Professional Documents

Culture Documents

10 1 1 67 4347

Uploaded by

SasankOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 1 1 67 4347

Uploaded by

SasankCopyright:

Available Formats

Comparison of Turbine Discharge Measured by Current

Meters and Acoustic Scintillation Flow Meter at

Fort Patrick Henry Power Plant

By David D. Lemon, ASL Environmental Sciences Inc., Sidney, B.C., Canada, Charles W. Almquist, Principia Research Corp.,

Knoxville, TN, USA, Ward W. Cartier, ASL Environmental Sciences Inc., Patrick A. March, Tennessee Valley Authority,

Norris, TN, USA and Thomas A. Brice, Tennessee Valley Authority, Chattanooga, TN, USA.

ABSTRACT

Performance tests were conducted on Unit 1 at the Tennessee Valley Authoritys Fort Patrick

Henry Plant on September 24 25, 1997. These tests included measurements of the discharge

through the turbine using current meters and the Acoustic Scintillation Flowmeter (ASFM). Fort

Patrick Henry is a low-head, short intake plant typical of the type for which current meters have

been the traditional and only effective method for measuring discharge. Unit 1 is rated at 21

megawatts and is equipped with a Kaplan turbine. The intake to the turbine consists of two bays,

each 21.65 ft high and 17.67 ft wide. The net head for the plant is approximately 65 ft.

Measurements of the discharge through the turbine were made at two power levels: the Most

Efficient Load (MEL) and the Maximum Sustainable Load (MSL). The ASFM is a new

instrument which offers some unique advantages for measuring intake flows in plants of this

type. It is non-intrusive, and its deployment in intake gate slots is straightforward, allowing data

to be collected with a minimum of plant down-time. The measurements described here were

taken to assess the ASFMs accuracy under operational conditions. Flow measurements at the

same unit settings were made using current meters operated by the Norris Engineering

Laboratory, for comparison with the ASFM results. The ASFM and current meter measurements

were made sequentially. Immediately following data collection discharges were computed

independently and then compared. These results for both techniques agreed to within 1%, after

correction for small head differences between the measurements.

Introduction

Acoustic scintillation drift is a technique for measuring flows in a turbulent medium, such as

water or air, by analyzing the variations (with position and time) of sound which has passed

through it. Scintillation in this context refers to random variations in the intensity of the sound

caused by the variations in the refractive index of the water produced by the turbulence which is

always present in any natural flow. The ASFM measures the speed of the current from the

transverse drift of the acoustic scintillations observed across two relatively closely-spaced

- 2 -

propagation paths. The method has been used for many years to measure winds in the

atmosphere and ionosphere (Ishimaru, 1978; Lawrence, Ochs & Clifford, 1972; Wang, Ochs &

Lawrence, 1981), more recently for measuring currents and turbulence in ocean channels

(Clifford & Farmer, 1983; Farmer & Clifford, 1986; Farmer, Clifford & Verrall, 1987; Lemon &

Farmer, 1990) and in hydroelectric plants (Birch & Lemon, 1993; Lemon, 1995; Lemon & Bell,

1996); its derivation is well-established.

The ASFM measures the lateral (i.e. along-path) average of the component of the flow

perpendicular to the acoustic path. It is therefore well-suited for collecting data for discharge

measurements, since the product of the path length with the lateral average of the normal

component of flow gives the element of discharge at the depth of the path. Sampling at several

levels in the vertical and integrating then gives the discharge.

Application in Hydroelectric Plants

Measurement of the discharge for a turbine requires that a location in the intake be chosen as the

measurement plane, and a number of sampling paths be established across it. The transducers

can either be fixed to the intake walls, for a permanent installation, or attached to a frame

deployed into a gate slot, if one is available. Using a frame in a gate slot allows the ASFM to be

moved from one unit to another relatively quickly and easily, if the slots are all the same size.

The number of paths required to sample in the vertical is achieved either by placing transducers

at every desired height on the frame, or by using fewer transducers and moving the frame to the

required elevations. In either case, the discharge is computed by integrating the horizontal

component of the laterally-averaged velocity over the height of the intake.

The ASFM measurements at Fort Patrick Henry were planned to coincide with discharge

measurements using current meters, to be carried out by the Norris Engineering Laboratory after

installation of an upgraded turbine in Unit 1. Discharge would thus be measured by both

methods, under the same circumstances, which would afford an opportunity to make a direct

comparison of the two, and assess the accuracy of the ASFM in measuring discharge under

operational conditions. Measurements of the discharge were planned for two operating points,

and were to be made sequentially by the two methods, as the same support frame was to be used

by the current meters and the ASFM, in order to keep the measurement conditions as close as

practically possible to being identical.

Fort Patrick Henry is a 40MW low head plant equipped with two Kaplan turbines. Each turbine

is configured with a two-bay intake and a single gate slot for each bay. Unit 1 has two

rectangular intake bays, each 21.65 feet high and 17.67 feet wide. The unit operates at a net head

of approximately 65 feet with a maximum rated output of 21 MW. The distance from the deck

to the bottom of the gate slot is 76 feet.

- 3 -

Measurements

Discharge measurements were planned for two test points: 1 (MEL: Most Efficient Load) and 2

(MSL: Maximum Sustainable Load), corresponding to the expected maximum efficiency and

maximum power output, respectively. Data were first collected with the current meters at test

point 1. The meters were then removed, the ASFM transducers were mounted and data was

collected by the ASFM system at test points 1 and 2. The ASFM transducers were then removed

and replaced with current meters for measurement at test point 2. The current meter data for test

point 1 were collected September 24; all the remaining data were collected September 25.

ASFM Data Collection

The components of the ASFM are shown in Figure 1. The instrument was set up with one pair of

transducers for each intake bay, mounted on the same frames used for the current meters. Cables

from the transducers ran to a transmitter canister and receiver/switching canister, mounted on the

deck between the two gate slots. A set of surface cables connected the canisters to the data

acquisition and control module, set up under a protective cover on the deck.

Measurements were taken at 13 separate elevations in each intake bay (Table 1). The frames

were first lowered to level 1, and held there. Flow data were collected for 120 seconds in Bay 1,

then for 120 seconds in Bay 2. The frames were then lowered to level 2 and the process was

repeated down to, and including, level 13.

Table 1: Measurement Levels

Level Elevation (ft) Level Elevation (ft) Level Elevation (ft)

Roof 53.92 5 59.77 10 71.95

1 54.25 6 62.24 11 73.66

2 54.61 7 64.74 12 74.86

3 55.81 8 67.23 13 75.27

4 57.54 9 69.70 Floor 75.60

Current Meter Data Collection

The principle of current meter-based flow determination is to measure the flow velocities at a

number of points across a section of the intake, and then to numerically integrate these point

flow velocities over the intake area to determine the total flow. The current meters used in these

tests are horizontal-axis propeller meters which are specially designed to respond only to the

horizontal component of the flow velocity vector. The flow velocity at a given current meter

location is determined by counting the number of revolutions of the propeller over a fixed period

of time, and then applying calibration curves to convert the average rotational speed to velocity.

At Fort Patrick Henry, the current meters were mounted in a horizontal line on the same two

frames (one for each intake bay) as were used for the ASFM measurements. Eight current

meters were mounted on each frame, arranged so that the spacing between the current meters

- 4 -

was closer near the wall and further apart near the center of the frame. Full coverage of the

intake was achieved by successively lowering the frame to each of the thirteen vertical elevations

given in Table 1. At each vertical location, the revolutions of the current meter propellers were

counted for a period of three minutes using automatic data acquisition, and the average velocity

at each current metering point was determined from these counts. More detail on the current

metering method can be found in the IEC test code for hydraulic turbines (IEC, 1991) and the

ISO code for current meter flow measurement (ISO, 1988).

Figure 1: Major ASFM system components.

Results

ASFM Velocity Distribution

The ASFM measured a laterally-averaged value of the flow speed and inclination for each of the

frame positions in each intake. That value is also an average over the sampling time at each

frame level, which in this case was 120 seconds. They are shown graphically in Figure 2 as

scaled vectors on a cross-sectional view of the intake. The number at the base of each arrow is

the flow speed in feet/second. The sharp variation in the velocity of the flow in the lower five

feet of the intake is likely due to a partial blockage of the trash rack.

Data Acquisition & Control Module

TRANSMITTER

CANISTER

TRANSDUCER CABLES

SURFACE CABLES

TRANSDUCER

TX Cable

RXCable

CTRLCable

ICC Cable

RECEIVER/SWITCHING

CANISTER

GATE SLOTFRAME

- 5 -

Discharge Computation: ASFM

The roof and floor of the intake tunnel, and the path followed by the sides of the frame holding

the ASFM transducers define a plane surface, S, through which the flow into the intake bay must

pass.

If z is the vertical coordinate, then the discharge, Q, in terms of the laterally-averaged velocity v

is:

where v(z) is the magnitude of the laterally averaged flow at elevation z, (z) is the

Figure 2: Laterally-averaged ASFM velocity vectors.

corresponding inclination angle, L is the width between the transducer faces (17.58 feet for Bay

1; 17.60 feet for Bay 2) and H is the height of the tunnel roof above the floor. The lateral

averaging performed by the ASFM is continuous, while the sampling in the vertical was at

thirteen discrete points. Calculating Q then requires estimation of the integral in equation 1

when the integrand is known at a finite number of points. The integral was evaluated

numerically using an adaptive Romberg integration, with a cubic spline interpolation in the

integrand between the measured points. The horizontal component of the velocity is forced to

zero at the floor of the tunnel, along a boundary layer curve of the form:

[z/z

0

]

1/n

(2)

( ) [ ] ) 1 ( cos ) (

0

dz L z z v Q

H

=

BAY 1

EL 53.92 ft

EL75.60 ft

BAY 2

EL 53.92 ft

EL 75.60 ft

BAY 1

EL53.92 ft

EL75.60 ft

BAY 2

EL53.92 ft

EL75.60 ft

MEL MSL

- 6 -

between the floor and the first measured point, z

0

, where n takes a value between 7 and 10,

depending on the thickness of the boundary layer expected above the tunnel floor. Because of

the proximity of the entrance, n was set to 10. At the roof, because of the open boundary at the

gate slot, the horizontal component of the velocity was not forced to zero, but was extrapolated

to the roof elevation H along the cubic spline fitted to the measured points with the second

derivative forced to zero at the endpoint.

Figure 3 shows the horizontal component of velocity, v

h

, for both intake bays for both conditions

1 and 2. The boundary layer assumption at the floor is shown as a dotted line.

Figure 3: Horizontal component of velocity vs. depth measured by the ASFM. The dotted lines show the assumed

boundary layer.

The area between each of these curves and the depth axis is the discharge for the corresponding

bay and condition. Because the current meter and ASFM measurements were taken sequentially,

rather than simultaneously, corrections for head differences between the measurement times had

to be applied before comparing the results of the two methods. The head differences measured

by the TVA test team resulted in correction factors of 0.99870 and 0.99751 for the MEL and

MSL measurements, respectively, to be applied to the ASFM discharge values. Table 2 lists the

discharges (before and after correcting for head differences) measured by the ASFM in each bay

as well as the total for both operation conditions.

Table 2: ASFM Discharges

MEL MEL MSL MSL

Q

ASFM

(cfs) Q

ASFM

, scaled (cfs) Q

ASFM

(cfs) Q

ASFM

, scaled (cfs)

Bay 1 1393.6 1391.8 2089.8 2084.6

Bay 2 1345.2 1343.5 2025.5 2020.4

Total 2738.8 2735.3 4115.3 4105.0

ASFM v

h

vs. Depth, MEL

50

55

60

65

70

75

80

0 1 2 3 4 5 6 7

v

h

(ft/sec)

D

e

p

t

h

(

f

t

)

Bay 1

Bay 2

ASFM v

h

vs Depth, MSL

50

55

60

65

70

75

80

0 1 2 3 4 5 6 7

v

h

(ft/sec)

D

e

p

t

h

(

f

t

)

Bay 1

Bay 2

- 7 -

Discharge Computation: Current Meters

The basic equation for computation of the flow from the point velocities measured in an intake

bay is

=

H L

h

dz dy z y v Q

0 0

) , ( (3)

where v

h

(y,z) is the horizontal component of the flow velocity at horizontal location y and

vertical location z, and L and H are the width and height of the intake bay at the current metering

location. This is very similar to Equation 1 for integration of the ASFM data, except that an

explicit integration of the data along the horizontal is required.

Equation 3 is evaluated numerically using a cubic spline integration technique described in detail

in the ISO standard for current meter measurements (ISO, 1988). At the boundaries of the flow

section, the boundary layer follows the equation presented in Equation 2. In addition, a small

correction factor is included to account for the blockage effect of the current meter frame on the

flow, which causes a slight increase in velocity at the current metering section (ISO, 1988).

Comparison of Discharge Results

The current meters recorded only the horizontal component of the velocity. Figure 4 shows the

vertical profiles of the horizontal component of the laterally-averaged velocity measured by both

methods for the MEL and MSL runs. The small differences between the profiles measured by

Figure 4: Comparison profiles of horizontal velocity, ASFM and current meters, both conditions.

Bay 1

MEL

MSL

50

55

60

65

70

75

80

0 1 2 3 4 5 6 7

v

h

(ft/sec)

D

e

p

t

h

(

f

t

)

ASFM

Current

Meters

Bay 2

MEL

MSL

50

55

60

65

70

75

80

0 1 2 3 4 5 6 7

v

h

(ft/sec)

D

e

p

t

h

(

f

t

)

ASFM

Current

Meters

- 8 -

the two methods are at least partly due to changes in the flow distribution which took place

during the interval between the two measurements. No correction has been made in these plots

for the changes in head which were applied to the discharge comparisons.

Figure 5 shows the discharge measured by the ASFM plotted against the discharge measured by

the current meters, for the individual bays and the total, for both conditions. The error bars

shown on the points are 1% for both quantities. The dotted line is the line of perfect

agreement; the solid line is the least-squares regression of the ASFM discharge on the current

meter values. The slope is 0.9947, with an R

2

coefficient of 0.9988. The least squares line

represents overall agreement between the discharges, over the measurement range, to within

0.5%. The largest single difference in total discharge is for the MSL case, where the difference

is 1.0%. Those measurements were made consecutively, and some of the difference may be

caused by real variations in the flow conditions.

Figure 5: Discharge comparison, ASFM vs. current meters (by TVA method).

The laterally-averaged current meter velocities were then integrated using the same algorithm

used for the ASFM data, to investigate the dependence of the discharge on the integration

method. The results are listed in Table 3.

Table 3: ASFM and Current Meter Discharge (Meters by ASL Integration)

MEL MEL MSL MSL

Q

CM

(cfs) Q

ASFM

, scaled (cfs) Q

CM

(cfs) Q

ASFM

, scaled (cfs)

Bay 1 1347.5 1391.8 2060.2 2084.6

Bay 2 1360.0 1343.4 2071.9 2020.4

Total 2707.5 2735.3 4132.1 4105.0

In this case, the least squares fit line has a slope of 0.998, and an R

2

of 0.9985. The overall

agreement as represented by the slope of the line has improved slightly to 0.2%, and the largest

difference in total discharge remains at 1%, but for the MEL case rather than the MSL case. In

both instances, the individual bay discharges differ by larger amounts, up to 3%, however the

MEL

MSL

partial discharges,

MEL

partial discharges,

MSL

QASFM = 0.9947QCM

R

2

= 0.9988

0

500

1000

1500

2000

2500

3000

3500

4000

4500

0 500 1000 1500 2000 2500 3000 3500 4000 4500

Q

CM

( c f s )

Q

A

S

F

M

(

c

f

s

)

Meas ur ement s

1:1 line

Least squar es l i ne

- 9 -

differences in the two bays are always of opposing sign, so that the difference in the total

discharge is always 1% or less. That suggests that the discharge differences in individual bays

are likely due to small changes in the flow distribution between the bays in the time between the

two measurement runs, while the total discharge remained relatively unchanged.

Conclusions

Flow rate measurements were performed at TVAs Fort Patrick Henry plant using a traditional

current metering method and using the relatively new acoustic scintillation technique. Each

method was used to measure the flow at two different power outputs. The flow measurements

were made in succession, with care being taken to keep the unit discharge constant between tests.

Both sets of measuring equipment were mounted on a moving frame installed in the intake gate

slot which traversed the flow from top to bottom at 13 discrete elevations. The flow into the

intake possessed a significant vertical component, so that the ability of each method to resolve

the horizontal component required for the discharge computations was crucial.

Comparison of flow rate results showed good agreement between the two methods,

demonstrating that the ASFM has the accuracy required to measure turbine discharge under

operational conditions. Depending on the numerical integration procedure used, the overall

agreement between the two methods ranged from 0.2% to 0.5%. The largest single difference in

the total discharge was 1.0%. Comparison of the measured vertical profiles of the horizontal

velocity component showed good general agreement, although there were differences in the

details of the profiles. Also, there were differences in the individual bay flow computations,

although these differences tended to be opposite in sign so that the agreement in total discharges

was good. These differences may have been due to actual variability in the flow distributions

over the two days that the tests were conducted, but there is no way to confirm this from the

available data.

Acknowledgements

TVA funding for these tests was provided through the Hydro Modernization Program and the

Technology Advancements Division. Mitch Blevins of TVAs Norris Engineering Laboratory

(NEL) provided the mechanical engineering support required for both the current meter and

acoustic scintillation measurements. The excellent support of the NELs shop and

instrumentation section are gratefully acknowledged. M. Clarke and R. Chave of ASL were

responsible for the ASFM hardware and software and were instrumental in its successful

operation.

References

Birch, R. and D. Lemon, 1993. Acoustic flow measurements at the Rocky Reach Dam. Proc. WaterPower '93,

ASCE, 2187-2196.

Clifford, S.F. and D.M. Farmer, 1983. Ocean flow measurements using acoustic scintillation. J. Acoust. Soc. Amer.,

74 (6). 1826-1832.

- 10 -

Farmer, D.M. and S.F. Clifford, 1986. Space-time acoustic scintillation analysis : a new technique for probing ocean

flows. IEEE J. Ocean. Eng. OE-11 (1), 42 - 50.

Farmer, D.M., S.F. Clifford and J.A. Verrall, 1987. Scintillation structure of a turbulent tidal flow. J. Geophys. Res.

92 (C5), 5369 - 5382.

IEC (International Electrotechnical Commission), 1991. Field acceptance tests to determine the hydraulic

performance of hydraulic turbines, storage pumps, and pump -turbines, IEC Publication 41-1991, Bureau Central de

la Commission Electrotechnique Internationale, Geneva, Switzerland, November 1991.

Ishimaru, A., 1978. Wave Propagation and Scattering in Random Media. Academic Press, N.Y. 572 pp.

ISO (International Standards Organization), 1988. Measurement of Clean Water Flow in Closed Conduits -

Velocity-Area Method Using Current-Meters in Full Conduits and Under Regular Flow Conditions, ISO

Publication 3354-1988, Geneva, Switzerland, 1988.

Lawrence, R.S., G.R. Ochs and S.F. Clifford, 1972. Use of scintillations to measure average wind across a light

beam. Appl. Opt., Vol. 11, pp. 239 - 243.

Lemon, D.D. and D.M. Farmer, 1990. Experience with a multi-depth scintillation flowmeter in the Fraser Estuary.

Proc. IEEE Fourth Working Conference on Current Measurement, Clinton, MD. April 3-5, 1990. 290 - 298.

Lemon, D. D. 1993. Flow measurements by acoustic scintillation drift in the Fraser River estuary. Proc. IEEE

Oceans '93, II-398 to II-403.

Lemon, D. D. 1995. Measuring intake flows in hydroelectric plants with an acoustic scintillation flowmeter.

Waterpower 95, ASCE, 2039 - 2048.

Lemon, D. D. and P. W. W. Bell 1996. Measuring hydraulic turbine discharge with the Acoustic Scintillation Flow

Meter. Proc. IGHEM, Montreal, 1996.

Wang T.I., G.R. Ochs and R.S. Lawrence, 1981. Wind measurements by the temporal cross-correlation of the

optical scintillations. Appl. Opt., Vol. 20, pp. 4073 - 4081.

Authors

David Lemon is Vice-president of ASL Environmental Sciences Inc., and specializes in underwater

acoustics applied to flow measurements. He has been in charge of ASLs development of the ASFM since

its beginning in the mid 1980s.

Charles Almquist is Principal Engineer with Principia Research Corporation in Knoxville, TN. He is

responsible for hydromachinery performance testing and efficiency improvement projects.

Ward Cartier is an Engineering Physicist with ASL Environmental Sciences Inc. His work includes

instrument development and application in the field.

Patrick March is Senior Product Development Manager for TVAs Resource Management business and a

co-founder and director of Hydro Resource Solutions LLC. He has thirty years of hydro power

experience primarily in the areas of performance improvement, monitoring and flow measurement.

Thomas Brice is a Mechanical Engineer with TVAs Hydro Modernization Program. His work includes

turbine runner replacement performance analysis.

You might also like

- Advanced Composite Bearings & Wear Parts For Hydro PowerDocument12 pagesAdvanced Composite Bearings & Wear Parts For Hydro PowerSasankNo ratings yet

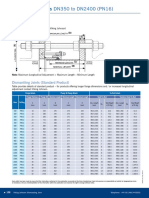

- Dismantling Joints: DN350 To DN2400 (PN16)Document2 pagesDismantling Joints: DN350 To DN2400 (PN16)SasankNo ratings yet

- National Pension System (Enps) - Subscriber Registration FormDocument8 pagesNational Pension System (Enps) - Subscriber Registration FormSasankNo ratings yet

- Effects of Load Variation On A Kaplan Turbine Runner: ArticleDocument13 pagesEffects of Load Variation On A Kaplan Turbine Runner: ArticleSasankNo ratings yet

- Quantifiable Crack Detection in Newly Installed Pelton TurbineDocument4 pagesQuantifiable Crack Detection in Newly Installed Pelton TurbineSasankNo ratings yet

- FSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreDocument4 pagesFSAF 22314: SAF and SAW Pillow Blocks With Bearings With A Cylindrical BoreSasankNo ratings yet

- Piping Elbows - Thrust Block ForcesDocument5 pagesPiping Elbows - Thrust Block ForcesSasankNo ratings yet

- Means To Complete The Second Law of Power Retrieval .: Jets & Buckets For Pelton WheelsDocument20 pagesMeans To Complete The Second Law of Power Retrieval .: Jets & Buckets For Pelton WheelsSasankNo ratings yet

- Calculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedDocument28 pagesCalculation of The Parameters of Model Hydraulic Turbine Using The Value of The Specific SpeedSasankNo ratings yet

- WWW - Lamelosa.in: 2 BHK Auspicious Homes at WakadDocument18 pagesWWW - Lamelosa.in: 2 BHK Auspicious Homes at WakadSasankNo ratings yet

- JobAdvertisement 116413Document2 pagesJobAdvertisement 116413SasankNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 1 - Pdfsam - 51 - Pdfsam - Jane Bennett Vibrant Matter A Political Ecology of Things 2010 PDFDocument25 pages1 - Pdfsam - 51 - Pdfsam - Jane Bennett Vibrant Matter A Political Ecology of Things 2010 PDFAnna PrzytomskaNo ratings yet

- Least Cost PathDocument29 pagesLeast Cost PathGaneshan ParamathmaNo ratings yet

- Compact Heat Exchanger DesignDocument52 pagesCompact Heat Exchanger DesignoperationmanagerNo ratings yet

- ECON1203 PASS Week 3Document4 pagesECON1203 PASS Week 3mothermonkNo ratings yet

- Introductory Circuit Theory by Guillemin ErnstDocument580 pagesIntroductory Circuit Theory by Guillemin ErnstJunaid IqbalNo ratings yet

- Set Theory For The Working Mathematician - Krzysztof Ciesielski - 1997Document244 pagesSet Theory For The Working Mathematician - Krzysztof Ciesielski - 1997Jack Bullets100% (3)

- Notes On Set Theory and Probability Theory: Michelle AlexopoulosDocument37 pagesNotes On Set Theory and Probability Theory: Michelle AlexopoulosArXlan XahirNo ratings yet

- A History of PhotographyDocument49 pagesA History of PhotographyderghalNo ratings yet

- NA Curve FittingDocument31 pagesNA Curve FittingRadwan HammadNo ratings yet

- CC Relief DoorDocument7 pagesCC Relief DoorHim SatiNo ratings yet

- A1040 MiraDocument4 pagesA1040 MiramichelditommasoNo ratings yet

- Form 4 Chemistry Yearly Plan 2019Document2 pagesForm 4 Chemistry Yearly Plan 2019Jenny WeeNo ratings yet

- Data Sheets de Todos Cabos Da ListaDocument20 pagesData Sheets de Todos Cabos Da ListaLaercio ChissicoNo ratings yet

- Indian Standard: Specificati-OnDocument14 pagesIndian Standard: Specificati-On661982No ratings yet

- Semikron Datasheet Skiip 23ac126v1 25231080Document4 pagesSemikron Datasheet Skiip 23ac126v1 25231080Antonio Carlos CardosoNo ratings yet

- Material Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaDocument29 pagesMaterial Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaEdward Gustaf100% (3)

- Isolation and Purification of AlkaloidsDocument14 pagesIsolation and Purification of AlkaloidsLuděk SpurnýNo ratings yet

- Projects List: Mechanical EngineeringDocument4 pagesProjects List: Mechanical EngineeringNaga KiranNo ratings yet

- Bed Plate Main Engine BedplateDocument52 pagesBed Plate Main Engine BedplateSuhas KassaNo ratings yet

- Logistic Regression EBayDocument10 pagesLogistic Regression EBayPrateek ShuklaNo ratings yet

- Syllabus - Mathematical EconomicsDocument2 pagesSyllabus - Mathematical EconomicsMRVNo ratings yet

- CM 3.4 LRFD Culvert Design Loads PDFDocument68 pagesCM 3.4 LRFD Culvert Design Loads PDFJose Barquet TellezNo ratings yet

- Calculated MAWP MAPDocument4 pagesCalculated MAWP MAPhataefendiNo ratings yet

- Designing A MixerDocument12 pagesDesigning A MixerPrasanna KumarNo ratings yet

- Leica ICD Brochure enDocument4 pagesLeica ICD Brochure enCsaba GibártiNo ratings yet

- Introduction To Vehicle Electronic Systems and Fault DiagnosisDocument20 pagesIntroduction To Vehicle Electronic Systems and Fault Diagnosisyogita patil100% (1)

- How To Design Roof Purlins - A Solved Example - StructvilleDocument16 pagesHow To Design Roof Purlins - A Solved Example - StructvilleLavanyanNo ratings yet

- Experiences of ISFOC On Concentration Photovoltaic: Francisca RubioDocument49 pagesExperiences of ISFOC On Concentration Photovoltaic: Francisca RubioHikary AcevesNo ratings yet

- All1 58Document61 pagesAll1 58arisNo ratings yet

- RC2Document92 pagesRC2Chrisneil DelosreyesNo ratings yet