Professional Documents

Culture Documents

Lecture-24: Global & Stream Specific: and Its Relevance Key Words: T

Uploaded by

api-256504985Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture-24: Global & Stream Specific: and Its Relevance Key Words: T

Uploaded by

api-256504985Copyright:

Available Formats

TheconceptofT

min

anditsrelevanceModule:04Lecture24

Module : 04

Lecture-24 : Global & Stream specific T

min

anditsrelevance

Keywords:T

min

,HeatRecoveryapproachtemperature(HRAT).

Up till recently, the basic decision variable used in designing the HEN has been the minimum

approach temperature(T

min

) or Heat Recovery approach temperature(HRAT). The T

min

in

generalappears at onelocation between hot and cold composite curves calledheat recovery

pinch.AspinchpointisrelatedtoT

min

,ithasspecialsignificanceinthedesign.Thisisdueto

the fact that the pinch constitutes a bottleneck to heat recovery, in which the minimum

approachtemperaturedeterminesthedegreeofheatrecoverypossible.

The selection of T

min

values warrants some discussion. In heat recovery problems having a

pinch, the utility requirements are always sensitive to the selection of T

min

. Further, for any

heatrecoveryproblem,thechoiceofT

min

affectstheshapeoftheprocesssource/sinkprofile

andthusaffectstheheatexchangernetworktopology.Duetothisthefixedcostcomponentas

wellastheoperatingcostcomponentoftheHENvarieswiththeselectionofT

min

.

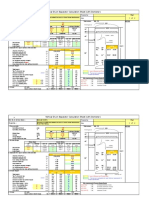

A four stream problem given in Table 3.8 from Lecture 10: Energy Targeting is reproduced

belowtoshowtheeffectofvariationofT

min

onutilityandfixedcost.

Table3.8:FourstreamproblemforloadintegrationandutilitypredictionforT

min

equalto

10C.

Nameofthestream SupplyTemperature

Ts,C

TargetTemperature

Tt,C

CP

kW/C

H

kW

Hot1 140 50 2 180

Hot2 90 40 6 300

Cold1 30 150 2 240

Cold2 70 125 3 165

Fig.24.1showsthecompositecurvesforT

min

=10C.

Fig.24.1AllTvaluesbetweenhotandcoldcompositesare

greaterthanT

min

values

70C

125C

150C

140C

50C

40C

30C

T,C

H,kW

HotCompositecurve

ColdCompositecurve

T

min

T

T

TheconceptofT

min

anditsrelevanceModule:04Lecture24

Fig.24.2showsthevariationinutilitydemandwhenT

min

ischangedstepsoftenfrom10Cto

50C. Table 24.1 Shows the values of hot and cold utility demand as well as internal heat

exchange.

Table24.1VariationinHotandcoldutilitydemandaswellasinternalheatexchangewithT

min

T

min

HotUtility,kW ColdUtility,kW Internal Heat

Exchange,kW

Total Heat

Exchange,kW

10C 175 250 155 580

20C 225 300 105 630

30C 245 320 85 650

40C 265 340 65 670

50C 285 360 45 690

FromtheTable24.1followingcanbeconcludedwiththeincreaseinT

min

ofaHEN:

1. Therequiredhotandcoldutilityamountincreases

2. The amount of internal heat exchange( process hot streams to process cold streams)

decreases

3. The Total heat exchange for the HEN increases. This diminishes the effect of area

reductionwhichonegetsbyincreasingT

min

ofaHEN.

Thus a complicated interaction between T

min

of a HEN and capital as well as operating cost

takesplaceasgivenbelow:

Fig.24.2ShowseffectofdifferentT

min

70C

125C

150C

140C

50C

40C

30C

T,C

H,kW

T

min

=10C

InternalHeat

Exchange

External

Hotutility

ExternalCold

utility

HotCompositecurve

ColdCompositecurve

T

min

=20C

T

min

=35C

TheconceptofT

min

anditsrelevanceModule:04Lecture24

IfT

min

isreducedthen:

1. Theamountofhotandcoldutilityreducesandthusitscost.

2. Theamountofprocesstoprocessheatexchangeincreasesandthustherequiredareaof

heat exchanger. This increases the fixed cost (capital cost) of the HEN. As overall heat

exchangealsodecreasesitsavesintermsofareaandthuscapitalcost.

3. The overall temperature driving force ( T) of the HEN decreases and thus the area of

the heat exchangers present in HEN increases increasing the fixed cost of heat

exchangers.

4. Loadsof heaters andcoolers decrease , therebyits fixed costdecreases. However,the

increases in the cost of heat exchangers transferring process heat invariably outweighs

thereductioninheaterandcoolercosts.

Thustheoverallinteractioncanbejudgedintermsofthetotalannualcost(TAC)oftheHEN.

The most appropriate value of T

min

( called optimum T

min

) or in other words the relative

positionsofthehotandcoldcompositecurvesisdeterminedbyaneconomictradeoffbetween

energy and capital. Once the correct economic value of T

min

( through Supertargeting) is

knownthentheenergytargetsintermsofthevaluesofhotandcoldutilitiesareautomatically

fixed.

Thetradeoffbetweenenergy(operatingcost)andcapital(fixedcost)inthecompositecurves

suggestthatonaverage,individualexchangersshouldhaveatemperaturedifferencenoless

thanT

min

.Thisisexplainedbelow:

LetusconsiderthataparticularHENhassixnumbersofheatexchangersasshownbelow:

IftheheatexchangersaredenotedasHX1,HX2,HX3andHX4,HeaterasHRandcoolerasCR,

thenasperFig.24.3thesewillhave12numbersofT.IftheHeatRecoveryapproach

temperature(HRAT)andexchangerminimumapproachtemperature(EMAT)aresameandequal

toT

min

thenfollowingargumentsholdgood.

HX1 T

11

T

12

HX2 T

21

T

22

HX3 T

31

T

32

HX4 T

41

T

42

HR T

H1

T

H2

CR T

C1

T

C2

Fig.24.3AsixheatexchangerHEN

1 C

H

H1

H2

C3

C4

C5

1

2

2

3

3

4

4

TheconceptofT

min

anditsrelevanceModule:04Lecture24

Mathematically

Min.{T

11

,T

12

,T

21

,T

22

,T

31

,T

32

,T

41

,T

42

,T

H1

,T

H2

,T

C1

,T

C2

}T

min

Further,itshouldbenotedthatthetemperaturedifferencebetweenhotandcoldcomposite

curvesatpinchisequaltoT

min

.Whereas,forotherplacesitcreaseswhenonemovesaway

frompinchpoint.

TostarttargetingprocessonehastoassumeguessvalueofT

min

whichcanbetakenformthe

Table24.2ThistableprovidestypicalT

min

valuesfordifferentprocessesstreams.

Table24.2TypicalT

min

valuesforvarioustypesofprocesses

S.No. Industrialsector ExperienceT

min

Values

Comments

1 OilRefining 2040C Relatively low heat transfer coefficients,

parallel composite curves in many

application,foulingofheatexchangers

2 Petrochemical 1020C Reboiling and condensing duties provide

betterheattransfercoefficients,lowfouling.

3 Chemical 1020C AsforPetrochemical

4 Low

Temperature

Processes

35C Powerrequirementforrefrigerationsystemis

very expensive. T

min

decreases with low

refrigerationtemperatures

BelowaretypicalT

min

Valuesformatchingutilitiesagainstprocesssteams.Theseexperience

basedT

min

valuesareusefulinidentifyingtargetsforappropriateutilitiesloadsatvarious

utilitieslevels.

Table24.3TypicalT

min

valuesusedformatchingutilitylevelsagainstprocessstreams

Match T

min

Commends

StreamagainstProcessStream 1020C Good heat transfer coefficient for stream

condensingorevaporation

RefrigerationagainstProcessStream 35C Refrigerationisexpensive

FluegasagainstProcessStream 40C Lowheattransfercoefficientforfluegas

FluegasagainstStreamGeneration 2540C Goodheattransfercoefficientforstream

FluegasagainstAir(e.g.airpreheat) 50C Aironbothsides.Dependsonaciddew

CWagainstProcessstream 1520C Depends on whether or not CW is

competing against refrigeration.

Summer/Winter operation should be

considered.

TheconceptofT

min

anditsrelevanceModule:04Lecture24

TypicalT

min

valuesusedinretrofittargetingofrefineryprocesses,basedonLinnhoffMarchs

refinerystudies.ThecommendsprovidequalitativeexplanationforthechoiceofT

min

values

Table24.4TypicalT

min

valuesusedinretrofittargetingofvariousrefineryprocesses

Process T

min

Commends

CDU 3040C Parallel(tight)composites

VDU 2030C Relatively wider composites (compared to CDU) but

lowerheattransfercoefficients

Naphtha Reformer /

HydrotreaterUnit

3040C Heat exchanger network dominated by feed effluent

exchanger with P limitations and parallel temperature

drivingforces.

FCC 3040C SimilartoCDUandVDU

GasOilHydrotreater

/Hydrotreater

3040C Feedeffluent exchanger dominant. Expensive high

pressureexchangersrequired.Needtotargetseparately

forhighpressuresectionandlowpressuresection.

Residue

Hydrotreating

40C AsaboveforGasOilHydrotreater/Hydrotreater

Hydrogen

ProductionUnit

2030C Reformer furnace requires high T(30C50C). Rest of

theprocess:10C20C

AlowT

min,cont,i

canbeassignedinfollowingcases:

1. Aboilingorcondensingstreamwithhighheattransfercoefficients,

2. Abelowambientcryogenicstreamwhereeconomicsfavormaximumheatrecoveryto

decreaseexpensiverefrigerationcosts,

3. Astreamwhichislikelytoundergodirectcontactheatexchange(forwhichT

min,cont,i

maybesettozero)

InactualpracticefollowingfactsaretakencareofwhileselectingT

min

.

1. Theshapeofthecompositecurve.AhighervalueofT

min

isselectedifthehotandcold

compositecurvesarealmostparallelincomparisontocompositecurvewhichdiverge

sharply.Thisisforsimplefactthatforparallelcompositecurves,thetemperature

differencebetweenhotandcoldstreamswillbeclosetoT

min

setforthecomposite

curvesdemandinghighheattransferarea.Thiswillnothappenforexchangerscloseto

pinchpointbutforothersalsowhichareawayfrompinch.

2. InsystemswherefoulingiscommonorheattransfercoefficientsarelowhigherT

min

valuesintherangeof3040Cisusedtocompensatetheaboveilleffectstosome

extent.

TheconceptofT

min

anditsrelevanceModule:04Lecture24

NonglobalminimumTemperatureDifferenceandT

min

contributionsfor

individualstreams

Most work on HENS based on Pinch Analysis, uses a single basic parameter in the design,

namelythestreamindependentminimumapproachtemperatureforaheatexchangernetwork

which applies globally between all streams in the network. For many years, this has met the

requirementandcertainguidingvaluesofT

min

havebeenacceptedbydesignersforparticular

industrial problems. It is common in chemical plants to have a mixture of liquid and vapour

streams with one to two orders of magnitude difference in film heat transfer coefficients.

However, inappropriate match selection involving the heat transfer coefficients can yield a

largerareaevenifthecorrecttemperaturedifferencesareselected.

The major limitation with this approach is the concept of a single minimum approach

temperaturethatisusedasthebasicdesignparametertobevariedindeterminingthematches

of theinitial design.Although theeffect ofdifferent heattransfer coefficients is accountedfor

atthetotalcosttargetingstage,atthesynthesisstagetheconceptofasingleT

min

isapplied

to the problem. As shown recently by Gundersen and Grossman (1988), to insist on a single

global approach temperature for all exchangers in the network may put the engineer in

topological traps. Further, for very different film heat transfer coefficients it is no longer true

thatstrictverticalheattransfergivesthelowestareaandinvestmentcost.

TheconceptofstreamspecificTcontributionwasproposedtoincorporatenonverticalheat

transferforminimumareapredictions(Nishimura,1980;Ahmadetal.,1990).Thestream

specificcontributionscanbeappliedtoactualtemperaturesofthehotandcoldstreamsto

createshiftedtemperaturesasgiveninEq24.1andEq.24.2

T*

H,I

=T

H,i

T

min

,

cont,I

.(24.1)

T*

C,j

=T

C,j

+T

min

,

cont,j

(24.2)

where T*

H,i

, T

H,i

are the shifted and actual temperatures for Hot Stream i, T*

C,j

, T

C,j

are the

shifted and actual temperatures for Cold Stream j, and T

min,cont,i

and T

min,cont,j

are the

contributionstoT

min

forHotStreamiandColdStreamj.Sothatwheni

th

hotstreamtouches

with j

th

cold streams in a shifted composite curves then the temperature difference(T

min

)

betweentheseremainsT

min,cont,i

+T

min,cont,j

.

Theabovefactisexplainedthroughanexamplegivenbelow:

Suppose,iftheT

min

contributionforliquidstreamsistakentobe5Candthatforgasstreams

15C, then a liquidliquid match would have a T

min

= 10C, similarly a gasgas match would

give rise to T

min

= 30C and a liquidgas match would result in T

min

= 20C. The above

arrangementcanbeincludedintheproblemtablealgorithmeasily.Allthatisrequiredisthat

appropriate T

min

contribution for each stream is to be allocated based on some rules (

discussedbelow)andthenitissubtractedinthecaseofhotstreamsandaddedinthecaseof

cold streams. This would give rise to different interval temperatures compared with a global

TheconceptofT

min

anditsrelevanceModule:04Lecture24

minimum temperature difference. This transformation provides a heat cascade where the

streams with good heat transfer conditions can be matched with lower T, and vice versa.

During this process not only the interval temperatures (as well as temperature and enthalpy

intervals) but also the stream subsets are changed. Moreover, a altogether new pinch, called

diverse pinch point, is created. The differences between the conventional pinch with global

T

min

andthediversepinchvaluesaretechnicallydifferent.Thedifferenceinstreamsubsetsin

a temperature/enthalpy interval implies different pinch designs and consequently different

HENS.

Further, It is recommended that the individual film heat transfer coefficients should be taken

into account at the earliest possible stage of design when these film coefficients are order of

magnitude different from each other. In order to use streamdependent contributions to

minimum approach temperatures the streams are to be vertically shifted by a. value

proportionaltotheinverseoftheindividualfilmcoefficients.Theeffectsofthisproposalshould

be farreaching. Not only will it make the driving force distribution smoother but it will also

provide a more realistic initial network supertargeting andavoid some topological traps in the

synthesisofinitialheatexchangernetworks.

Underthisbackdropletusexaminethestreamdependentcontributionstominimum

approachtemperatureofferedbydifferentinvestigators[Ahmad,1985;Nishimuraetal.,1970;

Nishimura,1975;Nishimura,1980;E.REVandZ.FONYO,1991]:

Nishimuraetal.(1970)andNishimura(1975,1980)wereprobablyamongthefirstauthorsto

advocateit.Theyshowedforcaseswhereonelargehotstreamisintegratedwithseveralsmall

coldstreams,orviceversa,thattheoptimumvalueof(T

min)i

forstreamiwasgivenintermsof

theindividualheattransfercoefficientofthatstream,h

i

,by:

T

min

,

i

h

i

=constant (24.3)

Inthecaseofpluralheatsourcesandsinks,duetoitscombinatorialproblem,theextensionof

thisresultisquestionable.

Townsend(1989)forthecaseofmultiplehotstreamsmatchingmultiplecoldstreamsdefined

streamindividual"Tcontributions"asfollows:

T

i

h

i

=constant=a

WhereT

i

=theTcontributionfromthestreamiandh

i

=filmcoefficientofthestreami.

Aquitestraightforwardapproachistousestreamindividualcontributionstotheglobal

minimumapproachtemperaturepresentedbyAhmad(1985).HeextrapolatedNishimuras

resultstoageneralcase,i.e.thecontributionTforstreamiwasrelatedtoitsfilmtransfer

coefficientthroughtheequation

TheconceptofT

min

anditsrelevanceModule:04Lecture24

I

=

c

b

. (24.4 )

where C is a constant that is adjusted until the heat recovery level obtained by using the

contributionsisthesameaswhenusingasingleglobalT

min

.Unfortunately,theextrapolation

of Nishimuras results to general problems with plural heat sources and sinks is questionable

and, as will be discussed later in this paper, the determination of this T contribution is

ambiguous. Nevertheless, he provided the first systematic approach to adjusting the stream

temperaturessothatstreamswithgoodheattransferconditionscanbematchedwithlessT

i

andviceversa,thanwouldhavebeenverticalaccordingtotheoriginalmodel.

RevandFonyo(1991)proposedthediversepinchconcept,whichusesanindividual

contributionTforeachstream,accordingtothefollowingrelationship:

T

I

= kh

I

-z

(24. 5 )

wherekandzareempiricalparameters.ThevalueofkcanbeeasilycalculatedforanyT

min

,in

an iterative manner so that same hot and cold utility demands are achieved. The T

min

contributionforindividualstreamsprovidesaheatcascadewherethestreamswithgoodheat

transferconditionscanbematchedwithlowerT,andviceversa.

Example1

AnexamplewastakentoshowhowT

min

contributionforindividualstreamscanbeused.For

thispurposeanExampleproblemfrom(Ahmad,1985)wastakenupwithz=1asshownbelow

andthevalueofkforEq.24.5isdeterminedbymatchinghotandcoldutilitydemandsas

computedforT

min

=30C(Table24.5).

Table24.5AsevenstreamproblemtodemonstrateT

min

contributionassuggestedbyRevand

Fonyo(1991)

Stream(s) Ts,C Tt,C CP(kW/C) h(kW/(Cm

2

) T

min,cont,i

H1 159 77 2.285 0.1 7.099

H2 267 80 0.204 0.04 17.748

H3 343 90 0.538 0.50 1.419

C1 26 127 0.933 0.01 70.99

C2 118 265 1.961 0.50 1.419

HU 300 300 0.05 14.198

CU 20 60 0.20 3.549

TheproblemwassolvedbyAhmad,S.(1985)usingT

min

=30C

TheutilitydemandforT

min

=30Care:HU=145.672kWandCU=124.804kW

Table24.6HotandcoldutilitiesfordifferentvaluesofkofEq.24.5

IterationNo. Valueofk Hotutility,kW ColdUtility,kW

1. 0.600 131.937 111.069

TheconceptofT

min

anditsrelevanceModule:04Lecture24

2. 0.695 143.804 122.936

3. 0.7099 145.67 124.804

ThustheTmincontributionforindividualstreamscanbegivenas:

I

mn,cont,

= u.7u99b

-1

Table24.7ShiftedtemperaturetableusingT

min

=30C

Stream(s) Ts,C Tt,C Shifted

Ts,C

Shifted

Tt,C

H1 159 77 144 62

H2 267 80 252 65

H3 343 90 328 75

C1 26 127 41 142

C2 118 265 133 280

HU 300 300 285 285

CU 20 60 35 75

Table24.8ShiftedtemperaturesusingT

min

contributionforindividualstreams

Stream(s) Ts,C Tt,C Shifted

Ts,C

Shifted

Tt,C

T

min,cont,i

CP(kW/C) h

(kW/(Cm

2

)

H1 159 77 151.901 69.901 7.099 2.285 0.1

H2 267 80 249.252 62.252 17.748 0.204 0.04

H3 343 90 341.581 88.581 1.419 0.538 0.50

C1 26 127 96.99 197.99 70.99 0.933 0.01

C2 118 265 119.419 266.419 1.419 1.961 0.50

HU 300 300 285.802 285.802 14.198 0.05

CU 20 60 23.549 63.549 3.549 0.20

3

2

8

2

8

0

2

5

2

1

4

4

1

4

2

1

3

3

7

5

6

5

6

2

4

1

H1

H2

H3

C1

C2

(a)

P

i

n

c

h

3

4

1

.

6

2

6

6

.

4

2

4

9

.

3

1

9

8

1

5

1

.

9

1

1

9

.

4

9

7

8

8

.

6

7

0

6

2

.

3

H1

H2

H3

C1

C2

(b)

P

i

n

c

h

Fig.24.4Streamstructureandtemp.intervalsfor(a)T

min

as30C(b)T

min

contributionfor

individualstreams

TheconceptofT

min

anditsrelevanceModule:04Lecture24

Table24.10Minimumheatflowattemperature

intervalswhenT

min

contributionsforindividual

streamsconsidered.

ShiftedTemp.

level,C

Min.Heat

Flow,kW

Remarks

341.58 145.66 Minimum

Hotutility

266.42 186.10

249.25 161.67

197.99 99.18

151.90 0.0 Pinchpoint

119.42 4.32

96.99 51.29

88.58 76.74

69.90 123.23

62.25 124.80 Minimum

coldutility

Table24.9Minimumheatflowatinterval

temperaturesforT

min

=30C

ShiftedTemp.

level,C

Min.Heat

Flow,kW

Remarks

328 145.67 MinimumHot

utility

280 171.50

252 131.65

144 0 Pinchpoint

142 2.13

133 3.33

75 124.78

65 140.34

62 144.4

41 124.80 Minimumcold

utility

Fig.24.5(a)ShiftedcompositecurvetakingT

min

as30C(b)Shiftedcomposite

curvetakingT

min

contributionforindividualstreams

(b)

HU=145.66kW

CU=124.80kW

(a)

HU=145.67kW

CU=124.80kW

TheconceptofT

min

anditsrelevanceModule:04Lecture24

From the Fig24.4 to Fig 24.7 and Table 24.7to Table 24.10, it is clear that when T

min

contribution for individual streams are applied not only the interval temperatures (as well as

temperature and enthalpy intervals) but also the stream subsets are changed. Moreover,

altogether a new pinch, called diverse pinch point, is created. The differences between the

conventionalpinchwithglobalT

min

andthediversepinchvaluesaretechnicallydifferent.The

(b)

(a)

Fig.24.6(a)GCCtakingT

min

=30C(b)GCCtakingT

min

contributionforindividual

(a)

(a) (b)

Fig.24.7(a)DrivingforceplottakingT

min

=30C(b)DrivingforceplottakingT

min

contributionforindividualstreams

TheconceptofT

min

anditsrelevanceModule:04Lecture24

differenceinstreamsubsetsinatemperature/enthalpyintervalimpliesdifferentpinchdesigns

andconsequentlydifferentHENS.

The effect of using individual T contributions for individual streams, the distribution of the

heat transfer driving force is smoother. The same effect can be seen from the lower and

smootherplotinFig.24.7(Drivingforceplot(b))

Reference

1. Ahmad, S., 1985, Heat exchanger networks: cost tradeoffs in energy and capital. Ph.D.

thesis,UMIST

2. Linnhoff,B.andAhmad,S.,1986,Supertargeting,ortheoptimizationofheatexchanger

networks prior to design, in World Congress III, Chemical Engineering, Tokyo, Preprint,

Vol.4,pp.822825.

3. Gundersen, T. and Grossmann, I. E., 1988, Improved optimization strategies for

automated heat exchanger network synthesis through physical insight. AIChE Annual

Meeting,PaperNo.81g,Washington,DC.

4. Gundersen, T. and Naess, L., 1988, The synthesis of cost optimal heat exchanger

networks.Comput.Chem.Engng12,503530.

5. Ahmad,S.,Linnhoff,B.,Smith,R.,1990.Costoptimumheatexchangernetworks2

targetsanddesignfordetailedcapitalcostmodels.Computers&ChemicalEngineering

14(7),751.

6. Nishimura,H.etal.,1970,J.Chem.Engng.Japan34,1099l106.

7. Nishimura,H.,1975,TheoryonoptimalsynthesisofheatexchangesystemJapanUSA

JointSeminar,.Kyolo.

8. Nishimura,H.,1980,Atheoryfortheoptimalsynthesisofheatexchangersystems.J.

OptimizationTheoryApplic.30,423450.

9. E.REVandZ.FONYO,DiversepinchconceptforheatexchangeNetworksynthesis:the

caseofdifferentheatTransferconditions,ChemicalEngineerinqScience,Vol46,No.7,

pp.16231634,1991.

You might also like

- Pinch Technology: Minahil Qumreen 2015-CH-430Document38 pagesPinch Technology: Minahil Qumreen 2015-CH-430adnan100% (2)

- Che526: Pinch Technology: Department of Chemical Engineering Landmark University, Omu-AranDocument32 pagesChe526: Pinch Technology: Department of Chemical Engineering Landmark University, Omu-AranHirenNo ratings yet

- Heat IntegrationDocument47 pagesHeat IntegrationAnkitSinghNo ratings yet

- Computers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiDocument13 pagesComputers and Chemical Engineering: Pravin D. Ghuge, Nilesh A. Mali, Sunil S. JoshiSebastián Castañeda100% (1)

- Li 2014Document10 pagesLi 2014ArunNo ratings yet

- Lecture 18: Area Targeting 2: Module 04: Targeting Part (Equal Stream Heat Transfer Coefficient)Document11 pagesLecture 18: Area Targeting 2: Module 04: Targeting Part (Equal Stream Heat Transfer Coefficient)api-256504985No ratings yet

- Introduction To Aspen Plus 2013 Tutorial VDocument77 pagesIntroduction To Aspen Plus 2013 Tutorial VsyafieqNo ratings yet

- Hot and Cold Pinch PDFDocument7 pagesHot and Cold Pinch PDFYatharth SahuNo ratings yet

- PINCH ANALYSIS Part 1 - Pinch and Minimum Utility UsageDocument29 pagesPINCH ANALYSIS Part 1 - Pinch and Minimum Utility Usageraghavan1984No ratings yet

- Compounding of Steam TurbineDocument2 pagesCompounding of Steam TurbinejaihogoluNo ratings yet

- Aspen Plus Lesson 1 PDFDocument12 pagesAspen Plus Lesson 1 PDFsamandondonNo ratings yet

- Lecture 3 HEN Design SolutionDocument63 pagesLecture 3 HEN Design Solution翁宝怡No ratings yet

- Control System DesignDocument26 pagesControl System DesignChoochart Thongnark100% (1)

- ASPEN PLUS Lecture Presentation PDFDocument101 pagesASPEN PLUS Lecture Presentation PDFvenkatesh801No ratings yet

- Terephthalic AcidDocument8 pagesTerephthalic AcidWali AhsanNo ratings yet

- Lecture 2 - GCC and Utilities PlacementDocument21 pagesLecture 2 - GCC and Utilities Placement翁宝怡No ratings yet

- Heat Exchanger Networks: (Continued) Slide-2Document44 pagesHeat Exchanger Networks: (Continued) Slide-2Adheep DasNo ratings yet

- 1 - V.good Lectures PDFDocument89 pages1 - V.good Lectures PDFrawadNo ratings yet

- Performance Improvement of A Gas Turbine Cycle by Using A Desiccant-Based Evaporative Cooling SystemDocument13 pagesPerformance Improvement of A Gas Turbine Cycle by Using A Desiccant-Based Evaporative Cooling Systemشاكر العاقلNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Benefits of Multi-Solvent NRTL Models in Aspen PlusDocument8 pagesBenefits of Multi-Solvent NRTL Models in Aspen PlusAli_F50No ratings yet

- Lecture 1 Intro Energy TargetsDocument56 pagesLecture 1 Intro Energy Targets翁宝怡No ratings yet

- Supervisor: Co-Supervisor: Siguird SKOGESTAD Student:: Krister FORSMAN Quang Khoa LEDocument31 pagesSupervisor: Co-Supervisor: Siguird SKOGESTAD Student:: Krister FORSMAN Quang Khoa LEShuXianNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument3 pagesShell and Tube Heat Exchanger Design1AdityaPathania1No ratings yet

- 37 - 4 - Washington DC - 08-92 - 1855 PDFDocument9 pages37 - 4 - Washington DC - 08-92 - 1855 PDFMohamadMostafaviNo ratings yet

- CDB 4313 Heat Integration - Basic Heat IntegrationDocument25 pagesCDB 4313 Heat Integration - Basic Heat Integrationharvin raoNo ratings yet

- Lecture 4 - Loop and PathDocument44 pagesLecture 4 - Loop and Path翁宝怡No ratings yet

- ColumnA RadFrac ABCDocument5 pagesColumnA RadFrac ABCGaby HdzNo ratings yet

- Propylene-Propane - Howat Swift - McCabe ThieleDocument19 pagesPropylene-Propane - Howat Swift - McCabe ThieleFred FaberNo ratings yet

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4From EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Rating: 5 out of 5 stars5/5 (1)

- Pinch TechnologyDocument16 pagesPinch TechnologyAbubaker Faisal100% (1)

- Predict Storage-Tank Heat Transfer: PreciselyDocument6 pagesPredict Storage-Tank Heat Transfer: PreciselyRuben LealNo ratings yet

- Heat Exchanger Design Lecture - 07Document24 pagesHeat Exchanger Design Lecture - 07Mohmmad ShaikhNo ratings yet

- PD2055E1 MEP Multi Effect Plate DistillerDocument4 pagesPD2055E1 MEP Multi Effect Plate Distillergochi bestNo ratings yet

- Reactions in HYSYSDocument7 pagesReactions in HYSYSWagus GinanjarNo ratings yet

- Introduction To Aspen Plus-2012Document243 pagesIntroduction To Aspen Plus-2012pardise4000No ratings yet

- Vol-1, Issue-5Document7 pagesVol-1, Issue-5Ijrei JournalNo ratings yet

- Chemical Process Equipment DesignDocument9 pagesChemical Process Equipment Designraghu_iictNo ratings yet

- Reaction Kinetics (3) : Xuan Cheng Xiamen UniversityDocument35 pagesReaction Kinetics (3) : Xuan Cheng Xiamen Universityahmadhelmiase7621No ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Classes Hysys 5 Reactions and ReactorsDocument7 pagesClasses Hysys 5 Reactions and ReactorsAhmed AliNo ratings yet

- Application of Pinch Analysis Software: Hint: Cdb4313 - Heat IntegrationDocument49 pagesApplication of Pinch Analysis Software: Hint: Cdb4313 - Heat Integration翁宝怡100% (1)

- Furnace Heater DesignDocument7 pagesFurnace Heater DesignAaAaA_88No ratings yet

- Ethylene Dichloride ManufacturerDocument5 pagesEthylene Dichloride Manufacturerbarus goldenNo ratings yet

- Practice Problems SolutionsDocument9 pagesPractice Problems SolutionsPham Trong BinhNo ratings yet

- Mass & Energy Balance - Introduction To Process VariablesDocument75 pagesMass & Energy Balance - Introduction To Process VariablesMhmd RobertoNo ratings yet

- Understanding Heat Flux Limitations CCTI 2010Document8 pagesUnderstanding Heat Flux Limitations CCTI 2010B rgNo ratings yet

- Cansolv Testing of Cansolv DC 201 CO2 Capture System With Simulated Natural Gas Testing 2015Document28 pagesCansolv Testing of Cansolv DC 201 CO2 Capture System With Simulated Natural Gas Testing 2015arissaNo ratings yet

- Chapter 6Document41 pagesChapter 6Hotib PerwiraNo ratings yet

- Chapter 3 Process SimulationDocument19 pagesChapter 3 Process SimulationYang Yew Ren100% (1)

- Quick Learners Project: Department of Chemical EngineeringDocument20 pagesQuick Learners Project: Department of Chemical EngineeringMehul KarkarNo ratings yet

- A Brief Review of Para-Xylene Oxidation To Terephthalic Acid As A Model of Primary C-H Bond ActivationDocument12 pagesA Brief Review of Para-Xylene Oxidation To Terephthalic Acid As A Model of Primary C-H Bond ActivationleniucvasileNo ratings yet

- Entrainer For Acetic Acid Batch DistillationDocument5 pagesEntrainer For Acetic Acid Batch DistillationJeffrey SolisNo ratings yet

- CRE AssignmentDocument5 pagesCRE AssignmentKuldeepChoudharyNo ratings yet

- Vapour Compression For Propane-Propylene SplittersDocument3 pagesVapour Compression For Propane-Propylene SplittersJohnNo ratings yet

- Themodynamic Model Selection For CHEMCADDocument19 pagesThemodynamic Model Selection For CHEMCADratnakar patharkarNo ratings yet

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDocument32 pagesAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985No ratings yet

- UntitledDocument3 pagesUntitledapi-256504985No ratings yet

- Lecture 4.4: Transfer Molding and Compression Molding Transfer MoldingDocument5 pagesLecture 4.4: Transfer Molding and Compression Molding Transfer Moldingapi-256504985No ratings yet

- Lecture 4.6: ThermoformingDocument4 pagesLecture 4.6: Thermoformingapi-256504985No ratings yet

- UntitledDocument6 pagesUntitledapi-256504985No ratings yet

- Lecture 4.7: Rotational Molding and Blow MoldingDocument8 pagesLecture 4.7: Rotational Molding and Blow Moldingapi-256504985No ratings yet

- UntitledDocument27 pagesUntitledapi-256504985No ratings yet

- Lecture 4.2: Processing of PlasticsDocument3 pagesLecture 4.2: Processing of Plasticsapi-256504985No ratings yet

- LM 28Document13 pagesLM 28Deepak Kumar Kant KesriNo ratings yet

- Gopinath@acer Iitm Ernet inDocument3 pagesGopinath@acer Iitm Ernet inapi-256504985No ratings yet

- Lecture 4.1: Thermoplastics and ThermosetsDocument8 pagesLecture 4.1: Thermoplastics and Thermosetsapi-256504985No ratings yet

- 5 Abrasive Processes (Grinding)Document15 pages5 Abrasive Processes (Grinding)animi100% (1)

- Abrasive Processes (Grinding) : Version 2 ME, IIT KharagpurDocument13 pagesAbrasive Processes (Grinding) : Version 2 ME, IIT KharagpurRAVINDER KUMARNo ratings yet

- Only Questions HTDocument2 pagesOnly Questions HTrkiran05No ratings yet

- UntitledDocument12 pagesUntitledapi-256504985No ratings yet

- Heat Exchanger PDFDocument9 pagesHeat Exchanger PDFsunita45No ratings yet

- UntitledDocument13 pagesUntitledapi-256504985No ratings yet

- Module 7: Learning ObjectivesDocument1 pageModule 7: Learning Objectivesapi-256504985No ratings yet

- Uncontrolled IntersectionDocument16 pagesUncontrolled Intersectionapi-256504985No ratings yet

- What Are Heat Exchangers For?Document33 pagesWhat Are Heat Exchangers For?captainhassNo ratings yet

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDocument32 pagesAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985No ratings yet

- Traffic RotariesDocument9 pagesTraffic RotariesJinal MistryNo ratings yet

- Advanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" ExampleDocument32 pagesAdvanced Transport Phenomena Module 1 Lecture 2: Overview & "Hot Corrosion" Exampleapi-256504985No ratings yet

- UntitledDocument40 pagesUntitledapi-256504985No ratings yet

- Traffic SignsDocument6 pagesTraffic Signsapi-256504985No ratings yet

- Simulation Methods: DX X F PDocument7 pagesSimulation Methods: DX X F Papi-256504985No ratings yet

- UntitledDocument6 pagesUntitledapi-256504985No ratings yet

- UntitledDocument11 pagesUntitledapi-256504985No ratings yet

- UntitledDocument3 pagesUntitledapi-256504985No ratings yet

- UntitledDocument1 pageUntitledapi-256504985No ratings yet

- Midterm - Extemporaneous CompoundingDocument63 pagesMidterm - Extemporaneous CompoundingCamille WuNo ratings yet

- Self Heall PPT EditedDocument34 pagesSelf Heall PPT EditedYASHAS K CNo ratings yet

- Chapter 3 DynamicsDocument8 pagesChapter 3 DynamicsIzzat FatimaNo ratings yet

- Scrubber and Demister Sizing - Form 2Document2 pagesScrubber and Demister Sizing - Form 2eka resmana100% (2)

- Lab Manual Bio1Document31 pagesLab Manual Bio1deltaserrapapa0% (2)

- Module Electricity and MagnetismDocument21 pagesModule Electricity and MagnetismNoorain PurhanudinNo ratings yet

- Practice Test 42Document6 pagesPractice Test 42CachiNo ratings yet

- Improved Version of The Fischer-Zach Synthesis of Glycals: Vitamin B-12 Catalyzed Reductive Elimination of Glycosyl BromidesDocument2 pagesImproved Version of The Fischer-Zach Synthesis of Glycals: Vitamin B-12 Catalyzed Reductive Elimination of Glycosyl BromidesscadvijayNo ratings yet

- Coal Specs Sheet GAR 6400Document2 pagesCoal Specs Sheet GAR 6400Adhitya AchmadNo ratings yet

- Soil Mechanics and Foundation EngineeringDocument881 pagesSoil Mechanics and Foundation EngineeringGilberto Rendón Carrasco100% (4)

- Catipay Lorely LAB1 Part 1Document4 pagesCatipay Lorely LAB1 Part 1Lorely CatipayNo ratings yet

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- Unit I - Non-Destructive Testing:: An Introduction, Visual Inspection & Liquid Penetrant TestingDocument22 pagesUnit I - Non-Destructive Testing:: An Introduction, Visual Inspection & Liquid Penetrant TestingGunasekaran JagadeesanNo ratings yet

- Physics 202 Experiment #7 Diffraction Grating Pre-LabDocument6 pagesPhysics 202 Experiment #7 Diffraction Grating Pre-LabDennis LingNo ratings yet

- Pantelides1978 PDFDocument62 pagesPantelides1978 PDFTeam LeTranNo ratings yet

- Engine Control Module (ECM) X1 (L95)Document1 pageEngine Control Module (ECM) X1 (L95)carloNo ratings yet

- Thermal PropertiesDocument14 pagesThermal PropertiesLivian TeddyNo ratings yet

- Mass Transfer Equipments (Tray Towers)Document26 pagesMass Transfer Equipments (Tray Towers)AjaykumarNo ratings yet

- (L2) Capacitance 11th May PDF NotesDocument39 pages(L2) Capacitance 11th May PDF Notessweta yadavNo ratings yet

- 3.0 Electrolyzer Assembly - 4.0 ElectrolysisDocument22 pages3.0 Electrolyzer Assembly - 4.0 ElectrolysisJuan Carlos Ataurima PucceNo ratings yet

- 1 Wladimir SabugaDocument9 pages1 Wladimir Sabugatimtim1111No ratings yet

- Control Design: Unit 3Document44 pagesControl Design: Unit 3Nihar PandithNo ratings yet

- Dropper NEET 2.0 - Updated PlannerDocument1 pageDropper NEET 2.0 - Updated Planner187nabeelrNo ratings yet

- Deep Set Enclosed Lineshaft Component PartsDocument1 pageDeep Set Enclosed Lineshaft Component PartsFayez Al-ahmadiNo ratings yet

- Smart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Document1 pageSmart Test Series: Q.1 Circle The Correct Answers. (6x1 6)Eeman AkbarNo ratings yet

- On-Demand Manufacturing of Clinical-Quality BiopharmaceuticalsDocument15 pagesOn-Demand Manufacturing of Clinical-Quality BiopharmaceuticalscyannNo ratings yet

- Cambridge International AS & A Level: CHEMISTRY 9701/23Document20 pagesCambridge International AS & A Level: CHEMISTRY 9701/23Aadista BhattaNo ratings yet

- Gallimore - Unified Field Theory Research Book - Using Subjective Response To PSI-Plasma For Analysis of Properties Neutral Charge Plasma Fields (1974)Document124 pagesGallimore - Unified Field Theory Research Book - Using Subjective Response To PSI-Plasma For Analysis of Properties Neutral Charge Plasma Fields (1974)mkilani@butterflyltd.com100% (1)

- DPP No. # C1 (Jee-Main) : Vikaas (Ja) - Chemistry Dpps Booklet-3Document21 pagesDPP No. # C1 (Jee-Main) : Vikaas (Ja) - Chemistry Dpps Booklet-3JanuaryNo ratings yet

- Soil, Plant and Water Analysis - ICARDA 2013Document244 pagesSoil, Plant and Water Analysis - ICARDA 2013Olesea CojocaruNo ratings yet