Professional Documents

Culture Documents

Compression Behavior of Thin Gusset Plates

Uploaded by

Donald Essen0 ratings0% found this document useful (0 votes)

17 views18 pagesUse of cold-formed steel members for truss applications is gaining widespread acceptance. There is little technical information regarding the behavior and design of thin gusset plates in compression.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUse of cold-formed steel members for truss applications is gaining widespread acceptance. There is little technical information regarding the behavior and design of thin gusset plates in compression.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views18 pagesCompression Behavior of Thin Gusset Plates

Uploaded by

Donald EssenUse of cold-formed steel members for truss applications is gaining widespread acceptance. There is little technical information regarding the behavior and design of thin gusset plates in compression.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 18

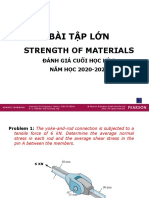

Seventeenth International Specialty Conference on Cold-Formed Steel Structures

Orlando, Florida, U.S.A, November 4-5,2004

Compression Behavior of Thin Gusset Plates

D. G. Lutz

l

and R. A. LaBoube

2

Abstract

The use of cold-formed steel members for truss applications is gaining

widespread acceptance in the United States. However, there is little technical

information regarding the behavior and design of thin gusset plates in

compression. Thus, a study has been initiated at the University of Missouri-

Rolla aimed at investigating the behavior of thin gusset plates in compression.

Key parameters that were considered in the experimental study were the

thickness of the gusset plate sheet steel which ranges from 0.058 inches (1.47

mm) to 0.103 inches ( 2.62 mm); width and length of the gusset plates, fastener

location, and fastener pattern.

Introduction

The use of cold-formed steel members for truss applications is gaining

widespread acceptance in the United States. Cold-formed steel truss design in

the United States is based on the American Iron and Steel Institute (AISI)

publication North American Specification for the Design of Cold-Formed Steel

Structural Members (2001) and the Standard for Cold-Formed Steel Framing-

Truss Design (2001). However, neither the specification nor the standard

includes guidelines for the design of gusset plates. These plates are critical for

connecting structural elements in the same plane. Truss systems commonly

utilize gusset plate connections, as illustrated by Figure 1.

This study focused on the general behavior of thin flat gusset type plates in

compression. The test data was compared against current design methodologies

lGraduate Student, Department of Civil Engineering, University of Missouri-

Rolla

2Distinguished Teaching Professor, Dept. of Civil Eng., University of Missouri-

Rolla

801

802

and modifications were suggested. Both edge stiffened and unstiffened gusset

plates were studied.

Literature Review

One of the earliest studies in the United States on gusset plates was performed

by Whitmore (1952) at the University of Tennessee. His study focused on the

stress distribution within aluminum plate connections: Whitmore concluded that

the stresses start at the outside edge of the top row of fasteners and propagate

out at an angle close to 30. The stresses continued to spread out at this angle

until they reached the last row of fasteners. The stresses then continued nearly

parallel to the original line of fasteners. This pattern has become known as the

Whitmore Section and is illustrated in Figure 2.

Truss Top

Chord

Gusset Plate

Truss Web

Truss Top

Chord

Figure 1 Roof Truss with Gusset Plate Connection

803

Figure 2 Whitmore Section

Thornton (1984) presented a design methodology for brace connections in heavy

construction. Thornton proposed a method for calculating the capacity of a

gusset plate in compression. The author suggested that the plate be analyzed as

an effective column. Thornton's analytical model is based on assumptions that

have only been verified for thick gusset plates. The effect of a thin gusset plate

in the connections had not been previously examined.

An unpublished technical paper by Babich (2002) described a design

methodology for thin, flat gusset plates used for cold-formed steel truss design.

Babich suggested two methods for the design of compression plate connections.

The first method was based on a modified Thornton approach. Babich also

suggested a method that utilized a plate buckling approach. The critical

buckling stress was calculated and then averaged to take into account the non-

linear and post-buckling stress distribution within the plate. A plate buckling

coefficient, k, equal to 1.25 was used.

The plate buckling design methodology proposed by Babich is based on plate

theory and research performed by others on thick gusset plates. The axial

compressive strength of the compression plate is calculated as follows:

Where:

Where:

Ae

=

Fy

=

E

=

k

=

11 =

t

=

P compute = Ae fay

Effective area of member = W

eff

t

Specified minimum yield point

Modulus of elasticity

Plate buckling coefficient = 1.25

Poisons Ratio = 0.3

Plate thickness, in.

(1)

(2)

(3)

804

Weff is to be taken as the lesser of the following:

The gusset plate width

1.25 times the least width of the connected members

The Whitmore Section as shown in Figure 2.

A compilation of test data on gusset plates loaded in compression was

assembled by Dowswell and Barber (2004). The data is based on both

experimental tests and finite element models. The test data was separated into

five different categories. These included compact corner-braces, non-compact

corner-braces, extended corner-braces, single-brace gusset plates, and Chevron-

brace gusset plates. A statistical analysis was performed on the calculated

strength using Thornton's method and the tested load capacity. Suggestions

were then offered as to what value should be used for the effective length, and

the effective length factor, for each category of brace. Of the five test data

categories, the single-brace gusset plate tests most closely resembled that of a

typical roof truss gusset plate connection. The smallest thickness that was tested

in the study was a 0.256 in. thick plate.

UMR EXPERIMENTAL INVESTIGATION

An experimental study was initiated at the University of Missouri-Rolla to

explore the behavior of the thin steel gusset plates in compression. A testing

apparatus was developed that would accommodate the variables of the testing

program and ensure consistent dimensions between tests. Three variables were

considered in the testing program: plate thickness, plate width, and fastener

pattern. The fastener pattern controlled two of the parameters, the effective

length and the effective plate width.

Eleven different fastener patterns were chosen for testing. These patterns were

designed to show the effect of the parameters that were to be investigated. A

sketch of the general test setup can be seen in Figure 3. Details regarding the

fastener patterns are given by Lutz (2004). A summary ofthe dimensions of

each individual test can be found in Table 1.

Material Properties. The mechanical properties of the gusset plate material

were determined by performing standard tensile coupon tests (ASTM A370,

2002). A summary of the average results can be found in Table 2.

805

Test Specimen Fabrication. Each test specimen consisted of two rectangular

hollow structural steel (HSS) sections oriented perpendicular to each other with

two thin gusset plates on each side, as shown in Figure 4. Bolts were used

instead of screws to provide a test fixture that would be reusable during the

testing program. The bolts were lA in. (6.4 mm) diameter Grade 8. Holes were

drilled into both HSS sections for use both during testing and to provide a

template for drilling the holes in the plates. These holes were precisely placed

using the digital readout on the milling machine. A spacer was placed between

the two tubes to maintain a consistent gap, Lg, (Fig. 3) as specified by the

layouts of the different tests.

I

I

I

! Wf

: t--I

I

Vertical

Member

i L,

I I

,---Lg -.!-------:--:----!.- Leff

L wp---l

FRONT

Horizontal

Member

Plate Thickness

(t)

SIDE

Figure 3 Typical Connection Detail

The small bolts provided a fastener pattern that was comparable to a screw

fastener pattern and ensured that the plates failed before the fasteners. The nuts

were finger tightened to represent the low clamping action provided by screws.

Edge Stiffened Plate Fabrication. The effect of an edge stiffener on the gusset

plate was also studied. A typical stiffened plate with a 5/8 inch edge stiffener is

shown in Figure 5.

806

Test Procedure. The tests were performed using a universal testing machine.

The load was continuously applied until the test specimen either stopped taking

load or the bottom of the vertical HSS section came into contact with the

horizontal HSS section.

TEST RESULTS

Unstiffened Gusset Plates. The flat unstiffened gusset plates comprised the

majority of the test program. Each test specimen configuration was duplicated

with similar failure modes and maximum loads achieved.

Table 1 Test Parameters

Plate Effective Effective Length of Fastener Fastener HSS Plate

Specimen

Thickness Width Lenqth

GlIP_ Lenllth Width Width Width

No. t W,ff L,ff Lg L, W, W, Wp

(in) (in) (in) (in) (in) (in) (in) (in)

1A 0.0585 3.23 1 0.125 1.5 1.5 4 6

18 0.0749 3.23 1 0.125 1.5 1.5 4 6

1C 0.1027 3.23 1 0.125 1.5 1.5 4 6

2A 0.0585 4.73 1 0.125 1.5 3 4 6

2B 0.0749 4.73 1 0.125 1.5 3 4 6

2C 0.1027 4.73 1 0.125 1.5 3 4 6

3A 0.0585 5.00 1 0.125 3 3 4 6

3B 0.0749 5.00 1 0.125 3 3 4 6

3C 0.1027 5.00 1 0.125 3 3 4 6

4B 0.0749 4.00 1 0.125 3 3 4 4

5B 0.0749 3.23 1 0.125 1.5 1.5 4 12

6A 0.0585 3.23 2.5 0.125 1.5 1.5 4 6

6B 0.0749 3.23 2.5 0.125 1.5 1.5 4 6

6C 0.1027 3.23 2.5 0.125 1.5 1.5 4 6

7B 0.0749 3.23 1.125 0.25 1.5 1.5 4 6

8B 0.0749 4.73 2.5 0.125 1.5 3 4 6

9A 0.0585 3.23 1.75 0.125 1.5 1.5 4 6

9B 0.0749 3.23 1.75 0.125 1.5 1.5 4 6

9C 0.1027 3.23 1.75 0.125 1.5 1.5 4 6

10A 0.0585 4.96 1 0.125 3 1.5 4 6

10B 0.0749 4.96 1 0.125 3 1.5 4 6

10C 0.1027 4.96 1 0.125 3 1.5 4 6

11A 0.0585 3.23 4 0.125 1.5 1.5 4 6

11B 0.0749 3.23 4 0.125 1.5 1.5 4 6

11C 0.1027 3.23 4 0.125 1.5 1.5 4 6

Note: See Figure 3 for parameter definitions; 1 inch = 25.4 mm.

The typical failure mode for specimen type 14ga and 16ga having either 6 in. or

4 in. widths was a lateral buckling of the plates as is shown in Figure 6. For the

12 in. wide 14ga and 16ga specimen types, the failure mode was a localized

buckling of the plate in the vicinity of the Whitmore Section. The 12ga

807

specimen types deformed axially until the vertical and horizontal HSS sections

came in bearing contact with each other. The contact between the HSS sections

was considered a failure. Minor buckling was noted in the plates.

Table 2. Material Properties

Uncoated

Yield Point

Tensile Percent

Specimen

Thickness Strength Elongation

Type t Fy Fu

(in) (psi) (psi) (%)

12ga 0.1027 44,385 56,052 41

14ga 0.0749 51,563 60,051 36

16ga 0.0585 33,750 48,161 27

Note: 1 ksi = 6.89 MPa, 1 inch = 25.4 mm.

Figure 4 HSS Test Fixture Sections

808

Figure 5 Typical Stiffened Plate

Figure 6 Typical Lateral Buckling of Unstiffened Plate

Table 3 summarizes the results of the tests conducted on the un stiffened plates.

Test 2C-l failed with a local buckling in the webs of the horizontal HSS and

therefore test 2C-2 was not performed.

809

Edge Stiffened Gusset Plates. The edge stiffened gusset plates were tested to

gain insight into the increased strength that the stiffeners might provide. The

typical failure mode for these plates was a plate buckling in the Whitmore

Section with deformation in the stiffeners and a slight out-of-plane sway. Table

4 summarizes the results of the edge stiffened tests. For the two specimen types

investigated, a similar strength increase of approximately 25% was achieved.

UMR Data Analysis

The data obtained from the test program was used to develop both a plate model

and a column model for determining compressive strength of a gusset plate

(Lutz,2004). This paper presents only the plate model.

The test results were used to back calculate the plate buckling coefficient, k,

required to achieve the tested load capacity. This process yielded an average k

value of approximately 4.0. According to Yu (2000), k equal to 4.0 would

correspond to a situation where all four sides of the plate are simply supported.

The connected members and fastener acted together to provide a simply

supported condition for the edges of the plates, justifying the use of k equal to

4.0.

The three effective width criteria, Weff, as proposed by Babich, were considered

but the test results and analysis justified using only the smaller of the Whitmore

section and the plate width. There was no justification found in the test data for

the use ofthe 1.25 times the width ofthe connected member.

One variable that was not taken into account in the Babich plate model was the

effective length ofthe plate, Leff (Fig. 3). As depicted by Figure 7 a bilinear

relationship existed between the P ",stIP compu'" ratio and the width to length,

WefflLeff, ratio.

8lO

Table 3 Unstiffened Gusset Plate Test Results

Specimen

Ptestlll Ptestll2

Specimen

Ptestlll Ptestll2

No.

(lbs/platel (Ibs/plate)

No.

Jlbsplatel

1A 5,188 6,313 6C 11,775 11,400

18

12,275 10,175 78 9,188 9,588

1C 17,000 17,500 88 13,863 11,888

2A 7,175 7,400 9A 5,850 4,738

28 14,538 14,363 98 9,050 10,500

2C 19,150

-

9C 14,750 14,000

3A 5,900 5,500 10A 5,263 6,588

38 14,400 16,125 108 12,363 12,613

3C 22,725 17,950 10C 17,000 17,050

48 11,550 10,625 11A 3,625 3,113

58 13,800 11,613 118 6,875 5,188

6A 4,263 5,813 11C 10,550 9,775

68 8,888 9,125

Table 4 Edge Stiffener Test Results

Specimen

Ptestlll Ptestll2

Test %

Average Strength

No.

(Ibs/platel Jibs/plate) (Ibs/plate) Increase

tA 5,188 6,313 5,750

27%

S1A 7,595 7,000 7,298

6A 4,263 5,813 5,038

24%

S6A 5,950 6,530 6,240

Note: SIA and S6A were edge stiffened Plates

811

1.6

1.4

1.2

t

a

/

r'*

/.

/

t

I!;. 0.8

J

0.6

0.4

0.2

W.,Il

Figure 7 P tesJPcompute versus W

eff

/ Leff

A modified analytical model was thus developed as follows:

For W eff I Leff:S 1.5

Po = Pcompute(0.47 Weff + 0.3J

Leff

For Weff / Leff >1.5

Where:

(4)

(5)

(6)

(7)

(8)

Where:

=

=

=

=

=

812

Effective area of gusset plate = Weff t

Specified minimum yield point, ksi

Modulus of elasticity = 29,500 ksi

Plate buckling coefficient = 4.0

Poisons ratio = 0.3

Uncoated plate thickness, in.

W

eff

shall be taken as the lesser of the following:

The gusset plate width

The Whitmore width as shown in Figure 2

Leff shall be taken as the average length between the last row of

fasteners of adjacent members, shown as Avg. (11,12,13) in Figure 8.

The P tes/P n ratio was calculated using the analytical model represented by

Equations 4 through 8, and is given in Table 5. The mean and standard

deviations were calculated to be 1.07 and 0.15, respectively, and is illustrated by

Figure 9.

DESIGN RECOMMENDATION

The factors of safety for Allowable Stress Design and Resistance factors for

Load and Resistance Factor Design and Limit State Design were calculated in

accordance with the AISI Specification (AISI, 2001)

The nominal axial strength, P n, of a thin, flat gusset plate in compression is

calculated as follows:

(9)

USA and Mexico Canada

Qc(ASD) I <Dc(LRFD) <Dc(LSD)

2.50

I

0.60 0.50

For W

eff

/ L

eff

:::; 1.5

813

fay = Weff + 0.3J

Leff

For Weff / Leff > 1.5

Where:

J

Where:

Ae

Fy

E

k

!1

=

=

=

=

=

Effective area of gusset plate = W

eff

t

Specified minimum yield point, ksi

Modulus of elasticity = 29,500 ksi

Plate buckling coefficient = 4.0

Poisons Ratio = 0.3

Uncoated plate thickness, in.

W

eff

shall be taken as the lesser of the following:

The gusset plate width

The Whitmore plate width as shown in Figure 2

(10)

(11)

(12)

(13)

Leff shall be taken as the average length between the last row of

fasteners of adjacent truss members, Left =( 11 +12 + 13 )/3, (Figure 11).

The equations are applicable within the limits of the investigation.

- Uncoated design base metal thickness: 0.059 in. - 0.103 in.

- Design yield point: 33 ksi - 52 ksi

- Weft / Left ratio: 0.8 - 6.0

- Plates with edge stiffeners could be conservatively designed using these

equations.

814

Conclusions

A total of 49 specimens were tested to study the behavior of thin gusset plates in

compression. Based on the test results a design methodology was established for

thin gusset plate connections in compression.

A limited number of tests were performed to determine the strength gain in

gusset plates with edge stiffeners. The test results showed an approximate

strength increase of 25% for the plates.

815

Table 5 Ptes/Po Ratio for the Analytical Model

Test

P

n P test#l P test#2

P test#l

Ptest#2/Pn

No. /P

n

Ibs/plate Ibs/plate Ibs/plate

1A 5,044 5,188 6,313 1.03 1.25

1B 10,110 12,275 10,175 1.21 1.01

1C 15,088 17,000 17,500 1.13 1.16

2A 5,505 7,175 7,400 1.30 1.34

2B 11,077 14,538 14,363 1.31 1.30

2C 17,581 19,150 - 1.09 -

3A 5,715 5,900 5,500 1.03 0.96

3B 11,517 14,400 16,125 1.25 1.40

3C 18,716 22,725 17,950 1.21 0.96

4B 10,696 11,550 10,625 1.08 0.99

5B 10,110 13,800 11,613 1.36 1.15

6A 4,557 4,263 5,813 0.94 1.28

6B 9,133 8,888 9,125 0.97 1.00

6C 13,629 11,775 11,400 0.86 0.84

7B 10,110 9,188 9,588 0.91 0.95

8B 11,077 13,863 11,888 1.25 1.07

9A 5,044 5,850 4,738 1.16 0.94

9B 10,110 9;050 10,500 0.90 1.04

9C 15,088 14,750 14,000 0.98 0.93

lOA 5,551 5,263 6,588 0.95 1.19

lOB 11,174 12,363 12,613 1.11 1.13

10C 17,832 17,000 17,050 0.95 0.96

lIA 3,415 3,625 3,113 1.06 0.91

lIB 6,845 6,875 5,188 1.00 0.76

lIC 10,216 10,550 9,775 1.03 0.96

Mean 1.07

Std. Dev.

0.15

Note: lIb. = 1.18 N

816

20000+---------------------------:;;1

15000+---------------7"":----_____ ..:"------__1

10000

5000

__

o 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

P n (Ibs/plate)

Figure 9 Evaluation of Analytical Model

Figure 10 Effective Length

References

Babich, W. (2002), "Good Practices Technical Note: Truss Gusset Plate

Design." Draft #5. Private Correspondence.

817

Dowswell, B., and Barber, S. (2004), "Buckling of Gusset Plates: A

Comparison of Design Equations to Test Data." Proceedings of the Annual

Stability Conference Structural Stability Research Council.

North American Specificationfor the Design of Cold-Formed Steel Structural

Members (2001), American Iron and Steel Institute, Washington, DC.

Standardfor Cold-Formed Steel Framing - Truss Design (2001), American Iron

and Steel Institute, Washington, D.C.

Standard Test Methods and Definitions for Mechanical Testing of Steel

Products, A370-02 (2002), American Society for Testing Materials

Thornton, W. (1984), "Bracing Connections for Heavy Construction."

Engineering Journal, American Institute of Steel Construction, Third Quarter,

pp. 139-148.

Whitmore, R.E. (1952), "Experimental Investigation of Stresses in Gusset

Plates." Bulletin No. 16. University of Tennessee Engineering Experiment

Station, Knoxville, TN.

Yu, W.W. (2000), Cold-Formed Steel Design, Third Edition, John Wiley and

Sons, New York, NY

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Pinned Base PlatesDocument61 pagesPinned Base PlatesHomero Silva100% (19)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mass Concrete Thermal ControlDocument33 pagesMass Concrete Thermal ControlMihnea-Bogdan NicolaescuNo ratings yet

- Impact TestingDocument27 pagesImpact Testingapi-3764139100% (2)

- Bolted Connection FatigueDocument12 pagesBolted Connection FatigueMahfuzur Rahman100% (1)

- Apendice 5 Asme VIII 2 PDFDocument12 pagesApendice 5 Asme VIII 2 PDFBrendaNo ratings yet

- Aisi 4340 Alloy Steel (Uns g43400)Document4 pagesAisi 4340 Alloy Steel (Uns g43400)LamhotFernandoSihombingNo ratings yet

- Fretting Fatigue On Thread Root of Premium Threaded ConnectionsDocument10 pagesFretting Fatigue On Thread Root of Premium Threaded ConnectionsJesus ZilchNo ratings yet

- Reciprocal Lattices Simulation Using MatlabDocument50 pagesReciprocal Lattices Simulation Using MatlabOmed Ghareb100% (5)

- Standard Drawing - Column ConnectionDocument21 pagesStandard Drawing - Column ConnectionAhmad Basshofi HabiebNo ratings yet

- Chapter 8 - Rock TestingDocument52 pagesChapter 8 - Rock TestingZulaikha Kamal67% (3)

- Design Concept RCC SuperstructureDocument5 pagesDesign Concept RCC SuperstructureSaroj BhattaraiNo ratings yet

- The History of JavaDocument582 pagesThe History of JavaDonald EssenNo ratings yet

- Is 516 Part 1 Section 1Document19 pagesIs 516 Part 1 Section 1devendra choudhary80% (5)

- Mind Map Thermal AnalysisDocument1 pageMind Map Thermal Analysisizzah hadiNo ratings yet

- Earth P Ressure Us Sing Gener Ral Limit An NalysisDocument1 pageEarth P Ressure Us Sing Gener Ral Limit An NalysisDonald EssenNo ratings yet

- Cementitious Underlayment (Maxxon Corp.)Document6 pagesCementitious Underlayment (Maxxon Corp.)Donald EssenNo ratings yet

- Concrete Accessories (Mar-Flex Waterproofing & Building Products)Document13 pagesConcrete Accessories (Mar-Flex Waterproofing & Building Products)Donald EssenNo ratings yet

- 2004 14Document20 pages2004 14Donald EssenNo ratings yet

- Aali Astra Agro Lestari TBK: APLN Agung Podomoro Land TBK AQUA Aqua Golden Mississippi TBKDocument10 pagesAali Astra Agro Lestari TBK: APLN Agung Podomoro Land TBK AQUA Aqua Golden Mississippi TBKDonald EssenNo ratings yet

- SECTPROPESSENZADocument5 pagesSECTPROPESSENZADonald EssenNo ratings yet

- Buckling of Columns PDFDocument11 pagesBuckling of Columns PDFAhmedHatifNo ratings yet

- Work Hardening DislocationsDocument14 pagesWork Hardening DislocationsAlhaega AnadaNo ratings yet

- Chapter 8 Two-Dimensional Problem SolutionDocument51 pagesChapter 8 Two-Dimensional Problem SolutionUNsha bee kom100% (1)

- Docslide - Us - Callister Concept Check AnswersDocument58 pagesDocslide - Us - Callister Concept Check AnswersJayant ChaudhariNo ratings yet

- RC Chapter 8Document14 pagesRC Chapter 8ianiroy130% (1)

- SM1001 Torsion Testing DatasheetDocument3 pagesSM1001 Torsion Testing DatasheetChriv SokundavannNo ratings yet

- IIIT RK Valley (Idupulapaya) Rajiv Gandhi University of Knowledge Technologies - Andhra PradeshDocument2 pagesIIIT RK Valley (Idupulapaya) Rajiv Gandhi University of Knowledge Technologies - Andhra PradeshshivaNo ratings yet

- Lecture 6 Grain Boundary Displocation Defects VancancyDocument8 pagesLecture 6 Grain Boundary Displocation Defects VancancyAl-Kawthari As-SunniNo ratings yet

- Đề Bài tập lớn - Môn Strength of MaterialsDocument10 pagesĐề Bài tập lớn - Môn Strength of MaterialsDinh leNo ratings yet

- Sheet 2Document5 pagesSheet 2Abdalla Mohamed AbdallaNo ratings yet

- NO-HLD-10-AET2-100045 - Rev02 Pipe Wall Thkns PDFDocument18 pagesNO-HLD-10-AET2-100045 - Rev02 Pipe Wall Thkns PDFABDUL KADHARNo ratings yet

- Dental Composite Resin: Dr. Rasha OWDA D.D.S, PH.D Restorative DentistryDocument54 pagesDental Composite Resin: Dr. Rasha OWDA D.D.S, PH.D Restorative DentistryArinaNo ratings yet

- Mechanical Properties of Composites: Professor Joe Greene Csu, ChicoDocument47 pagesMechanical Properties of Composites: Professor Joe Greene Csu, Chicogullo01No ratings yet

- Test For Buckling EulerDocument4 pagesTest For Buckling EulerGaurav GoyalNo ratings yet

- Thesis Pp1 40Document40 pagesThesis Pp1 4016562306No ratings yet

- Rockwell Hardness TestDocument2 pagesRockwell Hardness TestKrishnendu Ghosh100% (1)

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Strength of Materials-I Lecture-12 Problems' SolutionDocument16 pagesStrength of Materials-I Lecture-12 Problems' SolutionNadir Khattak Jr.No ratings yet

- Shear Strength Directshear PDFDocument5 pagesShear Strength Directshear PDFamor BagonNo ratings yet