Professional Documents

Culture Documents

2 HSE UK - Perspective On System Integrity For UK Pipelines and Risers

Uploaded by

Salah JallaliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 HSE UK - Perspective On System Integrity For UK Pipelines and Risers

Uploaded by

Salah JallaliCopyright:

Available Formats

Health and Safety

Executive

Health and Safety

Executive

HSE Perspective on UK Pipeline

and Riser Integrity Management

Douglas Souden

Principal Pipelines Inspector

Health & Safety Executive

Aberdeen

Seminar 19 October 2011, Stavanger: A System

Approach to Pipeline & Riser Safety and Integrity

HSE Information relating to Pipeline safety and integrity can be found on the HSE web site: http://www.hse.gov.uk/pipelines/index.htm

Scope of Presentation

Introduction and Background

UK Regulation, Integrity Management

Standards and Good Practice

KP4: Aging and Life Extension

Lessons Learned San Bruno

Leadership and SPIs

Summary of key points

Source: HSE

HSE Offshore Strategy

http://www.hse.gov.uk/offshore/priorities.htm

Leadership and SPIs

Safety Culture / Workforce Involvement

Asset Integrity (KP4 3 year programme)

Current Strategy Priorities:

OSD Mission Statement: Our mission is to assure safe management and

control of major accident hazard risks and prevent catastrophic incidents in the

offshore Oil and gas industry

Source: Step Change

HSE Offshore Pipeline Delivery Guide:

Encourage a proactive pipeline lifecycle Integrity Management approach

Deliver and share targeted and consistent intervention plans

Share lessons learned from incidents and investigations

Promote improved development and sharing of Industry good practice

UK Offshore Hydrocarbon Releases

Source: Step Change

Data Source: DECC (2009)

Pipelines Safety Regulations 1996

Regulation 13 - Maintenance

absolute legal duty to maintain in an efficient state, in efficient

working order and in good repair throughout the pipeline life cycle

secure safe operation

prevent loss of containment

Regulation 23 Major accident prevention document

identify hazards and pipeline integrity threats

formally record and document results

implement adequate safety management system

revise or replace as often as appropriate

Regulation 20 to 22 Notification to HSE

concerns significant changes affecting level of risk

notify at completion of concept design

Captures new MAHPs or changes to operating regime

Source: HSE

Source: HSE

Integrity Management: Standards

and Industry Good Practice

Provide a specific IM System framework and guidance in

support of main design codes

Initial USA - Onshore focused on critical risk areas

API 1160 (2001) and ASME B31.8S (2004)

More recent European issued guidance - aligned to subsea

pipeline systems:

DNV RP-F116 (2009 under review)

Engineering Institute Guidance (2009)

UK Oil & Gas Flexibles IM Guidance (2010)

New standards emerging for Life Extension:

NORSOK Standard Y-002 (2010)

Draft ISO Recommended Practice

Source: Energy Institute

Integrity Management System

Source: DNV RP 116

Aging Overview

Evidence of degradation and damage

OR

Insufficient knowledge / information to

know the extent of possible deterioration

________________________________

Need to consider effects of:

accumulating or accelerating

damage

modifications

obsolescence

changes of process & / or well

conditions

advances in knowledge and

technology

organisational issues / loss of

corporate knowledge

Source: HSE RR509

The 4 Stages of Equipment Life

Source: HSE

Degradation and Re-assessment

Accumulation of damage and

defects important

Effective monitoring & review of

degradation vital to support

ongoing integrity

Internal corrosion detrimental if

not predicted or controlled

Approach must be consistent

with lifecycle and reflect internal

inspection capability; or

Other type of periodic validation

of corrosion modelling via direct

measurement required

Time or Deterioration Rate

Deterioration

Model Worst Case

MAWT

Actual can only

be established

by

measurements

Monitoring Degradation

Periodic Validation and Assessment

Source: HSE RR509

Source: HSE

Pipeline Life Extension

Need to justify operation beyond

original design life conditions

Engineering investigation required

(backward & forward look) to verify

continued fitness for future service

Pipeline design codes call for a

formalised process and record

Industry Guidance provides

framework for assessment; eg

NORSOK Y-002 (Dec 2010)

Understanding the degradation

processes, good records and

effective management of aging are

crucial to successful life extension

Source: HSE

Source: HSE RR509

KP4 Aging and Life Extension

Planned 3 Year Inspection programme to 2013

with supporting activities and outputs:

Development of guidance and good practice

Appropriate research

Development of an Industry Network

Stakeholder Engagement

Feedback to Industry

Aim is to ensure that the risks to asset integrity

associated with Aging and life extension are

being controlled effectively

KP4 Inspection approach

Programme in 3 phases:

Phase 1 initial onshore then

offshore verification;

Phase 2 KP4 elements linked

to future offshore inspection;

Phase 3 Programme close

out and feedback

Multi-Discipline Team Approach:

Organisational factors; Structural integrity; Materials, Maritime

integrity; Process plant integrity; Fire & blast; Mechanical integrity;

Electrical & control systems integrity; Wells and Pipelines

Standardised approach: Use of templates

Some initial teething and calibration issues

Source: HSE

Source: HSE

KP4 Progress

KP4 Policy and Strategy documents on line

Campaign of industry/stakeholderawareness

Continued development of HSE web page

Inspection templates shared with Industry

Encouraged development of an Industry Network

Managed by Oil & Gas UK via Step Change web site

Over 90 members

Plans for UK Industry Guidance

Initiated update of HSE guidance on Thorough

Reviews OIS 4/2009

Phase 1 completed for first 3 duty holders

Lessons Learned - Recent Example of

Pipeline Integrity Failures

On 9 Sept 2010 a rupture occurred on

a 30 gas pipeline in California at San

Bruno operating at approx. 400psig

Eight people were killed and many

more injured and 38 homes destroyed

Evidence of Integrity Management

system failures

Video

Source: NTSB

US NTSB Report on San Bruno:

Safety Management Failings

No clear management focus on major

hazards and pipeline system safety.

Haphazard approach to record keeping and

management/data analysis.

'Threat identification' not sufficient.

Evidence of delays to critical pipeline repairs.

Insufficient resources available for pipeline

integrity assessments.

Resource bottlenecks meant some

important work not done.

S

o

u

r

c

e

:

N

T

S

B

Leadership and Performance

Indicators

Safety Leadership Process Safety Leadership Principals

Expectation that organisations with major hazard risks have

adopted the eight principles of major hazard leadership

developed by the Process Safety Leadership Group

(PSLG).

HSE will inspect using Leadership Assessment Tool (LAT)

Safety Performance Indicators (SPIs)

Expectation that operators will have developed an effective

suite of SPIs

Leading and Lagging indicators should be identified

Expect that a Gap Analysis will have been carried out

against HSG254

Most operators using a Traffic Light System approach

Summary of Key Points

Pipeline Integrity Management remains a key priority focus

for HSE, both offshore and onshore:

Related pipeline ageing and life extension issues will be

inspected as part of the KP4 Programme

HSE expect duty holders to have robust/effective integrity

management systems throughout the pipeline lifecycle:

Systems should reflect good practice and must be subject

to regular monitoring, audit and review

Strong leadership, effective use of SPIs and sharing of

lessons learned and good practice are important factors

Effective management of Aging is a vital component to

successful Life Extension projects

Formal review of Pipeline Life Extension expected in line with

good practice and emerging Standards

References

HSE Web Site Offshore Oil ad Gas Pages: Aging and Life Extension of Offshore Installations

http://www.hse.gov.uk/offshore/Aging

OIS 4/2009, Guidance on Management of Aging and Thorough Reviews of Aging Installations, Offshore

Information Sheet No. 4/2009, Health and Safety Executive, http://www.hse.gov.uk/offshore/infosheets/is4-

2009.pdf

DNV-RP-F116: Integrity Management of Submarine Pipelines October 2009

Energy Institute S813 Guideline on the Integrity Management of Subsea Facilities

Process Safety Leadership Group (PSLG) Principles of Process Safety Leadership

http://www.hse.gov.uk/comah/buncefield/pslgprinciples.pdf

HSE Delivery Guide on Major Accident Hazard Process Safety Indicators

http://www.hse.gov.uk/comah/guidance/process-safety-performance-indicators.pdf

HSE Research Report RR509 - Plant Aging: Management of equipment containing hazardous fluids or

pressure 2006 http://www.hse.gov.uk/research/rrhtm/rr509.htm

US NTSB Investigation Report into the San Bruno Natural Gas Transmission Pipeline explosion September

9, 2010 http://www.ntsb.gov/doclib/reports/2011/PAR1101.pdf

Step Change and Oil & Gas UK Aging and Life Extension Network

http://www.stepchangeinsafety.net/about/workgroups/Ageingandlifeextensionofoffshoreinstallations.cfm

OP010 - State of the Art Report on Flexible Pipe Integrity and Guidance Note on Monitoring Methods and

Integrity Assurance for Unbonded Flexible Pipes (2010)

http://www.oilandgasuk.co.uk/publications/viewpub.cfm?frmPubID=152

SINTEF Report (Clients PSA, Norway): Aging and life extension for offshore facilities in general and for

specific systems

NORSOK standard, Life Extension for Transportation Systems, Rev 1, Dec 2010

http://www.standard.no/en/Sectors/Petroleum/NORSOK-Standard-Categories/Y-Pipelines/Y-0021/

ISO/NP TS 12747, Draft ISO Recommended Practice: Petroleum & Natural Gas Industries - Pipeline

Transportation systems - Pipeline Life Extension, International Standards Organisation, 2008, Geneva,

Switzerland.

Any Questions?

Source: HSE

Source: HSE

Source: HSE

Source: HSE

Source: HSE

You might also like

- VALCO Air Liquide Valves ENG PDFDocument15 pagesVALCO Air Liquide Valves ENG PDFSalah JallaliNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Cone-RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Cone-RoofSalah JallaliNo ratings yet

- Classification ISO 8217 (2005)Document5 pagesClassification ISO 8217 (2005)Salah JallaliNo ratings yet

- Dedication To Delivery: Valco GroupDocument15 pagesDedication To Delivery: Valco GroupSalah JallaliNo ratings yet

- Catalogue de Formation BookletDocument12 pagesCatalogue de Formation BookletSalah JallaliNo ratings yet

- Pipeline Integrity Management Systems ": LEVEL FoundationDocument3 pagesPipeline Integrity Management Systems ": LEVEL FoundationSalah JallaliNo ratings yet

- LNG As Marine Fuel: Merchant Vessels - ConversionsDocument27 pagesLNG As Marine Fuel: Merchant Vessels - ConversionsSalah JallaliNo ratings yet

- CV Salah Jallali - English New RevDocument8 pagesCV Salah Jallali - English New RevSalah JallaliNo ratings yet

- Spec Peinture BacDocument2 pagesSpec Peinture BacSalah JallaliNo ratings yet

- Jensen Mixer Series 400 CatalogDocument12 pagesJensen Mixer Series 400 CatalogSalah JallaliNo ratings yet

- Evaluation of Losses of Gasoline Storrage TanksDocument31 pagesEvaluation of Losses of Gasoline Storrage TanksSalah JallaliNo ratings yet

- Procedure BASE LINE SURVEY of Pipework & PV EqpmtDocument9 pagesProcedure BASE LINE SURVEY of Pipework & PV EqpmtSalah Jallali100% (1)

- Vérification Des Évent T7CDocument1 pageVérification Des Évent T7CSalah JallaliNo ratings yet

- 6 - Ut Scan Report Separator #v-3001Document19 pages6 - Ut Scan Report Separator #v-3001Salah JallaliNo ratings yet

- API 650 & API 653 TrainingDocument56 pagesAPI 650 & API 653 TrainingSalah JallaliNo ratings yet

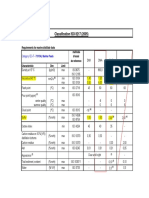

- Cuadro Comparativo AcerosDocument1 pageCuadro Comparativo Acerosfateruler51No ratings yet

- 2 PDFDocument51 pages2 PDFSalah JallaliNo ratings yet

- Materials Testing Lab, Corrosion Study, RBI, Failure Analysis, Advanced NDT Services, Training and ConsultingDocument23 pagesMaterials Testing Lab, Corrosion Study, RBI, Failure Analysis, Advanced NDT Services, Training and ConsultingahmedawadallaNo ratings yet

- Oiml R71 PDFDocument22 pagesOiml R71 PDFnknicoNo ratings yet

- Oiml R71 PDFDocument22 pagesOiml R71 PDFnknicoNo ratings yet

- CV Salah Jallali - English New RevDocument2 pagesCV Salah Jallali - English New RevSalah JallaliNo ratings yet

- Truck Loading System PDFDocument3 pagesTruck Loading System PDFSalah JallaliNo ratings yet

- Understanding "Position" in WeldingDocument116 pagesUnderstanding "Position" in WeldingThaksenNo ratings yet

- Steel TanksDocument75 pagesSteel TanksAnonymous b3NKZUbNo ratings yet

- Steve Crimaudo APITank Standards UpdateDocument36 pagesSteve Crimaudo APITank Standards UpdateSalah JallaliNo ratings yet

- Fiche Programme Doc Asme IxDocument5 pagesFiche Programme Doc Asme IxSalah JallaliNo ratings yet

- ASME A13.1-1996 Identification of Piping SystemsDocument13 pagesASME A13.1-1996 Identification of Piping SystemsRakesh MenonNo ratings yet

- Floormap3d PDFDocument4 pagesFloormap3d PDFSalah JallaliNo ratings yet

- Rosoft For TanksDocument1 pageRosoft For TanksSalah JallaliNo ratings yet

- D 1400 - 94Document3 pagesD 1400 - 94Salah JallaliNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- UntitledDocument37 pagesUntitledUnknown UserNo ratings yet

- Century 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthDocument8 pagesCentury 21 South Western Accounting Answer Key Free PDF Ebook Download Century 21 South Western Accounting Answer Key Download or Read Online Ebook Century 21 SouthJohn0% (4)

- Inglês - Degrees of ComparisonDocument4 pagesInglês - Degrees of ComparisonVersehgi IINo ratings yet

- Miracle Mills 300 Series Hammer MillsDocument2 pagesMiracle Mills 300 Series Hammer MillsSNo ratings yet

- Xgenus X-Ray PDFDocument61 pagesXgenus X-Ray PDFAli NuriNo ratings yet

- Ad 9915Document47 pagesAd 9915Jime nitaNo ratings yet

- Differential Settlement at Bridge ApproaDocument5 pagesDifferential Settlement at Bridge ApproaVictor De los ReyesNo ratings yet

- Casio AT 1 Service ManualDocument28 pagesCasio AT 1 Service ManualMario Gabriel MoralliNo ratings yet

- G20 SolutionDocument11 pagesG20 SolutionAbidemi Benjamen AttehNo ratings yet

- Critique of Violence - Walter BenjaminDocument14 pagesCritique of Violence - Walter BenjaminKazım AteşNo ratings yet

- Hemo TecaDocument17 pagesHemo TecaMafer PilcoNo ratings yet

- Yanmar Graafmachines SV17 PDFDocument10 pagesYanmar Graafmachines SV17 PDFAleksandar PetkovicNo ratings yet

- AIMMS Modeling Guide - Linear Programming TricksDocument16 pagesAIMMS Modeling Guide - Linear Programming TricksgjorhugullNo ratings yet

- Parkinson S Disease Detection Based On SDocument5 pagesParkinson S Disease Detection Based On SdaytdeenNo ratings yet

- ICorr CED CT01 InspectionAndTestingOfCoatings Issue1-2Document13 pagesICorr CED CT01 InspectionAndTestingOfCoatings Issue1-2AlineMeirelesNo ratings yet

- NEC G266 Quick Reference GuideDocument3 pagesNEC G266 Quick Reference GuideIonut Gabriel DascaluNo ratings yet

- Cooling and Sealing Air System: Gas Turbine Training ManualDocument2 pagesCooling and Sealing Air System: Gas Turbine Training ManualVignesh SvNo ratings yet

- Introduction To Neutrino Physics: Paolo LipariDocument85 pagesIntroduction To Neutrino Physics: Paolo LipariSubhankar HowladerNo ratings yet

- ISO 20000-1 Gap Analysis QuestionaireDocument15 pagesISO 20000-1 Gap Analysis QuestionaireUsman Hamid67% (6)

- Mech Syllabus R-2017 - 1Document110 pagesMech Syllabus R-2017 - 1goujjNo ratings yet

- Hilfswerk Wien-Salzburg - 11. Meio 2018Document9 pagesHilfswerk Wien-Salzburg - 11. Meio 2018FreieEnergieNo ratings yet

- KV Class 3 Half Yearly Previous Year Question Paper 2019 ComputerDocument2 pagesKV Class 3 Half Yearly Previous Year Question Paper 2019 Computer02 Aanya Gupta VII CNo ratings yet

- Samsung Galaxy Watch 5 Pro User ManualDocument131 pagesSamsung Galaxy Watch 5 Pro User Manualzyron100% (1)

- Ground Vehicle Operations ICAODocument31 pagesGround Vehicle Operations ICAOMohran HakimNo ratings yet

- Ultimate Electronics - Book - CircuitLabDocument3 pagesUltimate Electronics - Book - CircuitLabEldon50% (2)

- PienaDocument1 pagePienaMika Flores PedroNo ratings yet

- Wakit, Nico P.Document5 pagesWakit, Nico P.yeng botzNo ratings yet

- The Magical Number 5: Towards A Theory of Everything?Document27 pagesThe Magical Number 5: Towards A Theory of Everything?cesarfrancaNo ratings yet

- 1802SupplementaryNotes FullDocument235 pages1802SupplementaryNotes FullCourtney WilliamsNo ratings yet

- 01.introduction To Earth ScienceDocument29 pages01.introduction To Earth ScienceIshan Chua100% (1)