Professional Documents

Culture Documents

WWW - Red Bag Commissioning

Uploaded by

Marcio SócratesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WWW - Red Bag Commissioning

Uploaded by

Marcio SócratesCopyright:

Available Formats

Home About News Products Tools Library Forum Contact

search...

25-Oct-2013

Main Menu

Home

About

News

Products

Tools

Library

Forum

Contact

Library Content Menu

QA Standards

General Procedures

Department Procedures

Work Instructions

General Guides

Design Guides

Engineering Guides

General Standards

Design Standards

Engineering Standards

Specifications

Requisitions

Forms

Cost Codes

Papers

Library section

Visitalsoour'library'sectionwith

usefullengineeringanddesign

information.Weinviteyouto

providefeedbacktothesepages

toimprovethecontent.

_________________________

AdvancedPipingDesignisan

intermediate-level handbook

coveringguidelinesand

proceduresonprocessplantsand

interconnectingpipingsystems.

PCC Software

Softwareforcreationofpipeclassesand

mechanicalcalculationofpiping

components.Read more ...

LearnmoreabouttrainingonPlantEngineeringand

Design:

e-learningbyInternational Institute of Plant

Engineering and Design

VES Software

Softwareforthedesignandmechanical

calculationofpressurevesselsandheat

exchangers.Read more ...

Home General Standards BN-S-UC001B

BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning

activities

Table of contents

1.General Procedures

2.Specific Procedures

1. General Procedures

1.1 Vendor and Service Assistance

Contractor Client

a. IfdeemednecessarybyContractor,obtainmanufacturer's(vendor)

assistancetoensuresatisfactoryinstallationofequipment

X

b. Obtainmanufacturer's(vendor)assistanceatOwner'sexpenseif

requiredbyOwnerforrunin

X

1.2 Inspection

a. Provideinspectionoftheplanttocheckconformitytoflowdiagrams,

constructiondrawings,vendorprintsandspecifications

X

b. Arrangeforanyspecialpre-startupinspectionssuchasrequiredby

insuranceorgovernmentalagencies

X

c. Performroutineshopinspection X

d. Witnessshopinspectionasdesired X

e. Verifycompletionofworkandapproveplant.Checkanyexceptionsand

noteonaseparateworkorderlist(punchlist)

X

Note: Equipment which has been shop inspected will not be reopened for inspection in the field except as

specifically noted herein.

1.3 Permits

a. SecurepermitsandcertificationsrequiredinnameofContractorfor

designworkorforerectionwork

X

b. AssistOwnerathisexpenseintheprocurementofallpermitsand

certificationsrequiredtobesecuredinnameofOwnerforinitialoperation

oftheplant

X

c. SecureatOwner'sexpenseallpermitstobeissuedinnameofOwner

andrequiredforinstallation,use,occupancyandoperationoftheplant

X

1.4 Removal of Rust Preventatives

a. Removerustpreventativesandoilsusedtoprotectequipmentduring

theconstructionperiod

X

1.5 Maintenance and Spare Parts

a. Protectequipmentfromnormalweatherconditions,corrosionordamage

priortoplantmechanicalcompletion

X

b. Providecompanywithsparepartslistsasrecommendedbyvendors X

c. Providesparepartsandsupplies X

d. Providemaintenanceforequipment,includingsuchitemsasthecleaning

ofstrainersandtherepairingofsteamtraps,aftermechanicalcompletion

X

Translate

6 SelectLanguage

Gadgetspoweredby

Google

Pgina 1 de 6 BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning activities

25/10/2013 http://www.red-bag.com/jcms/general-standards/324-bn-s-uc001b-checklist-for-the-mechanical-completion-incl-pre-commissioning-acti...

1.6 Housekeeping

a. Provideconstructioncleanup,includingremovalofexcessmaterials,

temporaryfacilitiesandscaffolding,roughsweepingorrakingofjob

sitesandtrashpickup

X

b. Maintainhousekeepingaftermechanicalcompletionasrequiredforsafe

operation

XX

1.7 Instructions

a. TransmittoOwneranyvendors'ormanufacturers'instructionsand

drawings,asapplicable

X

b. ProvideOwnerwithanyspecialinstructions,suchasrequirementsfor

dryingliners

X

c. Maintainvendorinstructionfileforreadyretrieval X

2 Specific Procedures

2.1 Electrical Power and Lighting Systems - Account E

a. NotifyOwneroftestschedule X

b. Witnesstestswhennotifiedandrecordtestdataifdesired X

c. Makeinsulationtestofallwiringusingamegohmmeter X

d. Checklightingcircuitsandintensities X

e. Makeinsulationtestsofmotorwindingsandoftransformerwindingsfrom

phasetophase,andphasetogroundusingamegohmmeter

X

f. Makegroundingsystemteststodeterminecontinuityofconnectionsand

valueofresistancetoground

X

g. Arrangeforbreakdowntestsbymanufacturersonoilsamplesfromoil

insulatedtransformerslargerthan100kVA.Checkoillevelofall

transformers

X

h. Maketrialsandadjustmentsonallmotorcontrolandswitchgear

equipment

X

i. Testandsetswitchgearandmotorcontrolcenterrelaysforproper

functioning

X

j. Obtainlocalinspector's/authorityapprovalwhererequired X

k. Energizeallsubstationsaftercompletionofalltests X

l. Checkphasesequenceandpolarity X

m. Runelectricalmotorsuncoupled X

n. Checkbearing,windingtemperaturesandvibration XX

o. Checkinstallationofemergencyandinstrumentpowersystems X

p. Checkinstallationofelectricaltracingsystemandenergizesame X

q. ProvideOwnerwithrecordofworkcompleted X

2.2 Instrument Systems - Account K

a. Makenon-operatingcheckstoensureinstrumentoperability,i.e.remove

allshippingstops,checkpointertravelsandverifyinstrumentcapabilityto

measure,operateandstrokeinthedirectionandmannerrequiredbythe

processapplication

XX

b. Fieldcalibrateinstrumentswithstandardtestequipmentandmakeall

requiredadjustmentsandcontrolpointsettings

X

c. Fullypressurizeandenergizethetransmittingandcontrolsignalsystem,

openprocessconnectionsatprimarysensorsandfinalregulatorsand

makecontrolmodesettingsforautomaticoperationofequipmentasthe

plantisbroughtonstream

X

d. Installandconnectallsystemcomponentsandverifytheirconformance

withspecificationsanddesigncriteriaforfunctionandrangeusing

dummytransmittedsignalsasneeded

X

e. Cleanalltransmissionandcontroltubingbyblowingwithcooledand

filteredcleanairpriortoconnectingtoinstrumentcomponents

X

f. Cleanallairsupplyheadersbyblowingwithcleanairandcheckfor

tightness

X

g. LeaktestpneumaticcontrolcircuitsinaccordancewithISA

RecommendedPracticeRP7,1

X

h. Checkprocessleadpipingfortightness X

i. Checkallelectricalsignalsandalarmwiringforcontinuity,correct

sourcesofpowerandpolarity

X

j. Checkthermocouplesforproperjoiningofwires,positionofelementsin

wells,properpolarityandcontinuityofreceivinginstruments

X

Pgina 2 de 6 BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning activities

25/10/2013 http://www.red-bag.com/jcms/general-standards/324-bn-s-uc001b-checklist-for-the-mechanical-completion-incl-pre-commissioning-acti...

k. IdentifyorificeplatesbytagginganddelivertoOwner X

l. Isolate,orremove,ifnecessary,inlinecomponentssuchascontrol

valves,positivedisplacementmeters,turbinemeters,etc.forpressure

testingandreinstallsuchitems

X

m. Checkboresoforificeplates X

n. Installsuchplatesaftercompletionofflushingoperations XX

o. Isolateorremoveinlinecomponentsforflushingoperationsandreinstall

themonthecompletionofsuchoperations

XX

p. FillairlinelubricatorswithoilsuppliedbyOwner X

q. Checkdesignationandfunctionofeachisolatorandfuseinelectric

systems

X

r. Checkoperationofautomatictransfersystems,resetmechanisms,etc. XX

s. Loopcheckallinstrumentationfromfieldtocontrolroom. X

t. Witnessallloopchecks X

u. Cleangaugeglassesandcheckilluminators X

v. Strokeallcontrolvalves,on/offvalves,lubricateasrequired X

w. Checkallanalyzers,cleanandflushlinesto/fromarrangeforvendor

representationforcalibrationofanalyzersifrequired(e.g.

chromatographs)

X

x. Testandadjustallsafetydevicesandsealswherenecessaryusevendor

ifrequired

X

y. Installallsafetydevicese.g.pressurereliefvalvesaftertesting X

z. Supplyandinstallsealingliquids X

2.3 Piping - Account C

a. Hydrostaticallyorpneumaticallytestllpipingasrequiredbythedrawings

orspecifications

X

b. NotifyOwneroftestschedule X

c. WitnessfieldpressuretestswhennotifiedbyContractor X

d. Provideatownersexpenseanyspecialmediafortestpurposesand

facilitiesfortheirdisposal

X

e. Checkpipehangers,supports,guidesandpipespecialitiesforthe

removalofallshippinganderectionstops,andforthecorrectnessofcold

settingsforthedesignservice.Inaddition,provideOwnerwith

instructionsforhotsettings

X

f. Checkpipehangers,supports,guidesandpipespecialitiesforhot

settingsandmakeminoradjustmentsasnecessary

X

g. Installcarsealsonvalveswherenecessary X

h. Checkandrecordpositionofallcarsealedvalves X

i. Checksteamtracingfortightnessandcontinuity(usesteamwhen

available)andcheckpropertaggingofsupplyandreturns

X

j. Installallstrainers(temporaryandpermanent)spadesandspectacle

blindsascalledforondrawings.

X

k. Waterflushand/orairblowsmallborepiping.Waterflushlargeborepiping X

l. Carryoutchemicalcleaningasrequiredperjobspecification X

m. Operatesteamandwatersystemsforflushing,cleaningandtracing X

n. Blowdown/cleansteamlineswithsteame.g.turbinesinlets X

o. Witnessflushingandcleaning X

p. Cleanstrainersafterflushingandremoveifwarranted XX

q. Maintainrecordsofblindsinstalled X

r. ObtainOwner'sapprovalandpermitsandmaketieinsasrequiredby

applicablespecification

X

s. Isolateallsystemstoallowtieinstobemade X

t. Removeblindsandtemporarystrainersasrequiredduring

commissioning

XX

2.4 Towers - Account A

2.4.1Shop-fabricated:

a. Installallinternalsnotalreadyinstalledinfabricatingshop,including

trays,caps,grids,demisters,internalpiping,packingandlinings

X

b. Inspectallinternals X

c. Makenecessarycorrectionstointernals,removealldebrisandheavydirt X

Pgina 3 de 6 BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning activities

25/10/2013 http://www.red-bag.com/jcms/general-standards/324-bn-s-uc001b-checklist-for-the-mechanical-completion-incl-pre-commissioning-acti...

d. Carryoutfinalinspection X

e. Dochemicalcleaning,ifrequired XX

f. Dofinalflushingandmaketightnesstests X

g. Performnecessaryleakagetestsontrays X

2.4.2Field-Erected:

a. Superviseconstruction,codetestingandinstallationofinternals X

b. Inspectallinternals X

c. Makefinalmechanicalcleanout X

d. Carryoutfinalinspection X

e. Performnecessaryleakagetestsontrays X

f. Dochemicalcleaning,ifrequired XX

g. Dofinalflushingandtightnesstest X

2.5 Vessels - Account MR

a. Openaftererectiontoplaceanyinternalsrequiringfieldinstallationand

inspectattimeofinstallation.Openexternalmanwaysonvesselsfor

inspectionbyOwner

X

b. Cleanoutdebrisetc X

c. Witnessinspectionstotheextentdesired X

d. Openafterdryoutandchemicalcleaningandchargematerialsas

chemicals,resins,desiccantsandcatalysts(procurementbyOwner)

XX

Note: When vessels have been subjected to a shop test, they will not be further tested in the field but may be

included as part of a piping system test.

2.6 Tanks - Account M

a. Cleanoutdebris,etc. X

b. Carryoutchemicalcleaningasrequiredbyjobspecifications XX

c. Cureanddryoutanyspecialcementorprotectiveliningsinaccordance

withmanufacturers'specificationsandinstructions

X

d. Testinaccordancewithapplicablespecs X

e. Purgesystemsandchargechemicalsasrequired XX

f. Calibrationofproducttanks X

2.7 Shell and Tube Exchangers - Account T

a. Ifdesired,fieldinspectexchangerswhichhavebeenshopinspected X

b. Ifdesired,fieldtestexchangerswhichhavebeensubjectedtoashoptest X

2.8 Air-cooled Exchangers - Account T

a. Inspecttoensurethattemporaryshippingsupportsanderectionmaterial

havebeenremoved.Checkfordamage

X

b. Ifdesired,fieldtestexchangerswhichhavebeensubjectedtoashoptest X

c. Couplefantomotoraftermotorhasbeenrununcoupled X

d. Testandbalancefansasrequired.Checkbladesetting X

e. Testlouversandcontrolsofsame X

f. Checkforvibration X

2.9 Fired Heaters - Account H

a. Pressuretestinaccordancewithapplicablecode,asrequired X

b. Provideallnon-operatingprefiringchecksinaccordancewith

specificationsandmanufacturers'instructions

X

c. Blowfuellines,checkforcleanliness,andconnectburnerpiping XX

d. Checkproperfunctioningofregistersanddampers,andverifypositionof

indicators

X

e. Dryrefractoriesduringinitialfiringbyfollowingmanufacturer's

temperaturecycles

X

f. Conductboiloutandchemicalcleaningandflushingoperationsas

required

X

g. Obtainandchargeliquidheattransfermedia,ifrequired XX

h. Conductlightoff,dryingandpurgingoperations X

Pgina 4 de 6 BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning activities

25/10/2013 http://www.red-bag.com/jcms/general-standards/324-bn-s-uc001b-checklist-for-the-mechanical-completion-incl-pre-commissioning-acti...

2.10 Pumps, Compressors and Turbine Drivers - Account P-PC

a. Levelbaseplatesandsoleplatesandgroutallbearingsurfaces,cold

alignunitsandfurnishrecordofalignment

X

b. Checkforandremoveanyexcesspipingstresseswhichmaybeimposed

ontheequipment

X

c. Chemicallycleantheinstallationofanysealandlubeoilsystem,if

specified

X

d. Providealllubricantsrequired X

e. Chargethelubeandsealoilsystems XX

f. Circulateforcleaningpurposesanysealoil,lubeoilandcoolingsystems XX

g. Makevibrationtestswhendriveriscoupled.Checktemperatures X

h. Installmechanicalseals,permanentpackingandaccessoriesifrequired X

i. Hotalignpumps,compressors,turbines,etc. X

j. Coupleunitstodriversaftermotorshavebeentestrun X

k. Installtemporarystrainersinsuctionpiping X

l. Arrangeformanufacturesrepresentativestosuperviseerectionand

performtestonlargecompressors,turbines

X

m. Loopcheckauxiliariesonlargeequipmentwithvendorrepresentatives X

n. Witnessalltests,checksandtestrunsoflargecompressorsand

turbines.

X

2.11 Special Equipment - Account G

(Agitators,mixers,rotaryfilters,weighscales,materialshandlingequipment,vacuumequipment)

a. Fullyassemblerotaryfiltersexceptforfinalfiltermedia(clothorscreens) X

b. Installallfinalfiltermedia(cloth,precoat,etc.) X

c. Levelandcalibrateweighscaleswithassistanceofthemanufacturer's

representativeandsettareweightswherepossible

X

d. Manuallycheckmaterialshandlingequipmentforfreedomanddirection

ofmovement

X

e. Makeallfinaladjustmentsduringruninandanyperformancetests

required

X

f. Obtainvendor'sserviceengineerforstartup X

g. Testvacuumequipment,checkalljointsforleaks X

2.12 Boilers - Account H

a. Makehydrostaticpressuretestinaccordancewithapplicablecodes,if

requiredbyspecifications

X

b. Inspectinstallationforcompletenessandcorrectnessofinstallationand

makeothernon-operatingpre-firingchecksinaccordancewith

specificationsandmanufacturer'sinstructions

X

c. Checkproperfunctioningofregistersanddampersandverifypositionof

indicatorscheckoperationofsootblowersmechanically

X

d. Blowfuellines,checkforcleanlinessandconnectburnerpiping X

e. Dryrefractoriesduringinitialfiringbyfollowingmanufacturer's

temperaturecycles

X

f. Purge,flushanddrainsteammainsasnecessary XX

g. Obtainandchargetreatedwater(perspecifications)forboiloutandinitial

operationasrequired

X

h. Commissionauxiliariesasdetailedelsewhereundertheappropriate

equipmenttype

X

i. Conductboiloutandchemicalcleaningandflushingoperationsas

required

XX

j. Conductinitiallightoffwithassociatedchecksandadjustments X

k. Conductalloperatingtestsandobtainrequiredcertification X

2.13 Water Treating Plants

a. Inspectforcompletenessandcorrectnessofinstallationandmakeany

non-operatingcheckswhichmayberequired

X

b. Provideandinstallinitialchargeofionexchangeresinsandinertbed

material

X

c. Makethenecessaryoperatingtestsandadjustmentstowatertreatment

systems

X

Pgina 5 de 6 BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning activities

25/10/2013 http://www.red-bag.com/jcms/general-standards/324-bn-s-uc001b-checklist-for-the-mechanical-completion-incl-pre-commissioning-acti...

d. Provideallwatertreatmentchemicals X

e. Obtainservicesofwaterconsultanttoadviseandmonitor X

2.14 Water Systems

(Servicewells,coolingtowers,firewater,seawatersystems,etc.)

a. Inspectforcompletenessandcorrectnessofinstallationsandmakeany

non-operatingchecksrequired

X

b. Initiallycleancoolingtowerbasinandinstallscreensinsuctionpitpriorto

watercirculation

X

c. Testwelldeliveryandflushwellpipingifwellsarefurnishedby

Contractor

X

d. Flush,drainandcleancoolingwaterbasins XX

e. Cleanintakescreens XX

f. Operatefirepumpstocheckoutputofsystems X

g. Fillreservoirs,headtowers,etc. X

h. Arrangeforinsurancecompanyinspectionoffiresystemasrequired X

i. Obtainandinstallallfirefightingchemicalsasrequiredandportable

equipmentsuchashoses,fireextinguishersandrelatedequipment

X

2.15 Waste Disposal

a. Inspectfacilitiesforcompletenessandcorrectnessofinstallationand

makeanynon-operatingcheckstoensureconformancewith

specifications

X

b. Operateallequipmentandsupplyallchemicals,agents,etc.relatedto

wastetreatment

X

2.16 Buildings and Accessories

a. Checkinstallationofanybuildingsandaccessoriesincludingallheating,

ventilatingandairconditioningequipmenttoensurecompletenessand

conformancewithspecifications

X

b. Obtaincertificationthatallplumbing,wiringandelevatorinstallationarein

compliancewithlocalgovernmentalregulation

X

c. Testheating,ventilatingandair-conditioningunitsandmakeall

performancetests,ifweatherpermits,otherwisebyOwner

X

d. Obtaincertificateforoccupancyanduse,ifrequired X

2.17 Insulation and Painting - Accounts N and R

a. Inspectandacceptallmaterialsandfieldworkmanship X

b. Completeallinsulationworkasspecified X*

c. Completeallpaintingasspecified,weatherpermitting X*

* This work may extend beyond the date of mechanical completion.

'reliability is yet to become the most important characterstic of modern companies'

home|privacy|legal

2001-2013Red-Bag

Pgina 6 de 6 BN-S-UC001B Checklist for the Mechanical Completion, incl. pre-commissioning activities

25/10/2013 http://www.red-bag.com/jcms/general-standards/324-bn-s-uc001b-checklist-for-the-mechanical-completion-incl-pre-commissioning-acti...

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- p103-Stts-gec-Asi-ms-ele-005 - Method Statement For Cable Termination & Joint For HV SystemDocument10 pagesp103-Stts-gec-Asi-ms-ele-005 - Method Statement For Cable Termination & Joint For HV SystemAnandu AshokanNo ratings yet

- Basic Engineering Data SheetsDocument59 pagesBasic Engineering Data SheetsDave CNo ratings yet

- LC - en-US - 20147341 - SEW MotorDocument160 pagesLC - en-US - 20147341 - SEW MotorMarcio SócratesNo ratings yet

- S7 300 CP343-1-Lean-CX10 76Document50 pagesS7 300 CP343-1-Lean-CX10 76Marcio Sócrates100% (1)

- Handwritten Log 18feb15Document1 pageHandwritten Log 18feb15Marcio SócratesNo ratings yet

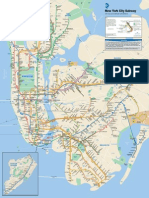

- New York City Subway: THE BronxDocument1 pageNew York City Subway: THE BronxMarcio SócratesNo ratings yet

- SC Upload File Directions Lincoln 1325668Document1 pageSC Upload File Directions Lincoln 1325668Marcio SócratesNo ratings yet

- Rw120 Guide - Ot4.enDocument128 pagesRw120 Guide - Ot4.enMarcio SócratesNo ratings yet

- Desvio Surge Siemens CCCDocument2 pagesDesvio Surge Siemens CCCMarcio SócratesNo ratings yet

- Turn-Taking and Gambits in Intercultural CommunicationDocument83 pagesTurn-Taking and Gambits in Intercultural CommunicationsanjamaviNo ratings yet

- Testing & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981Document14 pagesTesting & Maintenance of Transformers: Listing Type Test, Routine Test & Special Test As Per I.S. 2026-1981PKNo ratings yet

- Hve 2016 0009Document7 pagesHve 2016 0009Ioan-Viorel BanuNo ratings yet

- Safe Measurement Prevent Accident in Electr VehicleDocument8 pagesSafe Measurement Prevent Accident in Electr VehicleGary ClarkNo ratings yet

- Manual of PI9100 Vector Contorl Inverter V5Document240 pagesManual of PI9100 Vector Contorl Inverter V5Juan Carlos CosmeNo ratings yet

- Test Procedure - BusbarDocument4 pagesTest Procedure - Busbarmayur dhande100% (2)

- 4.8 - MD-SX Instruction (1309)Document56 pages4.8 - MD-SX Instruction (1309)jarekNo ratings yet

- RP12 16Document48 pagesRP12 16ferdad100% (1)

- Start-Up and Check-Out Procedures For Submersible Pumps: (Step-By-Step Procedures Courtesy of SWPA)Document5 pagesStart-Up and Check-Out Procedures For Submersible Pumps: (Step-By-Step Procedures Courtesy of SWPA)Diego Nicolás FERNANDEZNo ratings yet

- Cat Busbar enDocument22 pagesCat Busbar enarllanbd4706No ratings yet

- k120s K7MDR14UE ManualDocument11 pagesk120s K7MDR14UE ManualAhmed Hebeshe100% (1)

- Semiconductor Contactors Solid-State Relays: R100.xx and R300.xx Range R111, R12x and R31x RangeDocument18 pagesSemiconductor Contactors Solid-State Relays: R100.xx and R300.xx Range R111, R12x and R31x RangeHisham AllamNo ratings yet

- YMVK-mb ss Powerflex Cable for Energy DistributionDocument2 pagesYMVK-mb ss Powerflex Cable for Energy DistributionAnamulKabirNo ratings yet

- Enriching Technical Knowledge of T&D Professionals Biological Growths on Composite InsulatorsDocument10 pagesEnriching Technical Knowledge of T&D Professionals Biological Growths on Composite InsulatorsRamesh RavulaNo ratings yet

- Reliable Protection from Electric Fires and Electrocution with Earth Leakage RelaysDocument8 pagesReliable Protection from Electric Fires and Electrocution with Earth Leakage Relaysdinesh_kp7647No ratings yet

- Thermal Analysis of Overload Protection Relays Using Finite Element MethodDocument6 pagesThermal Analysis of Overload Protection Relays Using Finite Element MethodKiran KarthikNo ratings yet

- BS 5467Document34 pagesBS 5467AliNo ratings yet

- Grade 6 Performance Task TleDocument6 pagesGrade 6 Performance Task TlepatrixiaNo ratings yet

- Mamdouh Al HarbiDocument25 pagesMamdouh Al HarbiAjit SharmaNo ratings yet

- DELTA 4000: Reference Manual Applications GuideDocument48 pagesDELTA 4000: Reference Manual Applications GuidepetarlNo ratings yet

- SNBP Epc 00 Ins SPC 008Document41 pagesSNBP Epc 00 Ins SPC 008sugeng wahyudiNo ratings yet

- Gepco Internship Report by Abdul Haseeb 2020Document32 pagesGepco Internship Report by Abdul Haseeb 2020ABDUL HASEEB0% (1)

- Technical Specification AL-59 Conductor 893Document18 pagesTechnical Specification AL-59 Conductor 893pramjitNo ratings yet

- Finder 62 SeriesDocument12 pagesFinder 62 SerieskazishahNo ratings yet

- Kumwell 2019 price list for earthing and lightning protection productsDocument50 pagesKumwell 2019 price list for earthing and lightning protection productsWai Yan Soe Thwin100% (3)

- Mits97 Ingles Nov02Document46 pagesMits97 Ingles Nov02milad rouhiniaNo ratings yet

- Understanding Distribution SystemsDocument109 pagesUnderstanding Distribution SystemsBadarul MuneerNo ratings yet

- BEEDocument151 pagesBEESrimanth Raj SRNo ratings yet

- 72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems CorporationDocument4 pages72.5kV Dry Air Insulated Dead Tank Vacuum Circuit Breaker: Japan AE Power Systems CorporationBalaji VenkatesanNo ratings yet