Professional Documents

Culture Documents

Rawl Bolts and Capacity

Uploaded by

kevinisonlineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rawl Bolts and Capacity

Uploaded by

kevinisonlineCopyright:

Available Formats

Rawlbolt

Shield Anchor

Bolt Projecting

0.67

Rawlbolt

Shield Anchor

Bolt Projecting

Product Data

The Rawlbolt

Shield Anchor is the worlds most popular, high

quality torque controlled expanding anchor, combining ease of

installation with good load carrying capacity.

The Rawlbolt

Shield Anchor is the ideal general purpose

anchor bolt having higher degrees of expansion than other

types of expansion anchor and excellent tolerance to variations

in hole sizes. The collapsible ferrule ensures a positive

clamping force is transmitted to the fixture. Expansion shield is

available without the bolt. Where cracked concrete may exist an

alternative The Rawlbolt

Shield Anchor is available.

Available in:

Yellow passivated zinc-plated steel

Typical Applications:

Roller Shutter Doors Security Grills Steelwork

Fire Doors Machinery Barriers

Wall Plates Signs Fencing

Approvals:

The Rawlbolt

anchor is approved by major UK and International

Independent approval bodies.

For reduction factors for 8.8 grade bolts see page 3

For Installation see back cover

3 2 4 5

Rawlbolt

Shield Anchor: Bolt Projecting

CONCRETE,

BRICKWORK & STONE

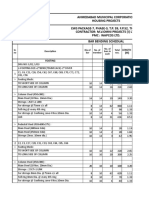

REF

M6 10P

M6 25P

M6 60P

M6

M8

M10

M12

M20

65

80

115

75

90

125

90

105

135

110

125

170

170

185

255

45

50

60

75

12

14

16

20

0

0

0

0

0

10

30

6.5

9.0

11

13

50

55

65

85

140

70 6.5 5.0

44-505

44-510

44-515

80 15 7.5

44-555

44-560

44-565

100 27 13

44-605

44-610

44-615

120 50 23

44-655

44-660

44-665

10

25

60

10

25

60

15

30

60

15

30

75

M8 10P

M8 25P

M8 60P

M10 15P

M10 30P

M10 60P

M12 15P

M12 30P

M12 75P

M20 15P

M20 30P

M20 100P

BOLT

SIZE

(d)

BOLT

LENGTH

(mm)

(l)

SHIELD

LENGTH

(mm)

(s)

FIXTURE THICKNESS

(mm)

HOLE DIAMETER

(mm)

PRODUCT

CODE

MAX

(mm)

(T

fix

)

IN STRUCTURE

(d

f

)

MIN

(mm)

(T

fix

)

IN FIXTURE

(d

f

)

MINIMUM

HOLE

DEPTH

(mm)

(h

o

)

MINIMUM

SUBSTRATE

THICKNESS

(mm)

(h

min

)

RECOMMENDED

TORQUE (Nm)

30N/mm

2

Concrete

(Nm)

(T

inst

)

20.5N/mm

2

Concrete

(Nm)

(T

inst

)

M16

M24

M16 15P

M16 35P

M16 75P

M24 75P

M24 120P

255

300

150

170

210

115

130

150

15

35

75

15

30

100

75

120

0

75

0

10

35

25

32

38

17

22

26 160

125 190 120 -

44-705

44-710

44-715

220 230 -

44-755

44-760

44-765

240 400 -

44-805

44-810

Spacing (Concrete)

TENSILE & SHEAR REDUCTION FACTORS

M6 M8 M10 M12 M16 M20 M24

60

80

100

120

150

180

210

250

290

330

370

420

0.80

0.70

0.90

1.0

0.80

0.70

0.90

1.0

0.80

0.70

0.90

1.0

0.78

0.70

0.85

0.93

1.0

0.70

0.78 0.70

0.85 0.78

0.93

1.0

Edge Distance for 5.8 Grade Bolts (Concrete)

TENSILE : EDGE REDUCTION FACTORS

30

M6 M8 M10 M12 M16 M20 M24

1.0 0.90 0.80 0.70

0.94 0.88

0.94

1.0

80

220

250

280

50 0.70

60 0.80 0.70

70 0.90 0.80 0.70

100 0.78

120 0.85 0.78

0.70

140 0.93 0.85

160 0.93 0.82

190 1.0

1.0

0.88 0.82

0.76

0.70 0.76

0.70

0.90

1.0

0.85 0.76

0.93 0.82

1.0 088

0.94

1.0

1.0

1.0

0.70

Concrete

Loads shown are for 30N/mm

2

(C20/25) concrete. For other

grades of concrete between 20 and 50N/mm

2

where the anchor

is in tension the load can be calculated using the following

empirical formula:

This calculation is not valid for shear.

By using spacers the anchor can be set at increased depths which

will generally improve the tensile performance. This option should

be considered for substrates of lower strength than 25N/mm

2

.

Brickwork

Loads shown are for 20.5N/mm

2

brick. The anchor should be

positioned a minimum of 300mm from the vertical edge of the

wall and four courses down from the top of an unrestrained wall.

Installing the anchor into mortar joints should be avoided.

Edge and Spacing Distances (concrete only)

The loads shown are applicable to characteristic edge and

spacing distances. For reduced edge and spacing distances,

reduction factors must be calculated from the appropriate tables

below.

Combined Load (concrete only)

When selecting an anchor which will carry a combined load,

ensure that the bolt size selected satisfies the following

equation:

(Edge and spacing reduction factors, if applicable, should be

applied to the safe tensile and safe shear loads).

+

1.2

Applied Tensile Load

Safe Static Tensile Load

Applied Shear Load

Safe Static Shear Load

x

Tensile SWL in

30N/mm

2

Concrete

Actual Concrete Strength

30

Design Data

SHEAR : EDGE REDUCTION FACTORS

0.67

0.50

0.83

1.0 0.83

1.0

0.67

0.83

1.0

0.60

0.73

0.87

1.0

0.73

0.87

1.0 0.67

0.83 0.67

1.0 0.83

1.0

Performance Data at Standard Embedment Depth

SIZE

M6

M8

.M10

M12

M20

M16

M24

3.3 4.4

4.8 5.6

6.2 8.9

9.7 12.9

31.2 37.5

21.3 24.1

38.0 54.1

6.8

8.7

13.7

19.9

60.0

36.9

86.6

12.2

15.4

21.2

30.9

100.5

73.1

125.5

80

100

120

160

250

190

280

120

150

180

250

330

290

420

1.8

2.3

2.9

4.3

Bolts above

M12 are not

recommended

in brickwork

CONCRETE 30N/mm

2

(C20/25) BRICKWORK 20.5N/m

2

SAFE WORKING LOAD

(kN)

Tension & Shear

CHARACTERISTIC SPACING DISTANCE

(mm)

SAFE WORKING LOAD (kN) FAILURE LOAD (kN) CHARACTERISTIC EDGE DISTANCE

(mm)

Tension & Shear Tension

Shear

5.8G 8.8G

9.7

12.4

19.6

28.5

82.6

53.0

119.0

14.9

19.0

30.2

43.8

132.0

81.3

190.5

Shear

5.8G 8.8G

80

100

120

160

250

190

280

100

120

160

180

300

260

350

Shear

5.8G 8.8G

Tension Tension

The characteristic edge and spacing distances quoted in the table

above are the minimum allowable for the quoted safe loads to apply.

Where the design dictates reduced edge and spacing

distances, the appropriate reduction factor/s from the tables

below must be applied to the safe working load.

Choose the required bolt diameter across the top of the table

and read down the left hand column until actual edge or

spacing distance is found. Read off the reduction factor where

the two lines intersect (interpolate as required). Multiply this

factor by the safe working load quoted in the table. On the

occasion that multiple close edge and/or spacing distances

occur, the appropriate reduction factors must be applied.

Reduction Factors - Edge and Spacing Distances for Bolt Projecting and Loose Bolt in Concrete

M6 M8 M10 M12 M16 M20 M24

0.50

0.50

0.60

0.50

0.50

PT 3054 3156/83

1

1

All steel assembly

for maximum

performance even in

fire situations

2

Provides a projecting

stud to support fixture

thicknesses during

installation and

removal up to 120mm

3

Ferrule marked with

hole diameter for

ease of installation

4

Pressed steel

segments ensure

consistent dimensional

accuracy and positive

expansion

5

Optimum taper nut

angle for maximum

expansion in all

substrates and unique

anit-rotation fins

SPACING

(mm)

EDGE

(mm)

Technical Advisory Service & + 44 (0) 141 638 7961 E-mail: techadvice@rawlplug.co.uk Technical Advisory Service Fax: + 44 (0) 141 273 2335 E-mail: techadvice@rawlplug.co.uk

Rawlbolt

Shield Anchor

Bolt Projecting

0.67

Rawlbolt

Shield Anchor

Bolt Projecting

Product Data

The Rawlbolt

Shield Anchor is the worlds most popular, high

quality torque controlled expanding anchor, combining ease of

installation with good load carrying capacity.

The Rawlbolt

Shield Anchor is the ideal general purpose

anchor bolt having higher degrees of expansion than other

types of expansion anchor and excellent tolerance to variations

in hole sizes. The collapsible ferrule ensures a positive

clamping force is transmitted to the fixture. Expansion shield is

available without the bolt. Where cracked concrete may exist an

alternative The Rawlbolt

Shield Anchor is available.

Available in:

Yellow passivated zinc-plated steel

Typical Applications:

Roller Shutter Doors Security Grills Steelwork

Fire Doors Machinery Barriers

Wall Plates Signs Fencing

Approvals:

The Rawlbolt

anchor is approved by major UK and International

Independent approval bodies.

For reduction factors for 8.8 grade bolts see page 3

For Installation see back cover

3 2 4 5

Rawlbolt

Shield Anchor: Bolt Projecting

CONCRETE,

BRICKWORK & STONE

REF

M6 10P

M6 25P

M6 60P

M6

M8

M10

M12

M20

65

80

115

75

90

125

90

105

135

110

125

170

170

185

255

45

50

60

75

12

14

16

20

0

0

0

0

0

10

30

6.5

9.0

11

13

50

55

65

85

140

70 6.5 5.0

44-505

44-510

44-515

80 15 7.5

44-555

44-560

44-565

100 27 13

44-605

44-610

44-615

120 50 23

44-655

44-660

44-665

10

25

60

10

25

60

15

30

60

15

30

75

M8 10P

M8 25P

M8 60P

M10 15P

M10 30P

M10 60P

M12 15P

M12 30P

M12 75P

M20 15P

M20 30P

M20 100P

BOLT

SIZE

(d)

BOLT

LENGTH

(mm)

(l)

SHIELD

LENGTH

(mm)

(s)

FIXTURE THICKNESS

(mm)

HOLE DIAMETER

(mm)

PRODUCT

CODE

MAX

(mm)

(T

fix

)

IN STRUCTURE

(d

f

)

MIN

(mm)

(T

fix

)

IN FIXTURE

(d

f

)

MINIMUM

HOLE

DEPTH

(mm)

(h

o

)

MINIMUM

SUBSTRATE

THICKNESS

(mm)

(h

min

)

RECOMMENDED

TORQUE (Nm)

30N/mm

2

Concrete

(Nm)

(T

inst

)

20.5N/mm

2

Concrete

(Nm)

(T

inst

)

M16

M24

M16 15P

M16 35P

M16 75P

M24 75P

M24 120P

255

300

150

170

210

115

130

150

15

35

75

15

30

100

75

120

0

75

0

10

35

25

32

38

17

22

26 160

125 190 120 -

44-705

44-710

44-715

220 230 -

44-755

44-760

44-765

240 400 -

44-805

44-810

Spacing (Concrete)

TENSILE & SHEAR REDUCTION FACTORS

M6 M8 M10 M12 M16 M20 M24

60

80

100

120

150

180

210

250

290

330

370

420

0.80

0.70

0.90

1.0

0.80

0.70

0.90

1.0

0.80

0.70

0.90

1.0

0.78

0.70

0.85

0.93

1.0

0.70

0.78 0.70

0.85 0.78

0.93

1.0

Edge Distance for 5.8 Grade Bolts (Concrete)

TENSILE : EDGE REDUCTION FACTORS

30

M6 M8 M10 M12 M16 M20 M24

1.0 0.90 0.80 0.70

0.94 0.88

0.94

1.0

80

220

250

280

50 0.70

60 0.80 0.70

70 0.90 0.80 0.70

100 0.78

120 0.85 0.78

0.70

140 0.93 0.85

160 0.93 0.82

190 1.0

1.0

0.88 0.82

0.76

0.70 0.76

0.70

0.90

1.0

0.85 0.76

0.93 0.82

1.0 088

0.94

1.0

1.0

1.0

0.70

Concrete

Loads shown are for 30N/mm

2

(C20/25) concrete. For other

grades of concrete between 20 and 50N/mm

2

where the anchor

is in tension the load can be calculated using the following

empirical formula:

This calculation is not valid for shear.

By using spacers the anchor can be set at increased depths which

will generally improve the tensile performance. This option should

be considered for substrates of lower strength than 25N/mm

2

.

Brickwork

Loads shown are for 20.5N/mm

2

brick. The anchor should be

positioned a minimum of 300mm from the vertical edge of the

wall and four courses down from the top of an unrestrained wall.

Installing the anchor into mortar joints should be avoided.

Edge and Spacing Distances (concrete only)

The loads shown are applicable to characteristic edge and

spacing distances. For reduced edge and spacing distances,

reduction factors must be calculated from the appropriate tables

below.

Combined Load (concrete only)

When selecting an anchor which will carry a combined load,

ensure that the bolt size selected satisfies the following

equation:

(Edge and spacing reduction factors, if applicable, should be

applied to the safe tensile and safe shear loads).

+

1.2

Applied Tensile Load

Safe Static Tensile Load

Applied Shear Load

Safe Static Shear Load

x

Tensile SWL in

30N/mm

2

Concrete

Actual Concrete Strength

30

Design Data

SHEAR : EDGE REDUCTION FACTORS

0.67

0.50

0.83

1.0 0.83

1.0

0.67

0.83

1.0

0.60

0.73

0.87

1.0

0.73

0.87

1.0 0.67

0.83 0.67

1.0 0.83

1.0

Performance Data at Standard Embedment Depth

SIZE

M6

M8

.M10

M12

M20

M16

M24

3.3 4.4

4.8 5.6

6.2 8.9

9.7 12.9

31.2 37.5

21.3 24.1

38.0 54.1

6.8

8.7

13.7

19.9

60.0

36.9

86.6

12.2

15.4

21.2

30.9

100.5

73.1

125.5

80

100

120

160

250

190

280

120

150

180

250

330

290

420

1.8

2.3

2.9

4.3

Bolts above

M12 are not

recommended

in brickwork

CONCRETE 30N/mm

2

(C20/25) BRICKWORK 20.5N/m

2

SAFE WORKING LOAD

(kN)

Tension & Shear

CHARACTERISTIC SPACING DISTANCE

(mm)

SAFE WORKING LOAD (kN) FAILURE LOAD (kN) CHARACTERISTIC EDGE DISTANCE

(mm)

Tension & Shear Tension

Shear

5.8G 8.8G

9.7

12.4

19.6

28.5

82.6

53.0

119.0

14.9

19.0

30.2

43.8

132.0

81.3

190.5

Shear

5.8G 8.8G

80

100

120

160

250

190

280

100

120

160

180

300

260

350

Shear

5.8G 8.8G

Tension Tension

The characteristic edge and spacing distances quoted in the table

above are the minimum allowable for the quoted safe loads to apply.

Where the design dictates reduced edge and spacing

distances, the appropriate reduction factor/s from the tables

below must be applied to the safe working load.

Choose the required bolt diameter across the top of the table

and read down the left hand column until actual edge or

spacing distance is found. Read off the reduction factor where

the two lines intersect (interpolate as required). Multiply this

factor by the safe working load quoted in the table. On the

occasion that multiple close edge and/or spacing distances

occur, the appropriate reduction factors must be applied.

Reduction Factors - Edge and Spacing Distances for Bolt Projecting and Loose Bolt in Concrete

M6 M8 M10 M12 M16 M20 M24

0.50

0.50

0.60

0.50

0.50

PT 3054 3156/83

1

1

All steel assembly

for maximum

performance even in

fire situations

2

Provides a projecting

stud to support fixture

thicknesses during

installation and

removal up to 120mm

3

Ferrule marked with

hole diameter for

ease of installation

4

Pressed steel

segments ensure

consistent dimensional

accuracy and positive

expansion

5

Optimum taper nut

angle for maximum

expansion in all

substrates and unique

anit-rotation fins

SPACING

(mm)

EDGE

(mm)

Technical Advisory Service & + 44 (0) 141 638 7961 E-mail: techadvice@rawlplug.co.uk Technical Advisory Service Fax: + 44 (0) 141 273 2335 E-mail: techadvice@rawlplug.co.uk

You might also like

- Engineering Bolt Clearance Dimensions ChartDocument1 pageEngineering Bolt Clearance Dimensions Chartmas ayuNo ratings yet

- Orion 18 Quick Start GuideDocument43 pagesOrion 18 Quick Start GuideMohd Haiqal100% (1)

- Chapter 20 Sections 1-87 SummaryDocument85 pagesChapter 20 Sections 1-87 SummaryHervé KoudouNo ratings yet

- Lionweld Kennedy GratingDocument40 pagesLionweld Kennedy Gratingscribd-123No ratings yet

- Qseries BS5950Document11 pagesQseries BS5950jpkedahNo ratings yet

- Mcnichols Master Catalog PDFDocument60 pagesMcnichols Master Catalog PDFing_julio_siviraNo ratings yet

- sp1406 - Ds - Manual Servo Drive Unidrive SP 1406Document1 pagesp1406 - Ds - Manual Servo Drive Unidrive SP 1406danteNo ratings yet

- Troubleshooting and Repairing LCD TVsDocument195 pagesTroubleshooting and Repairing LCD TVsManoranjan Yadav95% (21)

- Rawlbolt: Shield Anchor Loose BoltDocument2 pagesRawlbolt: Shield Anchor Loose BoltBappy IslamNo ratings yet

- Column 1: Made by DateDocument12 pagesColumn 1: Made by DateHafiz KamarudinNo ratings yet

- Hilti CatalogueDocument40 pagesHilti CatalogueMatt Tremoglie100% (1)

- Mechanical Anchoring BoltDocument6 pagesMechanical Anchoring BoltMani MaranNo ratings yet

- Welding Guide BrochureDocument4 pagesWelding Guide BrochureAnonymous 6aGAvbNNo ratings yet

- Code Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and MaterialsDocument6 pagesCode Description Unit Quantity Rate Amount: Sub Head: 26-New Technologies and MaterialsAtul GargNo ratings yet

- Reference Description of Problem Values Units: Infomile SolutionsDocument3 pagesReference Description of Problem Values Units: Infomile SolutionsdhawanaxitNo ratings yet

- Base Transceiver Station: Trans-Receiving Antenna For Communication PurposeDocument1 pageBase Transceiver Station: Trans-Receiving Antenna For Communication PurposeemmanuelNo ratings yet

- 06 Eurocodes Steel Workshop WALDDocument136 pages06 Eurocodes Steel Workshop WALDFrancisco RojasNo ratings yet

- Design Philosophy and Special RC Elements Question BankDocument8 pagesDesign Philosophy and Special RC Elements Question BanklavanyaNo ratings yet

- STEPOC 150dpiDocument6 pagesSTEPOC 150dpinick8081No ratings yet

- Test Track - Pluming Boq Final-GDocument12 pagesTest Track - Pluming Boq Final-Gsmathy68100% (2)

- Ground Slab Design (Zone-4)Document769 pagesGround Slab Design (Zone-4)AbhiNo ratings yet

- Hilti CatalogueDocument194 pagesHilti CatalogueFeleki AttilaNo ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- S-Frame Theory ManualDocument81 pagesS-Frame Theory ManualriefsaldyNo ratings yet

- Install Guide Spunlite Poles 2015Document6 pagesInstall Guide Spunlite Poles 2015Balaji PalaniNo ratings yet

- Price List 2017 PDFDocument32 pagesPrice List 2017 PDFOscar Waiharo50% (2)

- Pole CatalogueDocument19 pagesPole CatalogueTesfahun GirmaNo ratings yet

- Davit Trolley - Validation of Davit & Support BracketDocument17 pagesDavit Trolley - Validation of Davit & Support BracketRanjit S KashyapNo ratings yet

- Handrail StandardsDocument4 pagesHandrail StandardsSachin SithikNo ratings yet

- Inertia BaseDocument2 pagesInertia BasePackiaraj KrishnasamyNo ratings yet

- Alom aluminium profiles catalogueDocument112 pagesAlom aluminium profiles cataloguePrabartak DasNo ratings yet

- Thaltej BBS EditedDocument623 pagesThaltej BBS EditedMehta MalayNo ratings yet

- Table 1 of Road Note 27 PDFDocument1 pageTable 1 of Road Note 27 PDFFlavioMuhaleNo ratings yet

- 12m Octagonal Pole Design Column Base CalculationsDocument5 pages12m Octagonal Pole Design Column Base CalculationsJohn G Jose100% (1)

- ISMC StandardDocument2 pagesISMC StandardauazarNo ratings yet

- Catalog ChinaDocument61 pagesCatalog Chinaa.muhammadNo ratings yet

- Calculating The Amount of Aluminium Roofing Sheet For A BuildingDocument4 pagesCalculating The Amount of Aluminium Roofing Sheet For A BuildingDayo Idowu50% (2)

- Steel TablesDocument2 pagesSteel TablesAnonymous mcHqIfbnV1No ratings yet

- Weld Stress CalculationsDocument11 pagesWeld Stress CalculationsjlolhnpNo ratings yet

- BS8118 (Part)Document16 pagesBS8118 (Part)Hoe Tommy100% (1)

- HSFG bolt design capacitiesDocument5 pagesHSFG bolt design capacitiesSanthi KrishnaNo ratings yet

- Base Plate Shear Concrete Edge FailureDocument5 pagesBase Plate Shear Concrete Edge FailureJoel Nolan de Carvalho0% (1)

- Panasonic Conduits PDFDocument1 pagePanasonic Conduits PDFCharilyn EcheverreNo ratings yet

- NCCI Initial Sizing of Vertical BracingDocument8 pagesNCCI Initial Sizing of Vertical BracingCristian BlanaruNo ratings yet

- Alluminium Section PropertiesDocument4 pagesAlluminium Section PropertiesGihan ChathurangaNo ratings yet

- ALL Bowmans Catalogue With IndexDocument144 pagesALL Bowmans Catalogue With IndexEshan AlawalaNo ratings yet

- Rectangular Hollow Section-Hot Formed-BS en 10210-21997Document4 pagesRectangular Hollow Section-Hot Formed-BS en 10210-21997Jagdish ChhuganiNo ratings yet

- BoltDocument2 pagesBoltmuhannedNo ratings yet

- DIN 15018-1-1984, Cranes, Steel Structures PDFDocument38 pagesDIN 15018-1-1984, Cranes, Steel Structures PDFSebastian Velásquez MoralesNo ratings yet

- Rate List Supplier Mplun PDFDocument4 pagesRate List Supplier Mplun PDFyash100% (1)

- BS 5975 1996 FalseworkDocument16 pagesBS 5975 1996 FalseworkAnıl Özpirinçi0% (1)

- Single and Double Sliding Door DetailsDocument265 pagesSingle and Double Sliding Door DetailsUppala Krishna ChaitanyaNo ratings yet

- Halfen Coupler Mechanical Rebar SplicingDocument33 pagesHalfen Coupler Mechanical Rebar Splicingcarlosfilipegomes3994No ratings yet

- SA RawlboltDocument2 pagesSA Rawlboltpower_generator133850% (2)

- 9449 Macalloy Tension StructuresDocument16 pages9449 Macalloy Tension StructuresYam BalaoingNo ratings yet

- F.D. Accesssory BrochureDocument34 pagesF.D. Accesssory BrochureKallumRowlandsNo ratings yet

- MK4 Posttensioning SpecificationsDocument28 pagesMK4 Posttensioning SpecificationsshashireshNo ratings yet

- Ramset Specifiers Anchoring Resource Book ANZ - C101 PLUS Anchor StudsDocument8 pagesRamset Specifiers Anchoring Resource Book ANZ - C101 PLUS Anchor Studschintan_jajalNo ratings yet

- Dywidag High Strength BarsDocument4 pagesDywidag High Strength Barsnishchint100% (1)

- Gratings BrochureDocument22 pagesGratings BrochureN P Srinivasarao100% (2)

- Zinc Plated Shield Anchor Hex BoltDocument1 pageZinc Plated Shield Anchor Hex BoltMarko KavaricNo ratings yet

- Microcontroller configuration options guideDocument12 pagesMicrocontroller configuration options guidewesker2010No ratings yet

- Nittan Smoke DetectorsDocument1 pageNittan Smoke DetectorsShakti Kumar Achyut KurupNo ratings yet

- NCP1010, NCP1011, NCP1012, NCP1013, NCP1014 Self-Supplied Monolithic Switcher For Low Standby-Power Offline SMPSDocument23 pagesNCP1010, NCP1011, NCP1012, NCP1013, NCP1014 Self-Supplied Monolithic Switcher For Low Standby-Power Offline SMPSrehanNo ratings yet

- Cone Ranger: Mobile Cone Crushing UnitsDocument2 pagesCone Ranger: Mobile Cone Crushing UnitsYousef AlipourNo ratings yet

- SEO 7N60 7N65 Power MOSFET DatasheetDocument7 pagesSEO 7N60 7N65 Power MOSFET Datasheetsunder punjabiNo ratings yet

- TG16 - 14 Anchoring To The GroundDocument4 pagesTG16 - 14 Anchoring To The GroundDerek ReddinNo ratings yet

- Final Project PPTDocument20 pagesFinal Project PPTsadiqul azamNo ratings yet

- Armoire Midea MfgaDocument1 pageArmoire Midea MfgalacothNo ratings yet

- Computer Based ControllerDocument44 pagesComputer Based Controllerksjanarthanan_sriNo ratings yet

- DAC Presentation PDFDocument224 pagesDAC Presentation PDFLUIS FELIPE LIZCANO MARINNo ratings yet

- 3408E Industrial Engine Electrical System: Top ViewDocument2 pages3408E Industrial Engine Electrical System: Top ViewxuanNo ratings yet

- Trainer Privilege ProceduresDocument6 pagesTrainer Privilege ProceduressalooniNo ratings yet

- 8l Pkgcomparison 1220a 003Document1 page8l Pkgcomparison 1220a 003Ben LernerNo ratings yet

- Commercial Vehicle Aftermarket Catalog en UsDocument56 pagesCommercial Vehicle Aftermarket Catalog en UsAion RadamanthysNo ratings yet

- DKG 972Document6 pagesDKG 972David RamirezNo ratings yet

- MTH400 / MTH4000Document5 pagesMTH400 / MTH4000SORINNo ratings yet

- Model 800: Applications IncludeDocument2 pagesModel 800: Applications IncludeKikokNo ratings yet

- Volvo - Manutenzione e MotoreDocument209 pagesVolvo - Manutenzione e MotoreAlex VdbusscheNo ratings yet

- 20 - RT-flex - Mechanical Features PDFDocument75 pages20 - RT-flex - Mechanical Features PDFИгорь БакановNo ratings yet

- Electrical system malfunctions: Measuring engine cablesDocument1 pageElectrical system malfunctions: Measuring engine cablesuser1No ratings yet

- EtherWAN EX42005-00-1-A User ManualDocument20 pagesEtherWAN EX42005-00-1-A User ManualJMAC SupplyNo ratings yet

- Woodstick Price List 2023Document1 pageWoodstick Price List 2023simranNo ratings yet

- Komatsu PC 300-8 PDFDocument420 pagesKomatsu PC 300-8 PDFAbraham Huacasi100% (1)

- Flatmii 125 UserguideDocument11 pagesFlatmii 125 UserguidelimeoneNo ratings yet

- R-100 Data Sheet en A 0Document8 pagesR-100 Data Sheet en A 0Shah12No ratings yet

- Protection Engineering and Research Laboratories: Session VII: Transformer ProtectionDocument105 pagesProtection Engineering and Research Laboratories: Session VII: Transformer Protectionsupermannon100% (8)

- Brosur Elmo t3Document2 pagesBrosur Elmo t3ANISA DESYNo ratings yet

- Baumfolder FlexifoldDocument2 pagesBaumfolder FlexifoldKBR Graphics CanadaNo ratings yet