Professional Documents

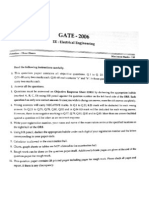

Culture Documents

Arc Flash Sample TO SHARE

Uploaded by

rupesh1000Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arc Flash Sample TO SHARE

Uploaded by

rupesh1000Copyright:

Available Formats

Power Study

Short Circuit

Protective Device Coordination

Arc Flash

Prepared for:

Prepared by:

Brian Arend

SSOE, Inc

Toledo, OH

barend@ssoe.com

419-255-3830, x 1997

Attested by:

Brian Arend P.E.

mm/dd/yyyy

Power Study

SSOE Inc.

5/27/2010

Table of Contents

1. System One-Line with Settings

2. Short Circuit Study

3. Protective Device Coordination

4. Arc Flash Study

mm/dd/yyyy

TO PAGE 5 TO PAGE 2 TO PAGE 4

UTILITY TO 211

S

P

211 MAIN XFMR

Nominal kVA 500.0 kVA

Pri RatedVoltage 12470 V

Sec RatedVoltage 480 V

Z% 2.1700 %

MAIN SWITCH

FEDERAL PACIFIC

LCL-800

Sensor/Trip 800.0 A

MAIN FDR

CableSize 500 AWG

Length 40.0 ft

QtyPerPhase 3

CABLED BUS

CableSize 500 AWG

Length 10.0 ft

QtyPerPhase 1

MAIN GEAR 2 FDR

CableSize 500 AWG

Length 40.0 ft

QtyPerPhase 1

211 MAIN XFMR SEC

480 V

MAIN GEAR 2 BKR

SQUARE D

LC

Sensor/Trip 600.0 A

Settings

Thermal Curve

INST LO (3000A)

MAIN GEAR 2

480 V

SHOP PANEL

480 V

MAIN GEAR

480 V

MAIN 2 BUS

480 V

MAIN BUS

480 V

MAIN GEAR 2 CONNECT

CableSize 5000 AWG

Length 1.0 ft

QtyPerPhase 1

MAIN GEAR CONNECT

CableSize 5000 AWG

Length 1.0 ft

QtyPerPhase 1

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

1

TO PAGE 3

WEST A/C #6 FUSE

BUSSMANN

FRS

Sensor/Trip 200.0 A

EAST A/C #1 FUSE

GOULD SHAWMUT

TRS

Sensor/Trip 150.0 A

LIGHTING PANEL FUSE

EDISON

ECSR

Sensor/Trip 200.0 A

LOOM#9 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

LOOM#10 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

LOOM#12 FUSE

LITTELFUSE

FLSR

Sensor/Trip 80.0 A

LOOM#7 FUSE

BUSSMANN

FRS

Sensor/Trip 60.0 A

LOOM#11 FUSE

BUSSMANN

FRS

Sensor/Trip 70.0 A

XFMR AL FUSE

BUSSMANN

FRS

Sensor/Trip 50.0 A

LOOM#6 FUSE

BUSSMANN

FRS

Sensor/Trip 60.0 A

OFFICE BLOWER FUSE

BUSSMANN

FRS

Sensor/Trip 60.0 A

BIG BATTERY CHARGER FUSE

BUSSMANN

FRS

Sensor/Trip 20.0 A

WEST A/C #6 FDR

CableSize 1 AWG

Length 300.0 ft

QtyPerPhase 1

EAST A/C #1 FDR

CableSize 1 AWG

Length 60.0 ft

QtyPerPhase 1

LIGHTING PANEL FDR

CableSize 3/0 AWG

Length 130.0 ft

QtyPerPhase 1

LOOM#9 FDR

CableSize 6 AWG

Length 180.0 ft

QtyPerPhase 1

LOOM#10 FDR

CableSize 6 AWG

Length 150.0 ft

QtyPerPhase 1

LOOM#12 FDR

CableSize 4 AWG

Length 170.0 ft

QtyPerPhase 1

LOOM#7 FDR

CableSize 10 AWG

Length 250.0 ft

QtyPerPhase 1

LOOM#11 FDR

CableSize 6 AWG

Length 140.0 ft

QtyPerPhase 1

N. VACUUMBKR

BUSSMANN

FRS

Sensor/Trip 60.0 A

N. VACUUMFDR

CableSize 6 AWG

Length 50.0 ft

QtyPerPhase 1

LOOM#6 FDR

CableSize 6 AWG

Length 110.0 ft

QtyPerPhase 1

OFFICE BLOWER FDR

CableSize 6 AWG

Length 110.0 ft

QtyPerPhase 1

BIG BATTERY CHARGER FDR

CableSize 12 AWG

Length 30.0 ft

QtyPerPhase 1

WEST A/C #6

480 V

EAST A/C #1

480 V

LOOM#9

480 V

LOOM #10

480 V

LOOM #12

480 V

LOOM#7

480 V

N. VACUUM

480 V

LOOM #11

480 V

LOOM#6

480 V

OFFICE BLOWER

480 V

BIG BATTERY CHARGER

480 V

LIGHTING PANEL

480 V

XFMR AL FDR

CableSize 2 AWG

Length 10.0 ft

QtyPerPhase 1

S

P

XFMR AL

Nominal kVA 30.0 kVA

Pri RatedVoltage 480 V

Sec RatedVoltage 208 V

Z% 4.2690 %

PANEL AL FDR

CableSize 2 AWG

Length 10.0 ft

QtyPerPhase 1

PANEL AL

208 V

MAIN GEAR

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

2

TO PAGE 2

OFFICE CONDENSOR FUSE

BUSSMANN

FRS

Sensor/Trip 30.0 A

UNIT #6 BLOWER FUSE

BUSSMANN

FRS

Sensor/Trip 25.0 A

AIR COMPRESSOR DRIER FUSE

BUSSMANN

FRS-R

Sensor/Trip 8.0 A

SMALL BATTERY CHARGER FUSE

BUSSMANN

FRS

Sensor/Trip 20.0 A

SHOP SANDER FUSE

BUSSMANN

FRS-R

Sensor/Trip 3.5 A

BLOWER EAST #1 FUSE

GOULD SHAWMUT

TRS

Sensor/Trip 40.0 A

LOOM#3 FUSE

BUSSMANN

FRS

Sensor/Trip 60.0 A

LOOM#8 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

LOOM#2 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

LOOM#5 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

LOOM#1 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

LOOM#4 FUSE

EDISON

ECSR

Sensor/Trip 60.0 A

OFFICE CONDENSOR FDR

CableSize 10 AWG

Length 170.0 ft

QtyPerPhase 1

UNIT #6 BLOWER FDR

CableSize 10 AWG

Length 320.0 ft

QtyPerPhase 1

AIR COMPRESSOR DRIER FDR

CableSize 12 AWG

Length 40.0 ft

QtyPerPhase 1

SMALL BATTERY CHARGER FDR

CableSize 12 AWG

Length 30.0 ft

QtyPerPhase 1

SHOP SANDER FDR

CableSize 12 AWG

Length 50.0 ft

QtyPerPhase 1

BLOWER EAST #1 FDR

CableSize 10 AWG

Length 60.0 ft

QtyPerPhase 1

LOOM#3 FDR

CableSize 6 AWG

Length 195.0 ft

QtyPerPhase 1

LOOM#8 FDR

CableSize 6 AWG

Length 220.0 ft

QtyPerPhase 1

LOOM#2 FDR

CableSize 6 AWG

Length 230.0 ft

QtyPerPhase 1

LOOM#5 FDR

CableSize 6 AWG

Length 140.0 ft

QtyPerPhase 1

LOOM#1 FDR

CableSize 6 AWG

Length 270.0 ft

QtyPerPhase 1

LOOM#4 FDR

CableSize 6 AWG

Length 170.0 ft

QtyPerPhase 1

OFFICE CONDENSOR

480 V

UNIT #6 CONDENSOR

480 V

AIR COMPRESSOR DRIER

480 V

SMALL BATTERY CHARGER

480 V

SHOP SANDER

480 V

BLOWER EAST #1

480 V

LOOM#3

480 V

LOOM#8

480 V

LOOM#2

480 V

LOOM#5

480 V

LOOM#1

480 V

LOOM#4

480 V

MAIN GEAR

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

3

TO PAGE 7 TO PAGE 6

MAIN GEAR 2

480 V

PANEL E (AH-4) BKR

SQUARE D

FA

Sensor/Trip 100.0 A

Settings

Fixed

50HP AIR COMPRESSOR BKR

SQUARE D

FA

Sensor/Trip 100.0 A

Settings

Fixed

LOOM #21 BKR

SQUARE D

FA

Sensor/Trip 90.0 A

Settings

Fixed

PANEL D (AH-3) BKR

SQUARE D

KA

Sensor/Trip 100.0 A

Settings

Thermal Curve

INST HI (1000A)

60HP AIR COMPRESSOR BKR

SQUARE D

KA

Sensor/Trip 125.0 A

Settings

Thermal Curve

INST LO (625A)

LOOM #17 BKR

SQUARE D

FA

Sensor/Trip 60.0 A

Settings

Fixed

PANEL E (AH-4) FDR

CableSize 2 AWG

Length 220.0 ft

QtyPerPhase 1

50HP AIR COMPRESSOR FDR

CableSize 2 AWG

Length 35.0 ft

QtyPerPhase 1

LOOM #21 FDR

CableSize 4 AWG

Length 170.0 ft

QtyPerPhase 1

PANEL D (AH-3) FDR

CableSize 4 AWG

Length 120.0 ft

QtyPerPhase 1

60HP AIR COMPRESSOR FDR

CableSize 2 AWG

Length 25.0 ft

QtyPerPhase 1

LOOM #17 FDR

CableSize 6 AWG

Length 100.0 ft

QtyPerPhase 1

50HP AIR COMPRESSOR #1

480 V

60HP AIR COMPRESSOR #2

480 V

LOOM #21

480 V

LOOM #17

480 V

PANEL E (AH-4)

480 V

PANEL D (AH-3)

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

4

TO PAGE 8

SHOP PANEL

480 V

PANEL AH-2 FUSE

BUSSMANN

DLS-R

Sensor/Trip 400.0 A

AIR HANDLER #2 BLOWER FUSE

GOULD SHAWMUT

TRS

Sensor/Trip 50.0 A

LOOM #32 KEVLOR FUSE

GOULD SHAWMUT

TRS

Sensor/Trip 30.0 A

PANEL AH FUSE

BUSSMANN

NOS

Sensor/Trip 100.0 A

UNIT #4 BLOWER FUSE

BUSSMANN

FRS

Sensor/Trip 60.0 A

SOUTH WEST #4 CONDENSOR FUSE

BUSSMANN

FRS

Sensor/Trip 110.0 A

SOUTH EAST #12 CONDENSOR FUSE

BUSSMANN

FRS

Sensor/Trip 110.0 A

AIR HANDLER #2 BLOWER FDR

CableSize 8 AWG

Length 260.0 ft

QtyPerPhase 1

LOOM #32 KEVL0R FDR

CableSize 10 AWG

Length 90.0 ft

QtyPerPhase 1

PANEL AH FDR

CableSize 2 AWG

Length 3.0 ft

QtyPerPhase 1

UNIT #4 BLOWER FDR

CableSize 8 AWG

Length 320.0 ft

QtyPerPhase 1

SOUTH WEST #4 CONDENSOR FDR

CableSize 4 AWG

Length 320.0 ft

QtyPerPhase 1

SOUTH EAST #12 CONDENSOR FDR

CableSize 2 AWG

Length 260.0 ft

QtyPerPhase 1

PANEL AH-2 FDR

CableSize 500 AWG

Length 150.0 ft

QtyPerPhase 1

AIR HANDLER #2 BLOWER

480 V

PANEL AH-2 FUSE2

LOOM #32 KEVLOR

480 V

UNIT #4 BLOWER

480 V

UNIT #4 CONDENSOR

480 V

UNIT #12 CONDENSOR

480 V

PANEL AH

480 V

PANEL AH-2

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

5

PANEL D (AH-3)

480 V

LOOM #23 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #19 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #16 BKR

SQUARE D

ED

Sensor/Trip 40.0 A

Settings

Fixed

LOOM #18 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #14 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #15 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #20 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #24 BKR

SQUARE D

ED

Sensor/Trip 30.0 A

Settings

Fixed

LOOM #13 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #23 FDR

CableSize 10 AWG

Length 180.0 ft

QtyPerPhase 1

LOOM #19 FDR

CableSize 12 AWG

Length 60.0 ft

QtyPerPhase 1

LOOM #16 FDR

CableSize 12 AWG

Length 40.0 ft

QtyPerPhase 1

LOOM #18 FDR

CableSize 12 AWG

Length 100.0 ft

QtyPerPhase 1

LOOM #14 FDR

CableSize 12 AWG

Length 60.0 ft

QtyPerPhase 1

LOOM #15 FDR

CableSize 10 AWG

Length 30.0 ft

QtyPerPhase 1

LOOM #20 FDR

CableSize 10 AWG

Length 60.0 ft

QtyPerPhase 1

LOOM #24 FDR

CableSize 10 AWG

Length 130.0 ft

QtyPerPhase 1

LOOM #13 FDR

CableSize 12 AWG

Length 70.0 ft

QtyPerPhase 1

LOOM #23

480 V

LOOM #19

480 V

LOOM #16

480 V

LOOM #18

480 V

LOOM #14

480 V

LOOM #15

480 V

LOOM #20

480 V

LOOM #24

480 V

LOOM #13

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

6

PANEL E (AH-4)

480 V

LOOM #25 BKR

SIEMENS

BQD

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #26 BKR

SIEMENS

BQD

Sensor/Trip 30.0 A

Settings

Fixed

LOOM #29 BKR

SIEMENS

BQD

Sensor/Trip 20.0 A

Settings

Fixed

LOOM #22 BKR

SIEMENS

BQD

Sensor/Trip 30.0 A

Settings

Fixed

LOOM #28 BKR

SIEMENS

BQD

Sensor/Trip 30.0 A

Settings

Fixed

LOOM #27 BKR

SIEMENS

BQD

Sensor/Trip 30.0 A

Settings

Fixed

LOOM #25 FDR

CableSize 10 AWG

Length 55.0 ft

QtyPerPhase 1

LOOM #26 FDR

CableSize 10 AWG

Length 30.0 ft

QtyPerPhase 1

LOOM #29 FDR

CableSize 10 AWG

Length 120.0 ft

QtyPerPhase 1

LOOM #22 FDR

CableSize 10 AWG

Length 60.0 ft

QtyPerPhase 1

LOOM #28 FDR

CableSize 10 AWG

Length 55.0 ft

QtyPerPhase 1

LOOM #27 FDR

CableSize 10 AWG

Length 45.0 ft

QtyPerPhase 1

LOOM #25

480 V

LOOM #26

480 V

LOOM #29

480 V

LOOM #22

480 V

LOOM #28

480 V

LOOM #27

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

7

PANEL AH-2

480 V

A/C #3 BKR

SQUARE D

ED

Sensor/Trip 110.0 A

Settings

Fixed

WELDING PLUG BKR

SQUARE D

ED

Sensor/Trip 50.0 A

Settings

Fixed

A/C #5 BKR

SQUARE D

ED

Sensor/Trip 110.0 A

Settings

Fixed

XFMR AL-2 BKR

SQUARE D

ED

Sensor/Trip 60.0 A

Settings

Fixed

LOOM #31 BKR

SQUARE D

ED

Sensor/Trip 20.0 A

Settings

Fixed

40HP VAC BKR

SQUARE D

ED

Sensor/Trip 60.0 A

Settings

Fixed

A/C #3 FDR

CableSize 2 AWG

Length 130.0 ft

QtyPerPhase 1

WELDING PLUG FDR

CableSize 6 AWG

Length 20.0 ft

QtyPerPhase 1

A/C #5 FDR

CableSize 2 AWG

Length 210.0 ft

QtyPerPhase 1

XFMR AL-2 FDR

CableSize 12 AWG

Length 10.0 ft

QtyPerPhase 1

LOOM #31 FDR

CableSize 12 AWG

Length 80.0 ft

QtyPerPhase 1

A/C #3

480 V

A/C #5

480 V

WELDING PLUGS

480 V

S

P

XFMR AL-2

Nominal kVA 6.0 kVA

Pri RatedVoltage 480 V

Sec RatedVoltage 208 V

Z% 3.3666 %

PANEL AL-2 FDR

CableSize 12 AWG

Length 10.0 ft

QtyPerPhase 1

PANEL AL-2

208 V

LOOM #31

480 V

40HP VAC FDR

CableSize 6 AWG

Length 100.0 ft

QtyPerPhase 1

40HP VAC

480 V

OWENS CORNING WICHITA FALLS BUILDING 211

ONE-LINE DIAGRAM - DEVICE SETTINGS

8

Client

Short Circuit Study

SSOE Inc.

5/27/2010

- 1 -

CLIENT

Short Circuit Report

Prepared for:

Prepared by:

Brian Arend

SSOE, Inc

Toledo, OH

barend@ssoe.com

419-255-3830, x 1997

mm/dd/yyyy

-1-

Attested by:

Brian Arend P.E.

mm/dd/yyyy

Client

Short Circuit Study

SSOE Inc.

5/27/2010

- 2 -

Table of Contents

A. Purpose

B. System Configuration

C. Computer Program Description

D. Computer Calculations

E. Assumptions

F. Conclusions

Appendix A Settings Report

Appendix B Short Circuit One-line

mm/dd/yyyy

-2-

Description of Analysis Software

Calculation Method

Client

Short Circuit Study

SSOE Inc.

5/27/2010

- 3 -

A. Purpose

To adequately supply the required power on demand to a facility's power distribution

system, electric utilities must maintain ample capacity in reserve. This reserve capacity,

in combination with the motor loads, can also supply excessive current to the distribution

system during a fault condition. The purpose of the Short Circuit Study is to examine

various components of the distribution system in order to calculate and analyze the

available current levels which can occur throughout the system during a fault condition.

The available fault currents can be hazardous to both equipment and personnel if not

considered and handled in a proper manner. This study provides necessary information

for sizing and setting overcurrent protection devices and selecting equipment bracing

levels by determining the maximum available 3-phase symmetrical fault currents that will

occur at all points in the distribution system down to the machine disconnects. Proper

selection and setting of overcurrent devices and sizing of equipment bracing are essential

to survive a fault with minimal effect and damage to the distribution system.

B. System Configuration

The electrical system at the facility had not previously been modeled. SSOE visited the

site and performed an electrical audit of panels, breakers, fuses, disconnects and wires.

Some panels were not detailed because they met the NFPA 70E exclusion rule, Article

130.3 Exception 1 for equipment below 125 KVA and 250V.

SSOE used this data to develop a one line drawing for the facility. This one line drawing

was the basis for the system model.

C. Computer Program Description

Mathematical calculations for this study were performed by a computer program. It was

necessary to review the data which was used in the program so that proper interpretation

can be applied to the results or output of the program. The program utilized for this study

was Power Tools for Windows by SKM Systems Analysis, Inc.

D. Computer Calculations

For the purpose of calculating short circuit current levels, the electrical distribution

system is reduced to a network of positive (+), negative (-), and zero (0) sequence

impedance elements (resistance (R) and reactance (X)) and power sources. Impedance

elements consist of cables, busways, transformers, transmission lines, reactors, and motor

and generator windings, while power sources are rotating motors, generators, and utility

fault contributions. Each node of this impedance network is assigned a "bus" number

corresponding to the equipment numbers as shown on the system one-line drawings.

Some arbitrary bus numbers were used for the equipment with no associated numbers.

Using these bus numbers, the computer program locates and interconnects all impedance

mm/dd/yyyy

-3-

Description of Analysis Software

Calculation Method

Client

Short Circuit Study

SSOE Inc.

5/27/2010

- 4 -

elements and power sources, thereby creating a model of the distribution system as it

physically exists.

The Short Circuit Program must be provided with physical information about each device

in the distribution system (i.e., transformer kVA and percent impedance; cable length,

size and utilization voltage; etc.) (see Appendices A and B). The input data is reduced to

per unit values of positive (+), negative (-) and zero (0) sequence resistance and

reactance, on a common MVA base, by using standard calculations and typical (or

nameplate) impedance values. The input data can be displayed on the computer screen or

printed out for ease of checking.

The fault components to be calculated by the Short Circuit Program are selected by the

user. For this study, the following components have been calculated: the instantaneous

component, the cycle, 3-cycle and 30-cycle (steady state) symmetrical and

asymmetrical components. This information is included in the output report.

The variable impedance of the arc during an arcing fault can reduce the fault current

magnitudes to those shown in the arcing fault report (IEEE Red Book, IEEE/ANSI Std.

141-1993, pg. 113-114)

E. Assumptions

During the course of calculating short circuit currents, various assumptions must be made

when exact information is not available or when the use of exact information would not

contribute to greater accuracy of the results. The SKM program utilizes a number of

default values for calculations. These values are utilized unless specific data has been

identified to vary from these default values. Assumptions made by SSOE in the input data

to the program are as follows:

1. ALL LENGTHS ARE APPROXIMATE

2. Panel schedules were obtained in the field. Client supplied SSOE with updated

panel schedules after the field visit. It as assumed that the data supplied by Client

was correct and superseded the data obtained by SSOE.

3. Lengths of feeders to both battery chargers from MAIN assumed to be 30ft.

4. Transformer feeding panel AL size approximated at 30KVA from upstream fuse

and conductor. Length of conductor and size on transformer secondary feed to

panel AL approximated at 10ft.

F. Conclusions

1. Most of the breakers and fuses in the system, as represented in this report, are

adequate. There are some cases where breakers or fuses are overdutied. See

below.

mm/dd/yyyy

-4-

Client

Short Circuit Study

SSOE Inc.

5/27/2010

- 5 -

a. The fuse feeding Panel AH from the Shop Panel has a rating of 10kA. The

calculated short circuit exceeds the rating of the fuse, therefore it is

overdutied. It is recommended to replace the fuse as soon as possible with a

fuse that has a higher rating.

b. The fuse feeding Panel E (AH-4) from Main Gear 2 has a rating of 18kA. The

calculated short circuit exceeds the rating of the fuse, therefore it is

overdutied. It is recommended to replace the fuse as soon as possible with a

fuse that has a higher rating.

c. The fuse feeding the 50hp Air Compressor #1 from Main Gear 2 has a rating

of 18KA. The calculated short circuit exceeds the rating of the fuse, therefore

it is overdutied. It is recommended to replace the fuse as soon as possible

with a fuse that has a higher rating.

d. The fuse feeding Loom #21 from Main Gear 2 has a rating of 18kA. The

calculated short circuit exceeds the rating of the fuse, therefore it is

overdutied. It is recommended to replace the fuse as soon as possible with a

fuse that has a higher rating.

2. Additionally, as was previously stated, there were a couple code violations in the

compressor room:

a. The two main panels do not have a service disconnect and they also are not

built as service entrance switchboards. Depending on the interpretation of the

National Electric Code, having these two service panels could be a violation

of article 225.34(A) which states that these two panels should be grouped.

b. The second section of the main gear does not have proper clearance between it

and the 60hp air compressor. The 60hp air compressor in front of this section

has a metal covering which classifies it as a grounded surface. The limited

approach boundary from this section to the covering of the air compressor

should be at least 42 inches. It is recommended that the compressor be moved.

mm/dd/yyyy

-5-

Client

Short Circuit Study

SSOE Inc.

5/27/2010

- 6 -

Appendix A

DEVICE SETTINGS REPORT

mm/dd/yyyy

-6-

Aug 05, 2009 15:08:47 Page 1

Project Name: OC

TCC Name: ALL.tcc

Reference Voltage: 12470 V

Current Scale: X 10^0

TCC Notes:

TCC Comment:

Fault Duty Option: Study Result - Bus Fault Current

-----------------------------------------------------------------------------------------

ALL INFORMATION PRESENTED IS FOR REVIEW, APPROVAL, INTERPRETATION,

AND APPLICATION BY A REGISTERED ENGINEER ONLY.

SKM DISCLAIMS ANY RESPONSIBILITY AND LIABILITY RESULTING

FROM THE USE AND INTERPRETATION OF THIS SOFTWARE.

-----------------------------------------------------------------------------------------

CAPTOR (Computer Aided Plotting for Time Overcurrent Reporting)

COPYRIGHT SKM SYSTEMS ANALYSIS, INC. 1983-2007

-----------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

Device Name: 211 MAIN XFMR TCC Name: ALL.tcc

Bus Name: BUS-0001 Bus Voltage: 12470V / 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: 2-Winding Transformer Damage Curve Rated Volts: 12470 LL/480 LL

Nominal Size: 500.0kVA

Impedance (%Z): 2.1700 Pri Connection: Delta

Inrush Factor: 12.0x Sec Connection: Wye-Ground

-----------------------------------------------------------------------------------------

Device Name: MAIN SWITCH TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: FEDERAL PACIFIC

Description: 800-6000A

Type: LCL Econolim

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: LCL-800 600V 800A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 800A

-----------------------------------------------------------------------------------------

Device Name: MAIN FDR TCC Name: ALL.tcc

Bus Name: 211 MAIN XFMR SEC Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 3

Size: 500 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: CABLED BUS TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 500 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: MAIN GEAR 2 FDR TCC Name: ALL.tcc

Bus Name: 211 MAIN XFMR SEC Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 500 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:47 Page 2

-----------------------------------------------------------------------------------------

Device Name: MAIN GEAR 2 BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 300-600A

Type: LC

AIC Rating: 65kA Fault Duty: 18730.3A

Frame: LC 480V 600A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 600A

Setting: 1) Thermal Curve

2) INST LO (3000A)

-----------------------------------------------------------------------------------------

Device Name: PANEL E (AH-4) BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-100A

Type: FA

AIC Rating: 18kA Fault Duty: 18730.3A

Frame: FA 480V 100A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 100A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: 50HP AIR COMPRESSOR BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-100A

Type: FA

AIC Rating: 18kA Fault Duty: 18730.3A

Frame: FA 480V 100A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 100A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #21 BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-100A

Type: FA

AIC Rating: 18kA Fault Duty: 18730.3A

Frame: FA 480V 90A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 90A

Setting: 1) Fixed

Aug 05, 2009 15:08:47 Page 3

-----------------------------------------------------------------------------------------

Device Name: PANEL D (AH-3) BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 70-250A

Type: KA

AIC Rating: 25kA Fault Duty: 18730.3A

Frame: KA 480V 100A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 100A

Setting: 1) Thermal Curve

2) INST HI (1000A)

-----------------------------------------------------------------------------------------

Device Name: 60HP AIR COMPRESSOR BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 70-250A

Type: KA

AIC Rating: 25kA Fault Duty: 18730.3A

Frame: KA 480V 150A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 125A

Setting: 1) Thermal Curve

2) INST LO (625A)

-----------------------------------------------------------------------------------------

Device Name: LOOM #17 BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-100A

Type: FA

AIC Rating: 18kA Fault Duty: 18730.3A

Frame: FA 480V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 60A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: PANEL E (AH-4) FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: 50HP AIR COMPRESSOR FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:48 Page 4

-----------------------------------------------------------------------------------------

Device Name: LOOM #21 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 4 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: PANEL D (AH-3) FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 4 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: 60HP AIR COMPRESSOR FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #17 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR 2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #25 BKR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SIEMENS

Description: 15-100A

Type: BQD

AIC Rating: 14kA Fault Duty: 4991.4A

Frame: BQD 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #26 BKR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SIEMENS

Description: 15-100A

Type: BQD

AIC Rating: 14kA Fault Duty: 4991.4A

Frame: BQD 480V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 30A

Setting: 1) Fixed

Aug 05, 2009 15:08:48 Page 5

-----------------------------------------------------------------------------------------

Device Name: LOOM #29 BKR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SIEMENS

Description: 15-100A

Type: BQD

AIC Rating: 14kA Fault Duty: 4991.4A

Frame: BQD 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #22 BKR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SIEMENS

Description: 15-100A

Type: BQD

AIC Rating: 14kA Fault Duty: 4991.4A

Frame: BQD 480V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 30A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #28 BKR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SIEMENS

Description: 15-100A

Type: BQD

AIC Rating: 14kA Fault Duty: 4991.4A

Frame: BQD 480V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 30A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #27 BKR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SIEMENS

Description: 15-100A

Type: BQD

AIC Rating: 14kA Fault Duty: 4991.4A

Frame: BQD 480V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 30A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #25 FDR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:48 Page 6

-----------------------------------------------------------------------------------------

Device Name: LOOM #26 FDR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #29 FDR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #22 FDR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #28 FDR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #27 FDR TCC Name: ALL.tcc

Bus Name: PANEL E (AH-4) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #23 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

Aug 05, 2009 15:08:48 Page 7

-----------------------------------------------------------------------------------------

Device Name: LOOM #19 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #16 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 40A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 40A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #18 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #14 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

Aug 05, 2009 15:08:48 Page 8

-----------------------------------------------------------------------------------------

Device Name: LOOM #15 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #20 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #24 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 30A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #13 BKR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 5797.1A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #23 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:48 Page 9

-----------------------------------------------------------------------------------------

Device Name: LOOM #19 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #16 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #18 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #14 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #15 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #20 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #24 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:48 Page 10

-----------------------------------------------------------------------------------------

Device Name: LOOM #13 FDR TCC Name: ALL.tcc

Bus Name: PANEL D (AH-3) Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: WEST A/C #6 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 200A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 200A

-----------------------------------------------------------------------------------------

Device Name: EAST A/C #1 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: GOULD SHAWMUT

Description: 15-600A

Type: TRS, 600V Class RK5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: TRS 600V 200A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 150A

-----------------------------------------------------------------------------------------

Device Name: LIGHTING PANEL FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 200A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 200A

-----------------------------------------------------------------------------------------

Device Name: LOOM 9 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

Aug 05, 2009 15:08:48 Page 11

-----------------------------------------------------------------------------------------

Device Name: LOOM 10 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: LOOM 12 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: LITTELFUSE

Description: 15-600A

Type: FLSR, 600V RK5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FLSR 600V 100A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 80A

-----------------------------------------------------------------------------------------

Device Name: LOOM 7 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: LOOM 11 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 100A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 70A

-----------------------------------------------------------------------------------------

Device Name: XFMR AL FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 50A

Aug 05, 2009 15:08:48 Page 12

-----------------------------------------------------------------------------------------

Device Name: LOOM 6 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: OFFICE BLOWER FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: OFFICE CONDENSOR FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 30A

-----------------------------------------------------------------------------------------

Device Name: BIG BATTERY CHARGER FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 20A

-----------------------------------------------------------------------------------------

Device Name: UNIT #6 BLOWER FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 25A

Aug 05, 2009 15:08:48 Page 13

-----------------------------------------------------------------------------------------

Device Name: AIR COMPRESSOR DRIER FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 1-600A

Type: FRS-R, 600V Class RK5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS-R 600V 8A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 8A

-----------------------------------------------------------------------------------------

Device Name: SMALL BATTERY CHARGER FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 20A

-----------------------------------------------------------------------------------------

Device Name: SHOP SANDER FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 1-600A

Type: FRS-R, 600V Class RK5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS-R 600V 4A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 4A

-----------------------------------------------------------------------------------------

Device Name: BLOWER EAST #1 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: GOULD SHAWMUT

Description: 15-600A

Type: TRS, 600V Class RK5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: TRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 40A

-----------------------------------------------------------------------------------------

Device Name: LOOM 3 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

Aug 05, 2009 15:08:48 Page 14

-----------------------------------------------------------------------------------------

Device Name: LOOM 8 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: LOOM 2 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: LOOM 5 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: LOOM #1 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: LOOM #4 FUSE TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: EDISON

Description: 7-600A

Type: ECSR

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: ECSR 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

Aug 05, 2009 15:08:48 Page 15

-----------------------------------------------------------------------------------------

Device Name: N. VACUUM BKR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 20691.2A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

-----------------------------------------------------------------------------------------

Device Name: WEST A/C #6 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 1 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: EAST A/C #1 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 1 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LIGHTING PANEL FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 3/0 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 9 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 10 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 12 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 4 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:48 Page 16

-----------------------------------------------------------------------------------------

Device Name: LOOM 7 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 11 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: XFMR AL FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 6 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: OFFICE BLOWER FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: OFFICE CONDENSOR FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: BIG BATTERY CHARGER FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:49 Page 17

-----------------------------------------------------------------------------------------

Device Name: UNIT #6 BLOWER FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: AIR COMPRESSOR DRIER FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: SMALL BATTERY CHARGER FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: SHOP SANDER FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 12 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: BLOWER EAST #1 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 3 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 8 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:49 Page 18

-----------------------------------------------------------------------------------------

Device Name: LOOM 2 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 5 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 1 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM 4 FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: N. VACUUM FDR TCC Name: ALL.tcc

Bus Name: MAIN GEAR Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: XFMR AL TCC Name: ALL.tcc

Bus Name: BUS-0118 Bus Voltage: 480V / 208V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: 2-Winding Transformer Damage Curve Rated Volts: 480 LL/208 LL

Nominal Size: 30.0kVA

Impedance (%Z): 4.2690 Pri Connection: Delta

Inrush Factor: 12.0x Sec Connection: Wye-Ground

-----------------------------------------------------------------------------------------

Device Name: PANEL AL FDR TCC Name: ALL.tcc

Bus Name: BUS-0119 Bus Voltage: 208V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:49 Page 19

-----------------------------------------------------------------------------------------

Device Name: PANEL AH-2 FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 10-600A

Type: DLS-R, 600V Class RK5

AIC Rating: 200kA Fault Duty: 19911.9A

Cartridge: DLS-R 600V 400A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 400A

-----------------------------------------------------------------------------------------

Device Name: AIR HANDLER #2 BLOWER FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: GOULD SHAWMUT

Description: 15-600A

Type: TRS, 600V Class RK5

AIC Rating: 200kA Fault Duty: 19911.9A

Cartridge: TRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 50A

-----------------------------------------------------------------------------------------

Device Name: LOOM #32 KEVLOR FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: GOULD SHAWMUT

Description: 15-600A

Type: TRS, 600V Class RK5

AIC Rating: 200kA Fault Duty: 19911.9A

Cartridge: TRS 600V 30A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 30A

-----------------------------------------------------------------------------------------

Device Name: PANEL AH FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 70-600A

Type: NOS (Obs.), 600V Class H

AIC Rating: 10kA Fault Duty: 19911.9A

Cartridge: NOS 600V 100A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 100A

-----------------------------------------------------------------------------------------

Device Name: UNIT #4 BLOWER FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 19911.9A

Cartridge: FRS 600V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 60A

Aug 05, 2009 15:08:49 Page 20

-----------------------------------------------------------------------------------------

Device Name: SOUTH WEST #4 CONDENSOR FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 19911.9A

Cartridge: FRS 600V 200A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 110A

-----------------------------------------------------------------------------------------

Device Name: SOUTH EAST #12 CONDENSOR FUSE TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: BUSSMANN

Description: 15-600A

Type: FRS, 600V Class K5

AIC Rating: 200kA Fault Duty: 19911.9A

Cartridge: FRS 600V 200A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size: 110A

-----------------------------------------------------------------------------------------

Device Name: PANEL AH-2 FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 500 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: PANEL AH-2 FUSE2 TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer:

Description:

Type:

AIC Rating: 0kA Fault Duty: 12631.9A

Cartridge: Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Size:

-----------------------------------------------------------------------------------------

Device Name: AIR HANDLER #2 BLOWER FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 8 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: LOOM #32 KEVL0R FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 10 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:49 Page 21

-----------------------------------------------------------------------------------------

Device Name: PANEL AH FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: UNIT #4 BLOWER FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 8 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: SOUTH WEST #4 CONDENSOR FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 4 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: SOUTH EAST #12 CONDENSOR FDR TCC Name: ALL.tcc

Bus Name: SHOP PANEL Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: A/C #3 BKR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 12631.9A

Frame: ED 480V 110A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 110A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: WELDING PLUG BKR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 12631.9A

Frame: ED 480V 50A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 50A

Setting: 1) Fixed

Aug 05, 2009 15:08:49 Page 22

-----------------------------------------------------------------------------------------

Device Name: A/C #5 BKR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 12631.9A

Frame: ED 480V 110A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 110A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: XFMR AL-2 BKR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 12631.9A

Frame: ED 480V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 60A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: LOOM #31 BKR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 12631.9A

Frame: ED 480V 20A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 20A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: 40HP VAC BKR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480.0V

Function Name: Phase

Manufacturer: SQUARE D

Description: 15-125A

Type: ED

AIC Rating: 18kA Fault Duty: 12631.9A

Frame: ED 480V 60A Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Trip: 60A

Setting: 1) Fixed

-----------------------------------------------------------------------------------------

Device Name: A/C #3 FDR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

Aug 05, 2009 15:08:49 Page 23

-----------------------------------------------------------------------------------------

Device Name: WELDING PLUG FDR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 6 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.

-----------------------------------------------------------------------------------------

Device Name: A/C #5 FDR TCC Name: ALL.tcc

Bus Name: PANEL AH-2 Bus Voltage: 480V

Curve Multiplier: 1

Time Multiplier: 1 Time Adder: 0

Description: Cable Damage Curve Qty/Ph: 1

Size: 2 Cont. Temp: 90 deg C.

Material: Copper Damage Temp: 250 deg C.