Professional Documents

Culture Documents

40.1.7 Pp. 65 - 68 - Sugarcane

Uploaded by

dangtuan270 ratings0% found this document useful (0 votes)

7 views4 pagesThe present study examines the lignocellulose degradation in solid state fermentation in sugarcane bagasse and rice straw by Aspergillus tamarii over a period of 21 days.

Original Description:

Original Title

40.1.7 Pp. 65 - 68 - Sugarcane

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe present study examines the lignocellulose degradation in solid state fermentation in sugarcane bagasse and rice straw by Aspergillus tamarii over a period of 21 days.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views4 pages40.1.7 Pp. 65 - 68 - Sugarcane

Uploaded by

dangtuan27The present study examines the lignocellulose degradation in solid state fermentation in sugarcane bagasse and rice straw by Aspergillus tamarii over a period of 21 days.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Cey. J. Sci. (Bio. Sci.

) 40 (1): 65-68, 2011

SHORT COMMUNICATION

COMPARISON OF LIGNOCELLULOSE BIODEGRADATION IN

SOLID STATE FERMENTATION OF SUGARCANE BAGASSE

AND RICE STRAW BY ASPERGI LLUS TAMARI I

D. Umasaravanan

1

*, J. Jayapriya

1

and R. Babu Rajendran

1,2

1

Department of Environmental Biotechnology, School of Environmental Sciences, Bharathidasan

University, Tiruchirapalli- 620024, India

2

Center for Marine Environmental Studies (CMES), Ehime University Matsuyama 790-8577, Japan

Accepted 21 May 2011

ABSTRACT

The present study examines the lignocellulose degradation in solid state fermentation in sugarcane

bagasse and rice straw by Aspergillus tamarii over a period of 21 days. Lignocellulose degradation in

sugarcane bagasse and rice straw, fortified with glucose was studied with and without ammonium sulphate.

In bagasse fermentation, when the substrate initially containing 17.4 lignin was fortified with 5

glucose in the absence of ammonium sulphate, a maximum lignin loss of 24.7 , was recorded. This

maximum lignin loss was accompanied by a minimum cellulose loss of 3 . In rice straw, fermentation

under the same conditions resulted in a maximum lignin loss of 45.5% and 2.8% loss of cellulose.

Efficiency of solid state fermentation using the two different substrates indicates that lignin loss is high in

comparison to cellulose loss.

Key words: lignin, cellulose, fortification, white rot fungi

INTRODUCTION

Lignocellulose compounds are the most

abundant agricultural residues in the world. They

are constantly being replenished by

photosynthesis. The, micro-organisms that are

able to degrade these compounds include fungi

as well as Actinomycetes and other bacteria.

They have an important role in the

biodegradation of lignocellulose (Holker et al.,

1999).

Agricultural crop wastes such as bagasse and

rice straw consist mainly of cellulose and hemi

cellulose while, the rest comprise of lignin,

nitrogenous compounds and ash

(Abdullah and

Zafar, 1999). Even though bagasse and rice

straw contain enough cellulose to make them

excellent sources of energy for ruminants, they

are poor quality feeds due to low digestibility,

poor palatability, low protein content and

bulkiness.

Solid state fermentation (SSF) processe can

be defined as the growth of microorganism

(mainly fungi) on moist solid materials in the

absence of free-flowing water. This processes

has been used for the production of food, animal

feeds and both pharmaceutical and agricultural

products (Cannel and Moo-Young, 1980; Moo-

Young et al., 1983).

The main advantage of SSF is its low

technology and high volumetric productivity,

thus reducing downstream processing costs. For

long, it had been thought that the main

advantages of SSF is due to water limitation of

the system so that a higher product concentration

is attained. An additional but less investigated

advantage of SSF may be the enhanced

physiological process in cell adhesion or biofilm

formation that is characteristic of SSF.

Solid state fermentation of lignocellulose

materials by white-rot fungi is receiving

attention, primarily because of the possibility of

converting these materials into more digestible

feedstuffs for ruminants (Reid and Seifert,

1982).

Furthermore, new applications of SSF have

been suggested for the production of antibiotics

(Barrios-Gonzales et al., 1988) secondary

metabolites (Trejo-Hernandez et al., 1992) and

enriched food stuffs (Senez et al., 1980). This

paper describes the efficiency of solid state

fermentation and lignocellulose degradation in

sugarcane bagasse and rice straw.

__________________________________________

*Corresponding authors email: usdevatech@gmail.com

Umasaravanan et al. 66

MATERIALS AND METHODS

Fungal strains and inoculum preparation

Aspergillus tamarii was isolated from marine

drift wood pieces and was identified using

Kolhmeyer manual (1979). The culture was

maintained on PDA at 5-7 C. Inoculum

preparation and substrate inoculation were

carried out as described by Abdullah and Zafar

(1996 and 1989).

Substrate preparation and fermentation

Sugarcane bagasse and rice straw were

chopped into 30-50 mm pieces and were

separately soaked in boiling water for 10 min

and the excess water was drained. About 25 g of

moistened bagasse and rice straw were

separately transferred into 1000 ml Erlenmeyer

flasks and used as the biodegradation substrate.

To each flask was added, 10 ml of nutrient

medium containing 5% glucose or glucose and

0.21% ammonium sulphate. Culture medium not

fortified with glucose and without ammonium

sulphate served as the control substrate. Flasks

contain the substrate were autoclaved at 120 C

and 1.06 kg cm

2

for 15 min and the

fermentation was carried out at 25 C for 21

days. The fermented and untreated substrates

were oven dried at 100-105 C, and ground to

less than 1 mm pieces for determination of

cellulose and lignin.

Determination of cellulose

To 1 g of dried sample, 15 ml of 80 acetic

acid and 1.5 ml of conc. nitric acid were added

and refluxed for 20 min. It was filtered and the

residue was washed with ethanol, dried in an

oven at 100-105 C and weighed (Material A). It

was then incinerated at 540 C (Material B).

Cellulose content was determined according to

the method of Van Soest and Wine (1967). All

experiments were carried out in triplicates.

Percentage of Cellulose (Material A)

(Material B)/Weight of the sample x 100

Determination of lignin

To 1 g of dried sample, 70 ml of 1.25

sulphuric acid was added. The mixture was

refluxed for 120 min, filtered and washed in

water. To this was added 30 ml of 72 sulphuric

acid and the material was allowed to stand for 4

h with occasional stirring. It was then filtered,

washed and dried at 100-105 C (Material A)

and incinerated at 540 C (Material B). Lignin

content was determined according to the

procedure of Van Soest and Wine (1967). All

experiments were carried out in triplicates.

Percentage of Lignin (Material A) (Material

B)/Weight of the sample x 100

Statistical analysis

The data in triplicates were tabulated and

mean values calculated according to Steel and

Torrie. 1986. Cellulose and lignin losses were

determined by TAPPI (Technical Association of

the Pulp and Paper Industry, USA) standard

methods T223 and T224. The percent loss of

cellulose and lignin was calculated as follows:

U1 (Go Co Gt Ct)/Go Co 100

Where Go and Gt are the dry weights of

substrate in grams at the beginning and end of

the fermentation respectively, and Co and Ct are

the dry weights of the components (cellulose and

lignin) at the beginning and end of the

fermentation, respectively.

RESULTS AND DISCUSSION

Cellulose and lignin content in untreated

sugarcane bagasse was 56.2% and 17.4%

respectively (Table 1) and in untreated rice straw

the values were 41.4% and 4.4% respectively

(Table 2). Fermentation of unfortified baggase

by Aspergillus tamarii for 21 days resulted in

12.63% of cellulose and 13.2% of lignin.

Fermentation of unfortified rice straw for 21

days resulted in 6.2% of cellulose and 29.5% of

lignin.

Supplementation of sugarcane bagasse with

5 glucose resulted in a decrease of 3.0% in

cellulose and 24.7% of lignin. For rice straw,

there was a 2.9% reduction in cellulose and

45.5% reduction in lignin content. Addition of

sugar helped in the hydrolysis of lignin. A

reduction in the loss of cellulose when 5

glucose was added to the fermentation medium

indicated that A. tamarii utilized glucose instead

of cellulose as a source of energy for fungal

metabolism including the production of

hydrolytic enzymes. These results agree with

Odier and Roch (1983), who reported that

degradation of poplar wood, by white rot fungi,

was stimulated by reduced glucose

concentration.

Addition of 0.21% ammonium sulphate to

the medium containing 5 glucose and

sugarcane bagasse showed a reduction of 8.89%

cellulose and 6.9% of lignin. Fermentation of

rice straw under similar conditions resulted in a

reduction of 3.4% cellulose and 11.4% lignin.

Lignocellulose biodegradation by Aspergillus tamari 67

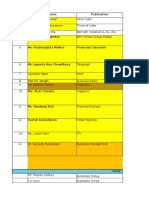

Table 1. Lignocellulose degradation of sugarcane bagasse with nutrient medium fortified with

nitrogen and carbon sources during solid-state fermentation by Aspergillus tamarii for 21 days at

25 C.

Substrate fortification Bagasse analysis g/100g Loss in constituents ( )

Cellulose Lignin Cellulose Lignin

Fresh bagasse not fermented 56.20.5 17.41.5 - -

5 Glucose 54.51.0 13.10.5 3.0 24.7

5 Glucose + 0.21 (NH

4

)

2

SO

4

51.20.8 16.21.1 8.9 6.9

Not fortified 49.10.3 15.11.0 12.6 13.2

Culture medium consists of 0.3 g MgSO

4

.7H

2

O, 2g KH

2

PO

4,

0.4 g CaCl

2

.2H

2

O, 0.1 g yeast extract

made to 1litre.

Table 2. Lignocellulose degradation of rice straw with nutrient medium fortified with nitrogen and

carbon sources during solid-state fermentation by Aspergillus tamari for 21 days at 25 C.

Substrate fortification Rice straw analysis g/100g Loss in constituents ( )

Cellulose Lignin Cellulose Lignin

Fresh bagasse not

fermented

41.40.4 4.40.4 - -

5 Glucose 40.21.2 2.40.5 2.8 45.5

5 Glucose +

0.21 (NH

4

)

2

SO

4

39.80.8 3.91.2 3.4 11.4

Not fortified 38.80.5 3.10.6 6.2 29.5

Culture medium consists of 0.3 g MgSO

4

.7H

2

O, 2 g KH

2

PO

4

,, 0.4 g CaCl

2

.2H

2

O, 0.1 g yeast extract

made to 1litre.

Ander and Eriksson (1997) also reported that

urea, casemic acid and ammonium phosphate

gave the lowest lignin degradation. Sources of

nitrogen have been reported to repress the

degradation by Ph. chrysosporium (Fenn and

Kirk, 1981). The ability of basidiomycetes to

recycle their own nitrogen has been reported by

(McDonald et al., 1977).

The most extensive lignin degradation was

observed when glucose was supplied to nitrogen

starved condition where Termitomyces sp.

preferentially degraded lignin in the presence of

5 glucose. Similar results have been reported

previously (Jalk et al., 1998).

Results reported here were in agreement with

those of Odier and Roch (1983) who reported

that degradation of C14 labeled poplar wood, by

several white rot fungi, was stimulated at

limiting glucose concentration. Abdullah et al.

(2004) indicated that lignin hydrolysis was best

at a marginal carbon/energy source for

maintenance of metabolism.

Decomposition of lignin was reported to take

place after profuse microbial growth. It was

further reported that no microorganism could

grow on carbohydrate-free medium and

decomposition of lignin was difficult in the

absence of readily degradable, high-energy

source (Costa et al., 2002). In conclusion, rice

straw, the major agricultural by-product of South

Asia, is high in lignin and cellulose than

sugarcane bagasse following degradation

through solid state fermentation.

ACKNOWLEDGEMENTS

The authors are grateful to Bharathidasan

University, Tiruchirapalli, India for the facilities

provided.

REFERENCES

Abdullah, N. and Zafar, S.I. (1996). Ligno-

cellulose degradation in solid-state fermentation

of sugar-cane bagasse by Trametes versicolor.

Int. J. Mush. Sci 1: 21-26.

Abdullah, N. and Zafar, S.I. (1999). Ligno-

cellulose biodegradation by white rot

basidiomycetes: Overview. Int. J. Mush. Sci 2:

59-78.

Umasaravanan et al. 68

Abdullah, N., Khan, A.D. and Ejaz. N. (2004).

Influence of nutrients, carbon and nitrogen

supplementation on biodegradation of wheat

straw by Trametes versicolor. Micol. Apl. Int.16:

7-12.

Ander, P. and Erikson, K.E. (1997). Selective

degradation of wood components by white rot

fungi. Physiol. Plant 41: 239-248.

Barrios-Gonzales, J., Tomasini, A., Viniegra-

Gonzalez, G. and Lopez, L. (1988). (Eds.)

Penicillin production by solid-state fermentation

in bioconversion of Agro-industrial Raw

Materials. Raimbault M. Orsrtom, Montpellier

Fr. Pp. 39-51.

Cannel, E. and Moo-Young, H. (1980). Proc.

Biochem 15: 2-7.

Costa, S.M., Goncalves, A.R. and Esposito, E.

(2002).Action of white-rot fungus Panus

tigrinus on sugarcane bagasse. Appl. Biochem.

Biotechnol. 98: 357-364.

Fenn, P. and Kirk, T.K. (1981). Relationship of

nitrogen to the onset and suppression of

lignolytic activity and secondary metabolism in

Phanerochaete chrysosporium. Arch. Microbiol.

130: 2407-2417.

Holker, U., Hofer, M. and Lenz, J. (1999).

Biotechnological advantages of laboratory-scale

solid-state fermentation with fungi. Journal of

Ferment. Technol. 39: 903-906.

Jalk, D., Nerud, R. and Siroka, P. (1998). The

effectiveness of biological treatment of wheat

straw by white rot fungi. Folia. Microbiol. 43:

687-689.

Kohlmeyer, J., and E. Kohlmeyer. (1979).

Marine Mycology. Academic Press., New York.

McDonald, P., Edwards, R.A. and Greenhalgh,

J.F.D. (1977). Animal Nutrition. 2

nd

Ed.

Longman, London. Pp. 479.

Moo-Young, M., Moreira, A.R. and Tengerdy,

R.P. (1983). Solid state DE fermentation of

cellulosic residues. In: The filamentous fungi.

vol. 4, (Eds) J.E. Smith, D.E. Berry and B.

Kristiansen, Edward Arnold, London.

Pp.114-117.

Odier, E. and Roch, P. (1983). Factors

controlling biodegradation of lignin in T wood

by various white rot fungi, In: Recent Advances

in Lignin Biodegradation Research. (Eds) T.

Higuchi, H.M. Chang and T.K. Kirk,. UNI.

Publishers Co. Ltd., Tokyo. Pp. 183-193.

Reid, I.D. and Seifert, K.A. (1982). Effect of an

atmosphere of oxygen on growth, respiration and

lignin degradation by white rot fungi. Can. J.

Bot 60: 252-260.

Senez, J.C., Rainbault, M. and Deschamps, F.

(1980). Protein enrichment of starchy substrate

for animal feeds by solid-state fermentation.

World Animal Review 35: 36-40.

Steel, R.G.D. and Torrie, J.H. (1986). Principles

and procedures of statistics. A Biometrical

Approach, 2

nd

Ed. McGraw-Hill, London, pp

633.

Trejo-Hernandez, M.R., Rainbault, M., Roussos,

S. and Lonsane, B.K. (1992). Potential of solid-

state fermentation for production of ergot

alkaloids. Letters in Applied Microbiology 15:

156-159.

Van Soest, P.J. and Wine, R.H. (1967). Use of

detergents in the analysis of fibrous feeds IV.

The determination of plant cell-wall

constituents. J. Assoc. Official Anal. Chem. 50:

50-55.

Zafar, S.I., Sheeraa, Q. and Abdullah, N. (1989).

Degradation of the lignocellulosic component on

wheat straw-Coriolus versicolor using solid state

fermentation under nitrogenstarved condition.

Biological Wastes 27: 67-70.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elevator Guide Rails Installation and AlignmentDocument12 pagesElevator Guide Rails Installation and Alignmentdangtuan27No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Selection of 3P-TPN-4P MCB & Distribution BoardDocument4 pagesSelection of 3P-TPN-4P MCB & Distribution Boarddangtuan27100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- I Like To Draw Cars and Trucks PDFDocument35 pagesI Like To Draw Cars and Trucks PDFdangtuan27No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Schedule Working - Off On SystemDocument3 pagesSchedule Working - Off On Systemdangtuan27No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Tepzz 59 Za - T: European Patent ApplicationDocument9 pagesTepzz 59 Za - T: European Patent Applicationdangtuan27No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Material Safety Data Sheet Product Name: Pva Adhesive PRODUCT CODE: 8711, 8712Document4 pagesMaterial Safety Data Sheet Product Name: Pva Adhesive PRODUCT CODE: 8711, 8712dangtuan27No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Catalog Thang Mang Cap enDocument20 pagesCatalog Thang Mang Cap endangtuan27No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Site Setup Plan - Hatton Road, CroydonDocument2 pagesSite Setup Plan - Hatton Road, Croydondangtuan27No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Thesis For The Degree of Licentiate of EngineeringDocument155 pagesThesis For The Degree of Licentiate of Engineeringdangtuan27No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Dampers: KD-T Non Return DamperDocument2 pagesDampers: KD-T Non Return Damperdangtuan27No ratings yet

- Electrophoretic Protein Pattern of Male and Female Haemolymph of Rhynchophorus Ferrugineus OlivierDocument7 pagesElectrophoretic Protein Pattern of Male and Female Haemolymph of Rhynchophorus Ferrugineus Olivierdangtuan27No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Method Statement For Test and Inspection of An Existing Lightning Protection/Earthing SystemDocument4 pagesMethod Statement For Test and Inspection of An Existing Lightning Protection/Earthing Systemdangtuan27No ratings yet

- Method Statement: Site Set Up: Compound, Parking & Material StorageDocument17 pagesMethod Statement: Site Set Up: Compound, Parking & Material Storagedangtuan27No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Daikin - Ducted - Oct 13 PDFDocument20 pagesDaikin - Ducted - Oct 13 PDFdangtuan27No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Installation InstructionsDocument3 pagesInstallation Instructionsdangtuan27No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 2013 PW Catalog Spreads-Metallicladder-SsDocument3 pages2013 PW Catalog Spreads-Metallicladder-Ssdangtuan27No ratings yet

- AVI202 Network Camera (D&N) : Thông tin chi tiếtDocument2 pagesAVI202 Network Camera (D&N) : Thông tin chi tiếtdangtuan27No ratings yet

- Bang Gia Schneider 06-2014 PDFDocument81 pagesBang Gia Schneider 06-2014 PDFdangtuan27No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Fan Coil O+M 2005Document16 pagesFan Coil O+M 2005dangtuan27No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Agri Anual ReportDocument307 pagesAgri Anual ReportVineet BhardwajNo ratings yet

- Sample Master's Capstone ProjectDocument49 pagesSample Master's Capstone ProjectMatt Hutson100% (1)

- David Conway A Nation of ImmigrantsDocument112 pagesDavid Conway A Nation of Immigrantsnerac34No ratings yet

- Herdsmen Farmers Conflict and Food Security in Nigeria A Case Study of Lau LgaDocument58 pagesHerdsmen Farmers Conflict and Food Security in Nigeria A Case Study of Lau LgaDaniel Obasi100% (3)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Chapter-I: Employee Welfare MeasuresDocument95 pagesChapter-I: Employee Welfare Measuresvidya_vinu97100% (1)

- AGGRAND® Natural Lawn CareDocument4 pagesAGGRAND® Natural Lawn CarePandMHillNo ratings yet

- Feeding, Training and Care of Your Labrador PuppyDocument2 pagesFeeding, Training and Care of Your Labrador PuppyFrancisco VilledaNo ratings yet

- IRRIGATION Notes PDFDocument77 pagesIRRIGATION Notes PDFniteshNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- House Hearing, 110TH Congress - Management by Exclusion: The Forest Service Use of Categorical Exclusions From NepaDocument111 pagesHouse Hearing, 110TH Congress - Management by Exclusion: The Forest Service Use of Categorical Exclusions From NepaScribd Government DocsNo ratings yet

- The International Handbook of Gender and Poverty Concepts, Research, PolicyDocument733 pagesThe International Handbook of Gender and Poverty Concepts, Research, PolicyArsalan Raza100% (4)

- Complete Notes On Unit - V - Ural PlanningDocument10 pagesComplete Notes On Unit - V - Ural PlanningShahin Kauser ZiaudeenNo ratings yet

- Out of DustDocument231 pagesOut of Dustheidy_the_witch150% (4)

- InfoCrop HelpDocument83 pagesInfoCrop Helppramod70248750% (2)

- (Week 4-5) Agricultural ExtensionDocument19 pages(Week 4-5) Agricultural ExtensionIts Me Kyla RuizNo ratings yet

- Formulation of Lipbalm of "Orange Fruit Juice" (Citrus X Aurantium L.) As AntioxydanDocument21 pagesFormulation of Lipbalm of "Orange Fruit Juice" (Citrus X Aurantium L.) As AntioxydanDevi YulikaNo ratings yet

- Sorghum Root and Stalk RotsDocument288 pagesSorghum Root and Stalk RotsFindi DiansariNo ratings yet

- Once Upon A Time There Was A Girl Name CindrellaDocument56 pagesOnce Upon A Time There Was A Girl Name CindrellaINDRAKURNIAWANSIRNo ratings yet

- Myanmar INGO Directory 2012Document96 pagesMyanmar INGO Directory 2012Ko Gree KyawNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pollen Studies in Tuberose Cultivars and HybridsDocument3 pagesPollen Studies in Tuberose Cultivars and HybridsShailendra RajanNo ratings yet

- Oxalis Del PERUDocument290 pagesOxalis Del PERUpanchofrancoNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument16 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Media ListAgriculture Commodities Engagement GridDocument17 pagesMedia ListAgriculture Commodities Engagement GridSudeep SenguptaNo ratings yet

- What Is The World BankDocument4 pagesWhat Is The World BankPrincess KanchanNo ratings yet

- The ManualDocument12 pagesThe ManualDiana DainaNo ratings yet

- Bio11 Ex 6,7,11 Plates UPDocument2 pagesBio11 Ex 6,7,11 Plates UPErika PotianNo ratings yet

- Adelaide Visitor Guide 08Document81 pagesAdelaide Visitor Guide 08Carlos YanezNo ratings yet

- Botany - Flower Structure PDFDocument5 pagesBotany - Flower Structure PDFMia Justine Soriano100% (1)

- RB - Palm OilDocument91 pagesRB - Palm Oilferdial2005No ratings yet

- Why Is The Aral Sea ShrinkingDocument6 pagesWhy Is The Aral Sea ShrinkingOmar BermudezNo ratings yet

- Philippines Water Resources Regions: Escoto Raeniel D. Bsce-VDocument14 pagesPhilippines Water Resources Regions: Escoto Raeniel D. Bsce-VMia ListaNo ratings yet

- Love Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)From EverandLove Life: How to Raise Your Standards, Find Your Person, and Live Happily (No Matter What)Rating: 3 out of 5 stars3/5 (1)

- Summary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedFrom EverandSummary: The Psychology of Money: Timeless Lessons on Wealth, Greed, and Happiness by Morgan Housel: Key Takeaways, Summary & Analysis IncludedRating: 4.5 out of 5 stars4.5/5 (82)

- The Age of Magical Overthinking: Notes on Modern IrrationalityFrom EverandThe Age of Magical Overthinking: Notes on Modern IrrationalityRating: 4 out of 5 stars4/5 (32)