Professional Documents

Culture Documents

Files Files Literature ProductLiterature Pumps Fpd-8-E

Uploaded by

sea_jazz0 ratings0% found this document useful (0 votes)

85 views16 pagesFlowserve offers innovative pumping solutions for every conceivable pipeline application, including oil, refined products, carbon dioxide (CO 2) liquid gases, water and slurry services. With more than 200 years of industrial pump experience and 100 years of pipeline pumping experience.

Original Description:

Original Title

Www.flowserve.com Files Files Literature ProductLiterature Pumps Fpd-8-e

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFlowserve offers innovative pumping solutions for every conceivable pipeline application, including oil, refined products, carbon dioxide (CO 2) liquid gases, water and slurry services. With more than 200 years of industrial pump experience and 100 years of pipeline pumping experience.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

85 views16 pagesFiles Files Literature ProductLiterature Pumps Fpd-8-E

Uploaded by

sea_jazzFlowserve offers innovative pumping solutions for every conceivable pipeline application, including oil, refined products, carbon dioxide (CO 2) liquid gases, water and slurry services. With more than 200 years of industrial pump experience and 100 years of pipeline pumping experience.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 16

Experience In Motion Experience In Motion

Pipeline Transportation Pumps

Crude Oil and Refined Products Water Slurry

2

Flowserve offers innovative pumping solutions

for every conceivable pipeline application,

including oil, refined products, carbon dioxide

(CO

2

) liquid gases, water and slurry services.

With more than 200 years of industrial pump

experience and 100 years of pipeline pumping

experience, Flowserve has earned a pre-eminent

position in the industry through advanced design,

engineered solutions, equipment re-rates and

customer service excellence.

Customers all over the world turn to Flowserve for

creative solutions that improve pipeline:

Safety

Life cycle cost

Experience ... Innovation ... Leadership

From the first pipelines, Flowserve leads the industry

through the development of innovative products and

creative solutions addressing the ever-increasing

requirements of flow and operating pressures.

The Trusted Partner in Global Pipeline Pumping

Case Study: Hydraulic Re-rate

Installation: DVS single-stage, double-suc-

tion horizontal split case pumps

on a 645 km (400 mi) pipeline

in northwest United States to

transport gasoline, diesel and

jet fuel. Pipeline diameters:

300 mm (12 in) through

500 mm (20 in).

Problem: Over the years, pump flow rate

had been significantly reduced,

running at 46% BEP. In addition

to lower efficiency, high vibration

levels increased maintenance and

operating costs.

Solution: Hydraulic re-rate to match

lower current rated duty

Replace impeller with lower

flow design

Reduce volute area to pull

back BEP

Increase volute cutwater

diameter (B Gap)

Benefit: Normal flow rate at 96% BEP

Energy savings >135 kW

(180 hp)

Increased MTBR, resulting in

maintenance savings

New volute lip extension tacked in place

Profitability

Reliability

BEP Range

Impeller Only

Impeller & Volute

Capacity as % of BEP

T

o

t

a

l

H

e

a

d

s

a

s

%

o

f

B

E

P

3

A Complete Range of Pipeline Pumps

Crude Oil and Refined Product Pipeline Pumps

Mainline/Booster Pumps

Single- and two-stage between bearings

Multistage, horizontal split case

Multistage, radially split double case

Multistage vertical canned

Twin screw multiphase

Auxiliary Pumps

Single-stage overhung

Vertical in-line

Submersible motor

Single-stage and multistage vertical wet pit

Single-stage and multistage vertical canned

Service-specific specialty designs

CO

2

Pipeline Pumps

Single-stage, between bearings, radially split

Multistage, horizontal split case

Multistage, radially split double-case

Water Pipeline Pumps

Single- and multistage overhung

Axially split, single-stage between bearings

Vertical turbine

Submersible motor

Horizontal, multistage ring section

Slurry Pipeline Pumps

Single-stage overhung

Hard metal

Metallic and non-metallic lined

Reciprocating positive displacement

All the Expertise You Need

Flowserve has the expertise to serve as the

overall systems manager for pipeline operations.

Working with architect and construction firms

or in-house design teams, Flowserve provides

turnkey services, pump-specific diagnostics,

maintenance and repair, and a full spectrum

of technical services to optimize the return on

pipeline investment.

Whether new equipment or system upgrades,

Flowserve aggressively advances pipeline pump

technology. Further information about system

and equipment upgrades may be found

beginning on page 14.

Market-Focused Customer Support

Flowserve pipeline specialists provide customers

the technical support necessary to develop

effective solutions for tough pipeline challenges.

These solutions can incorporate all manner of

specific market and customer preferences. They

offer technical advice and assistance throughout

each stage of the product life cycle. From

feasibility through pipeline design, inquiry

through order fulfillment, installation through

start-up and pipeline re-rates, Flowserve

specialists work with customers to successfully

achieve their operational goals.

flowserve.com

4

Crude Oil and Refined Product Pipeline Systems

CO

2

Pipelines

Flowserve has a significant amount of pioneering

experience in the design and supply of pumping

equipment for the transportation, injection

and re-injection of CO

2

. This capability is

the result of: prior work on other near and

supercritical fluids; and the development, design

and supply of the pumping equipment for

several CO

2

enhanced oil recovery projects.

Pumps typically used in this application

include horizontal axially split and radially split

multistage pumps as well as specially designed

high-pressure single-stage pumps. (See bulletin

FPD-17 for more information.)

Flowserve is the industrys preferred supplier of

petroleum product pipeline pumps. Reliability makes

Flowserve pumps the products of choice for unattended

mainline operation in some of the worlds most

inhospitable environments. No other manufacturer

offers a comparable breadth of products and services

for transportation, transfer, storage and cargo stripping.

Flowserve has reliable and cost-effective solutions

for the most demanding upstream and downstream

pipeline applications.

Offshore Pipelines

Flowserve offers a complete line of single- and multi-

stage pumps in either axial or radial split configurations.

These pumps are perfectly suited for main oil line,

transfer and tanker loading on offshore platforms.

With a history of operating pumps at capacities up to

9500 m

3

/h (41 825 gpm) and differential heads to

6000 m (19 685 ft), Flowserve has the proven products

capable of moving crude oil directly from the platform

to marine terminals or waiting tankers. And Flowserve is

the only manufacturer offering the safety and reliability

of shaft seals to ISO 21049/API 682.

Subsea

Flowserve is in the forefront of subsea technology with

the application of integrated multiphase pumping and

seabed processing systems.

Heritage Names

of Distinction

Byron Jackson

IDP

Pacific

Pleuger

United

Centrifugal

Worthington

Experience: Refined Products Pipeline

Installation: More than 300 DVS single-stage,

double-suction horizontal split case

pumps (sizes 24 x 27, 24 x 29,

30 x 27 and 30 x 29) with driver

sizes up to 3730 kW (5000 hp).

Application: One of the worlds largest

products pipelines, 4665 km

(2900 mi) from the Gulf Coast to

mid-/northeastern United States.

Pipeline diameters: 900 mm (36 in)

through 1050 mm (42 in).

5

flowserve.com

Diluent/Bitumen, Froth Transfer and

Synthetic Crude Pipelines

Flowserve pumps are especially suited to the unique

requirements of diluent/bitumen service for steam-

assisted gravity drainage (SAGD). Through extensive

knowledge of heat tracing and variable speed operation

along with close working relationships with Flowserve

seal experts and other mechanical seal suppliers,

Flowserve pumps are custom-designed to suit each

application. Typical models for this service include

vertical canned and horizontal single- and multistage

split case pumps.

In tar sands mining, Flowserve high-pressure, hard

metal slurry pumps feed a mixture of air, water and

bitumen down a pipeline from the sand extraction plant

at the mine to the base plant for further extraction and

refining. From here, axially split single- and multistage

pumps transport the synthetic crude to the refinery.

Products Cavern and Well Storage

Transfer Terminals

Flowserve leads the way in providing vertical

wet-pit and submersible motor pump solutions

for direct storage transfer pumping applications

in salt dome and cavern services. Additionally,

horizontal single- and multistage pumps offer

excellent injection solutions for indirect storage

transfer applications.

Crude Oil and Products Supply

Pipeline and Terminals

Flowserve takes pride in its breadth of products

designed for the transportation, transfer, stor-

age and cargo stripping of crude oil and finished

products for the pipeline market. With models

ranging from pipeline sampling pumps to large

radially split barrel mainline pumps, Flowserve

can provide a cost-effective solution for all

terminal and pipeline applications.

Ship, Tank Car and Truck

Loading Terminals

With a full line of ISO 2858/5199, ANSI B73.1,

ISO 13709/API 610, DIN and JIS compliant

designs, Flowserve maintains the largest family

of pumps to address any terminal application.

Low NPSH pumps in both horizontal and

vertical configuration are also available for

booster-station service.

Technical Services

From the Producing Fields to the Market,

Flowserve Has the Pipeline Pump Solution

1

2

4

5

6

DMX (BB3)

Axially Split, Multistage

WCC/WIK (BB5)

Multistage, Diffuser Collector, Barrel Casing,

Volute Collector

HDO/HSO (BB5)

Multistage, Volute Casing, Process Barrel

DVSH/LPN/LPLD (BB1)

Axially Split, Single-Stage

UZDL (BB1)

Axially Split, Two-Stage

ALT. BFD (BB1)

Double-Suction

DVSR (BB2)

Radially Split, Double-Suction,

Single-Stage

3

3 4 5 6 1

2 3 4 1

1 3 8

3 8 1

13 14 12

3 4 1

3 4 1

2 3 4 1

2

3 4

1

4 5 6

11

15

11

2 3 4 1

flowserve.com

7

10

11

12

13

14

15

8

9

WUJ/VTP (VS1)

Wet-Pit

VPC (VS6)

Vertical Turbine, Double-Casing

ALT. WUC (VS6)

Double-Casing Multistage

SUBM Deep-Well Submersible

(Pleuger water-filled) (Byron Jackson oil-filled)

ESP3

Vertical Immersion Sump

MP1

Multiphase

HPX (OH2)

Centerline Mounted

PVXM (OH3)

Vertical In-Line

Mark 3

TM

ASME and ISO Standards

Type M

Hard Metal

2 3 4 1

2 3 4 1

10 12 8

13 14

13 14 12

8

2 3 4 1 8 10

9 7

8

DMX (BB3)

Axially Split, Multistage

Flows to 2950 m

3

/h (13 000 gpm)

Heads to 2130 m (7000 ft)

Pressures to 275 bar (4000 psi)

Speeds to 6000 rpm

WCC/WIK (BB5)

Multistage, Diffuser Collector,

Barrel Casing

Flows to 4000 m

3

/h (17 610 gpm)

Heads to 3050 m (10 000 ft)

Discharge pressures to 650 bar

(9425 psi)

Speeds to 8600 rpm

HDO/HSO (BB5)

Multistage, Volute Collector,

Barrel Casing

Flows to 4000 m

3

/h (17 610 gpm)

Discharge pressures to 450 bar (6525 psi)

Speeds to 9000 rpm

DVSH/LPN/LPLD (BB1)

Axially Split, Single-Stage

Flows to 15 000 m

3

/h (65 000 gpm)

Heads to 565 m (1854 ft)

Pressures to 150 bar (2175 psi)

Speeds to 6000 rpm

UZDL (BB1)

Axially Split, Two-Stage

Flows to 2950 m

3

/h (13 000 gpm)

Heads to 685 m (2250 ft)

Pressures to 64 bar (910 psi)

DVSR (BB2)

Radially Split, Double-Suction

Single-Stage

Flows to 3635 m

3

/h (16 000 gpm)

Heads to 250 m (820 ft)

Pressures to 260 bar (3750 psi)

Mainline Pumps Operating Parameters

The Worlds

Most Complete

Line of Crude,

Petroleum and

CO

2

Pipeline

Pumps.

DVSH/

LPN/LPLD

UZDL

WCC

DVSR

DMX

HDO

Note: The above values indicate the typical performance envelope for the models listed.

Flowserve has significant experience beyond these limits. Consult your Flowserve

representative with your specific performance requirements.

9

HPX (OH2)

Centerline Mounted

Flows to 2000 m

3

/h (8800 gpm)

Heads to 350 m (1100 ft)

Pressures to 80 bar (1160 psi)

PVXM (OH3)

Vertical In-Line

Flows to 500 m

3

/h (2200 gpm)

Heads to 275 m (900 ft)

Pressures to 40 bar (600 psi)

Mark 3 ANSI and ISO

Flows to 4540 m

3

/h (20 000 gpm)

Heads to 220 m (720 ft)

Pressures to 27 bar (400 psi)

ESP3 Vertical Immersion Sump

Flows to 1300 m

3

/h (5700 gpm)

Heads to 90 m (300 ft)

Pressures to 12 bar (175 psi)

WUJ/VTP (VS1) Wet-Pit

Flows to 13 600 m

3

/h (60 000 gpm)

Heads to 2000 m (6560 ft)

Pressures to 200 bar (2900 psi)

flowserve.com

Auxiliary Services Pumps Operating Parameters

WUC/VPC (VS6) Vertical Turbine,

Double Casing

Flows to 13 600 m

3

/h (60 000 gpm)

Heads to 2000 m (6560 ft)

Pressures to 200 bar (2900 psi)

Pleuger SUBM

Deep-Well Submersible

(Water-Filled Design)

Flows to 6000 m

3

/h (26 415 gpm)

Heads to 800 m (2625 ft)

Motor sizes to 5000 kW (6700 hp)

Speeds from 200 to 3600 rpm

Byron Jackson SUBM

Deep-Well Submersible

(Oil-Filled Design)

Flows to 6000 m

3

/h (26 415 gpm)

Heads to 800 m (2625 ft)

Motor sizes to 1650 kW (2200 hp)

Speeds from 1000 to 3600 rpm

Specialty Designs

In-line, double-suction

Multistage, axially split, double-suction

Abrasive slurry pump

Positive displacement two-screw

PVXM

Mark 3

WUJ/VTP

Byron

Jackson

SUBM

HPX

ESP3

Pleuger

SUBM

WUC/VPC

10

Flowserve traces its history to the late 1790s when its

Simpson heritage brand began applying steam pumping

engines to municipal waterworks in the United Kingdom.

Today, Flowserve pumps are used extensively in:

Source water and transmission

Treated water distribution

Irrigation

Where surface water or groundwater is not readily

available, pipelines are required to transport water from

alternate sources to its destination.

Flowserve offers the industrys most complete and

diverse line of water transmission and distribution

pumps, including:

Horizontal, axially split, single-stage

Horizontal, radially split, end suction single-stage

Horizontal, axially split multistage

Between bearing, ring section multistage

Overhung product lubricated, ring section multistage

Submersible motor

Short-coupled, vertical turbine

Water Pipeline Systems

Heritage Names

of Distinction

Byron Jackson

IDP

Pleuger

United

Centrifugal

Worthington

Worthington Simpson

Case Study: Middle East Pipeline

Installation: 22 DMX axially split, two-stage

pumps (24 x 28) with driver

sizes to 16 780 kW (22 500 hp)

delivering 1.6 million bbl/d at

heads to 625 m (2050 ft).

Casing weights total equal

13 610 kg (30 000 lb).

Application: 1200 km (750 mi) pipeline

across rugged terrain in the

Middle East. Pipeline diameter

of 1400 mm (56 in)

Challenge: Maintain problem-free

operation across all flow

range requirements

Solution: Employ computational fluid

dynamics to analyze and

optimize impeller blade geometry

Result: New impeller design demonstrated

no cavitation, far exceeding

previous industry acceptance

criteria for high-energy impellers.

11

flowserve.com

LNN Axially Split, Single-Stage

Flows to 30 000 m

3

/h (132 000 gpm)

Heads to 300 m (980 ft)

Pressures to 40 bar (580 psi)

MEN End Suction

Flows to 340 m

3

/h (1500 gpm)

Heads to 120 m (395 ft)

Pressures to 15 bar (220 psi)

F-Line End Suction, Multistage

Flows to 500 m

3

/h (2200 gpm)

Heads to 250 m (820 ft)

Discharge pressures to 25 bar (365 psi)

Water Pipeline Pump Solutions Operating Parameters

VTP Vertical Turbine

Flows to 13 600 m

3

/h (60 000 gpm)

Heads to 700 m (2300 ft)

Sizes from 150 mm (6 in) to 1375 mm (54 in)

Pleuger and Byron Jackson SUBM

Deep-Well Submersible Motors

(Water-Filled or Oil-Filled)

Flows to 6000 m

3

/h (26 415 gpm)

Heads to 800 m (2625 ft)

Motor sizes to 5000 kW (6700 hp)

Speeds from 200 to 3600 rpm

WDX/NM Radially Split,

Multistage Ring Section

Flows to 3000 m

3

/h (13 210 gpm)

Heads to 700 m (2300 ft)

Pressures to 75 bar (1090 psi)

LNN

MEN

WDX

VTP

SUBM

F-Line

Note: The above values indicate the typical performance envelope for the models listed.

Flowserve has significant experience beyond these limits. Consult your Flowserve

representative with your specific performance requirements.

12

Flowserve offers a proven, application-tested

line of slurry pipeline pumps, including:

Titan Slurry pumps with a choice of hard

metal, rubber, elastomeric or ceramic liners

within metal armor

Type M hard metal abrasive slurry pumps

Type R rubber lined abrasive slurry pumps

HS and V reciprocating plunger pumps

Highly abrasive and often corrosive slurry creates an

extraordinarily difficult pumping environment. Typical

slurry pipeline applications include tailings (waste rock)

disposal, extraction plant to concentrator and

concentrator or washery to loading terminal. Coal

slurry, metal ore slurry and diluent/bitumen froth all

present severe corrosive and erosive challenges to

high-pressure pumping.

Flowserve is unequaled in its materials expertise,

offering an extensive selection of metallic and

non-metallic solutions. These include hard metal

and specialized hardening techniques, rubber and

elastomeric linings and even ceramic linings for the

most demanding services.

Slurry pipelines commonly employ multiple single-

stage pumps in series to develop the pressure required

to overcome pipe friction resistance. Series pumps

require high-pressure casings (i.e., higher tensile

strength material, more robust casing bolting, etc.) to

cope with the high internal pressures. Flowserve has

the necessary experience and engineering expertise

to meet these challenges.

Slurry Pipeline

Heritage Names

of Distinction

IDP

TKL

Wilson-Snyder

Worthington

Experience: Slurry Pipeline

Installation: Ten horizontal triplex

(three-cylinder) plunger

pumps with stainless steel

fluid ends. Rated for 220 m

3

/h

(970 gpm) at 84 bar (1220 psi)

discharge pressure.

Application: Fly ash removal from the

scrubbers of a coal-fired power

plant in China. Slurry of 35%

fly ash by weight in sea water

transported in a 22 km (13.7 mi)

disposal pipeline.

13

Titan Slurry Heavy-Duty, Rubber Lined

or Metal Lined

Flows to 3600 m

3

/h (16 000 gpm)

Heads to 90 m (300 ft)

Pressures to 40 bar (580 psi)

Packed gland, expeller or mechanical shaft seal

Multiple liner materials available

Natural rubber and polyurethane for fine solids and

mildly corrosive slurries

High chrome iron for applications containing coarse

solids, as well as those at higher pressures or high

temperatures

Ceramic materials (exhibiting outstanding abrasion

and corrosion resistance) for hot, corrosive slurries

Type M Hard Metal

Flows to 10 000 m

3

/h (44 000 gpm)

Heads to 90 m (300 ft)

Pressures to 50 bar (725 psi)

Packed gland, expeller or mechanical shaft seal

flowserve.com

V Vertical Reciprocating

Flows to 1140 m3/h (5000 gpm)

Standard pressures to 619 bar (8975 psi);

custom pressures to 2070 bar (30 000 psi)

Power to 3450 kW (4625 hp)

Speeds to 360 rpm

HS Multiplunger, Horizontal Reciprocating

Flows to 775 m3/h (3400 gpm)

Standard pressures to 555 bar (8030 psi);

custom pressures to 2070 bar (30 000 psi)

Power to 2560 kW (3430 hp)

Speeds to 530 rpm

Slurry Pipeline Pumps Operating Parameters

V

Type M

Titan

Slurry

HS

Note: The above values indicate the typical performance envelope for the models listed. Flowserve has significant experience beyond these limits.

Consult your Flowserve representative with your specific performance requirements.

14

Providing Unequaled Pump and

System Support

Flowserve can provide customers with everything from

simple consultation and equipment selection assis-

tance to complete turnkey and management services.

Customers can choose the level of support which best

meets their needs, including:

Complete Pipeline Systems Management

Shared responsibility for improved operational

performance, lower equipment ownership costs and

increased revenues

Combined world-class expertise in pumps, valves

and mechanical seals

Global Service and Technical Support

Worldwide network of service, repair and quick

response centers staffed by highly skilled engineers

Product and System Support

On-site repair

Site-specific training

Spare parts inventory and management programs

Auxiliary equipment

Training

LifeCycle Advantage agreements

1

Hydraulic Re-rates

for Optimal

Performance and

Reduced

Operating Costs

Services and Solutions

Technical Services

Hydraulic re-rates and upgrades

Mechanical upgrades and retrofits

Materials upgrades

Analytical diagnostic services

On-site pump system analysis and engineering

Computer-aided analysis to support reliability

and performance-based improvement projects

Reliability and energy improvement

Maintenance, Repair and Inspection Services

More than 140 service and manufacturing

facilities worldwide

Extensive on-site service and repair fleets

Technical Assessments

Flowserve is fully committed to maximizing

pipeline profitability. Flowserve engineers can

perform comprehensive equipment and sys-

tem audits to identify operational issues that

may be constraining output, increasing energy

consumption or otherwise elevating operating

costs. Proposed solutions are backed by life

cycle cost calculations. The following types of

assessments are available:

System

Energy

Bad actor

Safety, health and environmental

15

flowserve.com

Intelligent Process Solutions (IPS)

2

Through the application of advanced technologies,

Flowserve Intelligent Process Solutions (IPS) family

of products helps customers proactively manage

their plant assets to increase plant uptime and reduce

equipment life cycle costs. Flowserve offers advanced

monitoring solutions wired and wireless for

permanent and portable data collection and analysis of

vital plant assets.

Flowserve Educational Services

FES provides companies around the world with inno-

vative programs to teach best practices for maximum

equipment reliability and minimal total life cycle cost.

Training is conducted at Flowserve Learning Resource

Centers and on-site at the customers facility.

1 See bulletin FSG-104 for more information.

2 See bulletin PS-90-11 for more information.

Case Study: Hydraulic Re-rate

Installation: 11 pumping stations each with two or

three axially split, two-stage pipeline

pumps with integral crossovers. Each

pump is single volute with two different

rotor layouts for two head duties.

Viscous crude is being transported

from the Adriatic Sea to eastern Austria

through a 450 km (280 mi), 400 mm

(16 in) diameter pipeline.

Problem: Pumps were performing below

expectations, <78% efficiency, and

at higher operating cost.

Solution: Convert from single to double

volute casings

Create six different head duties

(instead of original two) with two

different rotor layouts

Fit different impellers for different

head duties

Reduce friction losses with

coatings and polishing

Change to open-end pipeline and

central control room operation

of all pump stations

Benefit: Efficiency increased to >85% BEP

Energy savings >113 kW (150 hp)

per pump

Increased MTBR, resulting in

maintenance savings

USA and Canada

Flowserve Corporation

5215 North OConnor Blvd.

Suite 2300

Irving, Texas 75039-5421 USA

Telephone: +1 937 890 5839

Europe, Middle East, Africa

Flowserve Corporation

Parallelweg 13

4878 AH Etten-Leur

The Netherlands

Telephone: +31 76 502 8100

Latin America

Flowserve Corporation

Martn Rodriguez 4460

B1644CGN-Victoria-San Fernando

Buenos Aires, Argentina

Telephone: +54 11 4006 8700

Telefax: +54 11 4714 1610

Asia Pacific

Flowserve Pte. Ltd.

10 Tuas Loop

Singapore 637345

Telephone: +65 6771 0600

Telefax: +65 6862 2329

flowserve.com

To find your local Flowserve representative:

For more information about Flowserve Corporation,

visit www.flowserve.com or call USA 1 800 728 PUMP (7867).

Bulletin FPD-8b (E) Printed in USA. October 2011. Flowserve Corporation

You might also like

- Elastic Foundation Young Modulus For Soils - 1Document1 pageElastic Foundation Young Modulus For Soils - 1sea_jazzNo ratings yet

- Iabmas MadeoDocument8 pagesIabmas Madeosea_jazzNo ratings yet

- 2018 01 05 - Dry Port Support RFP FINAL PDFDocument6 pages2018 01 05 - Dry Port Support RFP FINAL PDFsea_jazzNo ratings yet

- LetterDocument1 pageLettersea_jazzNo ratings yet

- Bolt Dimensions Clearances Manual of Steel Construction1990Document5 pagesBolt Dimensions Clearances Manual of Steel Construction1990sea_jazzNo ratings yet

- ch4 Mechanical Properties of Wood PDFDocument46 pagesch4 Mechanical Properties of Wood PDFdan-gabiNo ratings yet

- Beam Design ManualDocument28 pagesBeam Design ManualhangarrodNo ratings yet

- Settlement of Shallow Foundations On Granular Soils PDFDocument233 pagesSettlement of Shallow Foundations On Granular Soils PDFMUHAMMAD ALINo ratings yet

- Corrosion ProtectionDocument2 pagesCorrosion Protectionsea_jazzNo ratings yet

- Draft: Finite Element IDocument73 pagesDraft: Finite Element ISiavash KhademNo ratings yet

- L09 153Document14 pagesL09 153sea_jazzNo ratings yet

- 25 01Document5 pages25 01Sopon SrirattanapiboonNo ratings yet

- PI Schafer CMMIgranteesconf Paper PDFDocument4 pagesPI Schafer CMMIgranteesconf Paper PDFsea_jazzNo ratings yet

- 0354 46050305307MDocument14 pages0354 46050305307Msea_jazzNo ratings yet

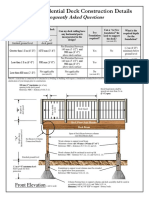

- Basic Deck Construction DetailsDocument3 pagesBasic Deck Construction Detailssea_jazzNo ratings yet

- Numerical Procedure For Ship Hydroelastic AnalysisDocument6 pagesNumerical Procedure For Ship Hydroelastic Analysissea_jazzNo ratings yet

- Ce 479 Wood Design Nds 01 ConnectionsDocument53 pagesCe 479 Wood Design Nds 01 Connectionssea_jazzNo ratings yet

- Neuberovo Pravilo PDFDocument21 pagesNeuberovo Pravilo PDFMark JurichNo ratings yet

- Hacking Structural Analysis. Join The CrewDocument3 pagesHacking Structural Analysis. Join The CrewLuis C. Pérez TatoNo ratings yet

- Awc NDS-2012Document200 pagesAwc NDS-2012brianchen0671% (7)

- Conversions of HSSDocument7 pagesConversions of HSSsea_jazzNo ratings yet

- L RFD Beam Load TablesDocument76 pagesL RFD Beam Load TablesFederico.IoriNo ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Non-Linear Static Push Over AnalysisDocument12 pagesNon-Linear Static Push Over Analysismrnicus100% (1)

- 223 STD Seismic Resistant Industrial Tanks SilosDocument74 pages223 STD Seismic Resistant Industrial Tanks Silossea_jazzNo ratings yet

- Pros and Cons of Pushover AnalysisDocument13 pagesPros and Cons of Pushover AnalysisMrugesh Shah100% (1)

- 223 STD Seismic Resistant Industrial Tanks SilosDocument74 pages223 STD Seismic Resistant Industrial Tanks Silossea_jazzNo ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- WSS Welding Symbols Study Guide LFDocument88 pagesWSS Welding Symbols Study Guide LFsea_jazz100% (3)

- Energy MethodsDocument5 pagesEnergy MethodsNikkei Pfeiffer TadiliNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Oil DA - MichiganClassic 2013Document254 pagesOil DA - MichiganClassic 2013deabtegoddNo ratings yet

- Table of Disruptive TechnologiesDocument1 pageTable of Disruptive TechnologiesMariaNo ratings yet

- AC Motor Control CircuitDocument19 pagesAC Motor Control CircuitnawitsNo ratings yet

- Guidelines Releasing New Connect Augmentation May08Document6 pagesGuidelines Releasing New Connect Augmentation May08ZIPDASHNo ratings yet

- Turbine Heat Rate Calculation - 210 MWDocument8 pagesTurbine Heat Rate Calculation - 210 MWAndri YantoNo ratings yet

- Welding Rod Consumption ControlDocument1 pageWelding Rod Consumption Controlalaid melarNo ratings yet

- Exide BtryDocument94 pagesExide BtryDivya ThakkerNo ratings yet

- List of PowerGrid ManualsDocument3 pagesList of PowerGrid ManualsAnonymous 2l8XJIVNo ratings yet

- Gri 101 Foundation 2016 PDFDocument30 pagesGri 101 Foundation 2016 PDFIlhamAkbarN.NasutionNo ratings yet

- 32 Volt-100 AmpDocument4 pages32 Volt-100 AmpsagarscorpionNo ratings yet

- Docklands: A Decade of TransformationDocument47 pagesDocklands: A Decade of TransformationWill Ntrix Postlethwaite100% (1)

- Speedmaster Inverter PDFDocument66 pagesSpeedmaster Inverter PDFRICHIHOTS2No ratings yet

- Flygt Dewatering Handbook Us PDFDocument68 pagesFlygt Dewatering Handbook Us PDFMechanical MaintenanceNo ratings yet

- CT Details Rishabh MakeDocument31 pagesCT Details Rishabh MakeSanjeev DhariwalNo ratings yet

- Belarus English 90-92Document222 pagesBelarus English 90-92njudit850% (2)

- The Future of Oil and Gas Business: Development of Local Content in Mozambique post-COVID-19Document11 pagesThe Future of Oil and Gas Business: Development of Local Content in Mozambique post-COVID-19manuel machavaNo ratings yet

- CT123012 - PXV - en - 0910Document2 pagesCT123012 - PXV - en - 0910elshan_asgarovNo ratings yet

- Boiler Feedwater Pump Balancing LineDocument2 pagesBoiler Feedwater Pump Balancing LineYanuar Krisnahadi0% (1)

- Vibration Monitoring 1Document4 pagesVibration Monitoring 1Anonymous DKv8vpNo ratings yet

- UatDocument108 pagesUatdhirendraNo ratings yet

- LT bill details for mobile towerDocument2 pagesLT bill details for mobile towerAMolNo ratings yet

- Air Curtain Catalog 2017 NewDocument7 pagesAir Curtain Catalog 2017 NewME SHOPNo ratings yet

- Plate Cooling TechnologyDocument8 pagesPlate Cooling TechnologyVivek SharmaNo ratings yet

- Selco Full CaseDocument18 pagesSelco Full CaseankhisNo ratings yet

- PDF Fasa Support CTLG 3af011 1710e 01 PDFDocument67 pagesPDF Fasa Support CTLG 3af011 1710e 01 PDFTechno AirNo ratings yet

- Non Destructive Testing of Rotors From The BoreDocument2 pagesNon Destructive Testing of Rotors From The BorePankaj KambleNo ratings yet

- The Role of The Agency For Export Promotion and Investment AttractionDocument14 pagesThe Role of The Agency For Export Promotion and Investment AttractionNatalita Rucavita0% (1)

- Energy Utilization IndexDocument3 pagesEnergy Utilization IndexRobertNo ratings yet

- HRW 20090301 Mar 2009Document68 pagesHRW 20090301 Mar 2009st_calvoNo ratings yet