Professional Documents

Culture Documents

Supplier Rating Calculator

Uploaded by

samcbsivCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supplier Rating Calculator

Uploaded by

samcbsivCopyright:

Available Formats

Supplier Rating System, Total Rating Calculator

Table of Contents

Rating Type

Supplier Rating Calculator

Supplier Rating System (SRS) Algorithm (information only)

Total failures past 12 months Parts received past 12 months

Calculated

PPM

Calculated Process Sigma Score

- - - 100.0%

Lots accepted past 12 months Total lots received past 12 months

- -

12 month delivery rating sum Total Lots received past 12 months

- -

#DIV/0!

Scoring elements and their weights

Quality 60%

Source, Incoming, Floor failures 54.5%

Incoming lot Acceptance 27.3%

SCAR 18.2%

Delivery 40%

On-time Delivery Rating 100.0%

#DIV/0!

18.2%

#DIV/0!

PPM

100.0%

Calculated LAR

#DIV/0!

Quantity Supplier Corrective Action

Requests (SCAR)

Number of SCARs dispositioned as "punitive" over the last 12 months

0

Calculated SCAR Score

LAR

Supplier Performance Index Multiplier =

#DIV/0!

#DIV/0!

On-time delivery rating

Quality Rating =

Delivery Rating = #DIV/0!

Delivery

Rating

Elements

Quantitative Rating =

Calculated Delivery Rating

Fill in white fields with your values

SRS QUANTITATIVE RATING CALCULATOR

#DIV/0!

54.5%

Scoring Element

Score

Quality

Rating

Elements

J.Bushnell SRS Rating Calculator 6/21/20149:27 AM

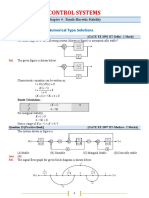

Supplier Rating System (SRS) Algorithm

Let:

1. R = SRS Quantitative Rating

2. QR = SRS Quality Rating

3. DR = SRS Delivery Rating

4. PSS = Process Sigma Score

5. SCAR = SCAR Score

6. RS = Receipt score for an individual lot received

7. TL = Total number of lots received over the past 12 months

8. PPM = Parts Per Million

9. LAR = Lot Acceptance Rate

Supplier ratings are calculated as follows:

R = 0.60 * (QR) + 0.40 * (DR)

QR = 0.545 * (PSS) + 0.273 * (LAR) + (SCAR)

If calculated PPM 500,000: PSS = 0

If calculated PPM < 500,000:

SCAR = 0.182 if 0 non-responses to a SCAR during past 12 months

SCAR = 0.12 if 1 non-response to a SCAR during past 12 months

SCAR = 0.06 if 2 non-responses to a SCAR during past 12 months

SCAR = 0.00 if > 2 non-responses to a SCAR during past 12 months

; for n lots received over the last 12 months

For an individual receipt, RS is equal to the following:

RS = 1.00 if shipment received 5 days early to 0 days late,

RS = 1.00 if early shipment indicator is set to Y and shipment received infinite days early to 0 days late

RS = 0.80 if early shipment indicator is set to N and shipment received >5 and 10 days early

RS = 0.60 if early shipment indicator is set to N and shipment received > 10 and 15 days early

RS = 0.40 if early shipment indicator is set to N and shipment received > 15 and 20 days early

RS = 0.20 if early shipment indicator is set to N and shipment received > 20 and 25 days early

RS = 0.00 if early shipment indicator is set to N and shipment received > 25 days early

6 0 . 1

Received Parts Total

) Failures Floor Failures Incoming Failures Source (

PPM E

03001 . 6

) PPM ln( * 221 . 2 37 . 29 8406 . 0 (

PSS

received) lots total of (number

accepted) lots quality of number (

LAR

TL

RS

DR

1

n

Example

If PPM is

equal to:

Calculated

PSS:

5 98.17%

10 95.62%

50 89.36%

100 86.50%

200 83.52%

500 79.37%

750 77.45%

1000 76.05%

2000 72.55%

3000 70.39%

5000 67.56%

10000 63.45%

15000 60.89%

20000 58.97%

25000 57.44%

50000 52.26%

75000 48.88%

100000 46.27%

150000 42.18%

200000 38.87%

250000 35.97%

300000 33.28%

350000 30.67%

400000 28.02%

450000 25.18%

500000 0.00%

600000 0.00%

700000 0.00%

800000 0.00%

900000 0.00%

If PPM is

equal to:

Calculated

PSS:

5 98.17%

10 95.62%

50 89.36%

100 86.50%

200 83.52%

500 79.37%

750 77.45%

1000 76.05%

2000 72.55%

3000 70.39%

5000 67.56%

10000 63.45%

15000 60.89%

20000 58.97%

25000 57.44%

50000 52.26%

75000 48.88%

100000 46.27%

150000 42.18%

200000 38.87%

250000 35.97%

300000 33.28%

350000 30.67%

400000 28.02%

450000 25.18%

500000 0.00%

600000 0.00%

700000 0.00%

800000 0.00%

900000 0.00%

You might also like

- Sr. No. Metric Goal Data Source Base Line: TallbrosDocument3 pagesSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapNo ratings yet

- Suppliers Evaluation Form - Aluminium Suppliers-2007Document6 pagesSuppliers Evaluation Form - Aluminium Suppliers-2007savan anvekarNo ratings yet

- Supplier Rating System SpreadsheetDocument2 pagesSupplier Rating System Spreadsheeteliteboy06100% (1)

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- Thyssenkrupp - Supplier Rating PDFDocument18 pagesThyssenkrupp - Supplier Rating PDFmihaichfNo ratings yet

- 12 MGD MRM Report Jan-2020Document156 pages12 MGD MRM Report Jan-2020Manish KaushikNo ratings yet

- X BAR R ChartDocument4 pagesX BAR R ChartGaurao WarungaseNo ratings yet

- 10-Part Air Gauge Measurement AnalysisDocument4 pages10-Part Air Gauge Measurement AnalysisSaurabh PhandNo ratings yet

- MSA Bias & GRRDocument2 pagesMSA Bias & GRRRamchandrarao DeshpandeNo ratings yet

- Template Format Gauge R & RDocument5 pagesTemplate Format Gauge R & RQC-Metinca Prima Industrial WorksNo ratings yet

- Aiag Gage R&R Part Number Average & Range Met: Required OutputsDocument34 pagesAiag Gage R&R Part Number Average & Range Met: Required OutputsAyu LusiyanaNo ratings yet

- Customer Survey Form T2m 2009Document1 pageCustomer Survey Form T2m 2009Peracha EngineeringNo ratings yet

- 1 - Supplier Rating - Including Premium Freight1Document1 page1 - Supplier Rating - Including Premium Freight1RAJESH DHOKALENo ratings yet

- Performance Management Plan (PMP)Document3 pagesPerformance Management Plan (PMP)Sephora DjenadiNo ratings yet

- VCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingDocument1 pageVCIPL PQCS-HM-01-40 Process Quality Control Sheet for Forging & TrimmingBalram JiNo ratings yet

- MTTR & MTBF TrendDocument2 pagesMTTR & MTBF TrendMASU BRAKE PADS QANo ratings yet

- Supplier Performance Rating ReportDocument6 pagesSupplier Performance Rating ReportVikas KashyapNo ratings yet

- Improving Our Quality Management SystemDocument1 pageImproving Our Quality Management SystemSanjay DhawasNo ratings yet

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Sidhi Alcast: Machine Maintenance RecordDocument1 pageSidhi Alcast: Machine Maintenance Recordpulkit gargNo ratings yet

- Alpha Drives: Vendor RatingDocument10 pagesAlpha Drives: Vendor Ratingdaniel_sasikumarNo ratings yet

- 8.5.1 Corrective Action FormDocument1 page8.5.1 Corrective Action FormvishvendanNo ratings yet

- A.1 Line Rejection, Escapes & Nope (Product SCAR Count)Document6 pagesA.1 Line Rejection, Escapes & Nope (Product SCAR Count)Mani Rathinam RajamaniNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- 8.fixture Inspection ReportDocument1 page8.fixture Inspection ReportBASAVA ENGINEERINGNo ratings yet

- PPAP Package for Inner Pipe PartDocument31 pagesPPAP Package for Inner Pipe PartPk NimiwalNo ratings yet

- IT Group Internal Audit Schedules and ReportsDocument11 pagesIT Group Internal Audit Schedules and ReportsBhavin SukhadiyaNo ratings yet

- MSP ProceduresDocument18 pagesMSP ProcedurestarunNo ratings yet

- MRM PlanDocument2 pagesMRM Plang.kannan100% (1)

- Annex 1 Legal Compliance Evaluation SheetDocument130 pagesAnnex 1 Legal Compliance Evaluation SheetChaitanya VamsiNo ratings yet

- SPC Chart BlankDocument1 pageSPC Chart BlankbowlinglmNo ratings yet

- List of Shelf Life ItemsDocument2 pagesList of Shelf Life ItemsDhinakaranNo ratings yet

- New Prod-DB and KPI 22Document5 pagesNew Prod-DB and KPI 22Senthilmani MuthuswamyNo ratings yet

- In House PPM MonitoringDocument2 pagesIn House PPM MonitoringSrinath NavadaNo ratings yet

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarNo ratings yet

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- Master List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoDocument6 pagesMaster List of Document Information (Formats) : S. No. Format No. Document Title Owner Rev NoSafety DeptNo ratings yet

- WI-R&D-33 - Field Validation of ClutchDocument3 pagesWI-R&D-33 - Field Validation of ClutchDisha ShahNo ratings yet

- Internal audit checklist for MR, CIP, training and customer complaintsDocument3 pagesInternal audit checklist for MR, CIP, training and customer complaintsganrashNo ratings yet

- Quality and Delivery RatingsDocument7 pagesQuality and Delivery RatingsAarm IndiaNo ratings yet

- Kpi ItDocument3 pagesKpi ItShailesh GuptaNo ratings yet

- Supplier Performance Scorecard ReviewDocument5 pagesSupplier Performance Scorecard Reviewsunil ayareNo ratings yet

- Personal Annual Plan For The Year: 2019: BAM International BV Projects Ade Tedi Subcon ManagerDocument3 pagesPersonal Annual Plan For The Year: 2019: BAM International BV Projects Ade Tedi Subcon ManagerMark RamirezNo ratings yet

- 10.roles, Responsibilities, Authority & AccountabilityDocument13 pages10.roles, Responsibilities, Authority & AccountabilitymuthuselvanNo ratings yet

- Roles and Responsibilities of Quality Assurance StaffDocument18 pagesRoles and Responsibilities of Quality Assurance StaffDhinakaranNo ratings yet

- 390018-Lito Garcia Junio-Production Team LeaderDocument3 pages390018-Lito Garcia Junio-Production Team LeaderATKNo ratings yet

- Attribute MSA 4th EditionDocument4 pagesAttribute MSA 4th EditionSachin RamdurgNo ratings yet

- Process Capability Study Report: U.T.L. L.T.LDocument7 pagesProcess Capability Study Report: U.T.L. L.T.Lt836549No ratings yet

- Capacity VerificationDocument4 pagesCapacity VerificationLucinei SantosNo ratings yet

- Quality Manual: Organization ChartDocument2 pagesQuality Manual: Organization ChartmuthuselvanNo ratings yet

- APQP (27) ElementsDocument31 pagesAPQP (27) Elementssam1hi5No ratings yet

- IATF 16949 Audit Status & Importance TrackerDocument5 pagesIATF 16949 Audit Status & Importance TrackerUlhas Kavathekar0% (1)

- Document NumberingDocument8 pagesDocument NumberingRaja RehaNo ratings yet

- 5S Checklist for Automotive Manufacturing FacilityDocument2 pages5S Checklist for Automotive Manufacturing FacilitySridharan VenkatNo ratings yet

- Process Performance MeasuresDocument2 pagesProcess Performance MeasuresKarthi ThiyagarajanNo ratings yet

- Final Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoDocument10 pagesFinal Inspection: Roles, Responsibilities & Authority What Where When Who How Man Hours Sr. NoVikas KashyapNo ratings yet

- SPC Study Shows Highly Capable ProcessDocument1 pageSPC Study Shows Highly Capable ProcessVenkateswaraa InsulationNo ratings yet

- EU Space Policy DirectorDocument1 pageEU Space Policy DirectorClau0% (1)

- Supplier Rating Calculator and AlgorithmDocument3 pagesSupplier Rating Calculator and AlgorithmShahnawaz PathanNo ratings yet

- STD PD R 01 Product Development ReportDocument6 pagesSTD PD R 01 Product Development ReportsamcbsivNo ratings yet

- Work R StressDocument4 pagesWork R StresssamcbsivNo ratings yet

- CSL New Tooling PhotoDocument8 pagesCSL New Tooling PhotosamcbsivNo ratings yet

- LBH-BD-D-01 Profile Format FileDocument43 pagesLBH-BD-D-01 Profile Format FilesamcbsivNo ratings yet

- Colorimetric TestDocument10 pagesColorimetric TestsamcbsivNo ratings yet

- WI 7 4 3 1 Supplier Quality and Packaging Requirements Manual Rev HDocument54 pagesWI 7 4 3 1 Supplier Quality and Packaging Requirements Manual Rev HsamcbsivNo ratings yet

- Rolling ProcessDocument22 pagesRolling ProcesssamcbsivNo ratings yet

- NCR Supplier Scorecard ProcessDocument11 pagesNCR Supplier Scorecard ProcesssamcbsivNo ratings yet

- Customer SatisfactionAudco ItaliaDocument3 pagesCustomer SatisfactionAudco ItaliasamcbsivNo ratings yet

- Component Approval Process Requirements ManualDocument20 pagesComponent Approval Process Requirements ManualsamcbsivNo ratings yet

- How To Stay Ina Work Environment: Posi IVEDocument28 pagesHow To Stay Ina Work Environment: Posi IVEXee JayNo ratings yet

- ADMP002 Vendor Selectionand Management Process 110203Document9 pagesADMP002 Vendor Selectionand Management Process 110203samcbsivNo ratings yet

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Formulae For Vendor RatingDocument3 pagesFormulae For Vendor RatingMadhavan RamNo ratings yet

- SWI Procedure ForgedDocument12 pagesSWI Procedure ForgedsamcbsivNo ratings yet

- Castings Defects Analyis With StimulationDocument8 pagesCastings Defects Analyis With StimulationsamcbsivNo ratings yet

- Bible of Vendor AuditDocument63 pagesBible of Vendor Auditrana_ehsan1163No ratings yet

- Entrepreneur TestDocument8 pagesEntrepreneur TestAriful RussellNo ratings yet

- 7 InspectionsEvaluation TestingDocument79 pages7 InspectionsEvaluation TestinghoangcokhiNo ratings yet

- Loan Calculator: Loan Amount: Annual Interest RateDocument6 pagesLoan Calculator: Loan Amount: Annual Interest RatekushalNo ratings yet

- Porosity in Castings AFS Transactions 2005Document28 pagesPorosity in Castings AFS Transactions 2005jlplazaolaNo ratings yet

- New Rabbit and Tortoise StoryDocument31 pagesNew Rabbit and Tortoise StoryAbd Rahman IbrahimNo ratings yet

- Asme 8 Division 1 - Page 103Document1 pageAsme 8 Division 1 - Page 103samcbsivNo ratings yet

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Astm Material Composition PDFDocument2 pagesAstm Material Composition PDFAlessandra ContiNo ratings yet

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Intec 2013 Brochure PDFDocument6 pagesIntec 2013 Brochure PDFkalirajgurusamyNo ratings yet

- Iso 8062Document1 pageIso 8062Asrar Ahmed100% (2)

- Bernoulli Formula With SampleDocument3 pagesBernoulli Formula With SampleIan DalisayNo ratings yet

- Sequential Testability Measures, RTL Testability and HazardsDocument47 pagesSequential Testability Measures, RTL Testability and HazardsPATEL RUTVIKNo ratings yet

- Logistic Regression Quiz - Predictive Modeling - Great LearningDocument8 pagesLogistic Regression Quiz - Predictive Modeling - Great LearningRanadip Guha100% (2)

- Predicting Fake Online Reviews Using Machine LearningDocument5 pagesPredicting Fake Online Reviews Using Machine LearningKeerthi GuruNo ratings yet

- Question 1: Bezier Quadratic Curve Successive Linear Interpolation EquationDocument4 pagesQuestion 1: Bezier Quadratic Curve Successive Linear Interpolation Equationaushad3mNo ratings yet

- Finite Element Methods For Maxwells Equations Peter Monk University of DelawareDocument38 pagesFinite Element Methods For Maxwells Equations Peter Monk University of DelawarekbNo ratings yet

- Background Study and Literature ReviewDocument22 pagesBackground Study and Literature ReviewHafizuddin TarmiziNo ratings yet

- Simulink Tutorial - Create Models and Simulate Dynamic SystemsDocument10 pagesSimulink Tutorial - Create Models and Simulate Dynamic SystemsroscovanulNo ratings yet

- Stability Analysis For A Class of Takagi-Sugeno Fuzzy Control SystemsDocument12 pagesStability Analysis For A Class of Takagi-Sugeno Fuzzy Control SystemsBộ Môn DieuKhienhocNo ratings yet

- Fractal Image Compression: Presented By: Sarika Rani EC3 YearDocument17 pagesFractal Image Compression: Presented By: Sarika Rani EC3 YearPrabhat SharmaNo ratings yet

- Capitulo 10 Metodos NumericosDocument42 pagesCapitulo 10 Metodos NumericosMarioAlbertoSimbronNo ratings yet

- Turbo Codes: Promises and Challenges ExplainedDocument5 pagesTurbo Codes: Promises and Challenges Explainedyancgece9763No ratings yet

- ISC CS Practical Specimen PaperDocument2 pagesISC CS Practical Specimen PaperSayak KolayNo ratings yet

- BDM Under Risk DetailsDocument7 pagesBDM Under Risk DetailsPramod kNo ratings yet

- Defuzzification Methods ExplainedDocument43 pagesDefuzzification Methods ExplainedsunilkumareceNo ratings yet

- Unit 3 Divide and Conquer: StructureDocument18 pagesUnit 3 Divide and Conquer: StructureJohn ArthurNo ratings yet

- Cs6711 Security Laboratory Manual 2 PDFDocument66 pagesCs6711 Security Laboratory Manual 2 PDFrachanapatil123100% (1)

- Lect 0825Document5 pagesLect 0825blabla9999999No ratings yet

- PSO AndryPinto InesDomingues LuisRocha HugoAlves SusanaCruzDocument42 pagesPSO AndryPinto InesDomingues LuisRocha HugoAlves SusanaCruzfaizazohraNo ratings yet

- Error Propagation JPDocument25 pagesError Propagation JPsihan wangNo ratings yet

- Artifical Intelligence Unit 5Document15 pagesArtifical Intelligence Unit 5KP EDITZNo ratings yet

- Mcclure SomDocument12 pagesMcclure SomHellen KatoNo ratings yet

- Control Systems: GATE Objective & Numerical Type SolutionsDocument14 pagesControl Systems: GATE Objective & Numerical Type SolutionsAakash DewanganNo ratings yet

- ARIMA (P, D, Q) ModelDocument4 pagesARIMA (P, D, Q) ModelselamitspNo ratings yet

- LU Decomposition With Gauss EliminationDocument4 pagesLU Decomposition With Gauss EliminationJigar ShethNo ratings yet

- 1 Introduction To Finite Element Methods For Electromagnetic Fields and Coupled ProblemsDocument128 pages1 Introduction To Finite Element Methods For Electromagnetic Fields and Coupled ProblemsPedro Vargas ChabléNo ratings yet

- Management Science Prelim - Ando RejieDocument3 pagesManagement Science Prelim - Ando RejieRejie AndoNo ratings yet

- Instructions:: Cause & Effect MatrixDocument3 pagesInstructions:: Cause & Effect MatrixAhmed MagdiNo ratings yet

- "Dynamics of Love": Mathematical Modeling (CO2011)Document16 pages"Dynamics of Love": Mathematical Modeling (CO2011)Curacao JTRNo ratings yet

- PML Lec1 Slides PDFDocument111 pagesPML Lec1 Slides PDFkishan shuklaNo ratings yet