Professional Documents

Culture Documents

VP Simulator

Uploaded by

sigmasundarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VP Simulator

Uploaded by

sigmasundarCopyright:

Available Formats

BASELINE

VALUE

NEW

VALUE

0% 0%

95.0% 95.0%

40 40

95% 95%

0% 0%

0% 0%

1.0 1.0

0.00

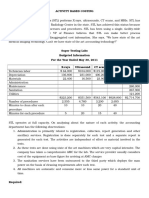

ITEM

FG

POLICY

FORE-

CAST

WEEKLY

AVERAGE

FORE-

CAST

WEEKLY

STDEV

CHANGE

OVER

HOURS

WEEKLY

CYCLE

HOURS

DEMAND

DURING

LEAD

TIME

BUFFER

STOCK

AVERAGE

ORDER

QUANTITY

100001 MTS 5,000 2,141 0.50 16.67 10,000 4,980 5,000

100002 MTO 500 0.20 1.67 500

100003 MTO 1,300 0.50 4.33 1,300

100004 MTS 2,500 3,071 0.20 4.17 5,000 7,143 2,500

100005 MTO 200 0.30 0.67 200

100006 MTO 700 0.50 1.17 700

100007 MTS 4,000 3,036 0.50 6.67 8,000 7,063 4,000

TOTALS 14,200 2.70 35.33 14,200

synchronousmanagement.com

Duplication of these materials is prohibited without the express written permission of Synchronous Management of Milford, CT.

OPERATING CONDITIONS

MACHINE UPTIME (PERCENT)

CHANGEOVER REDUCTION (PERCENT)

0.00

CUSTOMER SERVICE LEVEL (PERCENT)

WEEKS TO COVER

CYCLE TIME REDUCTION (PERCENT)

OUTSIDE PROCESSING LEAD TIME (WEEKS)

DEMAND INFORMATION

PROCESSING

INFORMATION

SUPERMARKETS

SELECT A NEW VALUE

VIRTUAL PULL SIMULATOR

This simulator is intended to be used in conjunction with our article on Virtual Pull.

We strongly suggest reading the article before using this simulation.

CHANGE IN WEEKLY FORECAST (PERCENT)

WEEKLY AVAILABLE TIME (HOURS)

MINIMUM

ANNUAL

INVENTORY

TURNS

OUTPUT

UNITS PER

HOUR

MAXIMUM

INVEN-

TORY

(UNITS)

MAXIMUM

INVEN-

TORY

(WEEKS) SCHEDULE

UNITS IN

PROCESS

UNITS ON

HAND

WEEK

1

WEEK

2

WEEK

3

WEEK

4

WEEK

5

19,980 4 5,000 5,000 5,000 5,000 9,000 5,000

950 200 700

1,500 4,200 3,300

14,643 6 2,500 8,000 2,500 6,000 2,500 4,200 2,500

317 1,700

900 702 1,100 4,300

19,063 5 4,000 7,553 4,220 4,000 4,000 4,000 4,000

53,686

guild@att.net 203-877-1287

Duplication of these materials is prohibited without the express written permission of Synchronous Management of Milford, CT.

14

VS.

BASE OF

14

CURRENT

INVENTORY

COVERAGE FUEL GAUGE

INSTRUCTIONS

By selecting new values from the OPERATING CONDITIONS slider boxes, you can

make changes in forecasted sales volume, required customer service level,

working hours, machine uptime, total changeovers, total cycle times, and outside

processing lead time - or any combination of these! You will then see the impact of

your changes on inventory turns and output per hour.

Then, set the schedule for the next production cycle by selecting a value from the

WEEKS TO COVER slider box so that the total SCHEDULE approximates the total of

the AVERAGE ORDER QUANTITIES (one production cycle).

To reset all OPERATING CONDITIONS and the WEEKS TO COVER to their

BASELINE values click here:

SELECT A NEW VALUE

Download

Virtual Pull Article

355

VIRTUAL PULL SIMULATOR

This simulator is intended to be used in conjunction with our article on Virtual Pull.

We strongly suggest reading the article before using this simulation.

VS.

BASE OF

355

WEEK

6

4,200

2,500

1,700

203-877-1287

Duplication of these materials is prohibited without the express written permission of Synchronous Management of Milford, CT.

FUEL GAUGE

INSTRUCTIONS

By selecting new values from the OPERATING CONDITIONS slider boxes, you can

make changes in forecasted sales volume, required customer service level,

working hours, machine uptime, total changeovers, total cycle times, and outside

processing lead time - or any combination of these! You will then see the impact of

your changes on inventory turns and output per hour.

Then, set the schedule for the next production cycle by selecting a value from the

WEEKS TO COVER slider box so that the total SCHEDULE approximates the total of

the AVERAGE ORDER QUANTITIES (one production cycle).

To reset all OPERATING CONDITIONS and the WEEKS TO COVER to their

BASELINE values click here:

You might also like

- Pom Sol 10Document5 pagesPom Sol 10amritranjan123_34249No ratings yet

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- Downtime Analysis: SER 076 Issue2Document3 pagesDowntime Analysis: SER 076 Issue2sigmasundarNo ratings yet

- 01-02-03-Aggregate Sales & Operations PlanningDocument65 pages01-02-03-Aggregate Sales & Operations Planningfriendajeet123No ratings yet

- ICAAP Overview Core Concepts TocDocument3 pagesICAAP Overview Core Concepts TocJawwad FaridNo ratings yet

- Wilkerson Case SubmissionDocument5 pagesWilkerson Case Submissiongangster91100% (2)

- Notes On Theory of Production and CostDocument6 pagesNotes On Theory of Production and CostSandeep K Biswal100% (2)

- Tesco Maintenance Guide PDFDocument136 pagesTesco Maintenance Guide PDFdraghiceanu50% (2)

- Hilton CH 6 Select SolutionsDocument19 pagesHilton CH 6 Select SolutionsRaymondSinegar100% (1)

- Product ProfitabilityDocument16 pagesProduct Profitabilitybrigadier786239190% (10)

- Cybernetic Analysis for Stocks and Futures: Cutting-Edge DSP Technology to Improve Your TradingFrom EverandCybernetic Analysis for Stocks and Futures: Cutting-Edge DSP Technology to Improve Your TradingRating: 5 out of 5 stars5/5 (1)

- Tourism PromotionDocument8 pagesTourism PromotionAnnaliza B. Sagat-SantosNo ratings yet

- Life Cycle Q&aDocument48 pagesLife Cycle Q&aanjNo ratings yet

- Revised Bloom's TaxonomyDocument17 pagesRevised Bloom's TaxonomyValerie Cruz - OcampoNo ratings yet

- Multistage Flowsheets Sabc1Document204 pagesMultistage Flowsheets Sabc1alonsogonzalesNo ratings yet

- Creative Brief TemplateDocument1 pageCreative Brief TemplateRenee GibbsNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireRohit Sharma50% (2)

- 16 SolutionsDocument10 pages16 SolutionsFebrie Dharma KuncoroNo ratings yet

- Disposable SyringeDocument5 pagesDisposable SyringePrabhu KoppalNo ratings yet

- Bergerac System Case Analysis-Group 1Document11 pagesBergerac System Case Analysis-Group 1Karan Trivedi100% (1)

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Ajustable Hospital Beds PsDocument11 pagesAjustable Hospital Beds PsManish PoddarNo ratings yet

- Case Stdy OPM545 (Boys and Boden)Document15 pagesCase Stdy OPM545 (Boys and Boden)wasab negiNo ratings yet

- 5 - CostDocument34 pages5 - CostAarogyaBharadwajNo ratings yet

- Production and Costs: The Short RUNDocument46 pagesProduction and Costs: The Short RUNAkshay DagurNo ratings yet

- 4 Production Functions - PPT IsoquantsDocument46 pages4 Production Functions - PPT IsoquantsVishal GalaNo ratings yet

- Alternate Aggragate PLanning MethodDocument2 pagesAlternate Aggragate PLanning MethodPraveen JosephNo ratings yet

- Evaluating Alternatives: Optimal Rate of Output Economies of ScaleDocument5 pagesEvaluating Alternatives: Optimal Rate of Output Economies of ScaleGene Justine SacdalanNo ratings yet

- Colorscope 20101029 v0 1 ABDocument20 pagesColorscope 20101029 v0 1 ABirquadri0% (1)

- Colorscope 20101029 v0 1 ABDocument19 pagesColorscope 20101029 v0 1 ABrahulrao70% (1)

- Strategic Capacity ManagementDocument36 pagesStrategic Capacity ManagementAbinash PadhyNo ratings yet

- Wasab Singh Negi (Assessment 2)Document4 pagesWasab Singh Negi (Assessment 2)wasab negiNo ratings yet

- Lecture 6 Cost Based DesignDocument27 pagesLecture 6 Cost Based DesignWajid RaheemNo ratings yet

- ABC Practice QuestionsDocument4 pagesABC Practice QuestionsShalvi Mithal100% (1)

- Operations Management Issues For A Sanitary Napkin MakerDocument18 pagesOperations Management Issues For A Sanitary Napkin Makerpulakguy100% (1)

- Discount Rate: Menetapkan Asumsi No Uraian Satuan JumlahDocument29 pagesDiscount Rate: Menetapkan Asumsi No Uraian Satuan JumlahteaNo ratings yet

- Unit 7 Capacity Planning: ObjectivesDocument10 pagesUnit 7 Capacity Planning: ObjectivesSujay Vikram SinghNo ratings yet

- Performance Drinks Case 2 QureshiDocument9 pagesPerformance Drinks Case 2 QureshiRabia Qureshi100% (2)

- Microeconomics - Tutorial Practice Attempt 8&9Document5 pagesMicroeconomics - Tutorial Practice Attempt 8&9Kelyn KokNo ratings yet

- White Paper On Work Order Closing VariancesDocument18 pagesWhite Paper On Work Order Closing VariancesadnanakdrNo ratings yet

- Bpls Project BudgetDocument5 pagesBpls Project Budgetapi-241467567No ratings yet

- MBA6404 - Managing For Productivity & Quality: Session 02: MEASUREMENT OF Productivity and Productivity BenchmarkingDocument34 pagesMBA6404 - Managing For Productivity & Quality: Session 02: MEASUREMENT OF Productivity and Productivity BenchmarkingNilushi FonsekaNo ratings yet

- Accounting 2Document7 pagesAccounting 2vietthuiNo ratings yet

- Front PageDocument7 pagesFront PageogundaretimmyNo ratings yet

- CH 22Document5 pagesCH 22ProfNDAcharyaNo ratings yet

- Aggregate Planning: @imt, NagpurDocument23 pagesAggregate Planning: @imt, Nagpurpriyanka valechhaNo ratings yet

- Year I Year II Year IIIDocument4 pagesYear I Year II Year IIIvNo ratings yet

- Making Investment Decisions With The Net Present Value Rule: Principles of Corporate Finance, 8/eDocument26 pagesMaking Investment Decisions With The Net Present Value Rule: Principles of Corporate Finance, 8/eMuneendra BhardwajNo ratings yet

- 2000jun01 Qa RR PM TaDocument4 pages2000jun01 Qa RR PM TaSharmashDNo ratings yet

- Bulkline 650-1000 IOM ENDocument24 pagesBulkline 650-1000 IOM ENfurtanNo ratings yet

- Voltage StabilizerDocument11 pagesVoltage StabilizerShreekant KashyapNo ratings yet

- Q & A - Sept 2018 - ABCDocument5 pagesQ & A - Sept 2018 - ABCvipsc201505No ratings yet

- Theory of Production - Graphs and Economic TermsDocument15 pagesTheory of Production - Graphs and Economic TermsGovindra ShippingNo ratings yet

- Crushing Plant Performance Optimization NZDocument13 pagesCrushing Plant Performance Optimization NZSolucionesPolimNo ratings yet

- Ballou10 ImDocument13 pagesBallou10 ImCarlos Huerta OrellanaNo ratings yet

- Mech - Adjustable Hospital BedsDocument7 pagesMech - Adjustable Hospital Bedssanjay_lingotNo ratings yet

- Chapter 3 Problems - Review in ClassDocument9 pagesChapter 3 Problems - Review in Classjimmy_chou1314No ratings yet

- Ice Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiDocument9 pagesIce Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiBunty RathoreNo ratings yet

- (181028) Quotation of BG-80E High-Efficiency Intelligent Film Coating Machine-2Document19 pages(181028) Quotation of BG-80E High-Efficiency Intelligent Film Coating Machine-2Unison Homoeo LaboratoriesNo ratings yet

- ABC - Activity Based CostingDocument6 pagesABC - Activity Based CostingShan rNo ratings yet

- Fonderia Di Torino S.P.A Case Answers: Submitted To Sir Suresh Kumar RajputDocument4 pagesFonderia Di Torino S.P.A Case Answers: Submitted To Sir Suresh Kumar RajputUzair Ahmed SoomroNo ratings yet

- Flip Flow ScreenDocument6 pagesFlip Flow Screenani1985No ratings yet

- Image0 (8 Files Merged)Document8 pagesImage0 (8 Files Merged)Fatima Ansari d/o Muhammad AshrafNo ratings yet

- Commercial & Service Industry Machinery, Miscellaneous World Summary: Market Values & Financials by CountryFrom EverandCommercial & Service Industry Machinery, Miscellaneous World Summary: Market Values & Financials by CountryNo ratings yet

- Introduction To WeldingDocument8 pagesIntroduction To WeldingsigmasundarNo ratings yet

- Developing Delivering: Locally. GloballyDocument21 pagesDeveloping Delivering: Locally. GloballysigmasundarNo ratings yet

- MMZG 522 Total Quality Management: Rajiv Gupta BITS Pilani August 2014Document48 pagesMMZG 522 Total Quality Management: Rajiv Gupta BITS Pilani August 2014sigmasundarNo ratings yet

- TPM Score Criteria WorksheetDocument2 pagesTPM Score Criteria WorksheetsigmasundarNo ratings yet

- Regcorr 5Document20 pagesRegcorr 5sigmasundarNo ratings yet

- Section 1: Make Allowances For ItDocument28 pagesSection 1: Make Allowances For ItsigmasundarNo ratings yet

- Process Capability Overview-TamilDocument2 pagesProcess Capability Overview-TamilsigmasundarNo ratings yet

- Industrial Statistics (2Ws02) : TeachersDocument3 pagesIndustrial Statistics (2Ws02) : TeacherssigmasundarNo ratings yet

- Graduate Lectures and Problems in Quality Control and Engineering Statistics: Theory and MethodsDocument4 pagesGraduate Lectures and Problems in Quality Control and Engineering Statistics: Theory and MethodssigmasundarNo ratings yet

- Quantitative Quality Management Through Defect Prediction and Statistical Process ControlDocument6 pagesQuantitative Quality Management Through Defect Prediction and Statistical Process ControlsigmasundarNo ratings yet

- ISE 542 Production Planning and Control: Due Date: March 2, SundayDocument2 pagesISE 542 Production Planning and Control: Due Date: March 2, SundaysigmasundarNo ratings yet

- Bajaj Auto Pvt. Ltd. Market Returns and Stock PriceDocument4 pagesBajaj Auto Pvt. Ltd. Market Returns and Stock PriceArron CarterNo ratings yet

- Junaidi IF 97 - Curriculum VitaeDocument1 pageJunaidi IF 97 - Curriculum VitaePetra Novandi BarusNo ratings yet

- East Dairies - CleantechDocument6 pagesEast Dairies - CleantechMiro TafraNo ratings yet

- HR Practices in BSNLDocument3 pagesHR Practices in BSNLabdullahgreen2No ratings yet

- QuestionnaireDocument4 pagesQuestionnaireVandana Insan100% (1)

- Keywords: Car, Midsize, MumbaiDocument1 pageKeywords: Car, Midsize, Mumbaizulfi66No ratings yet

- Lecture 4 - CAPM ProofDocument5 pagesLecture 4 - CAPM ProofShashank GuptaNo ratings yet

- PMP BrochureDocument1 pagePMP BrochureSoban KumarNo ratings yet

- Presentation ON Human Resource Accounting in Indian Company: Submitted By:-Vivek Jain 20110960Document9 pagesPresentation ON Human Resource Accounting in Indian Company: Submitted By:-Vivek Jain 20110960Vivek JainNo ratings yet

- QF 5 6-Management Review Agenda and MinutesDocument4 pagesQF 5 6-Management Review Agenda and MinutesRafik BizerteNo ratings yet

- SPPM Syllabus1Document2 pagesSPPM Syllabus1Dhanikonda Srinivasarao0% (1)

- Participatory Technology DevelopmentDocument12 pagesParticipatory Technology DevelopmentManiram PaudelNo ratings yet

- International BusinessDocument2 pagesInternational BusinessPrateek Sinha0% (2)

- Rusame33492Document1 pageRusame33492jinalpatel004No ratings yet

- XI Economics by Sir Rehan RanaDocument1 pageXI Economics by Sir Rehan RanaSyed Mairaj Ul HaqNo ratings yet

- Philips Vs MatsushitaDocument7 pagesPhilips Vs MatsushitaHendry Lukito50% (2)

- Sample Verbs For Learning OutcomesDocument2 pagesSample Verbs For Learning OutcomesgeraldygayNo ratings yet

- McKinley Village BrochureDocument11 pagesMcKinley Village BrochureJared GoyetteNo ratings yet

- Calculate Beta With ExcelDocument4 pagesCalculate Beta With ExcelSumit DuaNo ratings yet

- Introduction On HDFC BankDocument3 pagesIntroduction On HDFC BankAditya Batra50% (2)

- Mba - Ib Semester IVDocument3 pagesMba - Ib Semester IVHashmi EugineNo ratings yet

- Case 7.1Document3 pagesCase 7.1huhuei2005100% (1)

- Cash Flow Statement - Indirect MethodDocument5 pagesCash Flow Statement - Indirect MethodBimal KrishnaNo ratings yet

- A Brief History of Daniel J. Edelman China GroupDocument1 pageA Brief History of Daniel J. Edelman China GroupEdelmanAPACNo ratings yet

- ODI Open Data Stories 2014-03Document9 pagesODI Open Data Stories 2014-03Open Data InstituteNo ratings yet