Professional Documents

Culture Documents

IMS PP-01 Management Review of IMS

Uploaded by

TalalRaoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMS PP-01 Management Review of IMS

Uploaded by

TalalRaoCopyright:

Available Formats

g GE O&M Saif

IMS-PP-01 Page 1 of 4

Issue No. 00 uncontrolled if printed

PROCEDURE: Management Review of IMS

NUMBER: IMS-PP-01

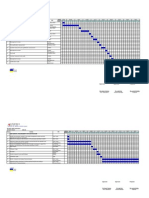

REVISION RECORD

IDENTIFICATION NUMBER: IMS-PP-01

Revision

No.

Revision

Date

Sections Affected Brief Description of Change

g GE O&M Saif

IMS-PP-01 Page 2 of 4

Issue No. 00 uncontrolled if printed

1. PURPOSE & SCOPE

To review the Integrated Management System for suitability, adequacy, effectiveness

and continual improvement.

2. DEFINITIONS

IMS, Integrated Management System

Top Management; Consists of Plant Manager, Operations Manager and Maintenance

Manager.

3. RESPONSIBILITIES

a. The Plant Manager, Operations Manager and Maintenance Manager are

responsible for conducting the IMS Management review. Top management may

invite any other person to attend the meeting to assist in conducting the review.

4.PROCEDURE

a. Management review of IMS is done once every 6 months.

b. At least two members of the top management must be present to complete the

quorum.

c. The review is based on an input report (after collection and analysis of

performance data) and recorded on a format given at F-PP-01.1

d. A copy of the input report is given to top management at least 3 days prior to

the management review meeting.

e. Top management reviews the performance of IMS and gives necessary decisions

and actions for further improvement of IMS.

g GE O&M Saif

IMS-PP-01 Page 3 of 4

Issue No. 00 uncontrolled if printed

f. The decisions and actions along with responsibility and target date for

completion are also recorded on F-PP-01.1

g. Top management ensures that its decisions and actions reflect the provision of

resources, the corrective and preventive actions that ought to be taken and the

actions needed for the continual improvement of the IMS system.

h. Minutes of meeting (F-PP-01.1) are kept as a record of management review.

i. The management review includes the following items:

Follow-up actions from previous reviews.

Review IMS Policy

Review of extent to which IMS Objectives and Targets have been achieved.

Results of IMS Audits. Discuss trends and weak areas.

Performance of QMS processes, outputs and operations.

Performance of OHS and EMS (Accident, incidents, spills, releases, near miss, hazards

reported and how actioned). Include both active and reactive measures of performance)

Compliance to QMS regulatory requirements

Compliance to OHS regulatory requirements

Compliance to EMS regulatory requirements

Customer complaints

Customer Feedback

Concerns and complaints from external interested parties.

Result of participation and consultation

Status of incident investigation, corrective and preventive actions.

Any other issues relating to improvement and integrity of IMS system.

Any changes/ addition to activities/ processes or products that could affect IMS

Management System including developments in legal and other requirements related to

HSE hazards and risks.

Resource needs.

Any changes in laws, circumstances, processes that could impact upon IMS.

Recommendations for continual improvements.

g GE O&M Saif

IMS-PP-01 Page 4 of 4

Issue No. 00 uncontrolled if printed

5. RECORD KEEPING

Record Number Record Name Maintained by

F-PP-01.1 Management review inputs, outputs

and decisions.

EHS Officer

You might also like

- Sample - Management Review MeetingDocument9 pagesSample - Management Review MeetingClaire TanNo ratings yet

- A Procedure For Change Management - TRACE INTERNATIONALDocument3 pagesA Procedure For Change Management - TRACE INTERNATIONALISO SRCAS100% (1)

- MRM AgendaDocument2 pagesMRM AgendaBAlaNo ratings yet

- Control of RecordsDocument3 pagesControl of Recordschahi100% (1)

- D - 14k - 3 - Delta Checklist ISO 14001-2015 - 20150917 - Short - EnglDocument9 pagesD - 14k - 3 - Delta Checklist ISO 14001-2015 - 20150917 - Short - EnglPRASAD SHETTYNo ratings yet

- Self Audit Checklist PresentationDocument20 pagesSelf Audit Checklist Presentationnashwan mustafaNo ratings yet

- SMCPGL Ims MRM - 2022Document37 pagesSMCPGL Ims MRM - 2022Smc PowerNo ratings yet

- SWOT ANALYSIS For ISO Context of The OrganizationDocument1 pageSWOT ANALYSIS For ISO Context of The OrganizationZach JavelonaNo ratings yet

- Internal Quality Audit Checklist v. 01Document5 pagesInternal Quality Audit Checklist v. 01Mohd AzisNo ratings yet

- Preview - Iso9001-2015.checklist For ISO 9001-2015Document6 pagesPreview - Iso9001-2015.checklist For ISO 9001-2015Jones RNo ratings yet

- QMS 3Document11 pagesQMS 3Ram MohanNo ratings yet

- FLVL-QHSE-SOP-F-006 Management Review MeetingDocument7 pagesFLVL-QHSE-SOP-F-006 Management Review MeetingmanjunathaNo ratings yet

- Iso 9001 Activity Plan '05Document3 pagesIso 9001 Activity Plan '05jvenrqzNo ratings yet

- Management ReviewDocument3 pagesManagement ReviewAfrizal Ramadhan0% (1)

- Procedure - Control of Third Party PropertyDocument2 pagesProcedure - Control of Third Party PropertychahiNo ratings yet

- Internal Audit IMS ChecklistDocument11 pagesInternal Audit IMS ChecklistBobby Lawrence100% (2)

- M09 Production and Service ProvisionDocument4 pagesM09 Production and Service ProvisionMay Ann DuronNo ratings yet

- Matrix ImsDocument6 pagesMatrix Imsmuhammad AndiNo ratings yet

- IMS Objectives Review Report, FY 19-20Document1 pageIMS Objectives Review Report, FY 19-20Chintala YesukiranNo ratings yet

- Management Review Agenda ISO 9001Document2 pagesManagement Review Agenda ISO 9001Allison Sontowinggolo100% (1)

- Mandatory Documents and Records Required by ISODocument3 pagesMandatory Documents and Records Required by ISOAli AliNo ratings yet

- QMS Auditor / Lead Auditor CourseDocument13 pagesQMS Auditor / Lead Auditor Courserevival195No ratings yet

- List of Mandatory Documents - IMSDocument1 pageList of Mandatory Documents - IMSprince100% (1)

- Appointment of Management Representative For IMSDocument3 pagesAppointment of Management Representative For IMSbudi_alamsyahNo ratings yet

- Management Review MinsDocument2 pagesManagement Review MinsIsmail SultanNo ratings yet

- Internal Audit Report - 2022Document2 pagesInternal Audit Report - 2022Camila AlmeidaNo ratings yet

- Audit Plan: Order No. Customer NoDocument2 pagesAudit Plan: Order No. Customer NofaradayNo ratings yet

- 014 IITS Internal AuditDocument5 pages014 IITS Internal AuditSirajul IslamNo ratings yet

- ISO 9001:2015 Awareness Training Quality Management System (QMS)Document30 pagesISO 9001:2015 Awareness Training Quality Management System (QMS)Jeelani BashaNo ratings yet

- Requirement For Iso 9001 2015Document3 pagesRequirement For Iso 9001 2015Anonymous r2EiqSrBNo ratings yet

- Integrated Management System: Title: Internal AuditDocument4 pagesIntegrated Management System: Title: Internal AuditjeyaseelanaNo ratings yet

- GP3101 ISO 14001 - 2004 ChecklistDocument5 pagesGP3101 ISO 14001 - 2004 ChecklistMagalyNo ratings yet

- FSMS-stage 02Document15 pagesFSMS-stage 02Arpita TripathiNo ratings yet

- Mandatory Documents and Records Required by ISO 9001Document2 pagesMandatory Documents and Records Required by ISO 9001aikqualityNo ratings yet

- Internal Quality Management System Audit Checklist (ISO9001:2015)Document46 pagesInternal Quality Management System Audit Checklist (ISO9001:2015)Hector Nicacio Mendoza100% (1)

- IMS Audit - Version 1Document11 pagesIMS Audit - Version 1arobNo ratings yet

- Risks and Oppurtunies ProcedureDocument5 pagesRisks and Oppurtunies ProcedureDr. Navya PakalapatiNo ratings yet

- Participant Workbook-ISO 9001 - 2015-Issue 02 Rev 03 Nov 2022-3Document52 pagesParticipant Workbook-ISO 9001 - 2015-Issue 02 Rev 03 Nov 2022-3Jadesh ChandranNo ratings yet

- EQMS Management ReviewDocument1 pageEQMS Management ReviewAdhi GunantoNo ratings yet

- ISO 9001:2015 Key Concepts Series: Context of The Organization and Interested Parties An Implementation ApproachDocument13 pagesISO 9001:2015 Key Concepts Series: Context of The Organization and Interested Parties An Implementation Approachqualiman1100% (1)

- Certified ISO 14001 Lead Auditor - Four Page BrochureDocument4 pagesCertified ISO 14001 Lead Auditor - Four Page BrochurePECBCERTIFICATIONNo ratings yet

- List of Procedures in IMS Procedure Manual KitDocument2 pagesList of Procedures in IMS Procedure Manual Kitaadwitya0% (2)

- Quality ObjectivesDocument1 pageQuality ObjectivessimsonNo ratings yet

- SLCP Verification ProtocolDocument62 pagesSLCP Verification ProtocolWILFREDO SSOCONSULTORESNo ratings yet

- ISO 9001 Audit Checklist in Human EnglishDocument9 pagesISO 9001 Audit Checklist in Human EnglishBryant Castillo Gonzalez50% (2)

- ISO 9001-2015 Supplier Audit Checklist SAMPLEDocument2 pagesISO 9001-2015 Supplier Audit Checklist SAMPLEFaisal0% (1)

- ISO 9001:2015 - Client Transition ChecklistDocument8 pagesISO 9001:2015 - Client Transition ChecklistYulissaPazNo ratings yet

- Training Flyer - IsO 9001 Public Trainings Rev2Document1 pageTraining Flyer - IsO 9001 Public Trainings Rev2lewgne08No ratings yet

- Guidelines For Supplier Audit: 1.1 Process Capability-Capabilitatea ProcesuluiDocument15 pagesGuidelines For Supplier Audit: 1.1 Process Capability-Capabilitatea ProcesuluiAdi SavaNo ratings yet

- ISO 9001 2015 Comparison and Guidance MatrixDocument45 pagesISO 9001 2015 Comparison and Guidance MatrixArdvarkNo ratings yet

- ISO2Q Auditor Transition Assessment Issue 1 2015Document20 pagesISO2Q Auditor Transition Assessment Issue 1 2015Hina KhurshidNo ratings yet

- Questions and Answers ISO 9001Document27 pagesQuestions and Answers ISO 9001مختار حنفىNo ratings yet

- P018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Document9 pagesP018 Internal Audit Procedure: ISO 9001:2008 Clause 8.2.2Álvaro Martínez Fernández100% (1)

- Ims MRM PDFDocument2 pagesIms MRM PDFilayaraja MKNo ratings yet

- Procedure For The Context of The OrganizationDocument3 pagesProcedure For The Context of The OrganizationSabari Raj100% (2)

- Audit Checklist 1Document2 pagesAudit Checklist 1Jagi NikNo ratings yet

- Qms MRM Input 2015Document1 pageQms MRM Input 2015venkatesanNo ratings yet

- Context of The OrganizationDocument1 pageContext of The OrganizationBAla100% (4)

- 06 The Creation of Wealth V03Document1 page06 The Creation of Wealth V03publius_federalistNo ratings yet

- 637221475488257446history 10THDocument140 pages637221475488257446history 10THhafsaNo ratings yet

- Scott County Youth Planning Report: Mayor Frank KlipschDocument14 pagesScott County Youth Planning Report: Mayor Frank KlipschMichelle O'NeillNo ratings yet

- Water Resources Planning & Management: Dr.P.Vincent, Professor, Dept - of Civil Engg Mepco Schlenk Engg - College, SivakasiDocument19 pagesWater Resources Planning & Management: Dr.P.Vincent, Professor, Dept - of Civil Engg Mepco Schlenk Engg - College, SivakasiManoj PrinceNo ratings yet

- Blackbirded Sicilians LouisianaDocument2 pagesBlackbirded Sicilians LouisianaAuntie DogmaNo ratings yet

- The Role of B.a.library in Social ChangeDocument14 pagesThe Role of B.a.library in Social ChangeghadeerrrrNo ratings yet

- Gacayno V Quezon CityDocument3 pagesGacayno V Quezon CityAngelGempNo ratings yet

- CHP#2Document2 pagesCHP#2H.H.A STATUSNo ratings yet

- Lkpd-Biography TextDocument8 pagesLkpd-Biography Textamy100% (1)

- Akbar How Should We Define GenocideDocument6 pagesAkbar How Should We Define GenocideTalha AftabNo ratings yet

- Peremptory International Law - Jus Cogens (A General Inventory) by Robert Kolb PDFDocument168 pagesPeremptory International Law - Jus Cogens (A General Inventory) by Robert Kolb PDFВасилий Романов100% (1)

- Holden and HomosexualityDocument5 pagesHolden and Homosexualityapi-238981017No ratings yet

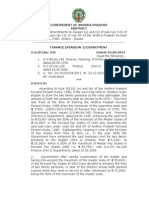

- Go.245 PensionsDocument4 pagesGo.245 PensionsbharatchhayaNo ratings yet

- SSC CGL 2019 Answer Key PDFDocument23 pagesSSC CGL 2019 Answer Key PDFAayushman SaraswatNo ratings yet

- MAY 19, 1898 JUNE 23, 1898: The Return of Aguinaldo To The PhilippinesDocument9 pagesMAY 19, 1898 JUNE 23, 1898: The Return of Aguinaldo To The PhilippinesCriziaClaire CosmeNo ratings yet

- PCGG v. Cojuangco, G.R. No. 147062Document17 pagesPCGG v. Cojuangco, G.R. No. 147062Lou AquinoNo ratings yet

- Role of Great Muslim Leaders in Urdu Press of Subcontinent in 19th and 20th CenturyDocument10 pagesRole of Great Muslim Leaders in Urdu Press of Subcontinent in 19th and 20th CenturyAdil SirNo ratings yet

- Hasil Tes TOEFL Batch 14Document169 pagesHasil Tes TOEFL Batch 14Rizal Ozi SetiawanNo ratings yet

- Quantitative Question - Doci - Set9Document9 pagesQuantitative Question - Doci - Set9Ss AaNo ratings yet

- Vikas Report NewDocument38 pagesVikas Report NewSimant YadavNo ratings yet

- Kiaer Christina Imagine No Possessions The Socialist Objects of Russian ConstructivismDocument363 pagesKiaer Christina Imagine No Possessions The Socialist Objects of Russian ConstructivismAnalía Capdevila100% (2)

- Gurrea V LezamaDocument2 pagesGurrea V LezamaEdward Kenneth Kung100% (1)

- Today's Security News - May 17 2017Document14 pagesToday's Security News - May 17 2017ElmerFGuevarraNo ratings yet

- Draft 4 Writing 3 DelilaDocument3 pagesDraft 4 Writing 3 Deliladirk lethulurNo ratings yet

- Module. Phil History 3 5 WeeksDocument5 pagesModule. Phil History 3 5 WeeksCharise OlivaNo ratings yet

- POB Ch08Document28 pagesPOB Ch08Anjum MalikNo ratings yet

- Pratibha Patil Political Career InformationDocument1 pagePratibha Patil Political Career InformationjasujunkNo ratings yet

- Ukpsc Apo Recruitment 2021Document2 pagesUkpsc Apo Recruitment 2021Rajesh K KumarNo ratings yet

- Bouyer - The Decomposition of CatholicismDocument59 pagesBouyer - The Decomposition of Catholicismhobojoe9127No ratings yet

- Yesodot Haolam Va'EraDocument4 pagesYesodot Haolam Va'EraBenjamin KhafiNo ratings yet