Professional Documents

Culture Documents

Yes We Kanban Morris

Uploaded by

Varun Kumar0 ratings0% found this document useful (0 votes)

14 views7 pagest

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views7 pagesYes We Kanban Morris

Uploaded by

Varun Kumart

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 7

1

Yes We Kanban! Introducing an Agile Methodology

to Manage Your Team

Bryan Morris, P.Eng., Verilab, bryan.morris@verilab.com

AbstractThis paper describes how a management tech-

nique known as Kanban can be adopted and adapted into an

ASIC/FPGA development ow. The key advantages of following

such a process is that it provides a visual overview of what your

team is working on, current blocking issues and bottlenecks in

your process, creates opportunities for the team to proactively

discuss their process and blocking issues on a regular basis, and

is easy to adapt to most existing team management structures.

Index Termsagile, kanban, lean manufacturing, ASIC/FPGA

management

I. INTRODUCTION

A key verication challenge is the ability to coordinate

and focus your teams activities. Along with the increasing

complexity of the ASICs and FPGAs under test, it is now

common for design verication to be the critical path for

many ASIC/FPGA projects. While improved tools and stan-

dardized methodologies will continue to help, I believe that

it is also important to investigate other ways of organizing

your team. Software teams have been successfully applying

agile techniques such as eXtreme Programming (XP), Evolu-

tionary Prototyping, Scrum and others for many years. The

techniques from these methodologies have been successfully

adapted in several ASIC/FPGA development ows. A more

recent methodology called Kanban offers some interesting

capabilities that can augment your teams existing management

ow.

Kanban originated in auto manufacturing [5] that became

part of the Lean Manufacturing focus. It has since been

adopted (and adapted) successfully for software development.

This paper provides background material to understand the

value that adopting a Kanban approach to your team man-

agement can bring. It also provides guidance on adopting and

adapting Kanban into your existing ow.

The key reasons to consider adopting a Kanban approach

in your IC development are as follows:

Kanban provides a visual representation of your process

ow enabling your team to easily pick out where there

are opportunities to optimize the work ow (i.e., in the

Lean manufacturing terminology to eliminate waste).

It highlights issues and bottlenecks in the process so that

the team can apply the correct resources to resolve any

issues as quickly as possible.

It creates opportunities for discussion to ensure that the

team is always working on the feature that has the highest

customer value.

It provides a more realistic view of the true current state

of the project, and a view to planned completion through

improved objective project metrics.

Most importantly, it is easy to adopt since you can start by

simply capturing your existing process, and then incrementally

optimize your teams or projects processes. In other words,

you dont have to change how your team is managed, but

can instead gradually introduce Kanban into your ow in an

incremental fashion.

If you want to know exactly what the current state your

project in an easy to understand way, identify bottlenecks and

quickly identify risks that become apparent during develop-

ment, try using Kanban.

Lastly, while there are many tools that assist teams in

following a Kanban approach, a key advantage of Kanban is

that it requires nothing fancier than a whiteboard and sticky

notes. This paper encourages teams to adopt this simplistic

approach to start.

While web-based Kanban solutions exist, I strongly dis-

courage their use while you are introducing this change

to your team. Ensure that your team is comfortable with

the techniques and underlying principles using the simple,

physical whiteboard and sticky-note method before attempting

an electronic approach.

II. CURRENT STATE OF AFFAIRS

Before we delve into why you should consider using Kan-

ban, it would helpful to capture the current issues that we face

in the design and verication of complex ASICs and FPGAS.

These issues include, but are not limited to the following:

increasing complexity of ASIC/FPGA development

increasing size of project team which in turn, increases

the complexity of internal communications within the

team

multi-site teams again, increasing the complexity of both

team dynamics and internal communications

understanding your projects true current state, and

limited opportunities to explore new techniques and

methodologies while still in development.

Every project has experienced at least one of these factors.

Our project management teams are highly capable individuals

usually with a great deal of experience and yet most teams are

incapable of producing a schedule and budget that doesnt go

off the rails shortly after starting. I know because Ive managed

many projects over many years and have spent endless hours

updating the schedule to account for something unexpected,

or some technical snag thats preventing progress.

Its time we admit that we simply cannot create a schedule

that is believable. Its not because we arent capable, the task

is intractable because by their very nature the ASICs/FPGAs

we create have too many unknowns and risks:

technical risks - we are usually building something that

has never been built before. Therefore, we have no prior

experience to deterministically gauge its complexity.

technology risks - frequently we are forced to use a new

tool, methodology or process technology. In most cases,

being the bleeding edge of technology means that well

need to deal with unforeseen bugs.

people risks - the team we start with in most cases is not

the team we end up with. Frequently, team members are

shifted on and off the project, or need to support past

work, or look at future possibilities.

resource risk - in many large companies any physical

resources such as compute farms, licenses, etc. must be

shared across multiple projects. Resource contention is

inevitable at some point in the project which will likely

lead to unplanned for delays.

Kanban is not a silver bullet that solves all these problems.

But it can help your team work in a focused, disciplined way,

understand their next highest value task that must be done,

and a clear understanding of whats left to do.

III. INTRODUCING KANBAN FOR ASIC/FGPA

DEVELOPMENT

Compared to some traditional, and perhaps, other agile

project management frameworks, Kanban is extremely simple

to understand. I believe that that simplicity is its core strength

and why I believe using Kanban can be a force for substantive

change in the way we work.

Kanban has six core practices:

1) Visualize your Workow

2) Limit Work in Progress

3) Manage Flow

4) Make Policies Explicit

5) Create opportunities for feedback

6) Improve Collaboratively, Evolve Experimentally

Each of these are discussed in greater details in the sections

below.

A. Visualize your Workow

At the heart of Kanban is the idea that the team needs to

see their workow. Only by using a visual representation of

your workow can you nd opportunities to improve it. In

fact, Kanban is roughly translated from Japanese as signboard

(or visual board).

A simple whiteboard consists of columns representing dif-

ferent phases in your workow and any task or activities ow

from the left (the start of your workow) of the board to

their completion on the right (when they are done). A simple

example is shown in Fig. 1 where your team has dened three

simple phases: Todo, In Progress, and Done. Similar to

many Kanban boards in use, this diagram is representative of

a white board with sticky-notes holding the task/activities that

need to be accomplished.

Movement ows from left to right as room becomes avail-

able from right to left. As shown in Fig. 2 where Feature

4 moves from In Progress to Done

Todo In Progress Done

Feature 1

P-1

BugFix

Feature 2

Feature 4

Feature 3

Fig. 1: Simple Kanban Board

Todo In Progress Done

Feature 1

P-1

BugFix

Feature 2

Feature 4

Feature 3

Fig. 2: Kanban Board Movement - a

Todo In Progress Done

Feature 1

P-1

BugFix

Feature 2

Feature 4

Feature 3

Fig. 3: Kanban Board Movement - b

Leaving space in In Progress for Feature 2 to be

pulled in from Todo as shown in Fig. 3

All activities are planned, tracked and visually represented

on a Kanban board. Regular and continuous opportunities are

provided to discuss as a team how to ensure that the team is

focused and working on the most important activity. As shown

Page 2 of 7

in Fig. 3 expedited activities such as bug xes can be visually

represented using a different colour.

A more realistic example is shown in Fig. 4. This board has

multiple workow phases:

Backlog : all the features/activities that need to be done.

Analysis : allowing time to understand and analyze the

problem, capturing the requirements, dening the exit

or donecriteria, and considering different architectural

approaches.

Design : capturing the initial design.

Implementing : implementing the solution.

Verifying : debugging and/or verifying the implemen-

tation is correct and meets the criteria dened during the

Analysis phase.

Done : The task / activity has met the exit criteria

Backlog Analysis Done

Feature

1

P-1

BugFix

Design Implementing Verifying

Doc:

Verif

Env

Feature

5

Feature

4

Feature

3

Feature

2

URGENT

Feature

6

Fig. 4: More Realistic Kanban Board

This board contains a separate URGENT workow al-

lowing those inevitable items that must be expedited. Of

course, this lane should be used infrequently. This board also

indicates documentation activities as a blue coloured sticky-

note.

The visual aspect of a Kanban board gives rise to team

discussions on how to optimize the teams processes and

methodologies to eliminate wasted time in the teams work-

ow.

As Kanban visualization allows the entire team to see the

complete process, this is a rst step to allowing the team to

optimize the process. As the team works on the project, there

is always time to make suggestions for adding or removing

steps from the process with the Kanban board evolving as

the process evolves. Having the board be highly visible creates

both a mechanism and an opportunity to discuss the process.

Typically this is done during short, focused daily meetings to

discuss progress and blocking issues (and ideally moving tasks

through the workow).

B. Limit Work In Progress

A typical approach to keeping your team busy is to give

them several features to implement concurrently, while also

ensuring that there is a constant ow of meetings, bugs and

quick tasks that need to be done. Clearly, this is not efcient

due to the need to context switch between tasks. It is more

effective to ensure that each person is focused on a smaller

number of tasks and allow them to work them through to

completion. That is the goal of this practice to Limit Work in

Progress.

Every project has constraints: people, compute power, li-

censes, planned vacation, etc. These constraints need to be

clearly identied and captured on the Kanban board. This is

done by assigning a work in progress (WIP) limit to each

column in a Kanban board reecting the constraints. For

example, lets assume we want to assign a WIP limit to an

Implementing phase. If we have four developers and make

the assumption that a developer can at most work on no more

than two tasks at a time, the resulting WIP limit is 8 (= 4

developers * 2 tasks/developer). This denes the maximum

number of tasks/activities that can happen during that phase

of the process.

In the example Kanban board in Fig. 5 below the

Implementing phase has a WIP Limit of 4, meaning

that only four tasks are allowed to be in process in the

Implementing phase at any one time. As shown in the

gure below, the Implementing phase has reached its WIP

limit at this point in the project.

Backlog

Analysis

(2)

Done

Feature

1

P-1

BugFix

Design (2)

Implementing

(4)

Verifying

(2)

Doc:

Verif

Env

Feature

5

Feature

4

Feature

3

Feature

2

URGENT

Feature

6

Feature

9

Feature

11

Featur

e 10

Feature

8

Fig. 5: Kanban board with Work In Progress Limits

As can be seen by this system the addition of numeric

values beside the column header indicate the WIP limits e.g.,

Analysis, Design and Verifying have a limit of 2

while Implementing has a limit of 4. Just to clarify the

team will decide on what is an appropriate number for these

columns. The initial WIP limits will start with a good estimate

of what they should be, and then these numbers will likely

change as the project progresses. Consider that in tweaking

these values you are attempting to create a steady ow of

work traversing from the start (on the left) to the nish (on

the right). WIP that are too low will create a bottleneck; WIP

that are too high will mean your team is working on too many

things at once.

A key point here is that Kanban uses what is called a pull

system. If you consider that WIP limits dene the number of

free slots available per column, then you can only move a task

Page 3 of 7

into the column when there is a free slot. For example, in Fig.

5 above the following facts can be asserted (looking from left

to right):

The team cannot start a new item from the Backlog

because the Analysis phase has hit is WIP limits.

However, once an item is complete in the Analysis

phase it can immediately move into the Design phase

because it has one free slot.

Similarly, any complete item in the Design phase cannot

move into the Implementing phase because it has hit

its WIP limit (Note: you must include everything in the

column even the expedited lane if you have one).

Similarly, the Verifying column cannot accept any

work from the Implementing column.

There are not limits to the Done column.

The pull concept is that tasks can only be pulled from the

right; rather than being pushed from the left. As well, it is

important for the team to dene entry and exit criteria into each

phase to ensure that you are accepting work that is complete.

Accepting anything less than complete will inevitably come

back to haunt you later in the project when almost complete

work must be re-inserted back into the ow usually at an

inopportune time in the project.

An important point regarding when things move from the

Backlog into the Analysis phase is that it provides an

opportunity to decide which task or feature provides the most

value at this time. As priorities often change throughout a

project due to new information or technical issues arising,

pushing the decision on what to implement next to as late

as possible is key value of using a continuous system like

Kanban.

Once you have WIP limits put in place, it becomes self-

evident where the bottlenecks exist in your process because

that particular element creates back-pressure for the up-stream

activities. As discussed earlier, increasing the WIP limits will

likely mean that tasks linger in a column for too long (and

your team is being stretched too thinly).

Once you have an initial set of WIP limits dened, they

will likely need to be tweaked as the project progresses. That

is natural and should be expected. One approach is simply

watch how smoothly the tasks ow across the Kanban board

and experimentally increase and decrease the WIP limits to

smooth that ow.

C. Manage Flow

The goal for any project is to ensure that you optimize

your team as effectively as possible. The visual aspect and

the WIP limits discussed in the previous sections help you in

identifying bottlenecks and helping the team to optimize the

ow of activities from start to nish. Kanban provides two

key metrics to objectively measure your teams productivity:

lead time and cycle time. It is easiest to describe these terms

visually.

The lead time is the time from when the task enters the

starting phase to when it exits the completion phase i.e., as

in our examples above, the time delta from when it is entered

into the Backlog column to when it is moved into the Done

column.

Fig. 6 illustrates the concept of a lead time.

Task enters

Backlog

Task enters

Done column

Backlog Analysis Design Implementing Verifying Done

Lead Time

Fig. 6: Lead Time

Lead time should also be managed to ensure that you are

delivering features in a timely manner. A team can optimize

their lead time through any of the following ways:

breaking a step into multiple smaller steps;

pulling together several smaller steps into one;

automation through scripting;

adding additional resources e.g., compute infrastructure;

and

additional testing / review cycles to limit downstream

waste activities.

A key challenge in ASIC/FPGA development is that the

same feature can be more complex in one domain than another.

For example, a particular feature can be harder to implement

in RTL than it is to verify, and vice-versa. Lead time can be

managed on ASIC/FPGA features by breaking the task into

applicable RTL, verication, etc. domains for your project.

However, a trailing integration task should be included

to ensure that when you say a feature is done, it includes

the integration of the separate domains into a complete

feature.

Another metric is cycle time that measures when work

actually started on the task, and when it is completed. This

is not measuring effort, but duration that the cycle stayed in

the system. Fig. 7 overlays the cycle time on the lead time

denition.

Task enters

Backlog

Task enters

Done column

Backlog Analysis Design Implementing Verifying Done

Lead Time

Start Task

Task

DONE!

Cycle Time

Fig. 7: Cycle Time

From the gure, it is clear that cycle time is the time it takes

for a feature to move from beginning to end of your process,

while lead time is the time between when the feature enters and

exits your process. Calculating the average lead time and cycle

time provides insights into your work ow. Average lead time

can provide empirical proof that your process is improving as

it gives a sense of the speed of delivery. While cycle time can

provide objective measurement of how long it takes to deliver

Page 4 of 7

a feature which can be used in future feature estimation and

planning.

1

Once you have gathered a good set of empirical data with

your lead times and cycle time you can then apply Littles Law

(from queueing theory) to calculate your teams throughput.

Little

sLaw The long-term average number of cus-

tomers in a stable system L is equal to the long-

term average effective arrival rate , multiplied by

the average time a customer spends in the system,

W, or expressed algebraically: L = W

Or expressed in terms for Kanban:

AvgCycleTime =

Avg.WorkinProgress

Avg.Throughput

(1)

where Throughput is the average departure rate from the

board.

As you tweak your process your throughput should reect

whether the change improved your work ow or not.

Using the last three core practices, the team can now

visually see the following problems in their workow:

identify the bottlenecks

when a task stays in a particular phase (or column) of

the workow for longer than normal

where a process ow can be optimized

The rule to manage your ow is intended to focus your team

on the fact that your entire process should be continuously

reviewed, looking for ways where your team can be made

more effective and productive. In other words, the key is to

nd and eliminate wasteful activities in your process.

For ASIC/FPGA teams it is encouraged that before you start

the Kanban process on your next project that everyone has a

clear understanding of the big picture for the project. This

should include the set of prioritized features that are expected

to be delivered, and an initial architectural view of how all

the features work together. To be clear this architectural view

should be all the pieces of the system, including but not limited

to RTL design, verication, physical design, and software, if

applicable.

By getting this view, and keeping it aligned with the actual

architecture as it evolves throughout the project, the team can

then provide some guidance on how the co-dependent features

should be developed. This reduces the likelihood of rework due

to building something incorrectly.

1) Examples of Waste: A key element of Kanban and Lean

Manufacturing was to put an emphasis on eliminating waste.

In a design environment this translates into wasteful activities

such as:

doing more than needed : Hey, this feature will be

handy someday, lets add it in.

The team should only focus on whats needed now.

Completing the task in the most optimal way. This does

1

Assuming that you dene a size for each feature. Many teams use crude

but effective T-shirt sizing for tasks i.e., small, medium, large and extra-large.

Then you can calculate a cycle time for all medium tasks. When planning for

a medium task you can then use the average cycle time for the medium task

to estimate how long it will take. Using empirical data will result in better

planning estimates than how many traditional teams do it.

not mean to preclude the very valuable task of architect-

ing a module/class to accommodate future features, but

to recognize that only work that adds value should be

considered.

make work : only create whats absolutely needed to

complete the work. Doing work that doesnt contribute

to the task at hand is a waste of effort.

We all know that ASICs are expensive projects. There-

fore, any extra or useless work should be strongly

discouraged by the entire team.

multi-tasking : cost of the context switch.

Kanbans WIP limits provides some limits to stretching

your team too thinly.

almost-done : not being completely done (done, done).

Kanban fosters the idea of clearly dening when a task

is done with entry and exit criteria from every column.

waiting for someone : I cant start that task until I get

it from Alice.

A visual board and daily meetings creates an opportunity

to indicate blocking tasks. Or to put a more positive spin

on it, the opportunity for your team to discuss ways of

avoiding blocking tasks by seeking solutions as a team.

A typical example in an ASIC project is when design is

waiting for a verication environment. Kanban can help

with this by splitting the verication tasks into creating

a simple sanity verication environment that is good

enough for designers needs, and then adding tasks that

adds more complexity to a verication environment.

wrong resource applied to the wrong task Get Bob

to do this, hes not busy.

Assigning someone not capable of doing the job because

they are available usually ends in sub-par quality work

that takes longer than desired, and inevitably needs to be

reworked later.

2

Any rework is a waste. While Kanban

does not provide any mechanism to highlight this issue,

it may assist in agging this as an issue since the task

will likely take longer than usual.

D. Make Policies Explicit

The goal of this core practice is to clearly articulate any

underlying policies in your work ow i.e, how things are really

done. Once articulated these become the facts for the project,

and therefore reducing any subjective analysis or emotional

baggage attached to that step in the process. As the saying

goes:

The best disinfectant is sunshine.

meaning in this case

3

that only once polices are in the open

and explicit can you dene why they are problematic.

These explicit policies can be discussed objectively with the

goal to improving the process. New process suggestions once

implemented can then become the new policies. Providing

clarity on how things should work avoids some wasteful

activities.

2

Unless this is viewed as a training opportunity which has great value.

3

Yes, it has other meanings.

Page 5 of 7

E. Create opportunities for feedback

It is important to create opportunities to review your pro-

cess with objective evidence gathered, or anecdotal based on

what actually happened. These opportunities can be used to

create ideas for improvement that everyone can agree upon

because youve focused the discussion on the facts. Ideally,

this feedback is done as soon as you have gathered sufcient

evidence to have a meaningful discussion which could be

measured in weeks or months.

When bottlenecks occur it is also an opportunity to discuss

ideas. These ideas can then be put into your backlog (or todo)

list to be prioritized and added when the next available slot in

your rst phase is free.

As well, the daily meeting provides an opportunity to

discuss issues in an objective way. The Kanban board being

a physical element allows people to talk about the board

rather than about a person. By transferring the discussion

about moving a task across the board (Whats preventing task

A from moving forward?), it eliminates some of the people

issues around (Why are you taking such a long time with task

A?). Discussion around those kind of issues are better suited

to a different forum than a team meeting.

F. Improve Collaboratively, Evolve Experimentally

Kanban provides some key metrics such as cumulative ow

diagrams (CFD) that can provide a realistic view on the current

state of the project, some insight into the projected schedule

going forward, and some key metrics to assist when doing

forward planning. All of this information dovetails nicely into

existing management reporting structures and can provide a

more realistic view of true project status than a Gantt chart

approach.

A cumulative ow diagram is calculated on a daily basis by

summing the total number of tasks in each column, plotting

that data onto a graph on a daily basis. The resulting diagram

(see Fig. 8 illustrating each phases daily task sum in a

different colour).

The following gure is an excellent (open-source) view of

the information that can be extracted from a CFD.

4

It may be difcult to see at this size, but the lead time and

cycle times can be extracted from this diagram as horizontal

lines:

lead time is the distance from the left-most of the rst

phase (Requirements and the left-most point on the

last phase (Test).

cycle time is the distance from the right-most of the rst

phase and the left-most point of the last phase.

Similarly, the amount of work left to complete can be

seen as the difference vertically between the Test and

Requirements. In fact, by plotting the trend lines for the

rst and last phases you can get an estimate of how much

effort is left before you complete the current set of features

from the point where the two trend-lines intersect. Of course,

this is a very coarse scheduling methodology due to the fact

4

Original diagram can be found at http://http://edn.embarcadero.com/

article/images/32410/cfd005.gif

Fig. 8: Cumulative Flow Diagram

that it does not take into account the complexity and size of

each feature or task in the backlog, nor of any future issues

that inevitably arise.

As Kanban is a continuous ow, you can at any point

have a discussion about changing an element in the process

work ow. Typically, this is due to a chronic condition of

one phase in the process being a bottleneck requiring

some consideration from the team on how to eliminate (or

ameliorate) the bottleneck. Ideally, this done from a position

of strong empirical data showing a persistent bottleneck so

that rational fact-based decisions can be reached such as the

CFD.

There are other metrics that can be gathered, but are beyond

the scope of this article.

Once the idea for improvement has been decided upon it

should be scheduled like any other task by adding into your

initial phase e.g., Backlog, and then implemented. As long

as you continue to gather metrics your team will be able to

objectively determine if the idea improved or degraded your

teams performance.

The underlying theory behind this core practice is that

you identify issues taking a long-term view, make changes

based on facts, and can then see whether the changes actually

improved your teams productivity.

IV. INTEGRATING KANBAN

This section provides guidance on how a team can integrate

the Kanban approach into their current workow. This is based

partially on my experience and other case studies from the

software development community.

Kanban compared to other Agile methods is a very low

overhead and simple methodology with simple rules that can

be easily adopted. The fact that it does not proscribe the steps

youll take in your process is part of its attraction because it

can be added into your existing work ow and then the team

can self-organize and, if necessary, continue to improve that

ow.

While this article has only scratched the surface to Kanban,

it also should be sufcient for a team to start to use it

Page 6 of 7

effectively. Advanced information can be found from some

of the material provided in the bibliography.

The remainder of this section attempts to identify what can

be done to incrementally adopt Kanban into your ow.

There are three Japanese terms to describe the movement

from novice to master:

shu : where we learn the basics of a technique or

methodology,

ha : where we understand the basics and incrementally

adopt and adapt new techniques, and

ri : where we have mastered the technique, use advanced

metrics and can innovate.

The closest equivalent Western phrase is probably crawl, walk,

run.

A. Shu - Introducing Kanban

The suggested phases to introduce Kanban to the team are

as follows:

Phase 1 - Training : Find a champion or champions to

learn about Kanban. An excellent grounding can be found

in [2].

Phase 2 - Visualize your Flow : Start with writing down

your current process using a whiteboard. That is, start

with how your team currently work right now. Not how

you want to work, but how you actually work. This is a

good place to start.

Ensure that the team understands the entry and exit

criteria for each phase.

Phase 3 - Add your WIP Limits Start adding WIP limits

grounded in reality. Good starting examples are to start

with the number of engineers in your group and then how

many tasks of each type they could reasonably handle. It

is a good idea to start low and work up when the evidence

indicates increasing the WIP is a good idea e.g., when

free slots remain open for too long, or the cycle time

is too long. This starts to identify the bottlenecks and

resource constraints.

Phase 4 - Review This can be done to varying degrees

throughout all the stages. The intent here is to encourage

discussions around the process and the bottlenecks. The

goal is to consider incremental improvements to whatever

it is your doing.

B. Ha - Using Kanban

Once you acquired basic skills in Kanban you can begin to

adopt

Capture Metrics Start capturing the metrics identied

in this article and in the reference material. This can

provide objective data from which pragmatic changes can

be applied. As well, it provides a baseline to objectively

determine if any process change have actually improved

your teams productivity.

Use Metrics : Use the metrics collected during any

discussions (or create opportunities to discuss the metrics)

so that you use empirical evidence to improve your

estimation of tasks/activities and for planning how much

work your team can reasonably handle.

C. Ri - Mastering Kanban

At this point, your team is fully versed in using Kanban.

Using your collected data you can now incorporate these into

your future planning sessions to estimate the duration of the

set of tasks before you. Your planning is now driven from

empirical evidence rather than hope-lled guesstimates. Since

the estimates are a based on empirical evident you will have

greater condence in their accuracy.

There are other techniques that are outside the scope of this

paper.

D. Kanban Caveat

Change is hard, disruptive and can be uncomfortable for

many different types of people on your team. It is strongly

advised that you adapt Kanban (or any new process) in an

incremental way. Be aware of the signicant people issues

around introducing a new technique. Most people will react

poorly when the change is not fully understood. By training

and introducing Kanban gradually, you will have a greater

chance of success.

V. CONCLUSION

In summary, Kanban is a simple process tool that can pro-

vide ASIC/FGPA teams with exibility and power to manage

their ow of work. The tools discussed in this paper are the

starting points to introducing Kanban incrementally, and then

as team working on optimizing your development process

using solid metrics to provide insights into the reasons behind

the change, and validation that the change was benecial.

Finally, discussion on Kanban in this article is meant only

to serve as an introduction. While Kanban itself is relatively

straightforward, the motivations for using it and the context

in which it was developed may require more explanation.

For more on Kanban and how Kanban is applied in lean

manufacturing and product development, refer to the further

reading such as [1], [2], [3], [4].

REFERENCES

[1] David Anderson, Kanban system for software engineering video pre-

sentation, (2011).

[2] David J Anderson, Kanban, successful evolutionary change for your

technology business, April 2010.

[3] N. Johnson B. Morris, Agile ic development with scrum, (2010).

[4] Skarin Kniberg, Kanban vs scrum, (2010).

[5] Taiichi Ohno, Toyota production system: Beyond large-scale production,

1988.

Page 7 of 7

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Pip PH DDocument316 pagesPip PH DVarun KumarNo ratings yet

- Integration of Lean and Agile Manufacturing Based On Principles From WikinomicsDocument9 pagesIntegration of Lean and Agile Manufacturing Based On Principles From WikinomicsVarun KumarNo ratings yet

- Table 4.1 Definition of Agility Evolution by Various AuthorsDocument6 pagesTable 4.1 Definition of Agility Evolution by Various AuthorsVarun KumarNo ratings yet

- Development of Checklist For Evaluating Sustainability Characteristics of Manufacturing ProcessesDocument21 pagesDevelopment of Checklist For Evaluating Sustainability Characteristics of Manufacturing ProcessesVarun KumarNo ratings yet

- Admission LetterDocument2 pagesAdmission LetterVarun KumarNo ratings yet

- Some Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationDocument6 pagesSome Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationVarun KumarNo ratings yet

- 7 Vol 2 No 2Document11 pages7 Vol 2 No 2Varun KumarNo ratings yet

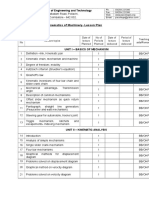

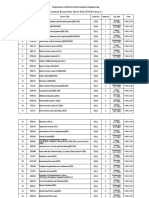

- Kinematics of Machinery-Lesson Plan: P.A. College of Engineering and TechnologyDocument4 pagesKinematics of Machinery-Lesson Plan: P.A. College of Engineering and TechnologyVarun KumarNo ratings yet

- Onion Rs7 Low Price Than Market Rate, Price Negotiable in Saravanampatti Contact 8220609999Document1 pageOnion Rs7 Low Price Than Market Rate, Price Negotiable in Saravanampatti Contact 8220609999Varun KumarNo ratings yet

- TQM Internal Mark 2014-2018 BatchDocument2 pagesTQM Internal Mark 2014-2018 BatchVarun KumarNo ratings yet

- 5 Tejinder SinghDocument2 pages5 Tejinder SinghVarun KumarNo ratings yet

- #CustomizedDocument1 page#CustomizedVarun KumarNo ratings yet

- Some Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationDocument6 pagesSome Practical Applications of E-Learning in OHS and Ergonomics in Higher EducationVarun KumarNo ratings yet

- Regulation 2008 - Lab Course - Criterion III - TemplateDocument78 pagesRegulation 2008 - Lab Course - Criterion III - TemplateVarun KumarNo ratings yet

- ASSIGNMENT II Answer KeyDocument3 pagesASSIGNMENT II Answer KeyVarun KumarNo ratings yet

- Sub: To Honor Our Alumnus Reg.: Place: Pollachi Date: 26-09-2016Document1 pageSub: To Honor Our Alumnus Reg.: Place: Pollachi Date: 26-09-2016Varun KumarNo ratings yet

- 5B-01-P96 (Malaysia)Document7 pages5B-01-P96 (Malaysia)Varun KumarNo ratings yet

- Mech & AutoDocument92 pagesMech & AutoVarun KumarNo ratings yet

- Summary of Surface Finish ParametersDocument3 pagesSummary of Surface Finish ParametersVarun KumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Terminal Exams Date Sheet-Fall 2020 (Version-1) : Department of Electrical and Computer EngineeringDocument6 pagesTerminal Exams Date Sheet-Fall 2020 (Version-1) : Department of Electrical and Computer EngineeringMuhammad Zaeem AkmalNo ratings yet

- Statement of PurposeDocument2 pagesStatement of PurposeTeferaNo ratings yet

- Cico No.3: Quick Setting and Rapid Hardening Admixture For Plain Cement Concrete and MortarDocument2 pagesCico No.3: Quick Setting and Rapid Hardening Admixture For Plain Cement Concrete and MortarankitraginiNo ratings yet

- Articificial IntelligenceDocument19 pagesArticificial IntelligenceDivyanshiNo ratings yet

- British Columbia Ministry of Transportation and InfrastructureDocument5 pagesBritish Columbia Ministry of Transportation and InfrastructureFarhanNo ratings yet

- 2022-10-11T005751.688Document1 page2022-10-11T005751.688Mohamed FahadNo ratings yet

- (W. H. Mosley, R. Hulse, J. H. Bungey (Auth.) ) Rei (B-Ok - Xyz) PDFDocument441 pages(W. H. Mosley, R. Hulse, J. H. Bungey (Auth.) ) Rei (B-Ok - Xyz) PDFHamidullah Afghan100% (1)

- Introducing of P&Id For Undergraduate StudentDocument8 pagesIntroducing of P&Id For Undergraduate StudenttyoNo ratings yet

- Assessment 1Document4 pagesAssessment 1Beman EasyNo ratings yet

- ISA S5.4-1991 Instrument Loop DiagramsDocument22 pagesISA S5.4-1991 Instrument Loop DiagramsHassanSadiqNo ratings yet

- Astm 139Document6 pagesAstm 139Kenny WongNo ratings yet

- Engineering Fundamentals An Introduction To Engineering 6Th Edition Moaveni Saeed Full ChapterDocument51 pagesEngineering Fundamentals An Introduction To Engineering 6Th Edition Moaveni Saeed Full Chapteranna.bowen401100% (4)

- CTLP 2012 Process Controls Course Outline Sept 2013Document3 pagesCTLP 2012 Process Controls Course Outline Sept 2013Kendall BirjueNo ratings yet

- BS5400!10!1980-Code of Practice For FatigueDocument78 pagesBS5400!10!1980-Code of Practice For Fatiguezlq10081008No ratings yet

- Hydrastep and Hydratect Water/Steam Monitoring SystemsDocument12 pagesHydrastep and Hydratect Water/Steam Monitoring Systemscytech6619No ratings yet

- ETABS Presentation 1Document56 pagesETABS Presentation 1V.m. Rajan100% (9)

- CP1 2 Draft 1 v7 (Public Comment)Document220 pagesCP1 2 Draft 1 v7 (Public Comment)Martin BrookesNo ratings yet

- Hydraulic Bearing PullerDocument28 pagesHydraulic Bearing PullerBoopathi KalaiNo ratings yet

- Jig Frame: Mechanical Engineering Design - CADDocument1 pageJig Frame: Mechanical Engineering Design - CADraka afriantoNo ratings yet

- Load Flow Analysis of 66 KV Substation Using ETAP SoftwareDocument4 pagesLoad Flow Analysis of 66 KV Substation Using ETAP SoftwareAnonymous CUPykm6DZ100% (1)

- Lateral Earth Pressure Cullman CompletoDocument36 pagesLateral Earth Pressure Cullman CompletoRodolfo RodriguezNo ratings yet

- 00 Class OrientationDocument12 pages00 Class OrientationRenz Jasper Bumagat LizaNo ratings yet

- Sushita 172 Report (BRIDGE DESIGN)Document9 pagesSushita 172 Report (BRIDGE DESIGN)SushitaBethSenobagoNo ratings yet

- MEC233Document4 pagesMEC233J Drei Ablin Law-ionNo ratings yet

- PreviewpdfDocument67 pagesPreviewpdfAurélien Kinet100% (1)

- Ee-103 Cep PDFDocument7 pagesEe-103 Cep PDFsajjadNo ratings yet

- AbstractDocument5 pagesAbstractSyed Azeem0% (1)

- CV Hamad SaeedDocument3 pagesCV Hamad SaeedHamad SaeedNo ratings yet

- Catalogo Aditamentos2Document6 pagesCatalogo Aditamentos2Johan Berndt0% (1)

- Module 1 Engineering Design ProcessDocument16 pagesModule 1 Engineering Design ProcessvivekNo ratings yet