Professional Documents

Culture Documents

PCI-140604e SCC

Uploaded by

Syapril JanizarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCI-140604e SCC

Uploaded by

Syapril JanizarCopyright:

Available Formats

Post-Tensioni ng System Beari ngs & Expansi on Joi nts Mai ntenance, Repair & Strengtheni ng BRIDGES Engi

BRIDGES Engi neeri ng

TRANSMITTAL

Fax. No. : +62 21

Address : esusanto175@gmail.com

To : PT SCC

Proyek YURY Plant III Pulo Gadung.

Pages : 01 (include this page)

Dated : 09 June 2014

Our Ref. : PCI-140604e

Subject : PCI-B207

o Pre-stress Engineering

o Construction Engineering

o Repair & Strengthening

o Bearings & Expansion J oints

o BRIDGES Engineering

PT PRESTRESS CONSTRUCTION

INDONESIA

Address:

Komp. Ruko Sentra Niaga Kalimalang

Blok A1/12A, J l. J end. Ahmad Yani

Bekasi 17144, INDONESIA

Tel.: +62 21 884 6932(H), 8893183

Fax: +62 21 884 8694

Email: hotman@pcindonesia.net

From: Ir. Hotman Sianipar, MTSi.

URGENT FOR REVIEW PLEASE COMMENT PLEASE REPLY PLEASE RECYCLE

Yang terhormat Bp. Eddy

Dalam presentasi ini kami akan tampilkan Balok Prestress PCI-B207 sebagai contoh yang akan

direview.

2. Gaya Prategang

Syarat 0,1 fc Ag:

Dari perhitungan kita dapat:

Ag =1.800.000 mm

2

, sedang kan fc=35 MPa=35 N/mm

2

.

Sehingga 0,1 fc.Ag=0,1 x 35 x 1.800.000=6.300.000 N=6.300 kN.

Gaya efektif yang ada pada balok tersebut adalah:

Gaya pra-tegang=3 x 19 x 96,6 kN=5.506,2 kN.

Kesimpulan: Syarat ini masih bisa terpenuhi.

Prategang memikul 25% dari gaya yang bekerja:

Hal ini akan kami tinjau momen pada balok.

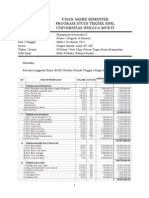

Load case Satuan Tumpuan L Tengah Tumpuan R Mo

SW kN-m -1.270 799 -1270 2.069

SDL kN-m -391 248 -395 641

LL kN-m -3.128 1.984 -3.155 5.125,5

Service kN-m -4.789 3.031 -4.820 7.835,5

Prategang kN-m 2.350 -1.488 2.350 3.838 atau 48,9%

14-06-09 To: Yuri Plant Page - 2 of 3

Post-Tensioni ng System Beari ngs & Expansi on Joi nts Mai ntenance, Repair & Strengtheni ng BRIDGES Engi neeri ng

Terlihat bahwa gaya pra-tegang memikul 48,9% dari beban yang bekerja pada balok. Menurut

kami syarat ini tidak menjadi syarat mutlak karena dalam kasus proyek ini perlu menjadi

pertimbangan bahwa kasus beban akibat LL hampir 250% beban SW.

Untuk kasus ini kami lakukan analisa daktilitasnya dengan melakukan analisan momen curvature

dengan program RESPONSE 2000. Dengan melakukan analisa terhadap penampang balok pada

daerah tumpuan (Momen negatif) dengan memodelkan sebagai penampang rektangular.

Dari hasil momen curvature didapat nilai curvature terbesar adalah 12,11 rad/km.

3. Momen sekunder

Dengan program RAPT yang sangat khusus untuk struktur beton pra-tegang, semua hal yang

berkaitan dengan analisa pra-tegang sudah dilakukan. Dengan menginput profil kabel pra-tegang

perlu, jumlah kabel pra-tegang perlu dan besar gaya penarikan kabel prategang perlu, RAPT

memberikan hasil analisa seperti sbb.:

1. Kehilangan gaya pra-tegang jangka pendek sepanjang kabel pra-tegang.

2. Kehilangan gaya pra-tegang jangka panjang sepanjang kabel pra-tegang.

3. Momen dan gaya geser akibat gaya pra-tegang.

4. Momen sekunder akibat gaya pra-tegang, Page 18/36 dan 19/36.

5. Kapasitas penampang sepanjang balok pra-tegang.

6. Lendutan pada balok pra-tegang baik jangka pendek maupun jangka panjang.

sudahseperti kehilangan gaya pra-tegangKapasitas balok dapat dilihat secara grafis pada

out put RAPT seperti pada Lampiran-2 hal-31 di mana terlihat bahwa sepanjang balok

kapasitas balok masih lebih besar dari pada Momen ultimate yang ada.

Pengaruh kolom/dinding

J ika dilakukan analisa parsial dengan melihat hanya terhadap satu balok pra-tegang akibat gaya

pra-tegang pada lantai yang bersangkutan. Pada kondisi parsial seperti ini didapatkan gaya yang

diserap oleh kolom/dinding akan relatif lebih besar. Namun dari hasil analisa yang pernah kami

lakukan dengan melakukan construction stage pada semua lantai balok pra-tegang. Dengan

memberi gaya pra-tegang pada lantai-lantai di atasnya akan mengurangi gaya yang diserap oleh

kolom/dinding di lantai bawahnya. Pengurangan gaya yang diserap oleh kolom/dinding ini akan

selesai setelah memberikan pra-tegang pada balok di 4 7 lantai di atasnya. Hal ini sangat

dipengaruhi oleh tingkat kekakuan dari kolom/dinding dan sifat tumpuan dasar kolom/dinding,

bersifat jepit atau bersifat sendi.

Terlampir juga kami kirimkan satu kasus study yang pernah dilakukan oleh Mark Fintel dan S. K.

Gosh terhadap Pengaruh Pra-tegang Pada Balok di Gedung 45 Lantai.

14-06-09 To: Yuri Plant Page - 3 of 3

Post-Tensioni ng System Beari ngs & Expansi on Joi nts Mai ntenance, Repair & Strengtheni ng BRIDGES Engi neeri ng

Demikian kami sampaikan hasil review ini untuk menjawab pertanyaan dari TPKB. Kami berharap

review ini bisa menjawab pertanyaan.

Atas perhatian dan kerja-sama semua pihak kami mengucapkan terima kasih.

Salam kasih dari kami,

PT Prestress Construction Indonesia

Hotman Sianipar

14-06-09 To: Yuri Plant Page - 4 of 3

Post-Tensioni ng System Beari ngs & Expansi on Joi nts Mai ntenance, Repair & Strengtheni ng BRIDGES Engi neeri ng

Lampiran 1

Project Name: GUDANG FASILITAS

Project Number: PCI-121201

Frame Description: PCI-B207

Designer: HOTMAN

C:\My PROJECT\1-NEXT PRO\140304PT_121201PosTen_Pulo Gadung\DESIGN\PCI-B207_ACI_140506.rpf

RAPT - Version: 6.3.1.0

Reinforced And Post-Tensioned Concrete Analysis & Design Package

Copyright(C) 1988 - 2011 PCDC Pty. Ltd. All Rights Reserved

Licensee

"PT Prestress Construction Indonesia

Jl. Pulau Andalas Raya Blok A1/1

Pulo Gebang Permai

Cakung Jak

10379063101111WPN1

Input

General

Design Code List

Material List

Reinforcement Type List

Member Type List

Panel Type List

Strip Type List

Column Stiffness List

Concrete - Spanning Members List

Concrete - Columns List

Top Reinforcement Cover mm

Bottom Reinforcement Cover mm

Top Reinforcement Axis Depth Limit mm

Bottom Reinforcement Axis Depth Limit mm

Concrete Unit Weight kn/m3

Self Weight Definition List

Pattern Live Load Y/N

Earthquake Design List

Moment Redistribution %

Design Surface Levels List

USA - ACI-318*SAVED*

Indonesia - Indonesia Materials*SAVED*

Bonded Post-Tensioned

Beam

Internal

One way - Nominal Width

Equivalent Column

35MPa

35MPa

40

40

40

40

25

User Defined

None

0

Extreme Surfaces

Span

Span Span

Length

Slab

Depth

Panel

Width

Left

Panel

Width

Right

mm mm mm mm

LE

1

RE

600

18000 250 8000 8000

600

Columns

Column Column

Grid

Reference

Support

Type

Column

Height

Above

Column

Width

Above

Column

Length

Above

Column

Height

below

Column

Width

below

Column

Length

below

Transverse

Column

spacing

Capital Depth

below

deepest

section

Pin

Base

below

Percentage

Column

Stiffness

Braced

frame

at this

column

A List mm mm mm mm mm mm mm mm Y/N % Y/N

1

2

1 Column 4000 1200 1200 7000 1200 1200 8000 0 N 100 Y

2 Column 4000 1200 1200 7000 1200 1200 8000 0 N 100 Y

Column Column

Shortening

Restrained

Punching

Shear

Check

required

Transverse

effective

depth

difference

Transverse

prestress

(P/A)

Y/N Y/N mm MPa

1

2

N Y 0 0

N Y 0 0

Beams

Beam

Number

Beam

Depth

Beam

Width

at

Slab

Beam

Width

Effective

Flange

Width

mm mm mm mm

1 1000 1200 1200 4500

Transverse Beams

Column Transverse

Beam Type

Transverse

Beam

Depth

Transverse

Beam

Width

List mm mm

1

2

beam 500 300

beam 500 300

Steps

Step

Number

DescriptionReference

Column

Distance from

Reference

Column

Flexible/Rigid

Step

A # mm List

1

2

1 600 Flexible Step

1 15400 Flexible Step

Steps(1) : Horizontal

Layer Shape

Attribute

Step this

attribute of

this shape

Step

Offset

Step

Width

Taper

Length

Fall

Width

Y/N mm mm mm mm

Slab Panel

Effective Beam Flange

Downturn Beam

N

N

N

N

N

N

Y 0 0 2000 -200

Y 0 0 2000 -200

Y 0 0 2000 -200

Y 0 0 2000 -200

Steps(2) : Horizontal

Layer Shape

Attribute

Step this

attribute of

this shape

Step

Offset

Step

Width

Taper

Length

Fall

Width

Y/N mm mm mm mm

Slab Panel

Effective Beam Flange

Downturn Beam

N

N

N

N

N

N

Y 0 0 2000 200

Y 0 0 2000 200

Y 0 0 2000 200

Y 0 0 2000 200

Load Cases

Load

Case

Load Type Load Definition Live Load

Deflection

Case

Description

List List Y/N A

1

2

3

4

5

Self Weight Moment/Shear Diagram SW

Initial Dead Load Moment/Shear Diagram SDL

Live Load Moment/Shear Diagram N LL

Earthquake Load Moment/Shear Envelope EX

Alternate Eq L Moment/Shear Envelope EY

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 2/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:07:24 License No.: 10379063101111WPN1

Frame Description: PCI-B207

1. Self Weight - Diagram Column

ColumnMoment in

Column

above

Moment in

Column

below

Reaction

kNm kNm kN

1

2

0 0 0

0 0 0

1. Self Weight - Diagram Span 1

PointLocationMomentShear

mm kNm kN

1

2

3

4

5

6

7

0 -1600 -580

600 -1270 -559

4500 261 -180

9000 799 18

13500 265 179

17400 -1270 560

18000 -1600 580

2. Initial Dead Load - Diagram Column

ColumnMoment in

Column

above

Moment in

Column

below

Reaction

kNm kNm kN

1

2

0 0 0

0 0 0

2. Initial Dead Load - Diagram Span 1

PointLocationMomentShear

mm kNm kN

1

2

3

4

5

6

7

0 -500 -190

600 -391 -171

4500 82 -55

9000 248 -8

13500 81 56

17400 -395 172

18000 -500 190

3. Live Load - Diagram Column

ColumnMoment in

Column

above

Moment in

Column

below

Reaction

kNm kNm kN

1

2

0 0 0

0 0 0

3. Live Load - Diagram Span 1

PointLocationMoment Shear

mm kNm kN

1

2

3

4

5

6

7

0 -4000 -1500

600 -3129 -1369

4500 653 -441

9000 1984 -64

13500 644 443

17400 -3156 1372

18000 -4000 1500

4. Earthquake Load - Envelope Column

Column Primary

Moment in

Column above

Primary

Moment in

Column below

Primary

Reaction

Reversal

Moment in

column above

Reversal

Moment in

column below

Reversal

Reaction

kNm kNm kN kNm kNm kN

1

2

0 0 0 0 0 0

0 0 0 0 0 0

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 3/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:07:31 License No.: 10379063101111WPN1

Frame Description: PCI-B207

4. Earthquake Load - Envelope Span 1

PointLocation Primary

Moment

Primary

Shear

Reversal

Moment

Reversal

Shear

mm kNm kN kNm kN

1

2

0 195 36 -195 -36

18000 -195 36 195 -36

5. Alternate Eq L - Envelope Column

Column Primary

Moment in

Column above

Primary

Moment in

Column below

Primary

Reaction

Reversal

Moment in

column above

Reversal

Moment in

column below

Reversal

Reaction

kNm kNm kN kNm kNm kN

1

2

0 0 0 0 0 0

0 0 0 0 0 0

5. Alternate Eq L - Envelope Span 1

PointLocation Primary

Moment

Primary

Shear

Reversal

Moment

Reversal

Shear

mm kNm kN kNm kN

1

2

0 2 1 -2 -1

18000 -2 1 2 -1

Load Combinations : Ultimate

Load

Combination

Description Prestress

Secondary

Adverse

Prestress

Secondary

Beneficial

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.# #.#

1

2

3

Live Load 1 1 1.2 1.2 1.6 0 0

Dead Load 1 1 1.4 1.4 0 0 0

Earthquake 1 1 1.2 1.2 1 1.4 1.4

Load Combinations : Short Term Service

Load

Combination

DescriptionLong-term

Prestress

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.#

1 Live Load 1 1 1 1 0 0

Load Combinations : Permanent Service

Load

Combination

DescriptionLong-term

Prestress

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.#

1 Live Load 1 1 1 0.75 0 0

Load Combinations : Deflection

Load

Combination

Description Long-term

Prestress

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.#

1

2

3

Short Term - Deflection 1 1 1 0 0 0

Permanent - Deflection 1 1 1 0 0 0

Initial - Deflection 1 1 1 0 0 0

Load Combinations : Transfer Prestress

Load

Combination

Description Transfer

Prestress

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.#

1 Transfer 1 1 0 0 0 0

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 4/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:07:39 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Load Combinations : Pre Existing

Load

Combination

Description Long-term

Prestress

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.#

1 Pre Existing 1 1 0 0 0 0

Load Combinations : Construction

Load

Combination

Description Long-term

Prestress

1. Self

Weight

2. Initial

Dead

Load

3.

Live

Load

4.

Earthquake

Load

5.

Alternate

Eq L

A #.# #.# #.# #.# #.# #.#

1 Construction 1 1 0 0 0 0

Load Case 1 : 1. Self Weight

0

1

18000

2

mm

800

1600

-800

-1600

0

kNm

Moment

0

1

18000

2

mm

200

400

-200

-400

0

kN

Shear

Load Case 2 : 2. Initial Dead Load

0

1

18000

2

mm

200

400

-200

-400

0

kNm

Moment

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 5/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:07:45 License No.: 10379063101111WPN1

Frame Description: PCI-B207

0

1

18000

2

mm

90

180

-90

-180

0

kN

Shear

Load Case 3 : 3. Live Load

0

1

18000

2

mm

2000

4000

-2000

-4000

0

kNm

Moment

0

1

18000

2

mm

700

1400

-700

-1400

0

kN

Shear

Load Case 4 : 4. Earthquake Load

0

1

18000

2

mm

90

180

-90

-180

0

kNm

Moment

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 6/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:07:51 License No.: 10379063101111WPN1

Frame Description: PCI-B207

0

1

18000

2

mm

20

-20

0

kN

Shear

0

1

18000

2

mm

90

180

-90

-180

0

kNm

Moment

0

1

18000

2

mm

20

-20

0

kN

Shear

Load Case 5 : 5. Alternate Eq L

0

1

18000

2

mm

1

2

-1

-2

0

kNm

Moment

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 7/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:07:57 License No.: 10379063101111WPN1

Frame Description: PCI-B207

0

1

18000

2

mm

0.5

1

-0.5

-1

0

kN

Shear

0

1

18000

2

mm

1

2

-1

-2

0

kNm

Moment

0

1

18000

2

mm

0.5

1

-0.5

-1

0

kN

Shear

Prestress

Tendon Normal or

upside down

profiles

Steel

Type

Steel

Diameter

Prestress

Type

Prestress

Anchorage

Size

Number

of

Strands

Number

of

Tendons

Spacing

of

tendons

Top

Cover

to

Duct

Bottom

Cover

to Duct

Left

Anchorage

Reference

Column

Distance to

left

anchorage

from column

List List List List List List #.# mm mm mm # mm

1

2

Strand 12.7mm MultiStrand 19 19 3 40 40 1 -600

Strand 12.7mm MultiStrand 7 7 2 40 40 1 -600

Tendon Left

Anchorage

Type

Right

Anchorage

Reference

Column

Distance to

Right

Anchorage from

Column

Right

Anchorage

Type

Stacked tendons,

No effect on

effective shear

width

Tendon

Length

List # mm List List mm

1

2

2 600 Individual 19200

2 600 Individual 19200

Tendon 1 : - Drape Locations

SpanTendon

Profile

Type

Length of Left End

Straight

Section/Start of

Drape Section in

Span

Length of Right End

Straight

Section/End of

Drape Section in

Span

Reverse

Curve

Radius

Number of

strands from

left end

terminating

in span

Extra

angle

change

in this

span

Tendon

Profile

Point

Spacing

Number

of strands

full length

of tendon

in span

List mm mm mm # #.# mm #

1 0 0 12461.4 0 0 914.4 19

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 8/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:03 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Tendon 1 : - Allowable Profiles

Span Tendon Cover

to centreline at

left end of

span

Tendon Cover

to duct at left

end of Parabola

Tendon Cover to

duct at low point

of parabola

Tendon Cover

to duct at right

end of Parabola

Tendon Cover

to duct at

right end of

span

Available

Parabola

Drape

Relative

Minimum

Tendon

Ratio

mm mm mm mm mm mm #.#

1 305.6 292.6 40 292.6 305.6 653.7 1

Tendon 1 : - Adopted Profiles

Span Profile

Height

Datum

Profile

height at

left end

of span

Profile

height at

left end of

parabola

Profile

Height at

midpoint of

parabola

Profile

height at

right end of

parabola

Profile

height at

right end

of span

Adopted

Parabolic

Drape

Percentage of

available

parabolic drape

adopted

Prestress

Force

Balanced

Uniform

Load

mm mm mm mm mm mm mm % kN %

1 1000 750 750 100 750 750 650 99.4 105.79 245.1

Tendon 1 : - Details

Reverse Curve at Left Anchorage Y/N

Reverse Curve at Right Anchorage Y/N

Percentage J acking Force %

Y

Y

75

Tendon 1 : - Jacking Sequence

Stage Proportion of

J acking force

applied at this

stage

Stressing

Time in

days

Concrete

Strength

% #.# MPa

100 7.817 28

0 0 0

0 0 0

0 0 0

Tendon 2 : - Drape Locations

Span Tendon

Profile Type

Length of Left End

Straight

Section/Start of

Drape Section in

Span

Length of Right End

Straight

Section/End of

Drape Section in

Span

Reverse

Curve

Radius

Number of

strands

from right

terminating

in span

Extra

angle

change

in this

span

Tendon

Profile

Point

Spacing

Number

of strands

full length

of tendon

in span

List mm mm mm # #.# mm #

1 -600 -600 5000 0 0 914.4 7

Tendon 2 : - Allowable Profiles

Span Tendon Cover

to centreline at

left end of

span

Tendon Cover

to duct at

right end of

span

Relative

Minimum

Tendon

Ratio

mm mm #.#

1 40 40 0

Tendon 2 : - Adopted Profiles

Span Profile

Height

Datum

Profile

height at

left end

of span

Profile

height at

right end

of span

Prestress

Force

mm mm mm kN

1 1000 750 750 106.82

Tendon 2 : - Details

Reverse Curve at Left Anchorage Y/N

Reverse Curve at Right Anchorage Y/N

Percentage J acking Force %

N

N

75

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 9/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:10 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Tendon 2 : - Jacking Sequence

Stage Proportion of

J acking force

applied at this

stage

Stressing

Time in

days

Concrete

Strength

% #.# MPa

100 6.741 27

0 0 0

0 0 0

0 0 0

Tendon 1 : - Gross Extension: 116.3mm - 3 - 19/12.7

Profile Heights

Span 1 Locat mm

Height mm

-600 0 900 1800 2700 3600 4500 5400 6300 7200 8100 9000 9900 10800 11700 12600 13500

750 720 720 650 520 395 290 200 130 85 55 45 55 85 130 200 290

Span 1 Locat mm

Height mm

14400 15300 16200 17100 18000 18600

395 520 650 720 720 750

Critical Profile Points

Span 1 Locat mm

Height mm

-600 -187.7 0 2394.2 9000 15605.8 18000 18187.7 18600

-292.5 -285.7 -279.5 -430.2 -955.5 -430.2 -279.5 -285.7 -292.5

Tendon 2 : - Gross Extension: 123.5mm - 2 - 7/12.7

Profile Heights

Span 1 Locat mm

Height mm

-600 314.3 1228.6 2142.9 3057.1 3971.4 4885.7 5800 6714.3 7628.6 8542.9 9457.1 10371.4 11285.7

750 725 725 725 725 725 725 725 725 725 725 725 725 725

Span 1 Locat mm

Height mm

12200 13114.3 14028.6 14942.9 15857.1 16771.4 17685.7 18600

725 725 725 725 725 725 725 750

Critical Profile Points

Span 1 Locat mm

Height mm

-600 18600

-277.5 -277.5

7

7

Tendon 1 : - 3 - 19/12.7

1 2

-300

-600

-900

0

mm

1

9

1

9

7

5

0

c

l

7

2

0

7

2

0

6

5

0

5

2

0

3

9

5

2

9

0

2

0

0

1

3

0

8

5

5

5

4

5

5

5

8

5

1

3

0

2

0

0

2

9

0

3

9

5

5

2

0

6

5

0

7

2

0

7

2

0

7

5

0

c

l

1

9

1

9

Tendon 2 : - 2 - 7/12.7

1 2

-300

-600

-900

0

mm

7

7

7

5

0

c

l

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

2

5

7

5

0

c

l

Reinforcement

Reinforcement

Use

Reinforcement

Type

Preferred

Bar Size

Number

of Legs

List List #

Flexural Bar

Flexural Mesh

Shear Option 1

D 400MPa

MP-100 500MPa

D 400MPa 13 4

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 10/36

Licensee: 06/05/2014 17:08:18 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Reinforcement

Use

Reinforcement

Type

Preferred

Bar Size

Number

of Legs

List List #

Shear Option 2

Shear Option 3

Punching Shear

D 400MPa 14 4

D 400MPa 16 4

D 400MPa 16 4

Reinforcement

Maximum

Bar

Spacing

Minimum

Bar

Spacing

Minimum

Continuous

Reinforcement

Minimum Span

Reinforcement

into End

Support

Minimum Span

Reinforcement

into Internal

Support

Infill

Bars

Stagger

Bars

mm mm #.# #.# #.# Y/N Y/N

Support Reinforcement

Span Reinforcement

304.8 63.5 0 N N

304.8 63.5 0 0 N N

Design Zones : Top

Layer

Number

Steel

type

Left End

Reference

Column

Distance to

left end of

bar

Bar stagger

length at left

end

Top Cover

at left end

Right End

Reference

Column

Distance to

right end of

bar

Bar stagger

length at

right end

Top Cover

at Right

end

Maximum

Bar Size

Minimum

Bar Size

Preferred

bar size

List # mm mm mm # mm mm mm List List List

1 Bar 1 -600 0 40 2 600 0 40 25 25 25

Layer

Number

Minimum

Number of

Bars

Maximum

Spacing of

Bars

Minimum

Steel area as

%

% in

Flange

# mm % %

1 0 0 0 0

Design Zones : Bottom

Layer

Number

Steel

type

Left End

Reference

Column

Distance to

left end of

bar

Bar stagger

length at left

end

Bottom

Cover at left

end

Right End

Reference

Column

Distance to

right end of

bar

Bar stagger

length at

right end

Bottom

Cover at

Right End

Maximum

Bar Size

Minimum

Bar Size

Preferred

bar size

List # mm mm mm # mm mm mm List List List

1 Bar 1 -600 0 40 2 600 0 40 25 25 25

Layer

Number

Minimum

Number of

Bars

Maximum

Spacing of

Bars

Minimum

Steel area as

%

% in

Flange

# mm % %

1 0 0 0 0

User Defined : Top

Layer

Number

Steel type Left End

Reference

Column

Distance

to left

end of

bar

Bar

stagger

length at

left end

Top

Cover

at left

end

% Development

of Left End of

Bar in Tension

% Development

of Left End of

Bar in

Compression

Right End

Reference

Column

Distance

to right

end of

bar

Bar

stagger

length at

right end

Top

Cover

at Right

end

List # mm mm mm % % # mm mm mm

1

2

3

D 400MPa 1 -560 0 56 50 0 1 5650 1650 56

D 400MPa 2 -5600 1650 56 0 0 2 560 0 56

D 400MPa 1 -560 0 56 0 0 2 560 0 56

Layer

Number

% Development

of Right End of

Bar in Tension

% Development

of Right End of

Bar in

Compression

Bar

Size

Number

of Bars

Spacing

of Bars

% in

Flange

Layer attached

after the

PreExisting Load

Case

% % List # mm % Y/N

1

2

3

0 0 25 4 0 0 N

50 0 25 4 0 0 N

0 0 25 5 0 0 N

User Defined : Bottom

Layer

Number

Steel type Left End

Reference

Column

Distance

to left

end of

bar

Bar

stagger

length at

left end

Bottom

Cover

at Left

end

% Development

of Left End of

Bar in Tension

% Development

of Left End of

Bar in

Compression

Right End

Reference

Column

Distance

to right

end of

bar

Bar

stagger

length at

right end

Bottom

Cover

at Right

End

List # mm mm mm % % # mm mm mm

1

2

D 400MPa 1 -560 0 56 0 0 2 560 0 56

D 400MPa 1 -560 0 156 50 0 1 5650 1650 156

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 11/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:24 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Layer

Number

Steel type Left End

Reference

Column

Distance

to left

end of

bar

Bar

stagger

length at

left end

Bottom

Cover

at Left

end

% Development

of Left End of

Bar in Tension

% Development

of Left End of

Bar in

Compression

Right End

Reference

Column

Distance

to right

end of

bar

Bar

stagger

length at

right end

Bottom

Cover

at Right

End

List # mm mm mm % % # mm mm mm

3 D 400MPa 2 -5600 1650 156 0 0 2 560 0 156

Layer

Number

% Development

of Right End of

Bar in Tension

% Development

of Right End of

Bar in

Compression

Bar

Size

Number

of Bars

Spacing

of Bars

% in

Flange

Layer attached

after the

PreExisting Load

Case

% % List # mm % Y/N

1

2

3

0 0 25 9 0 0 N

0 0 25 9 0 0 N

50 0 25 9 0 0 N

Design Data

Capacity Reduction factor (phi) for Flexure #.#

Capacity Reduction factor (phi) for Shear #.#

Material Factor for Concrete in Flexure #.#

Material Factor for Concrete in Shear #.#

Material Factor for Reinforcement #.#

Maximum Ratio of Neutral Axis Depth for Ductility #.#

Ductility Limit - Strain #.#

Ductility Check at Left End Column Y/N

Ductility Check at Right End Column Y/N

Minimum Reinforcement Strength Limit - #.##x M* #.#

Flexural Critical Section - Consider Transverse Beams Y/N

Flexural Critical Section - Distance from centre of Support #.#

Beam Left Sideface Cover (Internal) mm

Beam Right Sideface cover mm

Prestress Minimum Reinforcement Basis List

Shear Enhancement at Supports Y/N

Ast Value in Shear Calculations List

Limit Reinforcement Strain Y/N

Beam Shear Critical Section Location List

0.9

0.75

1

1

1

0

0.003

Y

Y

0

Y

-1

25

40

Program Default

N

Calculated

N

Code Critical Section

Maximum Service Stress Change - Prestressed Sections MPa

Maximum Service Stress Change - Reinforced Sections MPa

Relative Humidity %

Average Temperature C.

Prestress Losses Calculations based on List

Crack Width Calculations List

AS3600 Shrinkage and Temperature Reinforcement List

Degree of Restraint in Primary Direction %

Degree of Restraint in Secondary Direction %

Concrete Strength Gain Rate List

150

0

50

20

Program Default

Code default

Moderate

0

0

N

Concrete Tensile Strength for Deflection Calculations- #.##x (Fc)n #.#

Maximum Value of Ieff/Igross for Deflection Calculations #.#

Total Deflection Warning Limit - Maximum Span/Deflection #.#

Total Deflection Warning Limit - Maximum Deflection mm

Incremental Deflection Warning Limit - Maximum Span/Deflection #.#

Incremental Deflection Warning Limit - Maximum Deflection mm

Time of Loading in days #.#

Age Adjustment Factor #.#

Concrete Strength at Time of Loading MPa

Loaded Period in years #.#

Tension stiffening Approach List

-1

0.6

250

0

480

0

10

0.76

29.58

30

Modified Concrete Tensile Modulus Method

Live Load Pattern Factor #.#

Pattern Live Load for Ultimate Strength Y/N

Pattern Live Load for Crack Control Y/N

Pattern Live Load For Deflections Y/N

Pattern Live Load for Deflection Permanent Load Combination Y/N

Material Properties

Concrete

Description

Characteristic Compressive Strength

35MPa

35

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 12/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:31 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Mean Compressive Strength

Lower Characteristic Tensile Strength

Upper Characteristic Tensile Strength

Concrete Density

Design Concrete Modulus

Mean Concrete Modulus

Basic Shrinkage Strain

Shrinkage Multiplier

Basic Creep Factor

Concrete Strain at Peak Stress

Squash Load Factor

Concrete Strain Limit

40.47

3.55

6.39

2447

30793.1

33114.1

780

1

3.063

0.002

0.85

0.003

Prestress Strand

Diameter Area Breaking

Load

0.2%

Proof

Stress

1%

Stress

Breaking

Strain

Design

Strain

Limit

Elastic

Modulus

Plastic

Modulus

Basic

Relaxation

Weight Material

Factor

Flexure

Material

Factor

Shear

Material

Capacity

Reduction

Factor - Flexure

12.7 98.7 184 85 82 0.06 90 1.95e5 2200 2.5 0.77 -1 -1 -1

Material Capacity

Reduction Factor

- Shear

Include as

Flexural

Reinforcement for

Shear

Set as

default

Description

-1 Y Y

Bonded Multistrand

Anchorage

Size

Description Transfer

Concrete

Strength

Anchor

Friction

Draw-inMaximum

J acking

Force

Set as

default

7 PCI 25 2 6 75 N

19 PCI 25 2 6 75 N

Live

End

Deformed

Strand Dead

End

Nominal

Swaged Dead

End

Full

Swaged

Dead End

Ineffective Length mm

Force at Start of Transition %

Transition Length mm

Force at End of Transition %

100 100 100 100

100 40 50 100

0 1000 300 0

100 100 100 100

Number

of

Cables

Duct

Diameter

Duct Wall

Thickness

Centroid

Distance

Duct

Friction

Wobble -

Unintentional

Friction - K

Minimum

Reverse

Curve Radius

# mm mm mm #.# 1/m mm

5 55 2.5 12.1 0.2 0.003 3500

6 55 2.5 9.9 0.2 0.003 3500

7 55 2.5 8.2 0.2 0.003 3500

Live

End

Deformed

Strand Dead

End

Nominal

Swaged Dead

End

Full

Swaged

Dead End

Ineffective Length mm

Force at Start of Transition %

Transition Length mm

Force at End of Transition %

100 100 100 100

100 40 50 100

0 1000 300 0

100 100 100 100

Number

of

Cables

Duct

Diameter

Duct Wall

Thickness

Centroid

Distance

Duct

Friction

Wobble -

Unintentional

Friction - K

Minimum

Reverse

Curve Radius

# mm mm mm #.# 1/m mm

13 85 2.5 19.6 0.2 0.003 5600

14 85 2.5 18.4 0.2 0.003 5600

15 85 2.5 17.4 0.2 0.003 5600

16 85 2.5 16.3 0.2 0.003 5600

17 85 2.5 15.2 0.2 0.003 5600

18 85 2.5 14.1 0.2 0.003 5600

19 85 2.5 13 0.2 0.003 5600

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 13/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:37 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Reinforcement Bar

Designation Type Yield

Stress

Elastic

Modulus

Ductility Peak

Strain

Peak

Stress

Design

Strain

Limit

Material

Factor

Flexure

Material

Factor

Shear

Material

Capacity

Reduction

Factor - Flexure

Material Capacity

Reduction Factor

- Shear

Include as

Flexural

Reinforcement for

Shear

D Deformed 400 2.05e5 N 0.05 570 90 -1 -1 -1 -1 Y

Description

BJ TD40

Nominal

Bar Size

Bar

Diameter

Bar

Area

Bar

Inertia

Bar

Weight

Stock

Length

A mm mm2 mm4 kg/m mm

10 10 78.5 491 0.62 12000

12 12 113 1017.9 0.89 12000

13 13 132 1402.55 1.04 12000

14 14 154 1885.74 1.21 12000

16 16 201 3218 1.58 12000

18 18 254 5153 2 12000

19 19 284 6397.11 2.23 12000

22 22 380 11499 2.98 12000

25 25 491 19175 3.85 12000

28 28 616 30172 4.83 12000

29 29 661 34719 5.19 12000

32 32 804 51472 6.31 12000

36 36 1020 82448 7.99 12000

Elevation view

0

1

18000

2

mm

-300

-600

-900

0

mm

Plan view

0

1

18000

2

mm

2000

4000

-2000

-4000

0

mm

0

1

18000

2

mm

2000

4000

-2000

-4000

-6000

0

mm

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 14/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:43 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Warnings

Input

Warning:No Live Load Case defined for deflection calculations.

Output

No errors or warnings were found.

Frame Properties

Span 1

Length mm

Inertia mm4

Area mm2

600 600 2000 12800 2000 600 600

2.4e11 2.4e11 1.52e11 1.32e11 1.52e11 2.4e11 2.4e11

2.03e6 2.03e6 1.88e6 1.73e6 1.88e6 2.03e6 2.03e6

Column Members

Col

No.

Area

Above

Inertia

Above

Area

Below

Inertia

Below

# mm2 mm4 mm2 mm4

1 1.44e6 1.58e11 1.44e6 1.27e11

2 1.44e6 1.58e11 1.44e6 1.27e11

Prestress

Tendon Forces

Tendon 1 : - Gross Extension: 116.3mm - 3 - 19/12.7

Span 1

Locat mm

Transfer Strand kN

Total kN

Service Strand kN

Total kN

Slope #.#

Height mm

1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

110.07 111.34 111.34 112.36 113.82 114.33 114.33 114.65 114.65 115.46 115.46 115.87

6274.17 6346.31 6346.55 6404.39 6487.99 6516.82 6516.9 6535.19 6535.28 6581.37 6581.46 6604.63

97.63 98.67 98.67 94.83 96.17 95.93 95.93 96.06 96.06 96.18 96.18 96.27

5564.92 5623.92 5624.12 5405.18 5481.79 5468.23 5468.19 5475.55 5475.58 5482.35 5482.36 5487.5

0 -0.0481 -0.0482 -0.0883 -0.1435 -0.1284 -0.1284 -0.1204 -0.1203 -0.1003 -0.1003 -0.0903

-250 -264.4 -264.5 -298.5 -387.1 -489 -489.3 -538.8 -539 -649.1 -649.3 -696.9

Locat mm

Transfer Strand kN

Total kN

Service Strand kN

Total kN

Slope #.#

Height mm

4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500

115.99 115.99 116.81 116.81 118.2 119.6 120.91 119.47 119.47 118.64 118.64 118.55

6611.56 6611.65 6658.28 6658.37 6737.31 6817.23 6891.87 6810.07 6809.98 6762.41 6762.32 6757.62

96.09 96.09 94.87 94.87 93.86 95.32 96.28 97.34 97.34 98.56 98.56 98.68

5477.12 5476.97 5407.69 5407.56 5349.97 5433.27 5487.85 5548.34 5548.47 5617.74 5617.88 5624.71

-0.0873 -0.0872 -0.0672 -0.0672 -0.0336 0 0.0341 0.0682 0.0682 0.0883 0.0883 0.0903

-710.1 -710.3 -787.4 -787.5 -871.9 -900 -871 -784.1 -784 -705.9 -705.7 -696.9

Locat mm

Transfer Strand kN

Total kN

Service Strand kN

Total kN

Slope #.#

Height mm

14049 14051 15049 15051 15399 15401 16150 16900 17399 17401 17999

118.1 118.1 117.27 117.27 116.98 116.98 116.47 114.96 113.93 113.92 112.63

6731.61 6731.52 6684.5 6684.41 6668.09 6668 6638.56 6552.98 6493.77 6493.52 6419.72

98.58 98.58 98.44 98.44 98.32 98.32 98.56 97.2 101.03 101.02 99.96

5618.82 5618.81 5611.04 5611.02 5604.16 5604.2 5617.85 5540.33 5758.46 5758.26 5697.86

0.1013 0.1013 0.1214 0.1214 0.1284 0.1284 0.1434 0.0883 0.0482 0.0481 0

-644.3 -644.1 -533 -532.7 -489.3 -489 -387.2 -298.5 -264.5 -264.4 -250

Tendon 2 : - Gross Extension: 123.5mm - 2 - 7/12.7

Span 1

Locat mm

Transfer Strand kN

Total kN

Service Strand kN

Total kN

Slope #.#

Height mm

1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

126.57 126.79 126.79 126.92 126.67 126.28 126.28 126.12 126.12 125.73 125.73 125.54

1771.99 1775.03 1775.04 1776.85 1773.41 1767.92 1767.91 1765.73 1765.72 1760.26 1760.25 1757.53

112.72 112.67 112.67 107.7 106.97 106.08 106.08 105.99 105.99 105.71 105.71 105.55

1578.02 1577.38 1577.37 1507.84 1497.54 1485.13 1485.11 1483.83 1483.82 1479.96 1479.95 1477.66

0 0 0 0 0 0 0 0 0 0 0 0

-250 -250 -250 -250 -250 -250 -250 -250 -250 -250 -250 -250

Locat mm

Transfer Strand kN

Total kN

Service Strand kN

Total kN

Slope #.#

Height mm

4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500

125.48 125.48 125.09 125.09 124.44 123.8 123.15 122.53 122.53 122.17 122.17 122.13

1756.71 1756.7 1751.27 1751.26 1742.18 1733.14 1724.03 1715.39 1715.38 1710.32 1710.31 1709.81

105.52 105.52 105.32 105.32 104.82 104.13 103.52 102.87 102.87 102.39 102.39 102.34

1477.31 1477.31 1474.43 1474.42 1467.48 1457.87 1449.31 1440.16 1440.15 1433.5 1433.49 1432.78

0 0 0 0 0 0 0 0 0 0 0 0

-250 -250 -250 -250 -250 -250 -250 -250 -250 -250 -250 -250

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 15/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:50 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Locat mm

Transfer Strand kN

Total kN

Service Strand kN

Total kN

Slope #.#

Height mm

14049 14051 15049 15051 15399 15401 16150 16900 17399 17401 17999

121.93 121.93 121.57 121.57 121.45 121.45 121.28 121.1 120.98 120.98 120.78

1707.04 1707.03 1702 1701.99 1700.24 1700.23 1697.86 1695.45 1693.76 1693.75 1690.86

102.15 102.15 101.74 101.74 101.59 101.59 101.97 102.34 107.34 107.35 107.4

1430.08 1430.07 1424.42 1424.41 1422.22 1422.22 1427.63 1432.77 1502.83 1502.83 1503.58

0 0 0 0 0 0 0 0 0 0 0

-250 -250 -250 -250 -250 -250 -250 -250 -250 -250 -250

Tendon 1 : - Gross Extension: 116.3mm - 3 - 19/12.7

0

1

18000

2

mm

90

100

110

120

130

80

kN

96.6

Transfer Service Average

Tendon 2 : - Gross Extension: 123.5mm - 2 - 7/12.7

0

1

18000

2

mm

90

100

110

120

130

80

kN

105

Transfer Service Average

Tendon Actions

Distributed Forces Induced By Tendon Shape - Tendon 1 - 3 - 19/12.7

Load

No.

Prestress

Force

Ref Col

No.

Start

Location

Start

Value

End

Location

End

Value

Transfer

Factor

# kN A mm kN/m mm kN/m #.#

1 6663.13 1 0 442.04 1800 442.04 1.2096

2 6663.13 1 1800 -110.51 16200 -110.51 1.2096

3 6663.13 1 16200 442.04 18000 442.04 1.2096

Moments From Anchorage Eccentricity - Tendon 1 - 3 - 19/12.7

Moment

Start

e Prestress

Force

Span

No.

LocationTransfer

Factor

Moment

End

e Prestress

Force

Span

No.

LocationTransfer

Factor

kNm mm kN # mm #.# kNm mm kN # mm #.#

535.54 -97.2 6663.13 0 0 1.2096 -535.54 -97.2 6663.13 2 600 1.2096

Forces From Changes In Centroids - Tendon 1 - 3 - 19/12.7

Point Loads Point Moments

Ref

Col

Distance

From Col

Prestress

Force

Change

Of Slope

Vertical

Load

Charge Of

Centroid

Applied

Moment

Transfer

Factor

A mm kN #.# kN mm kN/m #.#

1 600 6663.13 0.0242 133.05 0 0 1.2096

1 2600 6663.13 -0.0242 -133.05 0 0 1.2096

1 15400 6663.13 -0.0242 -133.05 0 0 1.2096

1 17400 6663.13 0.0242 133.05 0 0 1.2096

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 16/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:08:56 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Moments From Anchorage Eccentricity - Tendon 2 - 2 - 7/12.7

Moment

Start

e Prestress

Force

Span

No.

LocationTransfer

Factor

Moment

End

e Prestress

Force

Span

No.

LocationTransfer

Factor

kNm mm kN # mm #.# kNm mm kN # mm #.#

142.97 -97.2 1733.61 0 0 1.1789 -142.97 -97.2 1733.61 2 600 1.1789

Forces From Changes In Centroids - Tendon 2 - 2 - 7/12.7

Point Loads Point Moments

Ref

Col

Distance

From Col

Prestress

Force

Change

Of Slope

Vertical

Load

Charge Of

Centroid

Applied

Moment

Transfer

Factor

A mm kN #.# kN mm kN/m #.#

1 600 1733.61 0.0242 35.52 0 0 1.1789

1 2600 1733.61 -0.0242 -35.52 0 0 1.1789

1 15400 1733.61 -0.0242 -35.52 0 0 1.1789

1 17400 1733.61 0.0242 35.52 0 0 1.1789

Forces from Tendon Profiles - Tendon 1 - 3 - 19/12.7

0

1

18000

2

mm

200

400

600

0

kN/m

-111

Forces from Changes in Section - Tendon 1 - 3 - 19/12.7

0

1

18000

2

mm

40

80

120

160

0

kN

Forces from Tendon Profiles - Tendon 2 - 2 - 7/12.7

0

1

18000

2

mm

50

100

150

200

0

kN/m

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 17/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:02 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Forces from Changes in Section - Tendon 2 - 2 - 7/12.7

0

1

18000

2

mm

10

20

30

40

0

kN

Secondary Forces

Tendon 1 :

Span

No.

End Tendon

Depth

Centroid

Depth

e Peff. MTotal MSec ReactionTransfer

Factor

# A mm mm mm kN kNm kNm kN #.#

1 Left 250 347.2 97.2 5508.38 -2363.18 1827.64 0 0

1 Right 250 347.2 97.2 5508.38 2363.18 1827.64 0 0

Tendon 2 :

Span

No.

End Tendon

Depth

Centroid

Depth

e Peff. MTotal MSec ReactionTransfer

Factor

# A mm mm mm kN kNm kNm kN #.#

1 Left 250 347.2 97.2 1470.54 -66.46 -76.51 -0 0

1 Right 250 347.2 97.2 1470.54 66.46 -76.51 0 0

Bending Moments

Load Cases

Secondary Transfer

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 -1364.39 -756.19 0

2 1364.39 756.19 0

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59

0 0 0 0 0 0 0 0 0 0 0 0

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500

Moment kNm

Shear kN

2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59

0 0 0 0 0 0 0 0 0 0 0 0

Span 1 Locat mm 14049 14051 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59 2120.59

0 0 0 0 0 0 0 0 0 0 0

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

2121

2121

2121

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 18/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:09 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

0 0

Secondary Service

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 -1126.69 -624.45 0

2 1126.69 624.45 0

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13

0 0 0 0 0 0 0 0 0 0 0 0

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500

Moment kNm

Shear kN

1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13

0 0 0 0 0 0 0 0 0 0 0 0

Span 1 Locat mm 14049 14051 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13 1751.13

0 0 0 0 0 0 0 0 0 0 0

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

1751

1751

1751

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

0 0

Prestress Transfer

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 -1364.39 -756.19 -0

2 1364.39 756.19 0

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 19/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:17 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

2936.94 2841.01 2840.17 2512.03 1770.4 938.95 937.04 607.19 605.58 -128.15 -129.49 -446.3

-0.53 -320.29 -524.18 -790.99 -1158.72 -1058.46 -855.38 -802.18 -801.91 -668.5 -668.23 -601.53

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500

Moment kNm

Shear kN

-534.44 -535.6 -1049.22 -1050.11 -1612.22 -1799.74 -1606.81 -1027.56 -1026.65 -506.37 -505.19 -446.3

-581.61 -581.35 -447.94 -447.67 -223.9 0 227.11 454.36 454.62 588.03 588.3 601.53

Span 1 Locat mm 14049 14051 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

-95.91 -94.56 645.84 647.46 937.04 938.95 1769.24 2512.03 2840.17 2841.01 2936.93

674.92 675.19 808.59 808.86 855.38 1058.46 1158.59 790.99 524.18 320.29 0.53

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

2840

-1800

2840

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-791

791

Prestress Service

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 -1126.69 -624.45 0

2 1126.69 624.45 0

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500 4649

Moment kNm

Shear kN

2429.64 2350.34 2349.64 2077.92 1464.14 776.11 774.53 501.84 500.51 -106.06 -107.16 -369.07 -441.94

-0.44 -264.78 -434.24 -654.81 -958.81 -875.93 -707.14 -663.15 -662.93 -552.65 -552.43 -497.28 -480.82

Span 1 Locat mm 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500 14049 14051

Moment kNm

Shear kN

-442.9 -867.5 -868.24 -1332.93 -1487.95 -1328.46 -849.6 -848.84 -418.73 -417.76 -369.07 -79.41 -78.29

-480.6 -370.31 -370.09 -185.1 0 187.75 375.61 375.84 486.12 486.34 497.28 557.95 558.17

Span 1 Locat mm 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

533.8 535.14 774.53 776.11 1463.18 2077.92 2349.64 2350.34 2429.64

668.46 668.68 707.14 875.93 958.7 654.81 434.24 264.78 0.44

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 20/36

Licensee: 06/05/2014 17:09:22 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

2350

-1488

2350

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-655

655

Load Case 1. Self Weight

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 0 0 0

2 0 0 0

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

-1599.45 -1270.55 -1269.61 -1073.72 -779.69 -485.26 -484.48 -328.24 -327.45 64.33 65.11 261

-579.97 -559.03 -558.9 -510.41 -437.62 -364.74 -364.54 -325.87 -325.67 -228.69 -228.49 -180

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500 14049 14051

Moment kNm

Shear kN

278.81 279.05 398.37 398.61 598.74 799 597.39 395.65 395.41 276.99 276.75 265 48.92 48.13

-173.44 -173.36 -129.44 -129.36 -55.7 18 78.79 139.61 139.68 175.39 175.46 179 232.63 232.83

Span 1 Locat mm 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

-344.67 -345.46 -482.43 -483.21 -778.01 -1073.21 -1269.61 -1270.55 -1599.45

330.33 330.52 364.52 364.71 437.88 511.15 559.9 560.03 579.97

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

-1270

799

-1270

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 21/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:29 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-510

511

Load Case 2. Initial Dead Load

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 0 0 0

2 0 0 0

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500 4649 4651

Moment kNm

Shear kN

-499.82 -391.18 -390.88 -330.36 -239.52 -148.56 -148.31 -100.04 -99.8 21.24 21.48 82 87.5 87.57

-189.97 -171.03 -170.97 -156.13 -133.85 -111.54 -111.48 -99.65 -99.59 -69.9 -69.84 -55 -53.44 -53.42

Span 1 Locat mm 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500 14049 14051 15049 15051

Moment kNm

Shear kN

124.39 124.46 186.21 248 184.95 121.86 121.79 84.75 84.67 81 13.99 13.75 -108.06 -108.3

-43 -42.98 -25.49 -8 16.16 40.34 40.37 54.56 54.59 56 72.33 72.39 102.07 102.13

Span 1 Locat mm 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

-150.78 -151.02 -242.44 -333.97 -394.88 -395.17 -499.83

112.48 112.54 134.82 157.13 171.97 172.03 189.97

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

-391

248

-395

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-156

157

Load Case 3. Live Load

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 0 0 0

2 0 0 0

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 22/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:34 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

-3998.55 -3130.45 -3128.03 -2644.13 -1917.79 -1190.48 -1188.54 -802.59 -800.65 167.16 169.1 653

-1499.78 -1369.22 -1368.76 -1250.03 -1071.8 -893.34 -892.86 -798.16 -797.69 -560.21 -559.74 -441

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500 14049 14051

Moment kNm

Shear kN

697.07 697.66 992.85 993.44 1488.57 1984 1478.08 971.85 971.26 674.08 673.48 644 109.08 107.13

-428.52 -428.35 -344.74 -344.57 -204.33 -64 127.42 318.95 319.18 431.62 431.85 443 573.77 574.25

Span 1 Locat mm 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

-865.28 -867.23 -1206.31 -1208.26 -1938.05 -2668.82 -3155.03 -3157.41 -3998.59

811.98 812.46 895.35 895.83 1074.24 1252.9 1371.76 1372.21 1499.79

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

-3128

1984

-3155

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-1250

1253

Load Case 4. Earthquake Load

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

ReactionReversal

Moment

Above

Reversal

Moment

Below

Reversal

Reaction

kNm kNm kN kNm kNm kN

1 0 0 0 0 0 0

2 0 0 0 0 0 0

Moment Shear Envelope

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-194.98 -182.02 -181.98 -171.17 -154.94 -138.69 -138.65 -130.02 -129.98 -108.36 -108.31 -97.5

-36 -36 -36 -36 -36 -36 -36 -36 -36 -36 -36 -36

194.98 182.02 181.98 171.17 154.94 138.69 138.65 130.02 129.98 108.36 108.31 97.5

36 36 36 36 36 36 36 36 36 36 36 36

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500 14049 14051

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-94.27 -94.23 -72.61 -72.56 -36.29 0 -36.81 -73.64 -73.69 -95.31 -95.35 -97.5 -109.39 -109.44

-36 -36 -36 -36 -36 -36 36 36 36 36 36 36 36 36

94.27 94.23 72.61 72.56 36.29 0 36.81 73.64 73.69 95.31 95.35 97.5 109.39 109.44

36 36 36 36 36 36 -36 -36 -36 -36 -36 -36 -36 -36

Span 1 Locat mm 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-131.06 -131.1 -138.65 -138.69 -154.92 -171.17 -181.98 -182.02 -194.98

36 36 36 36 36 36 36 36 36

131.06 131.1 138.65 138.69 154.92 171.17 181.98 182.02 194.98

-36 -36 -36 -36 -36 -36 -36 -36 -36

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 23/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:39 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

182

0

182

Moment 1 Moment 2

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

36

-36

Shear 1 Shear 2

Load Case 5. Alternate Eq L

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

ReactionReversal

Moment

Above

Reversal

Moment

Below

Reversal

Reaction

kNm kNm kN kNm kNm kN

1 0 0 0 0 0 0

2 0 0 0 0 0 0

Moment Shear Envelope

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500 4649 4651 5649 5651 7325

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-2 -1.87 -1.87 -1.76 -1.59 -1.42 -1.42 -1.33 -1.33 -1.11 -1.11 -1 -0.97 -0.97 -0.74 -0.74 -0.37

-1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1

2 1.87 1.87 1.76 1.59 1.42 1.42 1.33 1.33 1.11 1.11 1 0.97 0.97 0.74 0.74 0.37

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Span 1 Locat mm 9000 10699 12399 12401 13399 13401 13500 14049 14051 15049 15051 15399 15401 16150

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

0 -0.38 -0.76 -0.76 -0.98 -0.98 -1 -1.12 -1.12 -1.34 -1.34 -1.42 -1.42 -1.59

1 1 1 1 1 1 1 1 1 1 1 1 1 1

0 0.38 0.76 0.76 0.98 0.98 1 1.12 1.12 1.34 1.34 1.42 1.42 1.59

-1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1

Span 1 Locat mm 16900 17399 17401 17999

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-1.76 -1.87 -1.87 -2

1 1 1 1

1.76 1.87 1.87 2

-1 -1 -1 -1

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

1.87

0

1.87

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 24/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:44 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

1

-1

Shear 1 Shear 2

Load Combinations

Ultimate Flexure

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction Reversal

Moment

Above

Reversal

Moment

Below

Reversal

Reaction

kNm kNm kN kNm kNm kN

1 -1126.69 -624.45 0 -1126.69 -624.45 0

2 1126.69 624.45 0 1126.69 624.45 0

Moment Shear Envelope

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-7165.67 -5251.67 -5246.3 -4164.37 -2540.38 -914.23 -909.89 -46.94 -42.61 1869.27

-3323.57 -3066.83 -3065.87 -2799.89 -2400.65 -2000.88 -1999.82 -1787.67 -1786.61 -968.92

-1187.84 -575.29 -573.55 -214.58 324.24 863.78 865.22 1151.54 1152.97 2172.66

-1077.91 -1022.09 -1021.82 -933.15 -800.06 -666.79 -666.44 -595.72 -595.36 -868.12

Span 1 Locat mm 4001 4500 4649 4651 5649 5651 7325 9000 10699 12399 12401

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

1872.36 2231.33 2263.97 2264.41 2482.99 2483.43 2850.07 3216.93 2846.4 2475.65 2475.21

-417.67 -329 -317.64 -317.49 -241.42 -241.27 -113.67 14 132.93 251.93 252.07

2175.78 3207.53 3306.02 3307.34 3967 3968.32 5074.79 6181.93 5054.85 3927.11 3925.78

-867.34 -987.6 -957.89 -957.49 -758.51 -758.12 -424.36 -90.4 317.81 726.27 726.75

Span 1 Locat mm 13399 13401 13500 14049 14051 15049 15051 15399 15401 16150 16900

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

2257.56 2257.12 2235.53 1782.55 1779.31 -176.59 -180.95 -938.8 -943.16 -2574.29 -4207.6

321.93 322.07 329 990.13 990.91 1818.05 1819.11 2004.96 2006.03 2406.04 2806.57

3263.73 3262.41 3196.73 2088.86 2085.73 1117.31 1115.87 864.65 863.21 322.5 -218.92

966.53 967.01 990.8 889.33 890.11 605.36 605.71 667.8 668.16 801.79 935.59

Span 1 Locat mm 17399 17401 17999

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-5294.29 -5299.59 -7165.75

3073.07 3074.02 3323.58

-579.15 -580.88 -1187.85

1024.62 1024.89 1077.91

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

-5246

3217

-5294

Moment 1 Moment 2

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 25/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:51 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-2800

2807

Shear 1 Shear 2

Service

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction Reversal

Moment

Above

Reversal

Moment

Below

Reversal

Reaction

kNm kNm kN kNm kNm kN

1 -1126.69 -624.45 0 -1126.69 -624.45 0

2 1126.69 624.45 0 1126.69 624.45 0

Moment Shear Envelope

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-3668.18 -2441.85 -2438.88 -1970.28 -1472.86 -1048.19 -1046.81 -729.03 -727.39 146.66

-2270.16 -2364.06 -2532.87 -2571.38 -2602.09 -2245.55 -2076.03 -1886.83 -1885.88 -1411.45

-3668.18 -2441.85 -2438.88 -1970.28 -1472.86 -1048.19 -1046.81 -729.03 -727.39 146.66

-2270.16 -2364.06 -2532.87 -2571.38 -2602.09 -2245.55 -2076.03 -1886.83 -1885.88 -1411.45

Span 1 Locat mm 4001 4500 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

148.52 626.93 621.45 621.39 648.1 648.27 940.6 1543.05 931.95 639.77 639.61 617.08

-1410.5 -1173.28 -1136.22 -1135.72 -887.49 -887 -470.62 -54 410.12 874.52 875.06 1147.69

148.52 626.93 621.45 621.39 648.1 648.27 940.6 1543.05 931.95 639.77 639.61 617.08

-1410.5 -1173.28 -1136.22 -1135.72 -887.49 -887 -470.62 -54 410.12 874.52 875.06 1147.69

Span 1 Locat mm 13401 13500 14049 14051 15049 15051 15399 15401 16150 16900 17399

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

617.15 620.93 92.58 90.72 -784.21 -785.85 -1064.98 -1066.38 -1495.32 -1998.08 -2469.87

1148.24 1175.28 1436.69 1437.64 1912.84 1913.79 2079.49 2249.01 2605.65 2575.99 2537.87

617.15 620.93 92.58 90.72 -784.21 -785.85 -1064.98 -1066.38 -1495.32 -1998.08 -2469.87

1148.24 1175.28 1436.69 1437.64 1912.84 1913.79 2079.49 2249.01 2605.65 2575.99 2537.87

Span 1 Locat mm 17401 17999

Moment kNm

Shear kN

Reverse Moment kNm

Reverse Shear kN

-2472.8 -3668.23

2369.06 2270.16

-2472.8 -3668.23

2369.06 2270.16

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

-2439

1543

-2470

Moment 1 Moment 2

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 26/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:09:59 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-2571

2576

Shear 1 Shear 2

Transfer Prestress

Total Panel Column Moments And Reactions

Col

No.

Moment

Above

Moment

Below

Reaction

kNm kNm kN

1 -1364.39 -756.19 -0

2 1364.39 756.19 0

Moment Shear Diagram

Span 1 Locat mm 1 599 601 1100 1849 2599 2601 2999 3001 3999 4001 4500

Moment kNm

Shear kN

1337.49 1570.46 1570.56 1438.31 990.71 453.69 452.56 278.95 278.13 -63.83 -64.38 -185.3

-580.5 -879.32 -1083.08 -1301.4 -1596.34 -1423.2 -1219.92 -1128.04 -1127.58 -897.19 -896.73 -781.53

Span 1 Locat mm 4649 4651 5649 5651 7325 9000 10699 12399 12401 13399 13401 13500 14049

Moment kNm

Shear kN

-255.63 -256.55 -650.85 -651.51 -1013.48 -1000.74 -1009.42 -631.91 -631.24 -229.38 -228.44 -181.3 -46.99

-755.06 -754.7 -577.38 -577.03 -279.6 18 305.9 593.97 594.3 763.42 763.76 780.53 907.55

Span 1 Locat mm 14051 15049 15051 15399 15401 16150 16900 17399 17401 17999

Moment kNm

Shear kN

-46.43 301.17 302 454.61 455.74 991.22 1438.83 1570.56 1570.46 1337.48

908.01 1138.92 1139.38 1219.9 1423.18 1596.47 1302.15 1084.08 880.32 580.5

Moment

0

1

18000

2

mm

2000

4000

6000

8000

-2000

-4000

-6000

-8000

0

kNm

1571

-1001

1571

Shear

0

1

18000

2

mm

1000

2000

3000

4000

-1000

-2000

-3000

-4000

0

kN

-1301

1302

Flexural Design

Reinforcement

Span 1

Top Design (1) Bott Design (1) Top (1) Top (2) Top (3) Bottom (1) Bottom (2) Bottom (3)

Locat Area Depth Area Depth Area Depth Area Depth Area Depth Area Depth Area Depth Area Depth

mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm

601 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

1100 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 27/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:10:04 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Top Design (1) Bott Design (1) Top (1) Top (2) Top (3) Bottom (1) Bottom (2) Bottom (3)

Locat Area Depth Area Depth Area Depth Area Depth Area Depth Area Depth Area Depth Area Depth

mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm mm2 mm

1849 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

2599 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

2601 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

2999 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

3001 0 52.5 0 947.5 1964 68.5 0 0 2455 68.5 4419 931.5 4419 831.5 0 0

3999 0 52.5 0 947.5 982 68.5 0 0 2455 68.5 4419 931.5 2455 831.5 0 0

4001 0 52.5 0 947.5 982 68.5 0 0 2455 68.5 4419 931.5 2455 831.5 0 0

4500 0 52.5 0 947.5 982 68.5 0 0 2455 68.5 4419 931.5 2455 831.5 0 0

4649 0 52.5 0 947.5 982 68.5 0 0 2455 68.5 4419 931.5 2455 831.5 0 0

4651 0 52.5 0 947.5 982 68.5 0 0 2455 68.5 4419 931.5 2455 831.5 0 0

5649 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

5651 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

7325 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

9000 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

10699 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

12399 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

12401 0 52.5 0 947.5 0 0 0 0 2455 68.5 4419 931.5 0 0 0 0

13399 0 52.5 0 947.5 0 0 982 68.5 2455 68.5 4419 931.5 0 0 2455 831.5

13401 0 52.5 0 947.5 0 0 982 68.5 2455 68.5 4419 931.5 0 0 2455 831.5

13500 0 52.5 0 947.5 0 0 982 68.5 2455 68.5 4419 931.5 0 0 2455 831.5

14049 0 52.5 0 947.5 0 0 982 68.5 2455 68.5 4419 931.5 0 0 2455 831.5

14051 0 52.5 0 947.5 0 0 982 68.5 2455 68.5 4419 931.5 0 0 2455 831.5

15049 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

15051 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

15399 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

15401 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

16150 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

16900 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

17399 0 52.5 0 947.5 0 0 1964 68.5 2455 68.5 4419 931.5 0 0 4419 831.5

Tendon (1) Tendon (2)

Area Depth Area Depth

mm2 mm mm2 mm

5625.9 264.5 1381.8 250

5625.9 298.5 1381.8 250

5625.9 387.1 1381.8 250

5625.9 489 1381.8 250

5625.9 489.3 1381.8 250

5625.9 538.8 1381.8 250

5625.9 539 1381.8 250

5625.9 649.1 1381.8 250

5625.9 649.3 1381.8 250

5625.9 696.9 1381.8 250

5625.9 710.1 1381.8 250

5625.9 710.3 1381.8 250

5625.9 787.4 1381.8 250

5625.9 787.5 1381.8 250

5625.9 871.9 1381.8 250

5625.9 900 1381.8 250

5625.9 871 1381.8 250

5625.9 784.1 1381.8 250

5625.9 784 1381.8 250

5625.9 705.9 1381.8 250

5625.9 705.7 1381.8 250

5625.9 696.9 1381.8 250

5625.9 644.3 1381.8 250

5625.9 644.1 1381.8 250

5625.9 533 1381.8 250

5625.9 532.7 1381.8 250

5625.9 489.3 1381.8 250

5625.9 489 1381.8 250

5625.9 387.2 1381.8 250

5625.9 298.5 1381.8 250

5625.9 264.5 1381.8 250

RAPT 6.3.1.0 Project Name: GUDANG FASILITAS Page 28/36

Licensee: "PT Prestress Construction Indonesia 06/05/2014 17:10:10 License No.: 10379063101111WPN1

Frame Description: PCI-B207

Ultimate

Span 1

Design Moment Initial Condition Final Design Condition Reinforcement

Locat

Min