Professional Documents

Culture Documents

Powercrete J Application

Uploaded by

Jèfrì Pìném0 ratings0% found this document useful (0 votes)

147 views2 pagesPowercrete j Application

Original Title

Powercrete j Application

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPowercrete j Application

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

147 views2 pagesPowercrete J Application

Uploaded by

Jèfrì PìnémPowercrete j Application

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Powercrete J is a 100% Solids Epoxy used for corrosion and abrasion protection.

. This coating is applied over clean, bare

steel and adjacent plant applied or mainline coatings.The application is fast and easy. Simply followthese guidelines.

1. The 2-component

epoxy coating is

supplied in pre-

measured kits. PartA

(large container) is the

Base and Part B

(small container) is the

curing agent.

2. The Application Kit

contains a mask, Wet

FilmGauge, Gloves,

trowels, a PE stir stick,

and abrasive paper.

3. Insure that surfaces

are clean of grease,

oil, salts and other

contaminants. If

necessary, use

Acetone, MEK or other

suitable solvent.

Performcleaning when

pipe is 3C (5F)

above dewpoint.

4. Blast clean

surfaces to a near

white ISO-8501, NACE

No. 2, SA-2 1/2

(SSPC-SP 10) or

better using particle

blasting (sand or other).

Sweep blast adjacent

FBE or CTE coating.

50 mm(2") to either

side of cutback (the

bare steel area)

5. A 2.5-4 mil (63.5-

101.6 micron) surface

profile with sharp

angularity. Burnishing

or polishing must be

avoided. Surface

preparation can be

controlled using surface

profile tape. Dry surface

and insure ideal surface

preparation.

6. While not always

necessary, preheating

can be useful just

prior to application.

A. To eliminate

moisture, preheat the

cutback area to

approximately 40C

(104F).

B. To accelerate curing,

preheat the cutback

area to approximately

90C (194F).

7. Warmparts A &B

to 20C (68F) and

mix by pouring all of

part B into part A.

Thoroughly scrape

container and lid of B.

Slowly begin mixing to

avoid introducing air

into the mixture.

8. Use a mixing speed

that uniformly blends the

2 parts, but does not

create a vortex in the

mixture or spillage.

Note: Between 20C (68F) &40C (105F), mix for 2 - 3 minutes with a drill mixing paddle or 4 - 5 minutes with the stir stick. Blend both

parts to create a uniformcolor with no streaks.

1. Product

3. Surface Preparation

5. Surface Preparation

7. Combining &Mixing

6. Surface Preparation

4. Surface Preparation

2. Application Kit (ordered separately)

AG-PC-J -MANUAL-REV14-J an10

Page 1 of 2

Application Guide

J

Manual / Kit Application

8. Mixing

*: Berry Plastics does not supply these kits.

*

9. Reconfirmthat the

application

temperature is above

10C (50F)* & 3C

(5F)* above the dew

point. Then slowly

pour mixed epoxy onto

pipe. See Tips

belowfor additional

suggestions.

10. Use trowels,

brush or roller to apply

required minimum

thickness of coating to

the Field J oint. Cover

at least 50mm(2) of

the adjacent mainline

coating.

11 . Use a Wet Film

gauge to measure that

the desired minimum

thickness has been

achieved. Double

check around the weld

to insure minimum

desired thickness.

12. The curing rate*

will vary according to

pipe and ambient

application

temperature.

Refer to curing rate

chart to determine

when to performa

Shore Dcheck.

T ip: Masking tape may be applied to left &right 50mm(2) beyond cutback (see dotted lines) and later removed while the coating is still

tacky to create a straight edge and neat appearance

*Note: Powercrete J may be applied and cured at colder environmental temperatures if the pipe is heated during the application and cure..

Storage

For optimumperformance, store PowercreteEpoxy products in a dry, well-ventilated area. Maintain products in original packaging and

sealed until just before use. Avoid exposure to direct sunlight, rain, snow, dust or other adverse environmental conditions or contaminates.

NOTE: A void prolonged storage at temperatures above 40C (104F) or below5C (40F).

Safety Guidelines

Important: Read the MSDS prior to using the products. Product installation should be done in well-ventilated area and in accordance with

local health and safety regulations. These application guidelines are intended as a guide for standard products. Consult your Covalence

Specialty Materials representative for specific projects or unique applications

9

11 12

10

AG-PC-J -MANUAL-REV14-J an10

Berry Plastics warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when used in compliance with Berry Plastics

written instructions. Since many installation factors are beyond the control of Berry Plastics, the user shall determine the suitability of the products for the intended use and assume all risks and liabilities

in connection herewith. Berry Plastics liability is stated in the standard terms and conditions of sale. Berry Plastics makes no other warranty either expressed or implied. All information contained in

this technical data sheet is to be used as a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Part 1 - Cutlip and Center's Effective Public Relations. 11th Ed.Document127 pagesPart 1 - Cutlip and Center's Effective Public Relations. 11th Ed.Duyen Pham75% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Norsok Standard M-101Document62 pagesNorsok Standard M-101Popovici Alexandru100% (2)

- Hydrant Dispenser 1000gpmDocument2 pagesHydrant Dispenser 1000gpmJèfrì PìnémNo ratings yet

- F20-W21 - LP1 LP2 Instructions and Grading Rubric-STUDENT VersionDocument9 pagesF20-W21 - LP1 LP2 Instructions and Grading Rubric-STUDENT VersionjohnamenNo ratings yet

- Linde E18P-02Document306 pagesLinde E18P-02ludecar hyster100% (4)

- KOIKE Portables and Gas Equipment Catalogue v1.03 - Optimized - OptDocument72 pagesKOIKE Portables and Gas Equipment Catalogue v1.03 - Optimized - OptSergioNo ratings yet

- MTO Piping - Part3Document1 pageMTO Piping - Part3Jèfrì PìnémNo ratings yet

- Titanic Project Case StudyDocument1 pageTitanic Project Case StudyJèfrì PìnémNo ratings yet

- Hydrotest FormulaDocument17 pagesHydrotest FormulaEarnest007100% (2)

- BBJMB Airducts PdsDocument4 pagesBBJMB Airducts PdsJèfrì PìnémNo ratings yet

- Kuda LiarDocument1 pageKuda LiarJèfrì PìnémNo ratings yet

- Rolled Steel Angle Rings: Heavy Gauge Ductwork 171Document1 pageRolled Steel Angle Rings: Heavy Gauge Ductwork 171Jèfrì PìnémNo ratings yet

- Extracted Pages From Mechanical - Estimating - ManualDocument1 pageExtracted Pages From Mechanical - Estimating - ManualJèfrì PìnémNo ratings yet

- Hydrotest FormulaDocument17 pagesHydrotest FormulaEarnest007100% (2)

- Calculation and Formula GuideDocument15 pagesCalculation and Formula Guidecharles083No ratings yet

- Lets PDFDocument20 pagesLets PDFAugusto Manuel Inga SánchezNo ratings yet

- Calculation and Formula GuideDocument15 pagesCalculation and Formula Guidecharles083No ratings yet

- Productivity TablesDocument18 pagesProductivity TablesabcNo ratings yet

- Covalence HTLP80Document2 pagesCovalence HTLP80Jèfrì PìnémNo ratings yet

- ALDocument1 pageALJèfrì PìnémNo ratings yet

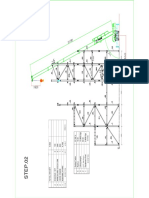

- Steel Structure Erection by 130T Step 02 of 09Document1 pageSteel Structure Erection by 130T Step 02 of 09Jèfrì PìnémNo ratings yet

- ETDocument1 pageETJèfrì PìnémNo ratings yet

- Introduction to Korea's Employment Insurance PlanDocument176 pagesIntroduction to Korea's Employment Insurance PlanCarlos Andrés NeyraNo ratings yet

- Introduction to Korea's Employment Insurance PlanDocument176 pagesIntroduction to Korea's Employment Insurance PlanCarlos Andrés NeyraNo ratings yet

- Schedule Pekerjaan Pembangunan Fix Crusher Pada PT Mifa BersaudaraDocument1 pageSchedule Pekerjaan Pembangunan Fix Crusher Pada PT Mifa BersaudaraJèfrì PìnémNo ratings yet

- GWC BackDocument1 pageGWC BackJèfrì PìnémNo ratings yet

- Coal SCHDocument3 pagesCoal SCHJèfrì PìnémNo ratings yet

- PDFDocument1 pagePDFJèfrì PìnémNo ratings yet

- Acad DPGDocument184 pagesAcad DPGBharathi RajaNo ratings yet

- Abcdefg XDocument1 pageAbcdefg XJèfrì PìnémNo ratings yet

- 360 Vault Installation Quick Start: Installing The Network License ManagerDocument4 pages360 Vault Installation Quick Start: Installing The Network License ManagerCarlos Condor A100% (1)

- Jotun Resist 86Document5 pagesJotun Resist 86Ansar AliNo ratings yet

- Mech & Piping - List ofDocument1 pageMech & Piping - List ofJèfrì PìnémNo ratings yet

- Wasbi Bank AnalysisDocument18 pagesWasbi Bank AnalysisHamadia KhanNo ratings yet

- MongoDB vs RDBMS - A ComparisonDocument20 pagesMongoDB vs RDBMS - A ComparisonShashank GuptaNo ratings yet

- Chapter FiveDocument12 pagesChapter FiveBetel WondifrawNo ratings yet

- Cache Memory in Computer Architecture - Gate VidyalayDocument6 pagesCache Memory in Computer Architecture - Gate VidyalayPAINNo ratings yet

- All India Corporate Photography Contest Promotes Workplace ArtDocument3 pagesAll India Corporate Photography Contest Promotes Workplace Artharish haridasNo ratings yet

- Product Models Comparison: Fortigate 1100E Fortigate 1800FDocument1 pageProduct Models Comparison: Fortigate 1100E Fortigate 1800FAbdullah AmerNo ratings yet

- Yamaha Stagepas 300Document54 pagesYamaha Stagepas 300Ammar MataradzijaNo ratings yet

- Dse Placement Report PDFDocument78 pagesDse Placement Report PDFAbhijithKríshñàNo ratings yet

- PhysRevResearch 4 043041Document6 pagesPhysRevResearch 4 043041marco juradoNo ratings yet

- Offer Letter - Kunal Saxena (Gurgaon)Document5 pagesOffer Letter - Kunal Saxena (Gurgaon)Neelesh PandeyNo ratings yet

- A400 PDFDocument4 pagesA400 PDFsnarmeNo ratings yet

- CP Exit Srategy Plan TemplateDocument4 pagesCP Exit Srategy Plan TemplateKristia Stephanie BejeranoNo ratings yet

- SSPC Paint 25 BCSDocument6 pagesSSPC Paint 25 BCSanoopkumarNo ratings yet

- Manual Circulação Forçada PT2008Document52 pagesManual Circulação Forçada PT2008Nuno BaltazarNo ratings yet

- Brochure of H1 Series Compact InverterDocument10 pagesBrochure of H1 Series Compact InverterEnzo LizziNo ratings yet

- Educ 3 ReviewerDocument21 pagesEduc 3 ReviewerMa.Lourdes CamporidondoNo ratings yet

- Dr Nael Qtati's E-Commerce Business Models Week 1 CourseDocument28 pagesDr Nael Qtati's E-Commerce Business Models Week 1 CourseMohammed LubbadNo ratings yet

- A Study On Capital BudgetingDocument2 pagesA Study On Capital BudgetingANKIT SINGHNo ratings yet

- Request For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarDocument1 pageRequest For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarRahmat KhanNo ratings yet

- Science Q4 Lesson BDA EarthquakeDocument41 pagesScience Q4 Lesson BDA EarthquakeAnaLizaD.SebastianNo ratings yet

- Daftar Pustaka Marketing ResearchDocument2 pagesDaftar Pustaka Marketing ResearchRiyan SaputraNo ratings yet

- Shenzhen Gooky Technology Co.,Ltd.: Laptop Price ListDocument1 pageShenzhen Gooky Technology Co.,Ltd.: Laptop Price ListOusman KabaNo ratings yet

- Spec 2 - Activity 08Document6 pagesSpec 2 - Activity 08AlvinTRectoNo ratings yet

- Newcomb Theodore MDocument20 pagesNewcomb Theodore MBang Ahmad UstuhriNo ratings yet

- Katie Todd Week 4 spd-320Document4 pagesKatie Todd Week 4 spd-320api-392254752No ratings yet

- Structure and Mechanism of The Deformation of Grade 2 Titanium in Plastometric StudiesDocument8 pagesStructure and Mechanism of The Deformation of Grade 2 Titanium in Plastometric StudiesJakub BańczerowskiNo ratings yet

- Duplex Color Image Reader Unit C1 SMDocument152 pagesDuplex Color Image Reader Unit C1 SMWatcharapon WiwutNo ratings yet