Professional Documents

Culture Documents

Lecture 6.2-CDB 2012-May 2014 PDF

Uploaded by

Ruben BenjaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 6.2-CDB 2012-May 2014 PDF

Uploaded by

Ruben BenjaniCopyright:

Available Formats

1

CDB2012

Health, Safety and

Environment

Machine Safeguarding

Lecture 6.2

Dr. Abrar Inayat

2

Introduction control measures through effective

machine guarding

Basic knowledge of lock out/tagout system.

Information of personal protective equipment (PPE)

OBJECTIVE

2

4

Mechanical Hazards

How to reduce

mechanical hazards?

MACHINE SAFEGUARDING

3

5

Machine Safeguarding - Purpose

To minimize the risk of accidents due to direct

contact between human (operator) and machine

Direct contact can be :

Operator direct contact with machine because of

fatigue, distraction, careless etc.

From machines such as flying chip and hot metal

splashes

Direct results of machine malfunction

4

7

Machine Safeguarding - Purpose

Safeguards are essential for protecting workers from

needless and preventable injuries.

Any machine part, function, or process which many

cause injury must be safeguarded.

Immediate corrective actions, including stopping the

machine, must be taken when a potential mechanical

hazard is observed

8

Machine Safeguarding

WHAT MAKES A GUARD EFFECTIVE ?

Must prevent human contact with any potentially

harmful machine part

Must not present a hazard in itself or create

interference

Must not allow objects to fall into moving parts

Allows safe maintenance and lubrication.

5

9

Machine Safeguarding

There are many ways to safeguard machines depending

on :

Type of operation

Size or shape of machine

Physical layout of the work area

Type of material

10

Machine Safeguarding

GUARDS (prevent) - are always preferred and

more practical to be used for power transmission

(motion).

DEVICES (control) - are sometimes a more

practical option when safeguarding point of operation.

6

11

Machine Safeguarding

GUARD DEVICE

12

Machine Safeguarding

Point of Operation Guards :

Fixed Guards

Interlocked guards

7

14

Machine Safeguarding

Lockout/Tagout System :

To protect against the unexpected activation of a

machine that is supposed to be turned off

Lockout system - a padlock is used to prevent a

machine from being turned on until the lock is

removed.

Tagout system similar to lockout system, but use

tag instead of lock

8

15

Machine Safeguarding

Lockout/Tag-out System

9

17

Machine Safeguarding

TRAINING

Safeguarding system cannot offer effective

protection against mechanical hazards unless the

worker knows how to use it and why.

Safety training is necessary for operators and

maintenance or set-up personnel when any new or

altered safeguards are put in service.

18

Machine Safeguarding

PROTECTIVE CLOTHING/PERSONAL

EQUIPMENT

Must appropriate for the particular hazards

Maintained in good condition

Properly stored when not in use to prevent damage

or loss

Kept clean and fully functional.

10

20

Mechanical Hazards/Machine

Safeguarding

CONCLUSION

Use tagout procedures before service,

maintenance, or repair jobs on machines or

equipment.

Follow standard operating procedures (SOP) :

implement safe work steps to check, set up

machines, start, and finish job or task.

Inspection and maintenance : inspect the

machinery, guards, and your entire work area,

regularly and often.

11

21

Mechanical Hazards/Machine

Safeguarding

Emergency preparation and regular drills : to

be prepared and able to respond effectively to

minimize loss.

Human factor planning : To allow operator

regular relief and change from repetitive tasks

on production lines, to avoid fatigue, strains,

sprains, and other injuries or accidents through

regular breaks and task variety.

Training : Conduct training on workplace

inspection, housekeeping and emergency

action and response.

12

You might also like

- Log Book WEEK NO: 5-6: Week No Date Brief Description of Daily ActivitiesDocument2 pagesLog Book WEEK NO: 5-6: Week No Date Brief Description of Daily ActivitiesRuben BenjaniNo ratings yet

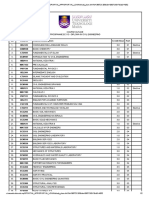

- No Course Course Description Credit Hour PartDocument2 pagesNo Course Course Description Credit Hour PartRuben BenjaniNo ratings yet

- SIP Guidelines - Ver 05Document55 pagesSIP Guidelines - Ver 05Ruben BenjaniNo ratings yet

- VCB 3073 Wastewater Engineering - SyllabusDocument3 pagesVCB 3073 Wastewater Engineering - SyllabusRuben BenjaniNo ratings yet

- Sit Sept 2016 - CveDocument22 pagesSit Sept 2016 - CveRuben BenjaniNo ratings yet

- List of CompaniesDocument96 pagesList of CompaniesRuben BenjaniNo ratings yet

- Assignment Cover PageDocument1 pageAssignment Cover PageRuben BenjaniNo ratings yet

- Schedule Geomatics Laboratory May 2014 Semester: Date Group Time FieldworkDocument2 pagesSchedule Geomatics Laboratory May 2014 Semester: Date Group Time FieldworkRuben BenjaniNo ratings yet

- Date: 21 May 2016 Venue: Sekolah Kebangsaan Seri IskandarDocument5 pagesDate: 21 May 2016 Venue: Sekolah Kebangsaan Seri IskandarRuben Benjani100% (2)

- Universiti Teknologi PETRONAS Civil Engineering Department January 2015 Semester VDB2043: Theory of Structures Assignment No. 1Document1 pageUniversiti Teknologi PETRONAS Civil Engineering Department January 2015 Semester VDB2043: Theory of Structures Assignment No. 1Ruben BenjaniNo ratings yet

- Assignment Cover (Any Course)Document1 pageAssignment Cover (Any Course)Ruben BenjaniNo ratings yet

- Department of Civil & Environmental Engineering Universiti Teknologi PETRONASDocument1 pageDepartment of Civil & Environmental Engineering Universiti Teknologi PETRONASRuben BenjaniNo ratings yet

- Lecture 8-CDB 2012-May 2014Document16 pagesLecture 8-CDB 2012-May 2014Ruben BenjaniNo ratings yet

- FAP0025 Tutorial Solutions PDFDocument25 pagesFAP0025 Tutorial Solutions PDFRuben BenjaniNo ratings yet

- Facee MAS May14Document7 pagesFacee MAS May14Ruben BenjaniNo ratings yet

- Request For Permission To UseDocument2 pagesRequest For Permission To UseRuben BenjaniNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Topic 3 Intellectual RevolutionDocument20 pagesTopic 3 Intellectual RevolutionOlive April TampipiNo ratings yet

- Storage Tanks Overfill Prevention Better PracticesDocument2 pagesStorage Tanks Overfill Prevention Better PracticesRicardo Bec100% (1)

- OB Case Study Care by Volvo UK 2020Document1 pageOB Case Study Care by Volvo UK 2020Anima AgarwalNo ratings yet

- FPGA Implementation For Humidity and Temperature Remote Sensing SystemDocument5 pagesFPGA Implementation For Humidity and Temperature Remote Sensing SystemteekamNo ratings yet

- Per Dev Dlp-1-2 - 3 SelfDocument6 pagesPer Dev Dlp-1-2 - 3 SelfMonisa SocorinNo ratings yet

- INJkon 01 4.0 ManualDocument93 pagesINJkon 01 4.0 ManualJansirani SelvamNo ratings yet

- GATE Chemical Engineering 2015Document18 pagesGATE Chemical Engineering 2015Sabareesh Chandra ShekarNo ratings yet

- GL Career Academy Data AnalyticsDocument7 pagesGL Career Academy Data AnalyticsDeveloper GuideNo ratings yet

- HP Scanjet N9120 (Service Manual) PDFDocument394 pagesHP Scanjet N9120 (Service Manual) PDFcamilohto80% (5)

- Lab 3 Report Fins RedoDocument3 pagesLab 3 Report Fins RedoWestley GomezNo ratings yet

- Analysis Chart - Julie Taymor-ArticleDocument3 pagesAnalysis Chart - Julie Taymor-ArticlePATRICIO PALENCIANo ratings yet

- TOEFL-Reading Question Type Definitions and ExplanationDocument5 pagesTOEFL-Reading Question Type Definitions and ExplanationSamara SampaioNo ratings yet

- Dpb6013 HRM - Chapter 3 HRM Planning w1Document24 pagesDpb6013 HRM - Chapter 3 HRM Planning w1Renese LeeNo ratings yet

- QSMT Chapter 1Document5 pagesQSMT Chapter 1Rachelle Mae SalvadorNo ratings yet

- Reviewer in PE&H 1st Quarter 18-19Document7 pagesReviewer in PE&H 1st Quarter 18-19rhex minasNo ratings yet

- Void Engineers (Convention: Mage The Ascension)Document6 pagesVoid Engineers (Convention: Mage The Ascension)Beth0% (1)

- DTS 600 GDO Installation ManualDocument12 pagesDTS 600 GDO Installation Manualpiesang007No ratings yet

- 19 71 Hydrologic Engineering Methods For Water Resources DevelopmentDocument654 pages19 71 Hydrologic Engineering Methods For Water Resources DevelopmentMartha LetchingerNo ratings yet

- A New Procedure For Generalized Star Modeling Using Iacm ApproachDocument15 pagesA New Procedure For Generalized Star Modeling Using Iacm ApproachEdom LazarNo ratings yet

- Pamphlet 89 Chlorine Scrubbing SystemsDocument36 pagesPamphlet 89 Chlorine Scrubbing Systemshfguavita100% (4)

- Admission: North South University (NSU) Question Bank Summer 2019Document10 pagesAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- Gates Crimp Data and Dies Manual BandasDocument138 pagesGates Crimp Data and Dies Manual BandasTOQUES00No ratings yet

- Classical Theories of Economic GrowthDocument16 pagesClassical Theories of Economic GrowthLearner8494% (32)

- Manitou 1350RDocument4 pagesManitou 1350RcandlaganNo ratings yet

- Measures of Indicator 1Document2 pagesMeasures of Indicator 1ROMMEL BALAN CELSONo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- Calculation ReportDocument157 pagesCalculation Reportisaacjoe77100% (3)

- A First Etymological Dictionary of BasquDocument29 pagesA First Etymological Dictionary of BasquDaily MailNo ratings yet

- I.A.-1 Question Bank EM-3 (Answers)Document11 pagesI.A.-1 Question Bank EM-3 (Answers)UmmNo ratings yet