Professional Documents

Culture Documents

Finite Element Modelling of Castings

Uploaded by

Vikas Garg0 ratings0% found this document useful (0 votes)

53 views5 pagesThis document contains FEA of castings.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains FEA of castings.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

53 views5 pagesFinite Element Modelling of Castings

Uploaded by

Vikas GargThis document contains FEA of castings.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Finite el ement model l i ng of

solidification in sand casti ngs

empl oyi ng an i mpl i ci t - expl i ci t

al gori thm

M. S a mo n d s , K. Mo r g a n a n d R. W. Le wi s

The f i ni t e el ement met hod is used t o model t he sol i di f i cat i on process i n a

sand casti ng. Wi t h a r el at i vel y coarse mesh, t her e is good agr eement

bet ween numer i cal and exper i ment al resul ts. An i mp l i c i t - e x p l i c i t t i me-

st eppi ng al gor i t hm demonst r at ed si gni f i cant c omput er t i me savings when

t he appr opr i at e sol ver was i mpl ement ed. Consi der at i on is also gi ven t o t he

pr obl em of capaci t ance mat r i x l umpi ng when quadr at i c el ement s are

empl oyed.

Key wor ds: mat hemat i cal model s, f i ni t e el ement , sand casti ngs, i mp l i c i t -

ex pl i c i t al gor i t hm

There has been increasing interest over the past t wo decades

in the use of numeri cal met hods t o model solidification

processes in metal castings. ~-3 With an accurat e predictive

model , the f oundr y will be able t o dramat i cal l y reduce

shrinkage por osi t y, det ermi ne the opt i mum pl acement and

size of risers, minimize trial runs and scrap met al , and even

cont rol the mechani cal properties of the finished castings

t hr ough modul at i on of t hermal gradients and solidification

rates.

Whereas the f'mite difference met hod has been used by a

number of researchers, 4' s and in many appl i cat i ons uses less

comput er time t han finite el ement s, it has the severe

disadvantage of being very unwi el dy when it comes t o

compl ex geometries such as those t ypi cal l y f ound in

casting. It is shown here t hat a t wo-di mensi onal finite

el ement program can give excel l ent results for a t apered

slab sand casting, even wi t h a fairly coarse mesh.

Concern has been voiced in some quart ers about the

effort t hat is wasted by model l i ng the t emper at ur e field in

the sand f or m .6 The aut hors, however, f ound it adequat e

t o use a single layer of quadrat i c el ement s in the sand. I f

an i mpl i ci t -expl i ci t f or mul at i on is used wi t h an appropri at e

solver, and the sand el ement s t aken as explicit, substantial

savings in comput er time can be realized in compari son

wi t h a fully implicit scheme.

Ma t h e ma t i c a l f o r mu l a t i o n

The finite el ement f or mul at i on of the heat conduct i on

equat i on is well d o c u me n t e d ] ' a Basically, st art i ng wi t h the

conservat i on of energy equat i on in a field g2, assuming no

mass t ransport and wi t h t emper at ur e- dependent t hermal

propert i es:

d H.

V. ( KV0 ) = p - - 0 (1)

dO

wi t h Dirich]et and Neuman boundary conditions on Fl and

F: respectively:

O ( x ) = O(x)f (t ) on F l (2)

KO .ti + q + h(O - - 0,4) = 0 on 1" 2 (3)

Discretizing the spatial domai n by finite el ement s and

empl oyi ng t he Galerkin procedure, 9 the fol l owi ng syst em

of differential equat i ons is obt ai ned:

CO + KO = F (4)

where t ypi cal component s of the mat ri ces C and K and

the vect or F are defi ned by:

Cii = p - ~ N i N ] d a (5)

I2

Ki]= f V Nj . ( KV Ni ) d ~ + f hNi Ni dF 2 (6)

i2 F 2

F i = -- f ( q- - hO A) U i dr= (7)

F:

Here N i denot es the finite el ement shape f unct i on associa-

ted wi t h node i of the finite el ement mesh. Lat ent heat

evol ut i on is account ed for by the t erm dH/dO, and march-

0307-904X/85/03170-05/$03.00

170 Appl. Math. Modelling, 1985, Vol. 9, June 1985 Butterworth & Co. (Publishers) Ltd

i ng i n t i me is a c c o mp l i s h e d b y a t wo s t e p p r e d i c t o r -

c o r r e c t o r a l g o r i t h m, wh i c h is gi ven as f ol l ows :

Pr e di c t or

[ C ( O n ) + A t " Y K ( O n ) ] o n + l = [ C ( O n ) - - A t n ( 1 - - 7 )

x K( On) ] O n + At nF( O n) ( 8)

Co r r e c t o r

[C(0~,) + at%K(O~)] ." +~ = ~ p . l [ C ( 0 ~ , ) - At"(1 - - 7 )

x K(0~,)] 0" + at" F (O~) ( 9 )

whe r e

0~, = / 3 0 ? . * 1 + ( 1 - 13) O n ( 1 0 )

and

On+l = On+l ( 11)

i . e. t he c or r e c t i ve i t e r a t i o n begi ns wi t h t he p r e d i c t e d

t e mp e r a t u r e ve c t or . The s u p e r s c r i p t n r ef er s t o t he t i me -

s t e p n u mb e r a nd p is t he n u mb e r o f c or r e c t i ve i t e r a t i ons .

Wi t h 3' = 13 = 1/ 2, one ha s an u n c o n d i t i o n a l l y s t abl e Cr a n k -

Ni c ol s on s c h e me wh i c h is s e c o n d - o r d e r a c c ur a t e i n t i me )

De p e n d i n g on t he n u mb e r o f i t e r a t i o n s r e qui r e d t o r e a c h

a s pe c i f i e d c onve r ge nc e l i mi t , t he t i me - s t e p ma y be in-

cr eas ed or de c r e a s e d.

Pr oc e e di ng a l ong fines si mi l ar t o t hos e o f Hughe s I l. ~2

a nd l i u , t3 t he i mp l i c i t - e x p l i c i t f o r mu l a t i o n f o r t he f i r st -

o r d e r s y s t e m gi ven i n e q u a t i o n ( 4) is as f ol l ows . The

e l e me n t s o f t he me s h ar e cl assi f i ed as expl i ci t (3' = 0) or

i mpl i c i t ( 0. 5 _~ 3' K 1. 0), e i t he r a pri ori or as a c o n s e q u e n c e

o f s o me cr i t er i a, a nd t he i r c o n t r i b u t i o n s t o t he gl obal K a nd

C ma t r i c e s ar e t r e a t e d a c c or di ngl y. I n t he case o f e xpl i c i t

e l e me n t s , f o r e x a mp l e , t he c a p a c i t a n c e ma t r i c e s mu s t be

l u mp e d . T o t hi s e nd, one wr i t es :

K = K I + K E ( 1 2 )

C = CI + CE ( 13)

F = F I + F E ( 14)

Cons i der e q u a t i o n ( 4) as i t appl i es t o a pa r t i c ul a r el e-

me n t . Ta ki ng V = 0 and -On+l as an i n t e r me d i a t e v e c t o r o f

n o d a l t e mp e r a t u r e s , ba s e d u p o n t i me l evel n, one can wr i t e:

CV n+l + KI On+l + KE ~n+l = F n+l ( 15)

~n+~ = 0 n + &t" Vn( l _ 7) ( 1 6 )

O n+l = 0 n +l + At "Vn+13" ( 17)

or r e wr i t i ng e q u a t i o n ( 17) :

v " * ~ = ( 0 " 1 - ~ " + ~ ) / A t " 7 ( 1 8 ) "=

Su b s t i t u t i n g ( 1 8 ) i n t o ( 15) gives:

C(On+ 1 _ ~n+ 1) + At n TKl On + 1 + A t " T KE ~ n + 1 ~_

= A t " T F n+l ( 19) "~

o

a nd r ear r angi ng:

x2_

[ C + A t " T K I ] O n + 1 = [ A t n T ( F n * 1 _ K e ~ n + l )

+ c # " + ~1 ( 2 o )

I f t he e l e me n t is e xpl i c i t , i . e. 7 = 0, t h e n ( 16) b e c o me s :

~n +l =On + A t n v n ( 21) F i g u r e l

b u t usi ng t he f a c t t h a t :

CV n + KO n = F n ( 22)

one sees t h a t :

v" = c- ' [F " - K 0 " ] ( 2 3 )

a nd:

c ~ " ' = c o " + Lxt " I F " - K O" ] (24)

Thi s is e x a c t l y t he same as t he r esul t t h a t w o u l d be pr o-

duced i f t he p r e d i c t o r ( 8 ) was used w i t h 7 = 0 t o gi ve

On+ 1 F u r t h e r , w i t h 7 = 0 i n ( 20) : ,

co " *1 = c ~ "*1 = c o" + at" [F " - K O" ] ( 2 5 )

whe r e n o w C, K a nd F ar e e va l ua t e d a t t he ne w t e mp e r a -

t ur e O h = ~ n * l + (1 - - 13) 0 n. Agai n, t he s a me r es ul t

oc c ur s i f t he c o r r e c t o r ( 9) is used I n t he f ul l y i mpl i ci t

case, i t c a n be s h o wn t h a t t he a l gor i t hm gi ven i n e q u a t i o n s

( 1 5 ) - ( 2 0 ) c a n be i mp l e me n t e d wi t h t he p r e d i c t o r - c o r r e c -

t o r s c h e me wi t h 7 = 1. I t is t h e r e f o r e ne c e s s a r y o n l y t o

s pe c i f y t he a p p r o p r i a t e val ue o f 3' f or e a c h e l e me n t a nd t he

r es ul t i ng gl obal l i near s y s t e m:

KEFFOn+ 1 ___FEFF ( 26)

wi l l have t he des i r ed pr ope r t i e s The e xpl i c i t e l e me n t s wi l l

c o n t r i b u t e t e r ms o n l y t o t he di agonal o f t he ma t r i x KEFF.

Thi s s t r u c t u r e ma y be mo s t f ul l y e x p l o i t e d wi t h an act i ve

c o l u mn pr of ' de s ol ver , H wh i c h onl y car r i es o u t t he Gaus s i an

e l i mi n a t i o n o n t hos e p a r t s o f t he ma t r i x whe r e of f - di a gona l

t e r ms oc c ur . Th u s , wi t h ma n y e xpl i c i t e l e me nt s , a con-

s i der abl e r e d u c t i o n i n s ol ut i on t i me ma y be r eal i zed.

E x p e r i m e n t a l a n d n u m e r i c a l r e s u l t s

A t a p e r e d sl ab o f a l u mi n i u m b r o n z e was cas t i n a resi n

b o n d e d si l i ca s and mo u l d . Th e r mo c o u p l e s wer e pl a c e d

d o wn t he cent r e- l i ne o f t he c a vi t y a nd t he t i me t o r e a c h t he

sol i dus t e mp e r a t u r e a f t e r p o u r was p l o t t e d as a f u n c t i o n o f

pos i t i on ( Fi gure 1) . Thi s e x p e r i me n t a l wo r k wa s c o n d u c t e d

a t t he Br i t i sh No n - Fe r r o u s Met al s Te c h n o l o g y Ce nt r e ,

Want age, UK.

The t e mp e r a t u r e - d e p e n d e n t t h e r ma l p r o p e r t i e s o f t he

me t a l wer e f o u n d f r o m r e f e r e nc e 14, a nd ar e s hown in

Tabl e 1. The l a t e n t h e a t was c a l c ul a t e d f r o m t hos e o f t he

c o n s t i t u e n t p u r e me t a l s b y a we i ght e d average The

AIBz t aper ed slab

9 0 - Numerical resul ts using l ow sand conducti vtti es

8 0 . . . . Numeri cal resul t s using high send conducti vi ti es

Experi ment al r esul t s

70 /

60 /

. / "

5(3 . /

s

40

30 ~ ' ~

20 ~ ' ~ _

1(3

0 I I I I I I I l I I I I

0 100 200 300 400 500 600

Di stance f r om end of casting ( mm)

Experimental and numeri cal results

A p p l . M a t h . Mo d e l l i n g , 1 9 8 5 , V o l . 9 , June 171

Tabl e I Mat er i al pr oper t i es f or a l u mi n i u m- b r o n z e

Composi ti on:

Copper 80. 5%

Al u mi n i u m 9. 5%

I ron 4. 5%

Nickel 5. 5%

Freezing Range: 1 0 8 0 - 1 0 5 0 C

Lat ent Heat : 2. 37 X 10 s J/ kg ( 56. 7 cal / g)

Specific Heat : 452. 2 J/ kg C

Density: 7600 kg/ m ~

Co n d u c t i v i t y as a f u n c t i o n of t emper at ur e:

Temper at ur e ( C) k (J/s m C)

200 5 4 . 4 2

4 0 0 46. 05

6 0 0 43. 95

8 0 0 41. 86

1000 41. 86

1200 41. 86

Tabl e 2 Mat er i al pr oper t i es f or sand

Density: 1444. 7 k g/ m ~

Hi gh c o n d u c t i v i t y cur ve as a f u n c t i o n of t emper at ur e (C):

k ---- 0. 6606 - - 2. 084 X 10 -4 T + 7. 741 X 10 -~ T a J/s m C

L o w c o n d u c t i v i t y cur ve as a f u n c t i o n of t emper at ur e (C):

k = 0. 2828 - - 1. 681 X 10 - " T + 1. 352 X 10 -~ T = J/s m C

Specific heat as a f u n c t i o n of t emper at ur e:

Temper at ur e (C) Cp ( J/ kg C)

200 975. 7

400 1092. 9

600 1151. 5

800 1159. 9

1000 1176. 7

propert i es of the particular sand used coul d not be de-

t ermi ned, but reference 15 gives a range of t ypi cal values

(see Table 2). Numerical results were obt ai ned wi t h the

highest and lowest sand conduct i vi t y curves, whi ch

bracket ed the experi ment al solidification times as shown in

Figure 1.

The vertical cross-section of the moul d and casting was

enmeshed wi t h 56 quadrat i c i soparamet ri c el ement s (see

Figure 2). The ext ernal boundar y of the sand el ement s

was fLxed at 20C, wi t h the initial t emper at ur e in t he sand

t he same. The t op boundar y of the riser was hel d at 1156C

while t he riser sides were per f ect l y insulated. The initial

t emperat ure of the met al was t aken as 1156C t hr oughout ,

and the initial t emper at ur e at t he i nt erface bet ween met al

and sand was 1080C, whi ch is the liquidus t emperat ure.

A condi t i on of perfect conduct i on was assumed at the

i nt erface, i.e. no t hermal resistance. For want of bet t er

i nf or mat i on, the l at ent heat was assumed t o evolve linearly

over the freezi ng range. Because t he slab is relatively thin,

convect i on in t he mel t woul d not be significant except in

the riser, so no effect f r om convect i on was i ncl uded.

Fr om an initial value o f 1.0 s, t he time-step was doubl ed

i f onl y one corrective i t erat i on was requi red t o reach a

convergence t ol erance of 0.5C. Three or mor e i t erat i ons

woul d cause t he time-step t o be halved. Originally, 3' and/3

in equat i ons ( 8) - ( 10) were t aken as 0.5 for all the el ement s.

Figure 3 shows the hi st or y o f t he solidus (1050C) cont our s

at 90 s intervals for t he case when the highest sand con-

duct i vi t y curve was used. Even wi t h such a coarse mesh,

t he shape and progression o f sol i di fi cat i on cont our s is in

accor d wi t h physi cal expect at i ons.

A slab casting wi t hout t aper was also model l ed, wi t h all

ot her condi t i ons i dent i cal t o t he previ ous casting. Figure 4

depi ct s t he sol i di fi cat i on cont our hi st or y, again at 90 s

intervals. The fact t hat a large por t i on o f t he slab solidifies

in one time interval, unlike the even progressi on f ound wi t h

the t apered casting, suggests t hat there woul d be feedi ng

probl ems in this region, resulting in shrinkage por osi t y.

This is, of course, what occurs in pract i ce. I f mor e exact

i nf or mat i on about the relationship bet ween fract i on

solidified and t emper at ur e were available, it woul d be

possible t o make a more definitive st at ement about likely

areas of underfeedi ng.

Using t he i mpl i ci t -expl i ci t al gori t hm, t he sand el ement s

were t hen all t aken t o be explicit, leaving 3' = 0.5 f or t he

Fi gur e 2 Fi ni t e el ement mesh (sand el ement s shaded)

]

>

Figure 3 S o l i d i f i c a t i o n f r o n t h i s t o r y f o r AI Bz sl ab ( t a p e r e d 1 : 2 0 )

1 7 2 A p p l . Ma t h . Mo d e l l i n g , 1 9 8 5 , V o l . 9, J u n e

Figure 4 Solidification front history for untapered slab highest

sand conductivity

metal. When a frontal solver was used, there was no im-

provement in the cpu (central processing unit) time per

iteration, as this solver could not take advantage of the

changed structure of the global stiffness matrix. In fact, the

global mat ri x is never actually formed. The frontal solver

has the i mport ant features t hat it makes node numberi ng

arbitrary and it requires less core space. When an active

column profile solver was used, however, the solution time

was reduced by 75% from t hat of the frontal solver. This is

with a mesh where 65% of the elements are explicit. A good

portion of this reduction is due simply to the fact t hat the

prof'de solver is faster in general than the frontal solver.

When the profile solver is used with 3' = 0.5 for all ele-

ments, however, a reduction of 39% still results due to the

implicit--explicit algorithm alone.

Ca p a c i t a n c e ma t r i x l u mp i n g

As not ed above, the capacitance matrices of the explicit

elements must be lumped to give KEF F the desired struc-

ture. With linear elements, this presents no problem: the

terms of a row may be simply summed to the diagonal.

This will be referred to as ' st andard' lumping. If this

procedure is adopt ed with the 8-noded serendipity element,

however, ill-conditioning is introduced 16 which causes

severe stability problems and loss of accuracy. Hinton t7

and Donea Is proposed two different lumping schemes to

restore stability. In Hinton' s met hod, the total heat

capacity is preserved and the terms of the lumped mat ri x

are proportional to the diagonal terms of the consistent

matrix. Donea introduces a new set of weighting functions

with which to form the lumped capacitance matrix.

Both of these schemes were used with the tapered slab

probl em and did, in fact, improve the stability. The

accuracy was degraded in bot h cases, however, with the

Hinton met hod being slightly better. In order to regain the

accuracy of the consistefit mat ri x, a modified predi ct or-

corrector algorithm was adopt ed for explicit elements:

Predictor

T n + l = [CD-- At K] T n

Co,

Corrector

CDT n+l = [CD-C] Tn+t + [C--ArK] T n

=,

CD is the capacitance matrix diagonalized by the Hinton

met hod. The effect of the consistent mat ri x is introduced

in the correct or step.

With the tapered slab probl em, when the convergence

tolerance was taken as 4.0C, this scheme converged to

within 1.0C of the consistent results, an error of less than

0.1%. What is more, it required fewer steps and iterations

to reach a given point in time. This added to the comput er

time savings due to the implicit-explicit algorithm alone.

Nine-noded Lagrangian elements were then used with

the same probl em. Standard and Hinton lumping, when

applied with the unmodified time-stepping algorithm, gave

nearly identical accuracy, with an error of less than 0.1%

when compared with the consistent results. The modified

predi ct or-correct or gave a slight i mprovement in accuracy,

but at the cost of more time-steps, iterations, and mat ri x

assembly time. Since standard lumping is somewhat faster

than Hi nt on' s met hod, it is most advantageous when

Lagrangian elements are used. In fact, even though a mesh

with Lagrangian elements requires solution for more

degrees-of-freedom, the total comput er time is less than

for 8-noded elements with the modified predi ct or-correct or

scheme described above, because fewer iterations are

required to obtain comparable accuracy.

Concl us i ons

In transient field problems involving mixed media with

widely different properties, such as metal casting in sand, a

substantial reduction in comput er time may be obtained

with an imphcit-explicit algorithm coupled with an active

column profile solver. When 8-noded serendipity elements

are used, a modified predi ct or-correct or scheme will

preserve accuracy. With 9-noded Lagrangian elements, only

standard lumping is required for good results.

No me n c l a t u r e

C capacitance mat ri x

Co diagonalized capacitance matrix

F right-hand side vector

h convective heat transfer coefficient

H enthalpy

K conductivity

n time-step

t~ unit outward normal to surface

p . mmber of corrective iterations

q specified heat flux

t time

x spatial coordinates

13 weighting factor for determining t emperat ure at which

to evaluate matrices

3' weighting fact or in two-level time-stepping scheme

F~ boundary with Dirichlet condition

F2 boundary with Neuman condition

p density

0 t emperat ure

intermediate t emperat ure

Appl. Math. Modelling, 1985, Vol. 9, June 173

0 . pr e di c t e d t e mp e r a t u r e

0,4 a mbi e nt t e mp e r a t u r e

s peci f i ed t e mp e r a t u r e

~2 spat i al d o ma i n

References

1 Henzel, J. G. and Keverian, J. ' Predicting casting solidification

patterns with a comput er' , Foundry 1964, 50-53

2 Weatherwax, R. B. and Riegger, O. K. ' Computer-aided solidifi-

cation study of a die-cast aluminium piston' , AFS Trans. 1977,

85, 317-322

3 Sahm, P. R. ' Applications-properties-microstructure-solidifi-

cation technologies: Challenge for computer simulation and

modelling foundry processes', Solidification Processes:

Computer Simulation and Modelling Workshop, CIATF-Cairo,

Nov. 1983, pp. 2-18

4 Jeyaraian, A. and Pehlke, R. D. 'Casting design by comput er' ,

AFS Trans. 1975, 101, 405- 412

5 Hansen, P. N. ' Numerical simulation of the solidification

process' , Solidification and Casting of Metals, Proc. Conf.

Metal Society, Sheffield, July 1977, (1979), pp. 350-356

6 Wei, C., Hansen, P. N. and Berry, J. T. ' The Q-dot met hod - A

compact technique for describing the heat flux present at the

moul d-met al interface in solidification programs' , Num. Meth.

Heat Transl. 1983, 2, 461- 472

7 Zienkiewicz, O. C. and Parekh, C. H. ' Two and three

dimensional isoparametric elements for transient field prob-

lems', Int. J. Num. Meth. Engng 1970, 2, 61-71

8 Morgan, K., Lewis, R. W. and Zienkiewicz, O. C. ' An improved

algorithm for heat conduction problems with phase change' ,

lnt. J. Num. Meth. Engng 1978, 12, 1191-1195

9 Zienkiewicz, O. C. and Morgan, K. ' Finite elements and

approximations' , John Wiley, New York, 1983

10 Hughes, T. J. R. ' Unconditionally stable algorithms for non-

linear heat conduction' , Comp. Meth. App. Mech. Engng

1977, 10, 135-139

11 Hughes, T. J. R. and Liu, W. K. ' Impl i ci t -expl i ci t finite

elements in transient analysis: Implementation and numerical

examples',ASME J. AppL Mech. 1978, 45, 375-378

12 Hughes, T. J. R., Pister, K. S. and Taylor, R. L. ' Impl i ci t -

explicit finite elements in nonlinear transient analysis', Cornp.

Meth. in AppL Mech. and Engng 1979 17/18, pp. 159-182

13 Liu, W. K. ' Development of mixed time partition procedures

for thermal analysis of structures' , lnt. J. Num. Meth. Engng

1983, 19, 125-140

14 Metals Handbook, 8th edn, Vol. 1, Properties and Selection of

Materials (ed. Lyman, T.), ASM, Novelty, Ohio, 1961,

pp. 1007, 1049, 1197, 1203-4

15 Pehlke, R. D., Marrone, R. E. and Wilkes, J. O. ' Comput er

simulation of solidification' , AFS Monograph, 1976, p. 69

16 Zienkiewicz, O. C. ' The finite element met hod' , 3rd edn,

McGraw-Hill, 1977, pp. 535-539

17 Hinton, E., Rock, T. and Zienkiewicz, O. C. ' A note on mass

lumping and related processes in the finite element met hod' ,

Earthquake Engng Struct. Dynamics 1976, 4, 245-249

18 Donea, J. and Laval, H. ' An improved formulation of the

parabolic isoparametric element for explicit transient analysis',

Earthquale Engng Struct. Dynamics 1979, 7, 23-29

174 Appl . Math. Modelling, 1985, Vol . 9, June

You might also like

- Rock Slope StabilityDocument12 pagesRock Slope StabilityWesley Marante100% (1)

- Doublet Lattice MethodDocument13 pagesDoublet Lattice MethodRocco Musci100% (1)

- ISRM-4CONGRESS-1979-235 - Stability Analysis of Underground Cavities in Fissured Rock MassesDocument6 pagesISRM-4CONGRESS-1979-235 - Stability Analysis of Underground Cavities in Fissured Rock Massescastille1956No ratings yet

- Design of Particulate Collectors Design of Particulate CollectorsDocument21 pagesDesign of Particulate Collectors Design of Particulate CollectorsarkczestNo ratings yet

- Problems Based On Interatomic and Intermolecular Forces: ElasticityDocument9 pagesProblems Based On Interatomic and Intermolecular Forces: ElasticityVijay AgarwalNo ratings yet

- Doppler Spectroscopy of Flows Transverse to Ultrasound BeamDocument4 pagesDoppler Spectroscopy of Flows Transverse to Ultrasound BeamBarengott RaNo ratings yet

- Application of The Finite Element Method To Molecular Quantum PDFDocument5 pagesApplication of The Finite Element Method To Molecular Quantum PDFhhakim32No ratings yet

- Brian T. Sutcliffe and Jonathan Tennyson - A Generalized Approach To The Calculation of Ro-Vibrational Spectra of Triatomic MoleculesDocument14 pagesBrian T. Sutcliffe and Jonathan Tennyson - A Generalized Approach To The Calculation of Ro-Vibrational Spectra of Triatomic MoleculesMddl2aNo ratings yet

- Martensen 1959Document62 pagesMartensen 1959topNo ratings yet

- Charged Vortices in An Abelian Higgs Model With Chern-Simons TermDocument3 pagesCharged Vortices in An Abelian Higgs Model With Chern-Simons TermФдучыфтвкщ Дгсутф ЬщефNo ratings yet

- Enhanced Eudml Content Accessible Layered-Pdf-Eudml-206586-0Document16 pagesEnhanced Eudml Content Accessible Layered-Pdf-Eudml-206586-0Karlstein DiaoNo ratings yet

- Deconvolution Technique Application To Spectral Contour AnalysisDocument12 pagesDeconvolution Technique Application To Spectral Contour AnalysisYassine ZidNo ratings yet

- Deconvolution Technique Application To Spectral Contour AnalysisDocument12 pagesDeconvolution Technique Application To Spectral Contour AnalysisYassine ZidNo ratings yet

- Deconvolution Technique Application To Spectral Contour AnalysisDocument12 pagesDeconvolution Technique Application To Spectral Contour AnalysisYassine ZidNo ratings yet

- Closed-Form Analytic Solution for Steady-State Comminution ProcessesDocument2 pagesClosed-Form Analytic Solution for Steady-State Comminution ProcessesDirceu NascimentoNo ratings yet

- Theoretical Improvements in Algorithmic Efficiency For Network Flow ProblemsDocument17 pagesTheoretical Improvements in Algorithmic Efficiency For Network Flow ProblemsNemo OudeisNo ratings yet

- Numerical Study On Flow Past 2D Square Cylinder by Large Eddy Simulation - Comparison Between 2D and 3D ComputationsDocument8 pagesNumerical Study On Flow Past 2D Square Cylinder by Large Eddy Simulation - Comparison Between 2D and 3D ComputationsMai ZhangNo ratings yet

- Analysis of Stirling Engine PerformanceDocument6 pagesAnalysis of Stirling Engine PerformanceAleksander NyczNo ratings yet

- Hydrodynamic Model of The Impact of A Solid On IceDocument6 pagesHydrodynamic Model of The Impact of A Solid On IceYaoke WenNo ratings yet

- Fkep#pcDocument13 pagesFkep#pcaarghjNo ratings yet

- DC DRIVES Principle of operation and construction reviewDocument5 pagesDC DRIVES Principle of operation and construction reviewBalasubramaniNo ratings yet

- Conde Nsa To AreDocument2 pagesConde Nsa To Aretrigger11sullyNo ratings yet

- Transformada de Laplace MITDocument11 pagesTransformada de Laplace MITÉzio MouraNo ratings yet

- Three Dimensional Temperature A N D Thermoelastic Stress Fields in A Heat Producing Sphere Arbitrary Surface Heat TransferDocument26 pagesThree Dimensional Temperature A N D Thermoelastic Stress Fields in A Heat Producing Sphere Arbitrary Surface Heat TransferSakuNo ratings yet

- 0 ' 1 T - 0 - , ) - K, Sin 4 (V + 0) - K - Sin 2 (:? - I) .Document4 pages0 ' 1 T - 0 - , ) - K, Sin 4 (V + 0) - K - Sin 2 (:? - I) .ehagar60No ratings yet

- Fortran Programming 2Document7 pagesFortran Programming 2Kesev KeshavNo ratings yet

- A Such ThatDocument3 pagesA Such ThatJandfor Tansfg ErrottNo ratings yet

- 9-Point Formula Provides Higher Accuracy Solution to Laplace's EquationDocument16 pages9-Point Formula Provides Higher Accuracy Solution to Laplace's EquationSajid IqbalNo ratings yet

- Dragnet Past QuestionsDocument1 pageDragnet Past QuestionsCHIBUIKE DANIEL33% (3)

- C.H Westcott, Et Al., Effective Cross Section and Cadmium Ratios For The Neutron On Spectra of Thermal ReactionsDocument18 pagesC.H Westcott, Et Al., Effective Cross Section and Cadmium Ratios For The Neutron On Spectra of Thermal Reactions최재원No ratings yet

- A CLASS OF MIN-CUT PLACEMENT ALGORITHMSDocument7 pagesA CLASS OF MIN-CUT PLACEMENT ALGORITHMS'Tasos SkourtisNo ratings yet

- Labour (Mazdoor) Required for Different WorksDocument5 pagesLabour (Mazdoor) Required for Different Worksbrotherkh26No ratings yet

- Triple resonance pulse transformer circuit patent detailsDocument4 pagesTriple resonance pulse transformer circuit patent detailsharishkumarsinghNo ratings yet

- In Production, With N Face Turning, ?ig. I, During Nachining TheDocument4 pagesIn Production, With N Face Turning, ?ig. I, During Nachining Theebi902000No ratings yet

- Laval Nozzle Flow CalculationsDocument8 pagesLaval Nozzle Flow CalculationsMatiasGuerrero100% (2)

- International Society For Soil Mechanics and Geotechnical EngineeringDocument5 pagesInternational Society For Soil Mechanics and Geotechnical EngineeringAbulmomen Rebwar Abdulrahman MohammedNo ratings yet

- Olo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelsDocument4 pagesOlo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelspabusaoNo ratings yet

- Z2 Gauge Model on the Truncated-Tetrahedron LatticeDocument5 pagesZ2 Gauge Model on the Truncated-Tetrahedron LatticeRudolf KiraljNo ratings yet

- Din 16901Document6 pagesDin 16901Trexa GyreueNo ratings yet

- Applied: A Comparison Between These Curves and Those TakenDocument12 pagesApplied: A Comparison Between These Curves and Those TakenHamaamNo ratings yet

- Effective Breadth ConceptDocument21 pagesEffective Breadth ConceptspamszafkaNo ratings yet

- Interpolator For A Computer Numerical Control SystemDocument6 pagesInterpolator For A Computer Numerical Control SystemJuan JacksonNo ratings yet

- MathewsDocument7 pagesMathewsSenoussi HamelNo ratings yet

- Parallel Prefix ComputationDocument8 pagesParallel Prefix Computationharicharan87No ratings yet

- Covellite To DigeniteDocument7 pagesCovellite To DigeniteMiizoreNo ratings yet

- Trudnowsky, Donnelly, HauerDocument2 pagesTrudnowsky, Donnelly, Hauerabhikirk99No ratings yet

- It That Matrix: Proceedings Seventh Workshop Geothermal Reservoir Engineering Stanford, December 1981. SGP-TR-55Document5 pagesIt That Matrix: Proceedings Seventh Workshop Geothermal Reservoir Engineering Stanford, December 1981. SGP-TR-55bongganongNo ratings yet

- A General Method For Solving Divide-and-Conquer RecurrencesDocument9 pagesA General Method For Solving Divide-and-Conquer RecurrencesAmadís MartinezNo ratings yet

- Cam Bri Dge Pu Blic School - I (I I (I (Fri R-TT Preparatory Examinatton 2 A R 4 - R 5 Sub.. - Mathematics M A RL S: B0Document4 pagesCam Bri Dge Pu Blic School - I (I I (I (Fri R-TT Preparatory Examinatton 2 A R 4 - R 5 Sub.. - Mathematics M A RL S: B0ultimatorZNo ratings yet

- SHUMLYANSKII - Stability Criterion of The Longitudinal-Torsional Vibrations of A Hoisting Cable With An End Load in Rigid GuidesDocument5 pagesSHUMLYANSKII - Stability Criterion of The Longitudinal-Torsional Vibrations of A Hoisting Cable With An End Load in Rigid GuidesAnonymous PsEz5kGVaeNo ratings yet

- Simplified Composite Procedures For Designing Bolted JointsDocument15 pagesSimplified Composite Procedures For Designing Bolted JointsvietnhutNo ratings yet

- Second Order Tensor Invariants in Continuum MechanicsDocument38 pagesSecond Order Tensor Invariants in Continuum MechanicsAishaBhattiNo ratings yet

- National Technical Information Service: ReproducedDocument15 pagesNational Technical Information Service: Reproducedsam0025No ratings yet

- Philips PM2517Document104 pagesPhilips PM2517Mohammad EssamNo ratings yet

- MITRES 18 007 Partv Sol03 PDFDocument37 pagesMITRES 18 007 Partv Sol03 PDFdebasree dasNo ratings yet

- A: Multistable Nonlinear Surface ModesDocument9 pagesA: Multistable Nonlinear Surface ModesmenguemengueNo ratings yet

- The Direct-Inspection Method in Systems With A Principal Axis of SymmetryDocument4 pagesThe Direct-Inspection Method in Systems With A Principal Axis of Symmetrychm12No ratings yet

- Roller KilnsDocument3 pagesRoller Kilnsjohan_nieuwoudtNo ratings yet

- Izzard, C. F.-The Surface-Profile of Overland-FlowDocument10 pagesIzzard, C. F.-The Surface-Profile of Overland-Flowjosue.angelo9459No ratings yet

- PSCB Recruitment 2021 for 856 Posts of Senior Managers, Managers, IT Officers, Clerks & StenosDocument16 pagesPSCB Recruitment 2021 for 856 Posts of Senior Managers, Managers, IT Officers, Clerks & StenosGurjeetNo ratings yet

- Answer KeyDocument1 pageAnswer KeyVikas GargNo ratings yet

- AIIMS ElectrochemistryDocument2 pagesAIIMS ElectrochemistryVikas GargNo ratings yet

- Cannon LPB3010Document0 pagesCannon LPB3010lenceNo ratings yet

- Apps On NT Best PracticesDocument11 pagesApps On NT Best PracticesVikas GargNo ratings yet

- Alpha Chemistry Classes: Alkaline Earth MetalsDocument14 pagesAlpha Chemistry Classes: Alkaline Earth MetalsVikas GargNo ratings yet

- AIIMS - Structure of AtomDocument3 pagesAIIMS - Structure of AtomVikas GargNo ratings yet

- Windows Firewall: If You Are Not Using A Network Environment (I.e. USB Connection Only)Document0 pagesWindows Firewall: If You Are Not Using A Network Environment (I.e. USB Connection Only)Milan KrcmarNo ratings yet

- WWW - Ppsc.gov - in PDF Pscscce2013 PresylDocument3 pagesWWW - Ppsc.gov - in PDF Pscscce2013 PresylVikas GargNo ratings yet

- Office of The Registering and Licensing Authority, U.T, Chandigarh Press NoteDocument1 pageOffice of The Registering and Licensing Authority, U.T, Chandigarh Press NoteVikas GargNo ratings yet

- Isothermal ExpansionDocument8 pagesIsothermal Expansionsoumalya481No ratings yet

- Benefits of DefragmentationDocument4 pagesBenefits of DefragmentationVikas GargNo ratings yet

- Fast Color Scan To A PDF File - 3Document1 pageFast Color Scan To A PDF File - 3Vikas GargNo ratings yet

- The Punjab Cooperative Agricultural Development Banks Rules, 1959Document14 pagesThe Punjab Cooperative Agricultural Development Banks Rules, 1959Vikas GargNo ratings yet

- Defrag TutorialDocument20 pagesDefrag TutorialVikas GargNo ratings yet

- 104 GK FactsDocument5 pages104 GK FactsankitbhargavakietNo ratings yet

- Amc GuideDocument2 pagesAmc GuideVikas GargNo ratings yet

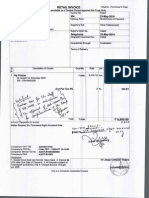

- Invoice HP Deskjet 2645Document1 pageInvoice HP Deskjet 2645Vikas GargNo ratings yet

- Panjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CDocument1 pagePanjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CVikas GargNo ratings yet

- General knowledge document covering important facts about IndiaDocument141 pagesGeneral knowledge document covering important facts about IndiaMudassir ShahNo ratings yet

- Detailed Advst. & Information of 1192 Posts of ClerksDocument9 pagesDetailed Advst. & Information of 1192 Posts of ClerksVikas GargNo ratings yet

- History of Modern IndiaDocument12 pagesHistory of Modern IndiaTanmay JagetiaNo ratings yet

- Panjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CDocument1 pagePanjab University, Chandigarh UGLAW-2013 Answers Key: D A B C A D C B C CVikas GargNo ratings yet

- Panjab University, Chandigarh PUTHAT-2013 Answers Key: B A D A C C C C D BDocument1 pagePanjab University, Chandigarh PUTHAT-2013 Answers Key: B A D A C C C C D BVikas GargNo ratings yet

- CET (PG) - 2013: Panjab University, Chandigarh Answers / KeyDocument35 pagesCET (PG) - 2013: Panjab University, Chandigarh Answers / KeyVikas GargNo ratings yet

- It Specialist Officers General Awarness Solved PaperDocument15 pagesIt Specialist Officers General Awarness Solved PaperVikas GargNo ratings yet

- CompscDocument11 pagesCompscVikas GargNo ratings yet

- It Officer Central Bank of IndiaDocument6 pagesIt Officer Central Bank of IndiaMondar DebNo ratings yet

- It Specialist Officers General Awarness Solved PaperDocument15 pagesIt Specialist Officers General Awarness Solved PaperVikas GargNo ratings yet

- IBPS Computer Awareness Sample Questions 4Document6 pagesIBPS Computer Awareness Sample Questions 4Brundaban MohapatraNo ratings yet

- Lineshaft Turbine Pump 1800 RPM 60 HZDocument156 pagesLineshaft Turbine Pump 1800 RPM 60 HZFayez Al-ahmadiNo ratings yet

- Fire Exit Doors SizeDocument3 pagesFire Exit Doors SizeBerlin Andrew SionNo ratings yet

- File Download ActionDocument45 pagesFile Download Actionecarter9492No ratings yet

- MySQL Backups Go Near-ContinuousDocument43 pagesMySQL Backups Go Near-ContinuousOleksiy KovyrinNo ratings yet

- DECIDE ChecklistDocument2 pagesDECIDE ChecklistGuilioNo ratings yet

- Sap Press Integrating EWM in SAP S4HANADocument25 pagesSap Press Integrating EWM in SAP S4HANASuvendu BishoyiNo ratings yet

- Nucor at A CrossroadsDocument10 pagesNucor at A CrossroadsAlok C100% (2)

- Health Promotion Throughout The Life Span 8Th Edition Edelman Test Bank Full Chapter PDFDocument30 pagesHealth Promotion Throughout The Life Span 8Th Edition Edelman Test Bank Full Chapter PDFDeborahAndersonmkpy100% (10)

- 201233646Document48 pages201233646The Myanmar TimesNo ratings yet

- SQL QuestionsDocument297 pagesSQL Questionskeysp75% (4)

- Slides Iso 17021 Be LacDocument117 pagesSlides Iso 17021 Be Lacjorge.s1943No ratings yet

- JavaScript ArraysDocument5 pagesJavaScript Arraysursu_padure_scrNo ratings yet

- SeminarDocument30 pagesSeminarRahul prajapatiNo ratings yet

- Study Guide For Kawabata's "Of Birds and Beasts"Document3 pagesStudy Guide For Kawabata's "Of Birds and Beasts"BeholdmyswarthyfaceNo ratings yet

- An Adaptive Memoryless Tag Anti-Collision Protocol For RFID NetworksDocument3 pagesAn Adaptive Memoryless Tag Anti-Collision Protocol For RFID Networkskinano123No ratings yet

- Research On Water Distribution NetworkDocument9 pagesResearch On Water Distribution NetworkVikas PathakNo ratings yet

- Verify File Integrity with MD5 ChecksumDocument4 pagesVerify File Integrity with MD5 ChecksumSandra GilbertNo ratings yet

- Validate Analytical MethodsDocument9 pagesValidate Analytical MethodsFernando Silva BetimNo ratings yet

- GTN Limited Risk Management PolicyDocument10 pagesGTN Limited Risk Management PolicyHeltonNo ratings yet

- METACOGNITION MODULEDocument4 pagesMETACOGNITION MODULEViolet SilverNo ratings yet

- Arduino Project: Smart Irrigation SystemDocument13 pagesArduino Project: Smart Irrigation SystemAleeza AnjumNo ratings yet

- Science and Technology Study Material For UPSC IAS Civil Services and State PCS Examinations - WWW - Dhyeyaias.comDocument28 pagesScience and Technology Study Material For UPSC IAS Civil Services and State PCS Examinations - WWW - Dhyeyaias.comdebjyoti sealNo ratings yet

- Interventional Radiology & AngiographyDocument45 pagesInterventional Radiology & AngiographyRyBone95No ratings yet

- Stages On The Empirical Program of RelativismDocument9 pagesStages On The Empirical Program of RelativismJorge Castillo-SepúlvedaNo ratings yet

- 12soal Uas - K.99 - Raditya - Bahasa Inggris Hukum (1) - 1Document3 pages12soal Uas - K.99 - Raditya - Bahasa Inggris Hukum (1) - 1Brielle LavanyaNo ratings yet

- Polygon RobotsDocument8 pagesPolygon Robotsapi-270154832No ratings yet

- Week Three Lesson Plan Bread and Jam For FrancesDocument2 pagesWeek Three Lesson Plan Bread and Jam For Francesapi-29831576No ratings yet

- Real Estate Development Business PlanDocument5 pagesReal Estate Development Business PlanA. FranciscoNo ratings yet

- Early Christian Reliquaries in The Republic of Macedonia - Snežana FilipovaDocument15 pagesEarly Christian Reliquaries in The Republic of Macedonia - Snežana FilipovaSonjce Marceva50% (2)

- 6 Grade English Language Arts and Reading Pre APDocument3 pages6 Grade English Language Arts and Reading Pre APapi-291598026No ratings yet