Professional Documents

Culture Documents

NPCIL Tube Fitting Specifications

Uploaded by

sumant.c.singh1694100%(1)100% found this document useful (1 vote)

418 views22 pageshhh

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenthhh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

418 views22 pagesNPCIL Tube Fitting Specifications

Uploaded by

sumant.c.singh1694hhh

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 22

NUCLEAR POWER CORPORATION OF INDIA LTD.

(A Govt. of India Enterprise)

SPECIFICATION NO. : PC-E- 274

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS.

REF. USI NO: 60614

REVISION NO. : 0

DATE OF ISSUE

(MONTH/YEAR)

: MAY, 2009

TOTAL NO. OF PAGES

(Including cover sheet &

Revision control sheet)

: 22

ORIGINAL

PREPARED BY: NARAYAN MANDAL, EE(C&I-PC)

A.S.N. IYER, DCE (C&I-PC)

CHECKED BY: CH. SRINIVASA RAO, ACE (C&I-PC)

REVIEWED BY: B.P. MAHESHWARI, CE (FHAC)

APPROVED BY: ANAND BEHRE, SO/H (C&I-PC)

(Name & Designation) (Signature) (Date)

(FOR REVISIONS - SEE REVISION CONTROL SHEET)

File Name: PC-E-274-R0.doc

REVISION CONTROL SHEET

DOCUMENT TYPE : TECHNICAL SPECIFICATION

NO. : PC-E-274 /Rev No. 0

TITLE : TECHNICAL SPECIFICATION ON

STAINLESS STEEL COMPRESSION TYPE TUBE

FITTINGS

REV. NO.

&

DATE

DESCRIPTION

OF

REVISION

REVISED BY

NAME &

SIGNATURE

CHECKED

BY NAME &

SIGNATURE

REVIEWED

BY NAME &

SIGNATURE

APPROVED

BY NAME &

SIGNATURE

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 1 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

1.0 SCOPE :

This specification covers the general technical requirements for the design,

manufacture, inspection, testing and supply of stainless steel compression type

(flareless) tube fittings in Instrumentation applications.

2.0 CONTENTS

1.0 SCOPE

2.0 CONTENTS

3.0 APPLICABLE, STANDARDS, SPECIFICATIONS

& DRAWINGS

4.0 MATERIALS PROCESSES

& WORKMANSHIP

5.0 REQUIREMENTS

6.0 INSPECTION AND TESTING

7.0 DOCUMENTATION

8.0 IDENTIFICATION

9.0 PACKING & SHIPPING

ANNEXURE 1 SAMPLE QUALITY ASSURANCE PLAN

TABLE- I DIMENSIONAL TOLERANCES OF TUBE

FITTINGS

TABLE-II DIMENSIONAL TOLERANCES OF SS TUBES

3.0

APPLICABLE STANDARDS , SPECIFICATIONS & DRAWINGS :

All the specifications and standards listed below, of the issue in effect on the date

of the pertinent tendering documents, apply as specified herein. In the event of

any conflict between the provisions of this specification and the documents listed

below, this specification shall govern -

ANSI- B-1.1 Unified Inch screw threads (UN and UNR Thread

Form) equivalent for tube end.

ANSI-B.1.20.1 - Pipe threads, general purpose

ASME Boiler and - Section III, Division I, Sub-Section NB for

Pressure Vessel Code Class -I components

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 2 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

ASTM-A-213 Standard Specification for Seamless ferritic &

austenitic alloy steel boiler super heater and heat

exchanger tubes.

SA-370 Specification for mechanical testing of steel product

ASTM-A-262 - Standard Practices for detecting susceptibility to

Inter granular attack in austenitic stainless steels

ASTM-A-276 - Standard Specification for Stainless Steel bars &

Shapes.

ASTM-A-314 - Standard Specification for Stainless steel billets and

bars for forging

ASTM-A-473 - Standard Specification for Stainless Steel Forgings

PP-M-107 - Technical specification for Seamless austenitic SS

tubing.

PP-P-198 - General Cleaning & handling requirements for

D2O/helium Services

SAE-J-514 - Hydraulic tube fittings

PB-P-541 - Methods and procedure for seismic qualification of

valves; panels devices; rotating and reciprocating

equipment; tanks, vessels, piping and supports.

PP-P-2014 - Procedure for ultrasonic examination of steel

forgings for general purpose.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 3 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

4.0 MATERIALS, PROCESSES & WORKMANSHIP :

4.1 Material, Processes And Parts

Materials, processes and standard parts shall be of good commercial quality and

in accordance with good practices pertinent to the manufacture of high quality

fittings for Nuclear Power Plants. All components of finished product shall have

material traceability

4.2 Workmanship

Workmanship shall be in accordance with high grade commercial practice

adequate to ensure satisfactory operation and service life. Fittings shall be free

from all burrs, loose scales and sliver which might become dislodged in usage

and all other defects which might affect their serviceability. All sealing surfaces

must be smooth to 0.8 microns(max).

No tool marks shall be permitted on the sealing surfaces. On the other surfaces

annular tool marks upto a maximum of 3 microns may be permitted.

5.0 REQUIREMENTS :

5.1 General

The tube fittings shall be capable of continuous satisfactory service over a period

of 40 years with minimum attention. Long term reliability under varying service

conditions is of prime importance and the use of high quality materials,

components, tools, equipments etc. in manufacturing and inspection of these

fittings is therefore required.

5.2 Material Requirements

Straight bodies, nuts and ferrules shall be from SS 316 conforming to ASTM-A-

276. Forgings shall conform to ASTM-A-314 & A-473. These fittings shall be

suitable for use on S.S. 304 L tubing conforming to ASTM-A-213 and NPCIL

specification PP-M-107, but with dimensional tolerances as per Table-II of this

specification.

5.3 Service Conditions

The fittings shall be suitable for the service under the following conditions -

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 4 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

Process Fluid : D

2

O/Water, air, hydraulic oil, steam, nitrogen, and helium

Maximum working pressure of process fluid - 200 kg/cm

2

(g)

Maximum working temperature - 325

o

C

5.4 Design and Construction

The compression fittings are those which require no preparation of the ends of the

tube other than that they are cut square, and in which the joint is made by

compression of two ferrules, on to the outside wall of the tube. The design of

these fittings shall be such as to permit tube entry and fitting make up without

removal of the nut and ferrules. All components shall be of the same material as

the fitting body for thermal compatibility and corrosion resistance.

Abrupt reductions of sections shall be avoided. Sharp corners of inadequate

fillets, excessive under cuts or excessive grooves at the junction of small sections

with large sections of fittings shall be avoided.

Unless otherwise specified, each socket shall be provided with an internal

shoulder or stop against which the inserted tube cut square with its axis, shall

abut. Bore-through fittings will not have any internal shoulder.

5.5 Designation of Sizes of Fittings

The fittings shall be designated with the outer diameter of the tube with which

it is to be used.

5.6 Wall Thickness, Overall Dimensions and Pressure Rating

Unless otherwise specified the wall thickness and overall dimensions of fitting

shall conform to SAE-J-514. However, the wall thickness of assembled fitting at

any point shall not be less than thickness established by ASME-Section III, Sub-

Section NB for the required service conditions (pressure and temperature rating).

5.7 Dimensional Tolerances

Dimensional tolerances for the various components of fittings shall be such, that

interchangeability of components of same size of fittings is possible.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 5 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

The dimensional tolerances on Internal Diameter (ID)of nut, ferrules and body

are given in Table-I for reference.

These fittings shall be suitable for use with S.S. tubing conforming to ASTM-A-

213 and NPCIL specification PP-M-107. However these tube fittings shall be

suitable for use with tube hardness in the entire range of 65 RB to 80 RB. The

dimensional tolerances of SS tubes proposed to be used with these fittings, are

given in Table-II.

5.8 Hardness

Hardness of the body and nut shall be in the range of RB 70 to RB 90.

Pull out strength, leak tightness, assembly-re-assembly and other performance

requirements covered in Section 6.0 are generally achieved by maintaining proper

hardness values for front ferrule, back ferrules and at the tip portion of the back

ferrule (The ferrule hardness shall not be less than Rockwell-B-90).

Bidder shall justify, how these functional requirements are met in the offered

fittings, indicating hardness values for front ferrules, back ferrules and at the tip

portion of the back ferrule.

5.9 Screw Threads

All Taper Pipe Threads (NPT) shall be in accordance with ANSI B-1.20.1

Straight threads shall be unified screw threads conforming to Class 2A and 2B of

ANSI-B-1.1. Threads conforming to the other standards shall be subject to the

approval of the Purchaser. Silver coating on Nut threads shall be done to avoid

galling during assembly.

5.10 PERFORMANCE

5.10.1 General

These tube fittings must be capable of working with(without leakages or failure)

various fluids (including Helium)at low or high temperature, from vacuum to high

pressures. They should have sealing capacity to hold all fluids as well as gripping

capability to withstand axial, lateral and torsional forces met within industrial

tubing installations.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 6 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

All the parts of the fittings should be concentric and should be capable of self-

alignment when assembled with the tubing specified in PP-M-107 Fittings should

not create torque or leave residual strain on tubing. They should have enough

tube support ahead of the seal to resist any vibration. They should not weaken the

tube wall. They should not significantly reduce flow area. They should have a

residual spring condition so that temperature cycling will not cause leakage. The

design of the fittings should be such that they should not require any special tools

for assembly and disassembly of the fittings.

The tube fittings when assembled with the recommended tubes must be capable of

withstanding the following types of forces, in any possible combination :

a) Internal pressure & pressure cycling

b) Tension or axial pull

c) Compression or axial push

d) Torque or twist

e) Vibration.

f) Temperature variation

Any combination of all the above forces is possible.

5.11 Cleanliness

The fittings shall be free from any metal particles, contaminant and other forms of

dirt. Manufacturer shall follow the Purchasers instructions specified in PP-P-198

General Cleaning and Handling Requirements for Instruments and Fittings for

use in Heavy Water and Helium Services. Failure to meet this requirement shall

result either in rejection or clean-up of all the fittings at the discretion of the

Purchaser. Fittings in the made-up condition shall be suitably heat sealed in

polythene bags and shall be stored in clean storage. Manufacturer shall submit

detailed cleaning and packing procedures along with his bid.

5.12 Lubricants And Sealants

The manufacturer shall specify if any lubricants or sealants are required and give

details of availability, composition, method of use etc. These compounds shall be

Sulphur and halogen free.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 7 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

5.13 Installation Procedures

The manufacturer shall provide the recommended installation procedures and the

list of installation tools. A sample copy of the instruction manual shall be

submitted with the bid.

6.0 INSPECTION AND TESTING

6.1 General

The contractor shall be responsible for, and perform all the inspection and testing

specified herein in a manner satisfactory to and subject to the approval of the

Purchaser.

The manufacturer shall supply all the materials required for testing. He shall

prepare and arrange the necessary test pieces and provide the personnel and

equipments for such testing as may be carried out at his premises in accordance

with this Specification. In the absence of such facilities at his works for

conducting the tests, the manufacturer shall, at his own expense, arrange for the

tests to be carried out elsewhere.

The Purchaser or his authorized representative shall have access to the

Contractors and Sub-Contractors premises at all reasonable times to the extent

necessary to assess compliance with the provisions of this specification. The

Purchaser or his authorized representative shall be offered all reasonable facilities

to satisfy himself that the fittings are being manufactured in accordance with this

Specification.

The Purchaser shall also have the right to conduct at his own expense any

additional inspection or testing deemed necessary by him, to confirm the

compliance with the provisions of this specification.

6.2 Inspection

The fittings shall be inspected to determine conformance with all the provisions of

this Specification with respect to material, workmanship and cleanliness.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 8 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

6.3 Tests

6.3.1 General

The Contractor shall notify the Purchaser, the date and location of performing

the tests, giving sufficient notice to enable the Purchaser or his authorized

representative to be present.

The test procedure shall be proposed by the Contractor and approved by the

Purchaser. The contractor shall provide all the test equipments required.

The Purchaser or his authorized representative shall have access to the calibration

certificates of the test equipments used for these tests.

The random samples (around 50 nos.)required for prototype qualification tests

shall be selected by the Purchaser or his authorized representative from the bulk

lot and the samples selected for testing shall not form part of the bulk quantity to

be supplied against the purchase order.

Before performing the test the tube fitting samples shall be assembled with

appropriate S.S. 304 L tubing as per PP-M-107. While making the assembly the

recommended assembly procedure/steps shall be followed.

6.3.2 Prototype Qualification:

If called for in the tender/purchase order, the contractor will manufacture a

limited number of sample fittings of various types and sizes (about 200Nos.)as

prototype fittings and offer to the purchaser for their detailed evaluation. Out of

these, a few (about 50 Nos.)randomly selected fittings of different types and sizes

shall be subjected to all the tests mentioned in section 6.3.3. Subsequently

Prototype fittings of each size shall be subjected to seismic qualification test. The

fitting shall be assembled so as to give unsupported tube length of 0.5 metre and

the seismic vibration tested in accordance with NPCIL Specification PB-P-541,

such that the Test Response Spectrum (TRS) envelops the Required Response

Spectrum(RRS) .

During the test, the assembled fitting shall be internally pressurized to 200

kg/cm2(g), keeping the tube end plugged/crimped.

There shall be no physical damage to the fitting, and no leakage observed during

the seismic test.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 9 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

The test setup (.i.e. mounting of assembly on vibration table) and detailed test

procedure shall be proposed by the manufacturer and subject to approval of the

purchaser.

There shall be no physical damage to the fitting, and no leakage observed during

the seismic test.

All the tests will be witnessed by the purchasers authorized representative. The

bulk production shall be started only after approval of the prototype fittings by the

purchaser.

6.3.3 Acceptance Tests :

Following tests shall be carried out on each lot of the fittings.

6.3.3.1 Tests on Raw Material

Raw material for body, nut and ferrules shall be tested for physical properties

(i.e. tensile strength, percentage elongation, hardness etc.), chemical analysis,

IGC and ultrasonic tests as per the relevant ASTM standards such as ASTM-A-

276, ASTM-A- 262 and NPCIL specification PP-P-1214. Physical test, chemical

analysis and IGC shall be carried out on the sample from each heat, whereas

ultrasonic test shall be carried out on 100% quantity.

6.3.3.2 Dimensional Checks

The following dimensional checks shall be carried out on 1% quantity of each

size and type of fittings (minimum 5 numbers) randomly selected by the

purchaser from each lot.

a) Complete checks of threads with the appropriate gauges/measuring

instruments..

b) Micrometer check on tool relief diameter.

c) Complete check of various dimensions of all components of fittings .

d) Visual check under magnification of ferrule surfaces, body seats and

threads.

e) Inspection of fittings for any forging imperfections (wherever applicable).

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 10 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

6.3.3.3 Hardness Test

One body, one nut, one front ferrule and one back ferrule of each size which have

passed the dimensional checks shall be tested to check the hardness to confirm the

requirement as per Section 5.8. These fittings shall not be taken for any other

tests.

6.3.3.4 Pull Out Test

The test is needed to establish that in tube fitting assembly the tension load

required to pull out the tubing out of the fitting, is much more than the force

exerted by rated hydrostatic test pressure. Three fittings of each size from each

lot shall be subjected to pull out test.

The test assembly shall be placed in a tension testing machine. The tension load

on the tube shall be increased at a rate not more than 55 kg/minute. The tension

load required to pull out the tube from tube fitting assembly shall be recorded.

The tension load shall be at least 4 times the force exerted by rated hydrostatic

test pressure. The remaining tests (i.e. tests mentioned in sections 6.3.3.5 thru

6.3.3.12) shall be continued only after successful completion of pull out test and

shall be performed on fresh samples. The failure of pull out test abandons all

further tests and will be a cause for rejection of lot.

6.3.3.5 Hydrostatic Test :

1% quantity from lot of each size of fittings, randomly selected from the fittings

checked for the dimensions and hardness shall be selected for hydrostatic test.

The fittings and their component parts when assembled with SS tubing as per PP-

M-107, shall be subjected to internal hydrostatic test pressure of 300 kg/cm

2

(g).

The pressure shall be applied gradually at the rate of 1.5 to 3.5 kg/cm

2

(g) per

second and maintained at the test pressure for not less than 10 minutes. No

deformation or visual leakage shall be seen in any of the fittings. The tested fitting

samples shall be dried thoroughly before proceeding for further tests

6.3.3.6 Air Leak Test :

All the fittings which have undergone hydrostatic test shall be subjected to Air

Leak test. The fittings and their component parts when assembled with SS tubing

as per PP-M-107 shall be capable of withstanding an internal air pressure of 7

kg/cm

2

(g). The pressure shall be maintained for not less than 10 minutes and the

appearance of bubbles from any fitting when immersed in water, shall cause for

rejection.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 11 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

6.3.3.7 Re-assembly Test :

Two fittings of each size from the fittings undergone hydrostatic and air leak tests

shall be subjected to 25 assemblies and re-assemblies with SS-304 L tube as per

PP-M-107.

After every fifth re-assembly, the fittings shall pass hydrostatic test as per Section

6.3.3.5. and air leak test as per Section 6.3.3.6.

6.3.3.8Temperature Cycling :

At least one fitting of each size which has undergone re-assembly test shall be

subjected to three temperature cycles, each of approximately 4 hours duration. In

each cycle, time taken to reach the highest temperature (325

o

C) from the lowest

(27

o

C) shall not be less than one hour and not more than 1 hours. Then the

fittings shall be kept at the highest temperature for one hour. The temperature

shall then be brought down to the lowest value in 1 to 1 hours. At the end of

the test, the fitting shall pass the air leak test as specified in Section 6.3.3.6.

6.3.3.9 Pressure Cycling

All the fittings which have undergone temperature cycling shall be subjected to

pressure cycling test comprising of pressurizing to 200 kg/cm

2

(g) and suddenly

depressurizing to a pressure of 1 kg/cm

2

(g) or less, at a rate of 30 to 100

cycles/minute for minimum 10

5

cycles. At the end of this test the fitting shall be

subjected to and shall pass the air leak test as specified in Section 6.3.3.6.

6.3.3.10Vibration (Non-Seismic) Test :

The assembled fittings shall be capable of withstanding non-seismic vibration

without any leak or fatigue failure. All the fittings which have undergone

pressure cycling shall be subjected to non-seismic vibration test.

The fittings shall be assembled so as to give an unsupported tubing length of 0.5

metre and subjected to vibrations for at least 5 x 10

5

cycles in each of two

mutually perpendicular directions. The frequency shall be 25 to 50 cycles per

second and the amplitude of oscillation shall be such so as to stress the tube to

25% of its tensile yield.

The fitting shall be rigidly fixed on a static test platform and the free end of the

tubing shall be subjected to vibrations. During vibration test the tube fitting

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 12 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

assembly shall be subjected to an internal pressure of 200 kg/cm

2

(g). The tube

fitting assembly may be pressurized from tube fitting end, keeping the tube end

plugged/crimped. The amplitude of oscillation shall be calculated based on

actual value of unsupported tube length in the test set up. At the end of this test

the fitting assemblies shall pass the air leak test as specified in Section 6.3.3.6.

The overall test procedure/test set up for this test shall be proposed by the

supplier/vendor and shall be subject to Purchasers approval.

6.3.3.11 Helium Leak Test

At least one fitting of each size, randomly selected from the lot of the

dimensionally checked fittings (as per section 6.3.3.2) and all the fittings which

have undergone all above tests upto non-seismic vibration test, shall be subjected

to helium leak test. The helium test pressure shall be 1 kg/cm

2

(g). Overall leak

rate shall not exceed 10

-6

standard cc/sec.

6.3.3.12 Final Pull Out Test

All the fittings which have undergone the tests mentioned in Section 6.3.3.5 thru

6.3.3.11 shall be subjected to final pull out test as specified in section 6.3.3.4.

6.3.3.13 Inspection And Test Failure

In the event of failure of sample fittings from a lot to meet the inspection and test

requirements specified herein, the entire lot will be rejected and the contractor

shall notify the Purchaser or his authorized representative.

7.0 DOCUMENTATION :

Schedules of submission of various documents by the Contractor are given in

following sections. All the documents shall be signed by the authorized

representative of the Contractor.

7.1 Documents to be furnished by the bidder alongwith the offer

All the documents listed below shall be furnished in triplicate along with the

offer.

a) Detailed technical literature on the offered fittings, indicating various

types, sizes, dimensions, material of construction, service conditions, tests

carried out, installation procedures, applicable standards etc.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 13 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

b) List of in-house manufacturing facilities.

c) List of in-house inspection and test facilities.

d) Standard QA plan followed by the bidder in the manufacture of tube

fittings, indicating incoming/in-process and final inspection & testing.

e) Quality Manual of the company.

f) Reference list of the customers to whom similar fittings have been

supplied and operating satisfactorily, indicating quantities supplied,

purchase order reference, order values, scheduled delivery dates and actual

dates of supply.

g) Lists of suppliers/sub-vendors of various materials and components used

in manufacturing of the SS tube fittings.

h) Point wise confirmation on each clause of this specification explaining

how the requirements are being met.

i) Copies of the test reports if the offered fittings have earlier undergone

various tests mentioned in this specification.

7.2 Documents required to be furnished immediately after placement of

Purchase Order

Immediately after placement of purchase order, three copies of following

documents shall be submitted for the Purchasers review and approval. The

Contractor shall commence manufacturing/testing of the equipment only after

specific approval of the relevant documents by the Purchaser.

a) General arrangement drawing of each type of fittings indicating overall

dimension, component dimensions and tolerances, material of construction

of each component hardness values, finish etc.

b) Detailed quality assurance plan indicating incoming, in-process and final

inspection and tests.

c) Detailed procedures for all the tests to be carried out on the equipment.

7.3 Documents required to be furnished alongwith the supply

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 14 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

a) Five copies of all as-built drawings, bill of material as covered in section

7.2 (a) along with their reproducibles.

b) Six copies of operation and maintenance manual giving functional

description, descriptive and illustrative literatures of all the components

sub assemblies, installation procedure etc. Six soft copies of the same shall

also be supplied in the form of CD/DVD .

c) Six sets of history dockets containing all material certificates/reports and

test reports. Six soft copies of the same shall also be supplied in the form

of CD/DVD.

In addition to the above, the manufacturer shall supply in triplicate,

certificate of compliance stating that the material supplied is in accordance

with all the provisions of this specification.

8.0 IDENTIFICATION : Each fitting shall be individually packed in a cellophane

bag along with an identification slip bearing the part number of the fitting.

Fittings of each type and size shall be packed in separate packages. All the

packages shall be clearly and legibly marked in suitable permanent manner with

the following information :

a) Purchase Order Number of the Purchaser

b) Item number of the Purchase Order

c) Details of the fittings and quantity of each type of fittings in the packages

9.0 PACKING & SHIPPING :

The Contractor shall make adequate provisions to protect the fittings supplied to

this Specification to ensure that, on arrival at the generating station or elsewhere

as may be advised by the Purchaser and after storage as may occur, they will not

have suffered corrosion, damage, or deterioration of any sort. The threads of all

the fittings shall be protected with suitable plastic caps/plugs. The packing shall

be suitable for tropical climate.

In no case will the supplier ship the material without obtaining written permission

or shipping release from the buyer or his authorized representative. Material shall

be shipped only after completion of all inspection and test formalities.

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 15 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

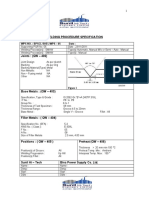

TABLE - I

DIMENSIONAL TOLERANCES OF TUBE FITTINGS

DIMENSIONAL TOLERANCES OF TUBE FITTINGS IN METRIC SIZES

Size of

Fittings (Tube

O.D.)

Nut

ID

mm

Front ferrule

ID

mm

Back ferrule

ID

mm

Body

ID

mm

3 mm. 3.20

3.13

3.20

3.13

3.20

3.13

3.20

3.13

6 mm. 6.20

6.13

6.20

6.13

6.20

6.13

6.20

6.13

10 mm. 10.20

10.13

10.20

10.13

10.20

10.13

10.20

10.13

12 mm. 12.20

12.13

12.20

12.13

12.20

12.13

12.20

12.13

16 mm 16.22

16.15

16.22

16.15

16.22

16.15

16.22

16.15

18 mm. 18.22

18.15

18.22

18.15

18.22

18.15

18.22

18.15

20 mm. 20.22

20.15

20.22

20.15

20.22

20.15

20.22

20.15

25 mm 25.22

25.15

25.22

25.15

25.22

25.15

25.22

25.15

DIMENSIONAL TOLERANCES OF TUBE FITTINGS IN INCH SIZES

Size of

Fittings (Tube

O.D.)

Nut

ID

mm

Front ferrule

ID

mm

Back ferrule

ID

mm

Body

ID

mm

1/8 (0.125) 0.133

0.130

0.133

0.130

0.133

0.130

0.133

0.130

1/4 (0.250) 0.258

0.255

0.258

0.255

0.258

0.255

0.258

0.255

1/2 (0.500) 0.508

0.505

0.508

0.505

0.508

0.505

0.508

0.505

5/8 (0.625) 0.633

0.630

0.633

0.630

0.633

0.630

0.633

0.630

3/4 (0.750) 0.758

0.755

0.758

0.755

0.758

0.755

0.758

0.755

1"(1.000) 1.010

1.007

1.010

1.007

1.010

1.007

1.010

1.007

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 16 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

TABLE- II

DIMENSIONAL TOLERANCES OF SS TUBES

DIMENSIONAL TOLERANCES OF SS TUBES (METRIC SIZES)

Outside dia (mm) Wall thickness (min.)

(mm)

Tolerances on O.D. (mm)

3 1.0 -0.00 + 0.10

6 1.2 -0.00 + 0.10

10 1.2 -0.00 + 0.10

12 1.5 -0.00 + 0.10

16 1.8 -0.00 + 0.12

18 2.1 -0.00 + 0.12

20 2.5 -0.00 + 0.12

25 3.0 -0.00 + 0.12

DIMENSIONAL TOLERANCES OF SS TUBES (INCH SIZES)

Outside dia inch Wall thickness (min.) inch Tolerances on O.D. inch

1/8 0.018 -0.000 + 0.002

1/4 0.049 -0.000 + 0.004

3/8 0.035 -0.000 + 0.004

3/8 0.049 -0.000 + 0.004

1/2 0.065 -0.000 + 0.005

5/8 0.065 -0.000 + 0.005

3/4 0.095 -0.000 + 0.005

7/8 0.095 -0.000 + 0.005

1 0.109 -0.000 + 0.005

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 17 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

ANNEXURE-I

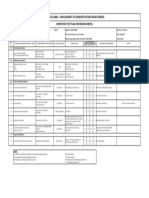

11. SAMPLE QUALITY ASSURANCE PLAN FOR STAINLESS STEEL COMPRESSION TYPE (FLARELESS) TUBE

FITTINGS

SL.

NO.

1

COMPONENT/

OPERATION

2

CHARACT-

ERISTIC

3

TYPE

OF

CHECK

4

CLASSIF-

ICATION

5

QUANTUM

OF CHECK

6

REFERENCE

DOCUMENT

7

ACCEPTANCE

NORMS

8

FORMAT

OF

RECORD

9

AGENCY

(P)(W)(V)

10

REMARK

11

1.0

RAW MATERIAL

Material for

body, nut &

ferrules

Chemical

Composition

Chemical

Analysis

MA

Sample from

each heat

Applicable

standards

Applicable

Standards

Test Report

3 2 1

To be done

in NPCIL

Approved

Lab

Non destructive

examination

Ultrasonic

Test

MA

100%

As per

PP-P-1214

ASTM

Standard

Test Report

3 2 1

To be done

in NPCIL

Approved

Lab

Physical

properties

Tensile

Strength

Hardness &

IGC Test

MA

Sample from

each heat

Applicable

standards

Applicable

Standards

Test Report

3 2 1

To be done

in NPCIL

Approved

Lab

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 18 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

SL.

NO.

1

COMPONENT/

OPERATION

2

CHARACT-

ERISTIC

3

TYPE

OF

CHECK

4

CLASSIF-

ICATION

5

QUANTUM

OF CHECK

6

REFERENCE

DOCUMENT

7

ACCEPTANCE

NORMS

8

FORMAT

OF

RECORD

9

AGENCY

(P)(W)(V)

10

REMARK

11

2.0

IN PROCESS/ROUTINE TEST

2.1 Checks on

Components

Threads Check Gauging MA 100% Manufact-urers

drawings

Manufact-urers

drawings

IQC Records 2 2 1

Dimensional

check on body,

nut, front

ferrule and back

ferrule

Measur-

ement

MA 100% Manufact-urers

drawings

Manufact-urers

drawings

IQC Records 2 2 1

2.2

Assembled

Fittings

Finish Visual MA 100% Manufact-urers

drawings

As per NPCIL

approved

drawing

Test Report 2 2 1

Overall

Dimensions

Measur-

ement

MA 100% Manufact-urers

drawings

As per NPCIL

approved

drawing

Test Report 2 2 1

3.0

ACCEPTANCE TEST

3.1 Body Dimensional

check

Measure-

ment

MA 2% of the lot NPCIL

approved

drawings

NPCIL approved

drawings

Test Report

2 1 1

Hardness Hardness

Test

MA 1 sample from

each lot

As per 4.8 of

PP-E-577

As per 4.8 of PP-

E-577 and plant

standard

Test Report 2 1 1

3.2 Nut Dimensional

check

Measure-

ment

MA 2% of the lot NPCIL

approved

drawings

NPCIL approved

drawings

IQC Records 2 1 1

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 19 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

SL.

NO.

1

COMPONENT/

OPERATION

2

CHARACT-

ERISTIC

3

TYPE

OF

CHECK

4

CLASSIF-

ICATION

5

QUANTUM

OF CHECK

6

REFERENCE

DOCUMENT

7

ACCEPTANCE

NORMS

8

FORMAT

OF

RECORD

9

AGENCY

(P)(W)(V)

10

REMARK

11

Hardness Hardness

Test

MA 1 sample per

size from each

lot

As per 4.8 of

PP-E-577

As per 4.8 of PP-

E-577 and plant

standard

Test Report 2 1 1

3.3 Front Ferrule Dimensional

check

Measure-

ment

MA 2% of the lot NPCIL

approved

drawings

NPCIL approved

drawings

IQC Records 2 1 1

Hardness Hardness

Test

MA 1 sample per

size from each

lot

As per 4.8 of

PP-E-577

As per 4.8 of PP-

E-577 and plant

standard

Test Report 2 1 1

3.4 Back Ferrule Dimensional

check

Measure-

ment

MA 2% of the lot NPCIL

approved

drawings

NPCIL approved

drawings

IQC Records 2 1 1

Micro Hardness Micro

Hardness

Test

MA 3 samples per

size from each

lot

As per 4.8 of

PP-E-577

As per 4.8 of PP-

E-577 and plant

standard

Test Report 2 1 1

3.5 Assembled

Fitting

Dimensional

check

Measure-

ment

MA 2% from each

lot

NPCIL

approved

drawings

NPCIL approved

drawings

IQC Records 2 1 1

3.5.1 Assembled

Fitting

Tension pull out

test

Perform-

ance

MA 1 fitting from

each size

As per 6.3.3.3

& 6.3.3.12 of

PP-E-577

NPCIL

Approved Test

Procedure

Test Report 2 1 1

3.5.2 Assembled

Fitting

Material

integrity and

strength

Hydro-static

Test

MA 1% of fitting As per NPCIL

approved test

procedure

As per NPCIL

approved test

procedure

Test Report 2 1 1

3.5.3 Assembled

Fitting

Leak tightness Air Leak

Test

MA 1% of fitting As per NPCIL

approved test

procedure

As per NPCIL

approved test

procedure

Test Report 2 1 1

NUCLEAR POWER CORPORATION OF INDIA LTD.

TECHNICAL SPECIFICATION

ON

STAINLESS STEEL COMPRESSION TYPE TUBE FITTINGS

Page 20 of 20

Rev. 0

60614/PC-E-274 MAY, 2009

SL.

NO.

1

COMPONENT/

OPERATION

2

CHARACT-

ERISTIC

3

TYPE

OF

CHECK

4

CLASSIF-

ICATION

5

QUANTUM

OF CHECK

6

REFERENCE

DOCUMENT

7

ACCEPTANCE

NORMS

8

FORMAT

OF

RECORD

9

AGENCY

(P)(W)(V)

10

REMARK

11

3.5.4 Assembled

Fitting

Reusability Re-assembly

Test

2 fittings from

each size

As per NPCIL

approved test

procedure

As per NPCIL

approved test

procedure

Test Report 2 1 1

3.5.5 Assembled

Fitting

Performance Temper-

ature cycling

test

MA 1 fitting from

each size

As per NPCIL

approved

procedure

As per NPCIL

approved

procedure

Test Report 2 1 1

3.5.6 Assembled

Fitting

Performance Pressure

Cycling Test

MA 1 fitting from

each size

As per NPCIL

approved

procedure

As per NPCIL

approved

procedure

Test Report 2 1 1

3.5.7 Fitting Assembly Performance Non-

Seismic

Vibration

MA 1 fitting from

each size

As per NPCIL

approved

procedure

As per NPCIL

approved

procedure

Test Report 2 1 1

3.5.8 Fitting Assembly Performance Seismic

Vibration

Test

MA 1 fitting from

each size

As per NPCIL

approved

procedure

As per NPCIL

approved

procedure

Test Report 2 1 1 To be

carried out

only on

prototype

fittings

3.5.9 Fitting Assembly Leak Tightness Helium

Leak Test

MA Quantity as per

Clause

6.3.3.11

PP-E-577

As per NPCIL

approved

procedure

As per NPCIL

approved

procedure

Test Report 2 1 1

3.6 Fittings Packing

& Dispatch

Final Assembly Visual MA 100% As per NPCIL

approved

specification

Approved

procedure

-- 2 1 1

LEGEND :

P = Performed by. V=Verified by 1. NPCIL

W = Witnessed by. MA=Major 2. Manufacturer 3. Third Party

You might also like

- Welded Tube Joint SpecDocument8 pagesWelded Tube Joint SpecAvinash ShuklaNo ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- Oil Gas Construction Factory L.L.CDocument2 pagesOil Gas Construction Factory L.L.CRenny DevassyNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- QAP CondenserDocument3 pagesQAP CondenserisaacNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- WPS PQR-05Document10 pagesWPS PQR-05Ranjan KumarNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Asme Section IX - NewDocument70 pagesAsme Section IX - NewAnaswarps100% (2)

- GMAWDocument12 pagesGMAWsushant47No ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDocument3 pagesTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNo ratings yet

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- WPS for FCAW Welding of SteelDocument2 pagesWPS for FCAW Welding of SteelHamid MansouriNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- I-963 Welder Certificate Smaw-Gtaw-1Document1 pageI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Butt JointsDocument21 pagesButt JointsRaj1-23No ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- ITP For Drum Screen InspectionDocument1 pageITP For Drum Screen InspectionkapsarcNo ratings yet

- Equivalent ASME en MaterialsDocument3 pagesEquivalent ASME en MaterialsChee WeiNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Wps Sp14 Reva PDFDocument9 pagesWps Sp14 Reva PDFravi00098No ratings yet

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDocument1 pageSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcNo ratings yet

- PQR WPS RequirementDocument2 pagesPQR WPS RequirementRameshBaskaranNo ratings yet

- Procedure For Ferrit TestingDocument11 pagesProcedure For Ferrit TestingKarrar TalibNo ratings yet

- Madina Trading WPS No. 017Document12 pagesMadina Trading WPS No. 017MAT-LIONNo ratings yet

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocument2 pagesQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNo ratings yet

- WPS-Shell To Tubesheet (CS-SS)Document1 pageWPS-Shell To Tubesheet (CS-SS)suria qaqcNo ratings yet

- QW 442 A Number PDFDocument1 pageQW 442 A Number PDFMadidj_2014No ratings yet

- Finished Goods Packing & Dispatch ProcedureDocument2 pagesFinished Goods Packing & Dispatch ProcedurePratik KarekarNo ratings yet

- TDC 003 - SS Pipes - r0Document1 pageTDC 003 - SS Pipes - r0samkarthik47No ratings yet

- Walk Down Punch ListDocument7 pagesWalk Down Punch ListGomathyselviNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- IRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFDocument3 pagesIRN - 18.07.2019 - Harshad Panchal - Revision-0 - Furnace Fabrica - JNK - PORVAIR - RIL PDFsaptarshi jashNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDocument2 pagesWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNo ratings yet

- WPQDocument10 pagesWPQayoki100% (3)

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Asme PQR DemoDocument3 pagesAsme PQR DemoMuthusamy AyyanapillaiNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument38 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilNo ratings yet

- Pressure Vessel Material Selection GuidelinesDocument3 pagesPressure Vessel Material Selection Guidelinesarjun SinghNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- General Specification FOR Material, Fabrication and Installation of StructureDocument58 pagesGeneral Specification FOR Material, Fabrication and Installation of Structuredang_noex56% (9)

- Steel Piping SpecificationDocument28 pagesSteel Piping Specificationfelixrich100% (2)

- Welding Procedure SpecificationDocument30 pagesWelding Procedure Specificationrahman196011100% (1)

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDocument23 pagesSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisNo ratings yet

- Introduction To Programmable Logic Controllers (PLC'S) : Industrial Control Systems Fall 2006Document47 pagesIntroduction To Programmable Logic Controllers (PLC'S) : Industrial Control Systems Fall 2006Hamidreza MoaddeliNo ratings yet

- L 03 (SS) (Ia&c) ( (Ee) Nptel)Document10 pagesL 03 (SS) (Ia&c) ( (Ee) Nptel)Abdelraheem S. AlkuorNo ratings yet

- Syllabus Weekly Contents MOOC 2015Document8 pagesSyllabus Weekly Contents MOOC 2015sumant.c.singh1694No ratings yet

- GIS Qualification CriteriaDocument4 pagesGIS Qualification Criteriasumant.c.singh1694No ratings yet

- Solar Energy Section 1 1 1 2 PDFDocument8 pagesSolar Energy Section 1 1 1 2 PDFsumant.c.singh1694No ratings yet

- Engineering Online Distance Learning Fees 201617Document2 pagesEngineering Online Distance Learning Fees 201617sumant.c.singh1694No ratings yet

- Corrected MemoDocument1 pageCorrected Memosumant.c.singh1694No ratings yet

- Solar Energy Section 5 AppendixDocument16 pagesSolar Energy Section 5 Appendixsumant.c.singh1694No ratings yet

- BillPayReceiptTataDocomo September 2016Document1 pageBillPayReceiptTataDocomo September 2016sumant.c.singh1694No ratings yet

- Useful physics constants and formulasDocument1 pageUseful physics constants and formulasMensajes De Texto GratisNo ratings yet

- Engineering Online Distance Learning Fees 201617Document2 pagesEngineering Online Distance Learning Fees 201617sumant.c.singh1694No ratings yet

- Rig Component PDFDocument23 pagesRig Component PDFjim carry93% (30)

- TATA DOCOMO - Instant Pay (2 Files Merged)Document4 pagesTATA DOCOMO - Instant Pay (2 Files Merged)sumant.c.singh1694No ratings yet

- Update Alumni Contact FormDocument1 pageUpdate Alumni Contact Formsumant.c.singh1694No ratings yet

- Invoice Service SampleDocument19 pagesInvoice Service SamplefalleppaNo ratings yet

- Document ChecklistDocument1 pageDocument Checklistsumant.c.singh1694No ratings yet

- Technip PCVDocument1 pageTechnip PCVsumant.c.singh1694No ratings yet

- Taxi Receipt Template 04Document1 pageTaxi Receipt Template 04sumant.c.singh1694No ratings yet

- DS 21 M 0012 - 0Document13 pagesDS 21 M 0012 - 0sumant.c.singh1694No ratings yet

- IC Final AuditDocument83 pagesIC Final Auditsumant.c.singh1694No ratings yet

- New Glen Rose Petroleum Application and Interview FormDocument3 pagesNew Glen Rose Petroleum Application and Interview Formsumant.c.singh1694No ratings yet

- Tata Docomo - Instant PayDocument2 pagesTata Docomo - Instant Paysumant.c.singh1694No ratings yet

- SDV 3011 DSDocument1 pageSDV 3011 DSsumant.c.singh1694No ratings yet

- Final Audit Neelam UnmannedDocument98 pagesFinal Audit Neelam Unmannedsumant.c.singh1694No ratings yet

- DS 21 M 0018 - 0Document13 pagesDS 21 M 0018 - 0sumant.c.singh1694No ratings yet

- Corrected MemoDocument1 pageCorrected Memosumant.c.singh1694No ratings yet

- Inapection Report - MCC ComponentDocument4 pagesInapection Report - MCC Componentsumant.c.singh1694No ratings yet

- Cable Schedule Heater 1Document1 pageCable Schedule Heater 1sumant.c.singh1694No ratings yet

- Chandrasekar's ProfileDocument3 pagesChandrasekar's Profilesumant.c.singh1694No ratings yet

- Tax ReportDocument58 pagesTax Reportsumant.c.singh1694No ratings yet

- Thermodynamics - Dilute SolutionsDocument89 pagesThermodynamics - Dilute Solutionsajay kumarNo ratings yet

- Chemical Bonding PropertiesDocument20 pagesChemical Bonding PropertiesHema LataNo ratings yet

- Statement of Work Accomplishment (Swa) Asof:: % Relative WTDocument2 pagesStatement of Work Accomplishment (Swa) Asof:: % Relative WTAljie CañeteNo ratings yet

- 2022 Mechanical Properties of UNS S39274 Superduplex Stainless Steel Work Hardened and Solution AnnealedDocument10 pages2022 Mechanical Properties of UNS S39274 Superduplex Stainless Steel Work Hardened and Solution Annealedvander alkminNo ratings yet

- Basic of Asme Sec IxDocument116 pagesBasic of Asme Sec IxHamid Mansouri100% (1)

- New Process for Acetic Acid Production from Ethylene OxidationDocument6 pagesNew Process for Acetic Acid Production from Ethylene OxidationAgus WahyudhiNo ratings yet

- PHY303-Smart Materials & Devices: Polymer NanocompositesDocument25 pagesPHY303-Smart Materials & Devices: Polymer NanocompositesPrashant KumarNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- 4.accelerated Solvent Extraction - Basics and ApplicationsDocument59 pages4.accelerated Solvent Extraction - Basics and ApplicationsDuc Nhon LENo ratings yet

- Degree of Unsaturation.: Prepared By: Efefany Jane H. JumaritoDocument10 pagesDegree of Unsaturation.: Prepared By: Efefany Jane H. JumaritoJodie Mer DayamaNo ratings yet

- Balance Doc 1Document7 pagesBalance Doc 1Alexa AnguloNo ratings yet

- Welding Traceability ReportDocument1 pageWelding Traceability ReportvinothNo ratings yet

- BS en 12070 PDFDocument13 pagesBS en 12070 PDFMina RemonNo ratings yet

- Learning From AiChEDocument74 pagesLearning From AiChEChuma Khan100% (1)

- English/Metric Gas Flow Rate Conversion ChartDocument1 pageEnglish/Metric Gas Flow Rate Conversion Chartjena_skNo ratings yet

- Design Tables For Flexible PavementDocument11 pagesDesign Tables For Flexible PavementAshebirNo ratings yet

- Clariant FargkartaDocument10 pagesClariant FargkartaJulia ChouNo ratings yet

- Module 6 (Materials & Hardware) SubModule 6.4 (Corrosion)Document30 pagesModule 6 (Materials & Hardware) SubModule 6.4 (Corrosion)Interogator5No ratings yet

- Berat BajaDocument25 pagesBerat BajaAchmad Zaki ZulkarnainNo ratings yet

- Delta MS500 Product Data SheetDocument9 pagesDelta MS500 Product Data SheetAmit KumarNo ratings yet

- Monitor Corrosion RatesDocument3 pagesMonitor Corrosion RatesbtjajadiNo ratings yet

- Standard Pipe Specification EN 10255Document1 pageStandard Pipe Specification EN 10255Burak KececiNo ratings yet

- Spartan: Use Code For Study Material, Personal Mentorship EtcDocument116 pagesSpartan: Use Code For Study Material, Personal Mentorship EtcMilan Kumar , 3815No ratings yet

- Chemical Bonding Agents and MortarsDocument14 pagesChemical Bonding Agents and MortarsakurilNo ratings yet

- 1 Evaluation of Peel BondDocument10 pages1 Evaluation of Peel Bondyok patchnakanNo ratings yet

- For K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Document12 pagesFor K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Ho JamesNo ratings yet

- Buffer Solution 1Document23 pagesBuffer Solution 1Arvit CtkhuNo ratings yet

- IR Unified Standard Schedule of Rates - 2021Document10 pagesIR Unified Standard Schedule of Rates - 2021Vinod KumarNo ratings yet

- Organic Compound NomenclatureDocument31 pagesOrganic Compound Nomenclaturetasneem100% (1)

- Free Knitting Patterns - Leaves Stitch Knitting PatternDocument3 pagesFree Knitting Patterns - Leaves Stitch Knitting PatternN CNo ratings yet