Professional Documents

Culture Documents

Design Integrity Report

Uploaded by

akankwasa100%(1)100% found this document useful (1 vote)

336 views24 pagesA three-storied condominium residential development (apartments) on plot 3 Kimera close, Bugolobi in Nakawa division of Kampala city. The original structural design calculations were prepared in India based on Indian design codes. This report shows a design review based on British standards i.e. BS8110 Part 1 of 1997. The structure was designed to meet both strength and serviceability requirements when subjected to both gravity and lateral loads.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA three-storied condominium residential development (apartments) on plot 3 Kimera close, Bugolobi in Nakawa division of Kampala city. The original structural design calculations were prepared in India based on Indian design codes. This report shows a design review based on British standards i.e. BS8110 Part 1 of 1997. The structure was designed to meet both strength and serviceability requirements when subjected to both gravity and lateral loads.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

336 views24 pagesDesign Integrity Report

Uploaded by

akankwasaA three-storied condominium residential development (apartments) on plot 3 Kimera close, Bugolobi in Nakawa division of Kampala city. The original structural design calculations were prepared in India based on Indian design codes. This report shows a design review based on British standards i.e. BS8110 Part 1 of 1997. The structure was designed to meet both strength and serviceability requirements when subjected to both gravity and lateral loads.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 24

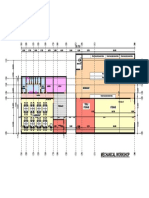

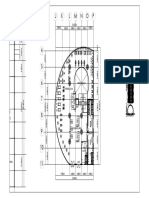

Proposed Condominium Residential Maissonnetts

on Plot 1 Bandali Close Nakawa Division Kampala

Structural Integrity Report and Design Calculations

Client:

Krish Developers and Consultants

P.O.Box 28341, Kampala

Date: March 2014

Report/Calculations by:

Checked /approved by:

2

Executive summary

This report presents the structural integrity report, analysis and design of a three-storied

condominium residential development (apartments) on plot 3 Kimera close, Bugolobi in

Nakawa division of Kampala city. The development comprises four blocks A,B,C and D. The

blocks are typical with the same design and dimensions.

The construction started and all the four blocks are halfway done i.e. up to the second floor

level. The original structural design calculations were prepared in India based on Indian

design codes. This report shows a design review based on British standards i.e. BS8110 Part 1

of 1997. The structure was designed to meet both strength and serviceability requirements

when subjected to both gravity and lateral loads.

Since the structure has already been constructed halfway, the KCCA planning committee

demanded for a structural integrity report for the as-is structure before approving further

construction to take place.

For strength design, the Limit state criteria were used where all standard load combinations

were considered and members were designed to resist the ultimate factored loads.

For serviceability design, beam deflections were limited to L/200 and L/360 where relevant

according to the BS8110 1997 structural use of reinforced concrete code. Cracking was also

controlled by the spacing limitations for reinforcement according to the design code.

Findings from integrity report

The quality of workmanship exhibited on the site is quite satisfactory with fair finishes and

straight edges. The structural drawings being used are followed strictly. Number and size of

reinforcing bars are all adhered to. The grade of concrete looks good and to the right grade.

Results from the structural design calculations indicate that the design conforms to the

BS8110 recommendations.

3

4

5

6

Table of contents

Executive summary .......................................................................................................................................... 2

Table of contents .............................................................................................................................................. 6

1 Introduction .............................................................................................................................................. 7

2 Visual inspection ...................................................................................................................................... 7

2.1 Design technique and philosophy .................................................................................................. 8

2.2 Loading ............................................................................................................................................. 8

2.3 Geotechnical Conditions .................................................................................................................. 8

2.4 Design Loadings ............................................................................................................................... 8

2.5 Deflection Criteria ........................................................................................................................... 9

2.6 Durability ....................................................................................................................................... 10

3 Framed structural system design .......................................................................................................... 11

3.1 Design of floor slab ........................................................................................................................ 11

3.2 Design of stair case ........................................................................................................................ 13

3.3 Design of beams .............................................................................................................................. 17

3.3.1 Design of ring beam ...................................................................................................................... 17

3.3.2 Design of columns ......................................................................................................................... 20

3.3.3 Design of foundation bases .......................................................................................................... 21

References ....................................................................................................................................................... 22

7

1 Introduction

This report shows the design calculations for the most critical elements of the structure. These

elements include the largest slab panel, the staircase, the beams, load-bearing walls, columns,

strip footings and foundation bases. For clarity refer to the architectural and structural

drawings attached.

2 Visual inspection

Scope of Visual Inspection

Prior to the commencement of visual inspection, the structural engineer obtained a set of the

buildings structural layout plans from the building owner. The availability of the structural

layout plan helped the structural engineer to:

(a) Understand the structural system and layout of the building;

(b) Identify critical areas for inspection;

(c) Identify the allowable imposed loads, in order to assess the usage and possibility of

overloading; and

(d) Verify if unauthorised addition or alteration works that affect the structure of the building

have been carried out.

In general, the structural engineer carried out, with reasonable diligence, a visual inspection

of:

a) The condition of the structure of the building

- to identify the types of structural defects

- to identify any signs of structural distress and deformation

- to identify any signs of material deterioration

b) the loading on the structure of the building

- to identify any deviation from intended use, misuse and abuse which can result in

overloading

c) any addition or alteration works affecting the structure of the building

8

- to identify any addition or alteration works which can result in overloading or adverse

effects on the structure.

Since there were no signs of any structural deterioration or defects, the visual inspection

should suffice and no further action needs to be taken.

2.1 Design technique and philosophy

It is proposed that the general structural format of the building will include a system of

approximately parallel T-beams on the columns/walls lines. Preliminary design has shown

that the depth of beams will be in the range on 425mm by 230mm wide. The slab will be

designed as a solid slab since that is already done on site.

2.2 Loading

Design codes and floor loadings

The building has been designed in accordance with the re following British standards:

o BS 6399-1 1996 for dead and imposed loads

o BS 6399 Part 2 1997 for wind loads

o BS 8110 1997 Structural use of concrete

o BS 5950 Part 1, 1985 Structural use of steel

The following design live loads will be used for this building:

2.3 Geotechnical Conditions

The ground conditions are were postulated by visual inspection and experience of the design

engineer. No geotechnical tests were carried out on the site hence a conservative soil bearing

capacity of 200kN/m has been used in these calculations.

2.4 Design Loadings

The following design loadings have been derived from the Courts Standards and Design Guide

2007, in conjunction with relevant British Standards:

Imposed Loads

Offices 2.5 kN/m (+ 1.0 kN/m for demountable partitions)

9

Court Rooms 4.0 kN/m

Circulation Areas 4.0 kN/m

Staircases 4.0 kN/m

Roof (with only limited access) 0.6 kN/m

Roof (with access) 0.75 kN/m

Superimposed Dead Loads

Ceiling and Services 0.5 kN/m

Raised Access Floor 1.0 kN/m

Blockwork Partitions 3.0kN/m generally but will be assessed by calculation

Wind Loading

Wind loading was assessed in accordance with BS 6399-2.

Basic Site Wind Speed Vb = 31m/s

Site Altitude _s = 10 m

Design wind pressures have been derived taking into account the altitude, relevant

topography and building geometry.

2.5 Deflection Criteria

The design code stipulates that the total deflection of the floors and total incremental

deflection of the floors cannot exceed 25 mm and 20 mm respectively. This criterion has been

strictly adhered to in all design considerations.

Design Movements

Settlement

Overall settlement of the building is not expected to exceed 25mm.

Differential settlement between piles is not expected to exceed 5mm.

Vertical Deflection limits

Concrete Slabs/Beams generally: Span/250

10

Concrete Edge Beams supporting masonry or glazing: Span/500

Concrete Slabs/Beams supporting brittle finishes: Span/360

Structural Steel Elements generally: Span/200

Structural Steel Elements supporting brittle finishes: Span/360

Horizontal Deflection Limits

Structural Elements supporting masonry or glazing: Span/500

Relative Floor to Floor movement generally: Height/300

2.6 Durability

Structural concrete elements of the built form are to have a design durability, which complies

with the requirements of BS8110: 1997. The exposure condition for each element is shown in

the calculations.

Design Life

All structural elements will be designed to achieve a minimum design life of 60 years.

Protective coatings to structural steelwork will be specified to provide a minimum period of

20 years to first maintenance. Any steelwork inaccessible after completion of the structure

will be specified to provide a minimum period of 60 years to first maintenance.

Fire Resistance

The design of structural elements is to be based on fire resistance levels to satisfy code

requirements as advised.

11

3 Framed structural system design

The framed structural system is designed to transfer vertical and horizontal loading through

the combined action of beams and columns network. The design of elements is therefore done

string with slabs followed by beams up to the column bases.

3.1 Design of floor slab

The typical slab for all floors below the terrace is similar in geometry hence all panels are

exactly the same. The only difference is the imposed loading on the slabs.

Ref: BS

8110: 1997

Calculations Output

Dimensional considerations: Slab panel S1

Lx = 4.4m , Ly = 5.0m

Ly/Lx = 1.14 ~ 1.2 (2-way slab panel)

Ly/lx = 1.14

Fig. 3.2

Table 3.4

Durability and fire resistance

Minimum floor thickness for 1.5 hour fire resistance = 110mm

Minimum concrete cover for continuous floors for 1.5 hour fire

resistance = 20mm

C = 20mm

Loading

Try a slab with thickness 125mm

Dead loads:

Self-weight = 0.125 x 24 = 3 kN/m

Finishes = 0.05 x 21 = 1.05 kN/m

Total characteristic dead load gk = 4.05 kN/m

Imposed/live loads

Qk for residential use) = 1.5 kN/m

Design loading, n = 1.4gk + 1.6qk

= 1.4 (4.05) + 1.6 (1.5) = 8.07 kN/m

H = 125mm

Gk =

4.05kN/m

Qk =

1.5kN/m

3.5.3.6

Table 3.14

Bending moment and shear

Moments

msx = sxlx, msy = sylx

for a 2-way slab panel with one short edge discontinuous,

support moment in x-direction Msx = 0.052 x 8.07 x 4.4 = 8.12 kNm

Mx = 8.12

kNm

12

Table 3.15

span moment in x-direction Msx = 0.039 x 8.07 x 4.4 = 6.09 kNm

support moment in y-direction Msy = 0.037 x 8.07 x 4.4 = 5.78 kNm

span moment in y-direction Msy = 0.028 x 8.07 x 4.4 = 4.37 kNm

Shear forces

Vsx = vx nlx , Vsy = vynlx

For a 2-way slab panel with one short edge discontinuous,

Shear force in x-direction Vsx = 0.44 x 8.07 x 4.4 = 15.62 kN

V = 15.62 kN

3.4.4.4

Table 3.25

Reinforcement steel: moment

Support moment steel,

With c = 20mm, assume a 12mm bar diameter,

Therefore effective depth d = 125 20 -12/2 = 99mm

Considering a 1m strip of slab,

K = M/fcubd = 8.12 x 10

6

/(25 x 1000 x 99) = 0.033 < 0.042

Z = 0.95d = 94.05mm

As= M/0.95fyZ

= 8.12 x 10

6

/(0.95 x 460 x 94.05)

= 197.56 mm

100As/bh = 100 x 197.56 /(1000 x 125) = 0.15% >As, min

Provide T10@300 cc, As = 262 mm

Span moment steel

Md = 6.09 kNm

K = M/fcubd = 6.09 x 10

6

/25 x 1000 x 99 = 0.025 < 0.042

Z = 0.95d = 0.95 x 99 = 94.05mm

As = M/0.95fyZ = 6.09 x 10

6

/ (0.95 x 460 x 94.05) = 148.2 mm

As < As,min calculated above for same section

Provide T10@125mm As = 800 mm (to increase resistance to

deflection)

Distribution steel

Md = 4.37 kNm

K = M/fcubd = 4.37 x 10

6

/25 x 1000 x 99 = 0.013 < 0.042

Z = 0.95d = 0.95 x 99 = 94.05mm

As = M/0.95fyZ = 3.25 x 10

6

/ (0.95 x 460 x 94.05) = 79 mm

Provide

T10@300 cc

Top steel

Provide

T10@150 cc

Bottom steel

layer 1

Provide

T8@200 cc

bottom steel

13

As < As,min calculated above for same section

Provide T8@200mm As = 251 mm

layer 2

Table 3.8

Table 3.7

Shear

Vd = 15.62 kN

= Vd/bvd = 15.62 x 10 / (1000x99) = 0.16 N/mm < 5N/mm <

0.8fcu = 4N/mm

c = 0.79 x (100As/bvd)^1/3 x (400/d)^1/4 x 1/m

100As/bvd = 100 x 524 /(1000 x 99) = 0.53 < 3 OK

400/d = 400/99 = 4 > 1 OK

c = 0.79 x 0.53^(1/3) x 4^0.25 x 1/1.25 = 0.72 N/mm

0.5c = 0.36 > , therefore no shear reinforcement required.

Shear OK

3.4.6.3

Table 3.9

Table 3.10

Deflection

Allowable span/effective depth ratio = 26 x m.f.

Actual span/effective depth ratio = 4015/99 = 40.6

Modification factor for tension steel m.f. is given by

m.f. = 0.55 + (477-fs)/(120x(0.9+M/bd))

M/bd = 6.09 x 10

6

/(1000 x99) = 0.52 kN/m

Fs = 2/3 x fy x As,req/As,prov = 2/3 x 460 x 123 /524 = 71.98 N/mm

M.f. = 0.55 + (477-71)/(120x(0.9+0.52)) = 2.93 but M.f. must be < 2

Hence M.f. = 2

Allowable span/effective depth ratio = 26 x 2 = 52 > 40.6

Deflection

OK

3.12.11.2.4

Cracking control

Clear spacing between bars = 200 mm 12 mm = 188 mm

47000/fs = 47000/71 = 661 mm

Therefore clear spacing < 661 mm and <300mm

Cracking OK

3.2 Design of stair case

The structure has one type of staircase; to be constructed in three positions 2 on block A and 1

on block B.

REF CALCULATIONS OUTPUT

Staircase

14

REF CALCULATIONS OUTPUT

Design parameters

Treads = 0.240 m

Risers = 0.175 m

Waist depth = 0.175 m

Width of stairs = 1.15 m

Effective span = 4.722 m

Concrete unit weight = 24 kN/m

Finishings unit weight = 21 kN/m

Imposed loading = 4.0 kN/m

Thickness of finishing = 0.025 m

Fcu = 25 N/mm

Fy = 460 N/mm

Table 3.3

Table 3.5

Durability and fire resistance

Nominal cover for grade 25 concrete with mild exposure = 25 mm

Minimum thickness of floor slab for 1.5 hours fire resistance = 110

mm

Fire resistance

OK

Loading and Internal reactions

Tan = 172/240 , = tan-1 0.73 = 36

Assume 1 m strip of stair case,

Dead load gk:

Weight of steps = 0.5 x 0.172 x 0.233 x 1 x 24/0.233 = 1.92 kN/m

Weight of waist = 0.15x 1 x 1 x 24/cos 36 = 4.27 kN/m

Weight of finishings = 0.05 x 1 x1 x 21/cos 36 = 1.25 kN/m

Weight of landing = 0.15 x 1 x 1 x 24 = 3.6 kN/m

Total dead load on landing = 3.6 + 1.05 = gk=4.65 kN/m

Total dead load on flight = 1.92+ 4.27 + 1.25 = gk= 7.44 kN/m

Design load on landing = 1.4gk+1.6qk = 1.4(4.65)+1.6(4.0) = 12.91

kN/m

Design load on flight = 1.4gk+1.6qk = 1.4(7.44)+1.6(4.0) = 16.82 kNm

15

REF CALCULATIONS OUTPUT

Design moment Md = 24.25 kNm

Design Shear Vd = 28.56 kN

Table 3.25

Reinforcements

Assume bar size = 16 mm,

Eff. Depth, d = 150 25-16/2 = 117 mm

K= M/ fcubd = 24.25 x 10

6

/(25 x 1000 x 117) = 0.071 < 0.156

Z = d(0.5 +(0.25-k/0.9) = d(0.5+(0.25-0.071/0.9) = 0.91d

As = M/0.87fyZ = 24.25 x 10

6

/ 0.87 x 460 x 0.91 x 117 = 569.12 mm

Provide = T12@150 mm = 753 mm

Distribution steel area should be > 0.13%bh

= > 0.13% x 1000 x 200 = 260 mm

Provide T10@200c/c = 392 mm

Provide Bottom

T12@150 mm

(As= 753 mm)

Provide

Distribution

T10@200 cc

(As=392 mm)

Table 3.8

Shear

Shear force Vd = 28.56 kN

V = V/bvd = 28.56 x 10

3

/ (1000 x 117) = 0.244N/mm

V= 0.8fcu = 0.825 = 4 N/mm

Dimensions OK.

100 As/bvd = 100 x 753 / (1000 x 117) = 0.64 N/mm

Vc = 0.79(100As/bvd)^1/3 x (400/d)^0.25 / m

= 0.79 x 0.64^1/3 x 2.4^0.25 /1.25 = 0.67 N/mm

V < 0.5 Vc = 0.30 N/mm

Shear resistance

OK

Table 3.9

Deflection

Basic span/effective depth ratio = 20

M/bd = 24.25 x 10

6

/(1000 x 117) = 1.77

Fs = 5fyAs,eq/8As,prov = 2 x 460 x 569 /(3 x 753) = 231.7 N/mm

Modification factor m.f. = 0.55 + (477-fs)/120(0.9+M/bvd) = 1.56

Limiting span/eff. Dept ratio = 20 x 1.56 = 31.2

Actual Span/eff. Depth ration = 3480/117 = 29.74

Actual < limiting and therefore deflection is ok

Deflection OK

Cracking control

16

REF CALCULATIONS OUTPUT

3.12.11.2.4

Clear spacing between bars = 150 mm 12 mm = 138 mm

47000/fs = 47000/231.7 = 202.8 mm

Therefore clear spacing < 202.8 mm

Cracking OK

17

3.3 Design of beams

The beam design was carried out using Prokon design software as shown in the following

attachments.

3.3.1 Design of ring beam

The ring beam is provided to receive the loading from the roof structures and to provide some

robustness to the entire structure especially as far as resistance to notional horizontal forces.

Although much of it is carried directly by the masonry walls, a few sections of it are suspended

at various openings and cantilevered points.

REF: BS

8110-1

CALCULATIONS OUTPUT

Table 3.2,

3.3, 3.4

Fig 3.2

Dimensional considerations

The most critical span where the ring beam is suspended is above the view

balcony, length = 4.15 m

For rectangular sections, simply supported the allowable span/eff. Depth

= 20

Assuming a modification factor of 1.2, then effective depth , d = 4150 /

(20x1.2) = 185.4 mm

Durability and fire resistance

For mild exposure conditions and 1.5 hour fire resistance provide a

concrete cover = 25 mm.

Assuming a link size of 8 mm and bar diameter of 16 mm, minimum depth

of ring beam, h = 185+25+8+16/2 =226 mm

Minimum beam width for 1.5 hour fire resistance = 200 mm take

architectural dimension of 200 mm.

Try beam depth h = 350 mm

Therefore effective depth, d = 350 -25-8-16/2 = 309 mm

Cover = 25 mm

B = 200 mm

H= 350 mm

Loading

Dead load:

- From purlins and tiles = 2.05 kN/m

18

REF: BS

8110-1

CALCULATIONS OUTPUT

- From trusses = 0.64 kN/m

- Self-weight of ring beam = 0.2x0.3x24x=1.44 kN/m

- Total dead load, gk = 4.13 kN/m

Live loads:

- From roof ,qk = 3.0 kN/m

Design load w = 1.4gk+1.6qk = 10.58 kN/m

Gk = 4.13 kN/m

Qk = 3.0 kN/m

W = 10.58

Bending moments and shear forces

Design moment Md = wl/8 = 10.58 x 4.45/8 = 26.2 kNm

Design shear force Vd = wl/2 = 10.58 x 4.45/2 = 23.5 kN

Md= 26.2 kNm

Vd = 23.5 kN

3.4.3

Table 3.25

Reinforcement

Assume bar size = 16 mm,

Eff. Depth, d = 35025-8-16/2 = 309 mm

K= M/ fcubd = 26.2 x 10

6

/(25 x 200 x 309) = 0.055 < 0.156

Z = d(0.5 +(0.25-k/0.9) = d(0.5+(0.25-0.055/0.9) = 0.93d

Hence Z = 0.93d

As = M/0.95fyZ = 26.2 x 10

6

/ 0.95 x 460 x 0.93x 309 = 208.6 mm

100AS/BH = 0.30 > As Min = 0.13

Provide = 2T16 bars, As = 402 mm

Provide 2T16 bars

Top and 2T16 bars

Bottom steel

Shear

Shear force Vd = 23.5 kN

V = V/bvd = 23.5 x 10

3

/ (200 x 309) = 0.38 N/mm

V= 0.8fcu = 0.825 = 4 N/mm Dimensions OK.

100 As/bvd = 100 x 402 / (200 x 309) = 0.65 N/mm

Vc = 0.79(100As/bvd)^1/3 x (400/d)^0.25 / m

= 0.79 x 0.65^1/3 x 1.29^0.25 /1.25 = 0.58 N/mm

V < Vc +0.4 = 0.98 N/mm therefore provide minimum links

Asv = 0.4xbvsv/0.87fy, assume a link spacing of 200 mm with mild steel

19

REF: BS

8110-1

CALCULATIONS OUTPUT

Table 3.25 stirrups, Asv = 0.4x200x200/0.87x250 = 73.56 mm , provide R8@200 mm

links

Provide links

R8@200 cc

3.4.6

Table 3.9

Table 3.10

Deflection

Basic span/effective depth ratio = 20

M/bd = 26.2x 10

6

/(200 x 309) = 1.37

Fs = 2fyAs,eq/3As,prov = 2 x 460 x 208.6/(3 x 402) = 159.1 N/mm

Modification factor m.f. = 0.55 + (477-fs)/120(0.9+M/bvd) = 1.71

Limiting span/eff. Depth ratio = 20 x 1.71 = 36

Actual Span/eff. Depth ration = 4450/309 = 14.4

Actual < limiting and therefore deflection is ok

Deflection OK

3.12.11.2.4

Cracking control

Clear spacing between bars = 200 mm 16 mm = 184 mm

Therefore clear spacing < 300mm

Cracking OK

20

3.3.2 Design of columns

The structure has been designed as a framed structure with the columns carrying the entire

loads from the beams and walls above.

The column design was also carried out using PROKON software and the relevant sheets are

attached below.

21

3.3.3 Design of foundation bases

The design of the foundation was carried out in order to safely transfer all the axial loads and

moment in the walls to the bearing ground (soil). The assumed soil bearing capacity based on

the nature of the soil is 200 kN/m.

22

References

Reynolds C.E., Steedman C.J. 1992. Examples of the Design of Reinforced Concrete Buildings to

BS 8110. 4

th

Edition

Ghosh S.K.,Domel Jr. W.A. 1992. Design of Concrete buildings for Earthquake and Wind forces

2

nd

Edition

Allen A.H. 1988. Reinforced Concrete design to BS 8110: simply explained. E.&F.N. Spon Ltd

Newyork, p. 133-137

Mosley W.H, Bungey J.H. 1990. Reinforced concrete design. Macmillan Press Ltd. Hampshire p

192-230

23

Appendix: Images of site works as-is

Figure 1:First floor slab (good and fair finishing)

Figure 2:Well-done blockwork with visibly strong mortar

24

Figure 3: Reinforcement doe as per original structural drawings

You might also like

- Two Storied Shed-2 - (30-08-21)Document116 pagesTwo Storied Shed-2 - (30-08-21)MD SohagNo ratings yet

- Structural Analysis Report OF Office Building IN Butwal, RupandehiDocument41 pagesStructural Analysis Report OF Office Building IN Butwal, RupandehiAsan GajurelNo ratings yet

- Steel Design Practical Design NotesDocument4 pagesSteel Design Practical Design NotesrangarajanNo ratings yet

- Load Calculations PDFDocument19 pagesLoad Calculations PDFJeffrey Buquing ValdezNo ratings yet

- Nirmal Asangaon Plot 8-9-Dbr 260219Document7 pagesNirmal Asangaon Plot 8-9-Dbr 260219Titus PraveenNo ratings yet

- ACI 318-14 RC Shear Wall Design - Short Walls PDFDocument9 pagesACI 318-14 RC Shear Wall Design - Short Walls PDFHuzil FernandezNo ratings yet

- Structural Steel Design CalculationsDocument21 pagesStructural Steel Design CalculationsthiệnNo ratings yet

- Staircase Handrail Design Using StaadDocument20 pagesStaircase Handrail Design Using StaadSukhbir SinghNo ratings yet

- Sign Board CalcsDocument34 pagesSign Board CalcsMimi MoragnNo ratings yet

- Design of Steel ShedDocument164 pagesDesign of Steel ShedKilaru HareeshNo ratings yet

- Zamildesignmanualnew 131129110110 Phpapp01 PDFDocument282 pagesZamildesignmanualnew 131129110110 Phpapp01 PDFBoto PodNo ratings yet

- Aluminium Rail Roof Top (R1)Document2 pagesAluminium Rail Roof Top (R1)krishna kumarNo ratings yet

- Design of Staircase - 3Document2 pagesDesign of Staircase - 3vinujohnpanickerNo ratings yet

- Structural Design CriteriaDocument15 pagesStructural Design Criteriashafiq_05100% (2)

- Struct ReportDocument40 pagesStruct Reportsam_antony2005No ratings yet

- CT-631. Design Calculation Sheet. Rev.01 PDFDocument136 pagesCT-631. Design Calculation Sheet. Rev.01 PDFErnest Navarro100% (1)

- Wind Load-Components and Cladding ExampleDocument2 pagesWind Load-Components and Cladding ExampleMallesh NenkatNo ratings yet

- Structural Design Report NBC105-2020Document122 pagesStructural Design Report NBC105-2020Prakash Singh RawalNo ratings yet

- Canopy - Final Design PDFDocument4 pagesCanopy - Final Design PDFDhina karanNo ratings yet

- Footing Design Result-RcdcDocument360 pagesFooting Design Result-RcdcJoseph Cloyd L. LamberteNo ratings yet

- 2.1 Wind LoadDocument2 pages2.1 Wind LoadNorman Christopher PalomoNo ratings yet

- MBS Installation HelpDocument26 pagesMBS Installation HelpMohamed SalikNo ratings yet

- DR - Majid Albana CalculationDocument22 pagesDR - Majid Albana CalculationStruct EngineeringNo ratings yet

- Isolated Footing For PedestalDocument3 pagesIsolated Footing For Pedestalkushaljp8989No ratings yet

- AL Jazeera Design Calculation PDFDocument9 pagesAL Jazeera Design Calculation PDFwaquarshaiNo ratings yet

- Foundation Design Calculation GondaDocument6 pagesFoundation Design Calculation GondaManinder ChaudharyNo ratings yet

- KW 17449 PDFDocument770 pagesKW 17449 PDFTrungNguyen100% (1)

- Fence Type-3: Design Calculation Sheet HYD-121 FenceDocument18 pagesFence Type-3: Design Calculation Sheet HYD-121 FenceAbhilash KowndinyaNo ratings yet

- Detail Design and Analysis of Earthquake PDFDocument59 pagesDetail Design and Analysis of Earthquake PDFSabih Hashim Alzuhairy100% (1)

- GRC Design and LoadsDocument4 pagesGRC Design and Loadsmohamed rafiNo ratings yet

- Structural Calculations For Metal Structure and Fence Legalization PlansDocument34 pagesStructural Calculations For Metal Structure and Fence Legalization PlansAlejandro MorelNo ratings yet

- Design and Calculation of Fixing GRC Elements: Rev. No: 1 Date: 26-SEP-15Document10 pagesDesign and Calculation of Fixing GRC Elements: Rev. No: 1 Date: 26-SEP-15Deepum HalloomanNo ratings yet

- Analysis and Design of High-Rise Building (G+30) Using Staad - ProDocument5 pagesAnalysis and Design of High-Rise Building (G+30) Using Staad - ProআকাশআহসানNo ratings yet

- Design Basis For Roof TrussDocument22 pagesDesign Basis For Roof TrussUmer AziqNo ratings yet

- Pre Egineered Structural Steel Stadium Design BasisDocument9 pagesPre Egineered Structural Steel Stadium Design Basissahil bendreNo ratings yet

- 2.0 Wind LoadDocument2 pages2.0 Wind LoadNorman Christopher PalomoNo ratings yet

- Assessment ReportDocument16 pagesAssessment ReportNalex GeeNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Structural Design StepsDocument4 pagesStructural Design StepsAnonymous ciKyr0tNo ratings yet

- Zed Purlins Dsample Design Calculations in XL FormatDocument10 pagesZed Purlins Dsample Design Calculations in XL FormatmoneofficeNo ratings yet

- AssignmentDocument23 pagesAssignmentIndustry Standard Structural DesignNo ratings yet

- Zamil Sample CalculationsDocument108 pagesZamil Sample CalculationsAshraf KhalifaNo ratings yet

- Rafter To Column Top Connection Design Given DataDocument10 pagesRafter To Column Top Connection Design Given DataSafi Zabihullah SafiNo ratings yet

- Base Shear CalculationDocument7 pagesBase Shear Calculationsurendra bhattaNo ratings yet

- Structural Analyis Report-PALPADocument36 pagesStructural Analyis Report-PALPAAastha AdhiakariNo ratings yet

- Structural Design ReportDocument12 pagesStructural Design ReportilijarskNo ratings yet

- Strip Footing ExampleDocument5 pagesStrip Footing ExampleBunkun15No ratings yet

- Flat Slab Design To Bs8110-Part 1-1997Document23 pagesFlat Slab Design To Bs8110-Part 1-1997sskamalakannanNo ratings yet

- Platform-Report FinaleDocument24 pagesPlatform-Report FinaleFeroz Khan PatthanNo ratings yet

- Part 6 Analysis and Design of Purlins W PDFDocument17 pagesPart 6 Analysis and Design of Purlins W PDFCalvin TehNo ratings yet

- Crack Width Check (CoP Concrete 2013) CPRDocument4 pagesCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNo ratings yet

- Design and Analysis OF Multi-Storied BuildingsDocument41 pagesDesign and Analysis OF Multi-Storied BuildingsDeepak Bharati100% (1)

- Z-Purlin Data Sheet Rev06. 19-2-17Document19 pagesZ-Purlin Data Sheet Rev06. 19-2-17Akhil VN100% (1)

- Precast Dowel ConnectionDocument1 pagePrecast Dowel ConnectionmathuNo ratings yet

- Project 2 ReportDocument26 pagesProject 2 Reportarjun kumarNo ratings yet

- 6m RTP Design ReportDocument25 pages6m RTP Design Reportmanohargud100% (1)

- Sample - Structural Investigation ReportDocument5 pagesSample - Structural Investigation ReportsherwinNo ratings yet

- Lecture Note 2Document47 pagesLecture Note 2Fun JinNo ratings yet

- DBR PDFDocument7 pagesDBR PDFrajeev shahNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Cannot Open GSDDocument8 pagesCannot Open GSDakankwasaNo ratings yet

- Midas Gen: RC Beam Serviceability Checking ResultDocument2 pagesMidas Gen: RC Beam Serviceability Checking ResultakankwasaNo ratings yet

- Kigumba Workshop InstrumentationDocument1 pageKigumba Workshop InstrumentationakankwasaNo ratings yet

- Footing Design MidasDocument8 pagesFooting Design MidasakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- Kigumba Workshop WELDINGDocument1 pageKigumba Workshop WELDINGakankwasaNo ratings yet

- Input Data: Notes: HistoryDocument5 pagesInput Data: Notes: HistoryakankwasaNo ratings yet

- The Advantages of Using EurocodesDocument2 pagesThe Advantages of Using EurocodesakankwasaNo ratings yet

- Protastructure Analysis ResultsDocument8 pagesProtastructure Analysis ResultsakankwasaNo ratings yet

- Prota Structural Analysis DocumentDocument5 pagesProta Structural Analysis DocumentakankwasaNo ratings yet

- Tekla Structural Designer 2017 Service Pack 4Document7 pagesTekla Structural Designer 2017 Service Pack 4akankwasaNo ratings yet

- Wall Types Library Edit Beam Wall Load Wall Types Library Building SetoutDocument3 pagesWall Types Library Edit Beam Wall Load Wall Types Library Building SetoutakankwasaNo ratings yet

- Tekla Structural Designer 2017 Service Pack 4Document7 pagesTekla Structural Designer 2017 Service Pack 4akankwasaNo ratings yet

- Ms Beams Columns Col. Bases.Document28 pagesMs Beams Columns Col. Bases.akankwasaNo ratings yet

- NEWS: Trimble Updates Core Tekla Structural SolutionsDocument5 pagesNEWS: Trimble Updates Core Tekla Structural SolutionsakankwasaNo ratings yet

- Tekla Structural Designer 2016: Reference Guides (BS)Document98 pagesTekla Structural Designer 2016: Reference Guides (BS)akankwasaNo ratings yet

- 1 00 561 U4089 - Rev 04 PDFDocument15 pages1 00 561 U4089 - Rev 04 PDFSandip SurNo ratings yet

- Building Design at Arup - Christian SchittichDocument161 pagesBuilding Design at Arup - Christian Schittichhashim.mjNo ratings yet

- Special Iconic Houses - The NetherlandsDocument11 pagesSpecial Iconic Houses - The NetherlandsAliaa Ahmed ShemariNo ratings yet

- F. F.slabDocument1 pageF. F.slabRatnesh PatelNo ratings yet

- To Be - Present Simple PDFDocument1 pageTo Be - Present Simple PDFElena CamarasanNo ratings yet

- Logcat 1689770402587Document9 pagesLogcat 1689770402587Ssanjnna Kavita GuptaNo ratings yet

- APP-CMC079-EN ASHRAE Standard 15 BookletDocument45 pagesAPP-CMC079-EN ASHRAE Standard 15 BookletJWNo ratings yet

- Cipres - Vinyl-Faced Gypsum Ceilings 2021Document14 pagesCipres - Vinyl-Faced Gypsum Ceilings 2021Joaquin LoveroNo ratings yet

- Sonotube® Commercial Concrete Forms PDFDocument3 pagesSonotube® Commercial Concrete Forms PDFAnubhav MukherjeeNo ratings yet

- EPC - Schedules - NH 2BDocument102 pagesEPC - Schedules - NH 2BOllie BhattNo ratings yet

- Hengzhu 2020 Version CatalogDocument314 pagesHengzhu 2020 Version CatalogNhok Nho Suy TinkNo ratings yet

- Calibration Report - Tape ExtensometerDocument3 pagesCalibration Report - Tape ExtensometerdavzuluetaNo ratings yet

- IOC DurgasoftDocument10 pagesIOC Durgasoftprashant110484No ratings yet

- Ashoka Buildcon LTD: NH - 32 Rajgunj - Chas - West Bengal Border Project Ason: Daily Progress ReportDocument11 pagesAshoka Buildcon LTD: NH - 32 Rajgunj - Chas - West Bengal Border Project Ason: Daily Progress ReportrushikshNo ratings yet

- Multi 2ndDocument1 pageMulti 2ndJared OlegarioNo ratings yet

- Indo Sarasenic Architectue PDFDocument22 pagesIndo Sarasenic Architectue PDFUma AgrawalNo ratings yet

- Design of Tank Wall As Horizontal Slab:: 8.50N/mm2 275.00N/mm2Document2 pagesDesign of Tank Wall As Horizontal Slab:: 8.50N/mm2 275.00N/mm2swabrightNo ratings yet

- Inferences: Inferences Literature Case StudyDocument1 pageInferences: Inferences Literature Case StudyAmaan Jahangir AlamNo ratings yet

- Baroque RococoDocument3 pagesBaroque RococoLindseyNo ratings yet

- Boq - Pani BhabanDocument116 pagesBoq - Pani Bhabanapi-26147616No ratings yet

- Christopher Alexander UDDocument32 pagesChristopher Alexander UDPARVATHY R S 170564No ratings yet

- TENARIS Wedge HPDocument8 pagesTENARIS Wedge HPBivolaru AndreiNo ratings yet

- Sump Design 10KLDocument30 pagesSump Design 10KLAnand SoniNo ratings yet

- Woodworks Grille Forte Installation GuideDocument29 pagesWoodworks Grille Forte Installation GuidemichelleNo ratings yet

- BS 1881-125-86 PDFDocument10 pagesBS 1881-125-86 PDFSam11111No ratings yet

- Checklist For Accessibility & Universal Design: The Aac MandateDocument8 pagesChecklist For Accessibility & Universal Design: The Aac Mandateeight0nNo ratings yet

- Historic Influences in Interior Design ArcDocument159 pagesHistoric Influences in Interior Design ArcEmanoel Noveda100% (1)

- Building Materials As Expression of Architectural DesignDocument8 pagesBuilding Materials As Expression of Architectural DesignWilfred CepilloNo ratings yet

- PT Load (Equivalent Load) : Beam IDDocument3 pagesPT Load (Equivalent Load) : Beam IDWahyu WidartoNo ratings yet

- Double Stem Type Rubber Gate Seals - Asian IndustriesDocument3 pagesDouble Stem Type Rubber Gate Seals - Asian IndustriesTamilchelvam MurogayahNo ratings yet