Professional Documents

Culture Documents

S3i Lifting Shackles Technical Information

Uploaded by

peachykrista0 ratings0% found this document useful (0 votes)

58 views4 pagesS3i PH shackles are made from PH 17 / 4, a martensitic precipitation / age hardening 17% chromium, 4% nickel stainless steel, offering high strength and hardness together with excellent corrosion resistance. Because of the critical dependence of the strength / corrosion characteristics on the heat treatment process it is imperative that no attempt is made to anneal.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentS3i PH shackles are made from PH 17 / 4, a martensitic precipitation / age hardening 17% chromium, 4% nickel stainless steel, offering high strength and hardness together with excellent corrosion resistance. Because of the critical dependence of the strength / corrosion characteristics on the heat treatment process it is imperative that no attempt is made to anneal.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

58 views4 pagesS3i Lifting Shackles Technical Information

Uploaded by

peachykristaS3i PH shackles are made from PH 17 / 4, a martensitic precipitation / age hardening 17% chromium, 4% nickel stainless steel, offering high strength and hardness together with excellent corrosion resistance. Because of the critical dependence of the strength / corrosion characteristics on the heat treatment process it is imperative that no attempt is made to anneal.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

S3i Limited 1 Faraday Close Snape Lane Harworth DN11 8RU

E info@s3i.co.uk T 01302 752504 Visit

S3i Lifting Shackles

Materials used

Technical Information Analysis (a typical analysis of PH 17/4)

Our lifting shackles are manufactured from two different grades of stainless steel used specifically for

different applications. The application and environment will determine which type of shackle should be used.

Shackles for general lifting applications

S3i PH shackles are made from PH 17/4, a martensitic precipitation/age hardening 17% chromium, 4%

nickel stainless steel, offering high strength and hardness together with excellent corrosion resistance. PH

shackles are heat treated to between condition H1025 and condition H1075 to achieve the optimum balance

of mechanical properties and resistance to corrosion: in this state PH 17/4 closely approaches stainless

types 302 and 304 for most corrosion agents.

Because of the critical dependence of the strength/corrosion characteristics on the heat treatment process it

is imperative that no attempt is made to anneal S3i PH shackles for whatever reason.

0.07% max

1.00% max

1.00% max

0.04% max

0.03% max

15.50 - 17.50%

3.00 - 5.00%

0.15 - 0.45%

3.00 - 5.00%

100%

Carbon

Manganese

Silicon

Phosphorus

Sulphur

Chromium

Nickel

Columbium & Tantalum

Copper

Iron

Mechanical Properties

10,900 kg/cm2 (H1025) to

10,190kg/cm2 (H1075) Iron

10,190 kg/cm2 (H1025) to

8,790kg/cm2 (H1075)

11,810 kg/cm2 (H1025) to

11,530kg/cm2 (H1075)

10,190 kg/cm2 (H1025) to

8,790kg/cm2 (H1075)

Ultimate Tensile Strength

Yield Strength (0.2%)

1

S3i Limited 1 Faraday Close Snape Lane Harworth DN11 8RU

E info@s3i.co.uk T 01302 752504 Visit

S3i Lifting Shackles

Shackles for lifting applications requiring a higher resistance to corrosion

Technical Information Analysis (a typical analysis of EN1008803 1.4404)

S3i E Pin shackles (D and Bow) are manufactured from ISO 1.4404 stainless steel and are proof-tested to

twice their Working Load Limit (WLL) using equipment calibrated to BS EN 10002-2 and NAMAS NIS 0424.

S3i stainless steel E Type shackles should be used in applications where corrosion resistance is of signifi-

cant importance. Stainless steels are possible solutions to corrosion problems and are ideally suited to

natural (water, city and landscape atmospheric) conditions. S3i stainless steel E Type shackles should NOT

be used in general lifting applications where corrosion resistance is not required. For such general lifting

applications please refer to the S3i PH range of lifting shackles. Due to the nature of stainless steel and the

possibility of work hardening/stress ageing, we strongly recommend that thorough inspection and mainte-

nance is carried out on a regular basis.

S3i stainless steel E Type shackles (D and Bow) are made from EN10088-3 1995 1.4404 stainless steel, a

work hardening Austensitic stainless steel.

Because of the critical dependence of the strength characteristics on the mechanical history of the material

the shackles should not be used if distorted in any way, it is imperative that no attempt is made to straighten

or modify the shape of these shackles for whatever reason.

Stainless steel grade EN10088 1.4404 is an iron-chromium-nickel alloy which is hardenable by cold working.

Nickel is the main element varied within the alloys of this class while carbon is kept to low levels. This grade

is slightly magnetic in the cold-worked condition, but is essentially non-magnetic in the annealed condition.

The austenitic types of stainless steel feature adaptability to cold forming and in general, the highest corro-

sion resistance. Type 316 (EN10088 1.4404) stainless steel contains molybdenum for better corrosion

resistance - particularly to pitting.

Please refer to EN 10088-3 1995 for chemical analysis and typical mechanical properties of 1.4401 and

1.4404 steel, which are also commonly known as grade 316 and 316L.

Carbon

Chromium

Nickel

Manganese

Silicon

Sulphur

Phosphorus

Molybdenum

Iron

0.03% max

16-18%

10-13%

2.0% max

1.0% max

0.03% max

0.04% max

2.0-3.0%

to 100%

2

S3i Limited 1 Faraday Close Snape Lane Harworth DN11 8RU

E info@s3i.co.uk T 01302 752504 Visit

S3i Lifting Shackles

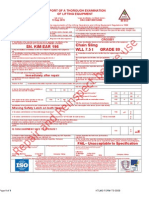

Testing S3i lifting shackles

All of our lifting shackles are inspected before they are tested and inspected again before they are

dispatched. A thorough examination takes place ensuring that:

The body of the shackle and pin are both compatible.

All markings are clearly legible.

The pin is the correct type for the body.

The threads of the pin and the body are in good order and function correctly.

The body and pin are not damaged in any way and are free from any dents, cracks, deformation etc.

All load rated shackles are supplied with a WLL and proof load test certificate in accordance with EN10204

3.1b. Each shackle is individually tested to its proof load (2 x WLL).

Each shackle is mechanically engraved with the following details

Working Load Limit (WLL).

Batch number specific to the test for that batch of shackles.

The grade of stainless steel which the shackle is manufactured from.

CE mark.

The Lifting Operations and Lifting Regulations (LOLER) 1998 specify that the following provisions apply to all

shackles used in a lifting application. It is the responsibility of the user to ensure that:

The equipment is safe and suitable for the intended use.

The equipment is supplied with a leaflet providing information on its safe use.

The personnel who use the equipment must be suitably trained.

The equipment must be maintained in a safe condition.

Record of conformity, test and examination etc. must be retained.

Instructions for use

Shackles should be inspected before use to ensure that:

all markings are legible.

the threads of the pin and the body are undamaged.

never use a safety type bolt/pin without using the split cotter pin.

the body and the pin are not distorted or unduly worn.

the body and pin are free from nicks, gouges, cracks and corrosion.

shackles may not be heat treated as this may affect their working load limit.

never modify, repair or reshape a shackle as this will affect the Working Load Limit.

All of our lifting shackles are inspected before they are tested and inspected again before they are

dispatched. A thorough examination takes place ensuring that:

The body of the shackle and pin are both compatible.

All markings are clearly legible.

The pin is the correct type for the body.

The threads of the pin and the body are in good order and function correctly.

The body and pin are not damaged in any way and are free from any dents, cracks, deformation etc.

All load rated shackles are supplied with a WLL and proof load test certificate in accordance with EN10204

3.1b. Each shackle is individually tested to its proof load (2 x WLL).

Each shackle is mechanically engraved with the following details

Working Load Limit (WLL).

Batch number specific to the test for that batch of shackles.

The grade of stainless steel which the shackle is manufactured from.

CE mark.

The Lifting Operations and Lifting Regulations (LOLER) 1998 specify that the following provisions apply to all

shackles used in a lifting application. It is the responsibility of the user to ensure that:

The equipment is safe and suitable for the intended use.

The equipment is supplied with a leaflet providing information on its safe use.

The personnel who use the equipment must be suitably trained.

The equipment must be maintained in a safe condition.

Record of conformity, test and examination etc. must be retained.

Instructions for use

Shackles should be inspected before use to ensure that:

all markings are legible.

the threads of the pin and the body are undamaged.

never use a safety type bolt/pin without using the split cotter pin.

the body and the pin are not distorted or unduly worn.

the body and pin are free from nicks, gouges, cracks and corrosion.

shackles may not be heat treated as this may affect their working load limit.

never modify, repair or reshape a shackle as this will affect the Working Load Limit.

3

S3i Limited 1 Faraday Close Snape Lane Harworth DN11 8RU

E info@s3i.co.uk T 01302 752504 Visit

S3i Lifting Shackles

Inspection of the S3i lifting shackle

4

Check for wear

and tear inside

the shackle body.

Ensure the shackle pin is fully tightened.

When a safety pin is used,ensure the split

pin is located correctly and secured.

When a safety pin is used, ensure the split

pin is located correctly and secured.

Check the body

for distortion.

Check for wear

on the shackle pin.

Check for wear

and tear inside

the shackle body.

Check the body

for distortion.

Check for wear

on the shackle pin.

Before the shackle is first put into use it should be examined for signs of damage.

If it is known, or suspected, that the shackle has been subjected to an excess load or the shackle shows any

sign of cracking, splitting or deformation it must be destroyed.

It is required that the shackles are regularly inspected and that the inspection should take place in accor-

dance with the safety standards given in the country of use. This is required because the products in use

may be affected by wear, misuse, overloading etc. with a consequence of deformation and alteration of the

material structure. Inspection should take place at least every 6 months and even more frequently when the

shackles are used in severe operating conditions.

You might also like

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveFrom EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveNo ratings yet

- Safety 2Document15 pagesSafety 2hyde2520015754No ratings yet

- Corporate Profile: For A Secure SocietyDocument14 pagesCorporate Profile: For A Secure SocietyAjay SinghNo ratings yet

- Adhesion Cross-Cut Test ExampleDocument2 pagesAdhesion Cross-Cut Test ExampleRaduNo ratings yet

- HSE Inspection Checklist: 1 Safety PromotionDocument4 pagesHSE Inspection Checklist: 1 Safety PromotionRanjan PrNo ratings yet

- Questions of Lifting AccessoriesDocument4 pagesQuestions of Lifting AccessoriesOwais MalikNo ratings yet

- Amfori BSCI Code of Conduct - English - December 2021Document10 pagesAmfori BSCI Code of Conduct - English - December 2021مروى مروىNo ratings yet

- 01 - QA - QC PlanDocument9 pages01 - QA - QC PlanProject m707No ratings yet

- 4 Legs Sling INA 182-1.Document1 page4 Legs Sling INA 182-1.Khalil ChabbouhNo ratings yet

- Interclene 5012Document4 pagesInterclene 5012Trịnh Minh KhoaNo ratings yet

- Tubecare Broucher PDFDocument16 pagesTubecare Broucher PDFRama Manikanta DondapatiNo ratings yet

- Inspection Mobile Elevating Work Platform (Aerial Lift)Document6 pagesInspection Mobile Elevating Work Platform (Aerial Lift)Jeremia SamosirNo ratings yet

- Level 3 Health and Safety in The WorkplaceDocument5 pagesLevel 3 Health and Safety in The WorkplaceKannan JaganNo ratings yet

- PR-DIV02-BTM-0001 Bolt Torquing Procedure SADARADocument10 pagesPR-DIV02-BTM-0001 Bolt Torquing Procedure SADARAvinothkumarNo ratings yet

- Macrographic Examination Report: Fillet SizeDocument1 pageMacrographic Examination Report: Fillet SizenourhenNo ratings yet

- HSES MGMT Plan Model ENGDocument10 pagesHSES MGMT Plan Model ENGKonstantinShevtsovNo ratings yet

- 1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceDocument11 pages1.0 2.0 The Importance of Maintenance 3.0 Maintenance Activites 4.0 Types of MaintenanceIstiQamahh MuhamadNo ratings yet

- Construction - Method Statement Format - I Whattam 2007Document2 pagesConstruction - Method Statement Format - I Whattam 2007alaaNo ratings yet

- Manpower Planning & Resourcing Mu001 B0816Document11 pagesManpower Planning & Resourcing Mu001 B0816anithanhNo ratings yet

- Course Outline - Scaffolding Safety Course-2 DayDocument2 pagesCourse Outline - Scaffolding Safety Course-2 Dayaliindian1No ratings yet

- GP Handling The WeaponDocument2 pagesGP Handling The WeaponBeder MirjanNo ratings yet

- Rigging & Lifting Operations - 150305 (EB)Document30 pagesRigging & Lifting Operations - 150305 (EB)S RNo ratings yet

- BS en ISO 8028-2000-Rubber And-Or Plastics Hose AssembliesDocument12 pagesBS en ISO 8028-2000-Rubber And-Or Plastics Hose AssembliesVenkata Rao100% (1)

- Section 033000 Cast-In-Place Concrete PDFDocument42 pagesSection 033000 Cast-In-Place Concrete PDFTargetRockNo ratings yet

- Method Statement Forwater Tank FixingDocument12 pagesMethod Statement Forwater Tank FixingJAMES neelNo ratings yet

- HSE Specification - Ionising Radiation SP 1237Document42 pagesHSE Specification - Ionising Radiation SP 1237mac1677No ratings yet

- SCMG Dashboard April 23 2021 With TaskDocument317 pagesSCMG Dashboard April 23 2021 With Taskallen zacariasNo ratings yet

- QA InspectorsDocument2 pagesQA InspectorsnorlieNo ratings yet

- Manual USLT2000 PDFDocument66 pagesManual USLT2000 PDFvrapciudorianNo ratings yet

- EEMUA Publications Catalogue May 2016Document5 pagesEEMUA Publications Catalogue May 2016malkaniravinderNo ratings yet

- Hardness Tester PortableDocument2 pagesHardness Tester Portablealfachemy100% (1)

- Lifting Eyes For Excavator BucketsDocument1 pageLifting Eyes For Excavator BucketsfernandojNo ratings yet

- Piper AlphaDocument4 pagesPiper AlphaIbrahim MuhammadNo ratings yet

- Sample: Excavator Inspection & Maintenance RecordDocument3 pagesSample: Excavator Inspection & Maintenance RecordbangladragosNo ratings yet

- NS Toolbox Sdftalk 006 Welding Consumable Control and TracebilityDocument1 pageNS Toolbox Sdftalk 006 Welding Consumable Control and TracebilityNeil SoansNo ratings yet

- NullDocument67 pagesNullMichael OkwuwaNo ratings yet

- Supplier Pre-Qualification Document - September 2020Document23 pagesSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesNo ratings yet

- Managing Safely v5 Course SyllabusDocument5 pagesManaging Safely v5 Course SyllabusYuri Dias SobrinhoNo ratings yet

- ACG 22 Requirements For Lifting Equipment Inspection BodiesDocument14 pagesACG 22 Requirements For Lifting Equipment Inspection BodiesramodNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- TRILOGI LOGISTICS LLC - MAR 18,2013 (Compatibility Mode) PDFDocument5 pagesTRILOGI LOGISTICS LLC - MAR 18,2013 (Compatibility Mode) PDFJijo PhilipNo ratings yet

- Quality Concept Lesson 1Document37 pagesQuality Concept Lesson 1AbdullahKedahiNo ratings yet

- Atex DirectiveDocument4 pagesAtex DirectiveMichaelNo ratings yet

- Accounts Payable Job ProfileDocument2 pagesAccounts Payable Job ProfileChester LowbyteNo ratings yet

- Cargo Net l3 Ast Le Adma 314Document6 pagesCargo Net l3 Ast Le Adma 314Anwar DeenNo ratings yet

- APL Index 452Document4 pagesAPL Index 452er_paramjeetgillNo ratings yet

- OTC Guide PDFDocument34 pagesOTC Guide PDFswordleee swordNo ratings yet

- CCJ 3q 2014 Full Issue PDFDocument136 pagesCCJ 3q 2014 Full Issue PDFJeeEianYannNo ratings yet

- 371-Rigging Start Up Check List Rev 000Document2 pages371-Rigging Start Up Check List Rev 000francisNo ratings yet

- Steel CstructionDocument18 pagesSteel CstructionChen QingNo ratings yet

- Safety AspectsDocument14 pagesSafety AspectsGanga DaranNo ratings yet

- Webbing SlingDocument3 pagesWebbing Slingmoha19841No ratings yet

- Impacto Charpy - Iso - 9016Document12 pagesImpacto Charpy - Iso - 9016Lucas MlbNo ratings yet

- Sn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentDocument1 pageSn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting Equipmentoriza100% (1)

- En PDF PDF p31378 enDocument3 pagesEn PDF PDF p31378 enpeachykristaNo ratings yet

- PL WB e 21032013Document7 pagesPL WB e 21032013peachykristaNo ratings yet

- LEVAC Slings Instruction Manual ENGLISHDocument20 pagesLEVAC Slings Instruction Manual ENGLISHpeachykristaNo ratings yet

- Busatec Application TableDocument1 pageBusatec Application TablepeachykristaNo ratings yet

- Comunication DataDocument104 pagesComunication DatapeachykristaNo ratings yet

- Straaltechniek 98CE 2000 50CE enDocument2 pagesStraaltechniek 98CE 2000 50CE enpeachykristaNo ratings yet

- UC400 S23 Cat.6: U/FTP Installation CableDocument3 pagesUC400 S23 Cat.6: U/FTP Installation CablepeachykristaNo ratings yet

- OWI 1000 DrawworksDocument54 pagesOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- Catalogo TycoDocument51 pagesCatalogo TycoCésar CutruneoNo ratings yet

- Etsy Business TemplateDocument28 pagesEtsy Business TemplatepeachykristaNo ratings yet

- Atest TipBDocument250 pagesAtest TipBpeachykristaNo ratings yet

- S VarcoDocument2 pagesS VarcopeachykristaNo ratings yet

- Catalog Incubator2013 IPEEDocument16 pagesCatalog Incubator2013 IPEEolunguNo ratings yet

- Transformer and Electronic Controllers For HVAC: WWW - Breve.plDocument9 pagesTransformer and Electronic Controllers For HVAC: WWW - Breve.plpeachykristaNo ratings yet

- Risk Analysis MatrixDocument1 pageRisk Analysis MatrixpeachykristaNo ratings yet

- Cust SpeDocument9 pagesCust SpepeachykristaNo ratings yet

- Plant and Equipment Risk Assessment Checklist1Document9 pagesPlant and Equipment Risk Assessment Checklist1peachykrista100% (1)

- Basic Rigging Training ManualDocument70 pagesBasic Rigging Training ManualsteelageNo ratings yet

- Generic Safety Manual v2Document266 pagesGeneric Safety Manual v2Gnalagnas KarlengianNo ratings yet

- Cat Truck Engine Serial Number Prefix ChartDocument2 pagesCat Truck Engine Serial Number Prefix Chartangelobor100% (7)

- Update ERCA Safety Warning 1 2011 WireRopeTerminationsDocument0 pagesUpdate ERCA Safety Warning 1 2011 WireRopeTerminationspeachykristaNo ratings yet

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriNo ratings yet

- VB 850Document333 pagesVB 850Laura ValentinaNo ratings yet

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Document23 pagesQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Fin 3 - Exam1Document12 pagesFin 3 - Exam1DONNA MAE FUENTESNo ratings yet

- Si KaDocument12 pagesSi KanasmineNo ratings yet

- Supply Chain Risk Management: Resilience and Business ContinuityDocument27 pagesSupply Chain Risk Management: Resilience and Business ContinuityHope VillonNo ratings yet

- COVID Immunization Record Correction RequestDocument2 pagesCOVID Immunization Record Correction RequestNBC 10 WJARNo ratings yet

- Spa ClaimsDocument1 pageSpa ClaimsJosephine Berces100% (1)

- MSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)Document10 pagesMSDS Bisoprolol Fumarate Tablets (Greenstone LLC) (EN)ANNaNo ratings yet

- Technical Engineering PEEDocument3 pagesTechnical Engineering PEEMariano Acosta Landicho Jr.No ratings yet

- Revenue Management Session 1: Introduction To Pricing OptimizationDocument55 pagesRevenue Management Session 1: Introduction To Pricing OptimizationDuc NguyenNo ratings yet

- DevelopmentPermission Handbook T&CPDocument43 pagesDevelopmentPermission Handbook T&CPShanmukha KattaNo ratings yet

- How To Attain Success Through The Strength of The Vibration of NumbersDocument95 pagesHow To Attain Success Through The Strength of The Vibration of NumberszahkulNo ratings yet

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 pagesEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- IBMC Competition Booklet 2013Document40 pagesIBMC Competition Booklet 2013Rollins Center at BYUNo ratings yet

- Permit To Work Audit Checklist OctoberDocument3 pagesPermit To Work Audit Checklist OctoberefeNo ratings yet

- Ting Vs Heirs of Lirio - Case DigestDocument2 pagesTing Vs Heirs of Lirio - Case DigestJalieca Lumbria GadongNo ratings yet

- TNCT Q2 Module3cDocument15 pagesTNCT Q2 Module3cashurishuri411100% (1)

- On Applied EthicsDocument34 pagesOn Applied Ethicsamanpatel78667% (3)

- The April Fair in Seville: Word FormationDocument2 pagesThe April Fair in Seville: Word FormationДархан МакыжанNo ratings yet

- How Can You Achieve Safety and Profitability ?Document32 pagesHow Can You Achieve Safety and Profitability ?Mohamed OmarNo ratings yet

- TATA Power - DDL:ConfidentialDocument15 pagesTATA Power - DDL:ConfidentialkarunakaranNo ratings yet

- bz4x EbrochureDocument21 pagesbz4x EbrochureoswaldcameronNo ratings yet

- DC0002A Lhires III Assembling Procedure EnglishDocument17 pagesDC0002A Lhires III Assembling Procedure EnglishНикола ЉубичићNo ratings yet

- Mcqs in Wills and SuccessionDocument14 pagesMcqs in Wills and Successionjudy andrade100% (1)

- Opel GT Wiring DiagramDocument30 pagesOpel GT Wiring DiagramMassimiliano MarchiNo ratings yet

- PRELEC 1 Updates in Managerial Accounting Notes PDFDocument6 pagesPRELEC 1 Updates in Managerial Accounting Notes PDFRaichele FranciscoNo ratings yet

- Pet Care in VietnamFull Market ReportDocument51 pagesPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- Strategic Management ModelsDocument4 pagesStrategic Management ModelsBarno NicholusNo ratings yet