagesOperations: The Plantemad sabriNo ratings yet

- Concepts For Green CementDocument8 pagesConcepts For Green Cementemad sabriNo ratings yet

- Tire and Tire ElementsDocument33 pagesTire and Tire Elementsemad sabri100% (1)

- Lubrication, Friction and Wear PDFDocument31 pagesLubrication, Friction and Wear PDFemad sabriNo ratings yet

- Oracle Silent InstallDocument5 pagesOracle Silent InstallAnuj SinghNo ratings yet

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Document20 pagesSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarNo ratings yet

- Mastertop TC 458 PDFDocument3 pagesMastertop TC 458 PDFFrancois-No ratings yet

- LDRDocument4 pagesLDRRaymond ValdezNo ratings yet

- Banyule Standard DrawingsDocument103 pagesBanyule Standard DrawingsTarek AbulailNo ratings yet

- Xxxpol / 65° Az 17.3 / 17.0 / 17.3 Dbi: DiplexedDocument2 pagesXxxpol / 65° Az 17.3 / 17.0 / 17.3 Dbi: DiplexedMahamoud HamoudNo ratings yet

- TBR Wipro LeanDocument8 pagesTBR Wipro LeanAnonymous fVnV07HNo ratings yet

- High Precision Ball Bearings SolutionsDocument71 pagesHigh Precision Ball Bearings SolutionsTravis DavisNo ratings yet

- Mi 05025Document16 pagesMi 05025walidNo ratings yet

- Tsi 20040109 PDFDocument2 pagesTsi 20040109 PDFenache_marian0% (1)

- Ce R&D/Dli-22/CHANDI/2010-2011 Ce R&D/Dli - 24/CHANDI/2010-2011Document61 pagesCe R&D/Dli-22/CHANDI/2010-2011 Ce R&D/Dli - 24/CHANDI/2010-2011rajjjjjiNo ratings yet

- Ma3022 Propeller Drydockingworks 1 Aug05Document18 pagesMa3022 Propeller Drydockingworks 1 Aug05NAGENDRA KUMAR DNo ratings yet

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 pagesPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinNo ratings yet

- Squashing Commits with RebaseDocument4 pagesSquashing Commits with RebaseDavid BeaulieuNo ratings yet

- Transmission Line Surveyors Face Challenges in Projecting Data onto MapsDocument3 pagesTransmission Line Surveyors Face Challenges in Projecting Data onto MapsTATAVARTHYCH HANUMANRAONo ratings yet

- Satrack Full Report New2Document17 pagesSatrack Full Report New2ammayi9845_930467904No ratings yet

- Part A: - To Be Filled in by Officer From Respective OrganisationDocument1 pagePart A: - To Be Filled in by Officer From Respective OrganisationArcont ScriptNo ratings yet

- TL2 Number SystemsDocument78 pagesTL2 Number SystemsKhushbu SavaliyaNo ratings yet

- Hydraulic: Centrifugal Pump Application Performance CurvesDocument1 pageHydraulic: Centrifugal Pump Application Performance CurvesEdwin ChavezNo ratings yet

- Mine Design and SchedulingDocument10 pagesMine Design and SchedulingLeandro FagundesNo ratings yet

- 30 Days Challenge For Electrical Engineeirng: Pantech SolutionsDocument11 pages30 Days Challenge For Electrical Engineeirng: Pantech SolutionsPerenpanathan Suganthan100% (1)

- Unit One: Wind LoadsDocument67 pagesUnit One: Wind Loadsabdu yimerNo ratings yet

- Technical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000Document88 pagesTechnical Data Demag Hoist Units Volume 2: Double-Rail Crab EZDH 600 - EZDH 1000 Double-Rail Crab EZLDH 600 - EZLDH 2000mohammad khoraminiaNo ratings yet

- CM700 Users GuideDocument13 pagesCM700 Users GuidenurazrreenNo ratings yet

- N-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDDocument9 pagesN-Channel Low QG Mosfet 30V, 100A, 3.3m: MOS-TECH Semiconductor Co.,LTDAnonymous p1ig0zX6p0No ratings yet