Professional Documents

Culture Documents

CSWP Sample Exam

Uploaded by

saptagunung0%(1)0% found this document useful (1 vote)

699 views9 pagesFor Preparation

Original Title

Cswp Sample Exam

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFor Preparation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

699 views9 pagesCSWP Sample Exam

Uploaded by

saptagunungFor Preparation

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

CSWP Sample Exam

Certified SolidWorks Professional: Solid Modeling Specialist (CSWP-CORE)

These questions are an example of what to expect in Segment 1 of the CSWP-CORE exam.

How to take this sample exam:

1. To best simulate the conditions of the real test, it is best NOT to print this exam. Since

the Virtual Tester client window runs concurrently with SolidWorks you must switch

back and forth between the two applications. Keeping this document open and consulting

it on your computer while running SolidWorks is the best method to simulate the real test

conditions.

2. The multiple choice answers should serve as a check for you to ensure that your model is

on the right track while completing this exam. If you do not find your answer in the

selections offered then most likely there is something wrong with your model at that

point.

3. Answers to the questions are on the last pages of this sample test document. There are

also hints that can help save time during the exam.

4. If you can complete this exam and get at least 4 out of the 5 questions correctly in 30

minutes or less then you should be ready to take the real CSWP - Segment 1 exam.

What you will need for the real CSWP exam:

1. A computer that is running SolidWorks 2008 sp3.1 or higher.

2. The computer must have a connection to the Internet.

3. A double-monitor is recommended but not necessary.

4. If you will be running the Virtual Tester client on a separate computer from the one that

is running SolidWorks, make sure there is a way to transfer files from one computer to

the other. You will be required to download SolidWorks files during the real test to be

able to correctly answer some of the questions.

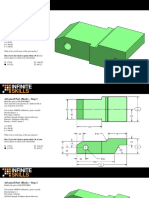

1. Initial part Stage 1: Build this part in SolidWorks.

Unit system: MMGS (millimeter, gram, second)

Decimal places: 2

Part origin: Arbitrary

Material: 6061 Alloy

Density = 0.0027 kg/cm^3

All holes through all unless shown otherwise

Use the following parameters and equations which correspond to the dimensions labeled in the images:

A = 172mm

B = 77mm

C = 104mm

D = 62mm

E = 10mm

F = Hole Wizard Standard: ANSI Metric Counter bore

Type: Hex Bolt ANSI B18.2.3.5M

Size: M12

Fit: Close

Through Hole Diameter: 15mm

Counter bore Diameter: 25mm

Counter bore Depth: 10mm

End Condition: Through All

X = B*1.25

Y = (B*1.5)-50

Hint #1: The dimensions that are to be linked or updated and are variable will be labeled with

letters. Any dimensions that are simple value changes from one stage to another will be circled in

the images.

Hint #2: To save the most time, make use of linked dimensional values and equations.

Measure the mass of the part.

What is the mass of the part (grams)?

a) 1628.62

b) 603.19

c) 1637.32

d) 606.41

2. Update the parameters of the initial part.

Unit system: MMGS (millimeter, gram, second)

Decimal places: 2

Part origin: Arbitrary

Material: 6061 Alloy

Density = 0.0027 kg/cm^3

All holes through all unless shown otherwise

Use the following parameters and equations which correspond to the dimensions labeled in the images:

A = 170mm

B = 75mm

C = 100mm

D = 60mm

E = 5mm

F = Hole Wizard Standard: ANSI Metric Counter bore

Type: Hex Bolt ANSI B18.2.3.5M

Size: M12

Fit: Close

Through Hole Diameter: 15mm

Counter bore Diameter: 25mm

Counter bore Depth: 10mm

End Condition: Through All

X = B*1.25

Y = (B*1.5)-50

Hint #1: The dimensions that are to be linked or updated and are variable will be labeled with

letters. Any dimensions that are simple value changes from one stage to another will be circled in

the images.

Hint #2: To save the most time, make use of linked dimensional values and equations.

Measure the mass of the part.

What is the mass of the part (grams)?

a) 1599.57

b) 1600.57

c) 1966.12

d) 1608.88

3. Update the parameters of the initial part.

Unit system: MMGS (millimeter, gram, second)

Decimal places: 2

Part origin: Arbitrary

Material: 6061 Alloy

Density = 0.0027 kg/cm^3

All holes through all unless shown otherwise

Use the following parameters and equations which correspond to the dimensions labeled in the images:

A = 186mm

B = 91mm

C = 124mm

D = 62mm

E = 8mm

F = Hole Wizard Standard: ANSI Metric Counter bore

Type: Hex Bolt ANSI B18.2.3.5M

Size: M12

Fit: Close

Through Hole Diameter: 15mm

Counter bore Diameter: 25mm

Counter bore Depth: 10mm

End Condition: Through All

X = B*1.25

Y = (B*1.5)-50

Hint #1: The dimensions that are to be linked or updated and are variable will be labeled with

letters. Any dimensions that are simple value changes from one stage to another will be circled in

the images.

Hint #2: To save the most time, make use of linked dimensional values and equations.

Measure the mass of the part.

What is the mass of the part (grams)?

a) 1963.02

b) 1969.10

c) 1964.02

d) 727.41

4. Stage 2

Unit system: MMGS (millimeter, gram, second)

Decimal places: 2

Part origin: Arbitrary

Material: 6061 Alloy

Density = 0.0027 kg/cm^3

All holes through all unless shown otherwise

Use the following parameters and equations which correspond to the dimensions labeled in the images:

A = 181mm

B = 89mm

C = 121mm

D = 60mm

E = 5mm

X = B*1.25

Y = (B*1.5)-75

Note: The equation for Y has changed.

Hint #1: The dimensions that are to be linked or updated and are variable will be labeled with

letters. Any dimensions that are simple value changes from one stage to another will be circled in

the images.

Hint #2: To save the most time, make use of linked dimensional values and equations.

Measure the mass of the part.

What is the mass of the part (grams)?

a) 901.80

b) 2491.94

c) 2431.87

d) 2434.87

5. Stage 2 - Update the parameters of the part.

Unit system: MMGS (millimeter, gram, second)

Decimal places: 2

Part origin: Arbitrary

Material: 6061 Alloy

Density = 0.0027 kg/cm^3

All holes through all unless shown otherwise

Use the following parameters and equations which correspond to the dimensions labeled in the images:

A = 174mm

B = 82mm

C = 114mm

D = 64mm

E = 10mm

X = B*1.25

Y = (B*1.5)-75

Note: The equation for Y has changed.

Hint #1: The dimensions that are to be linked or updated and are variable will be labeled with

letters. Any dimensions that are simple value changes from one stage to another will be circled in

the images.

Hint #2: To save the most time, make use of linked dimensional values and equations.

Measure the mass of the part.

What is the mass of the part (grams)?

a) 2230.60

b) 826.15

c) 2231.54

d) 2209.33

Answer and Hints

1) 1628.62g

2) 1600.57g

3) 1964.02g

4) 2434.87g

5) 2230.60g

DISCLAIMER: IT IS UP TO YOU TO RESEARCH THESE HINTS. BEING A PROFESSIONAL

LEVEL CERTIFIED SOLIDWORKS USER SHOULD ALSO INCLUDE THE ABILITY TO

RESEARCH SOLIDWORKS FUNCTIONALITY. CONSULT HELP, YOUR VAR AEs, THE

ONLINE FORUMS AND BLOGS.

Hint #1: Use Global Variables to manage the dimensions that are to be changed in each stage. This will

ensure that the dimensions to be changed change with as few clicks and possible and with little second

guessing.

Hint #2: Change the label of the dimensions in your part to A, B, C, D, X, and Y to visually keep track

of which dimensions are changing.

You might also like

- Certified Solidworks Professional Advanced Sheet Metal Exam PreparationFrom EverandCertified Solidworks Professional Advanced Sheet Metal Exam PreparationRating: 5 out of 5 stars5/5 (4)

- CSWP Sample Exam Solid Modeling SpecialistDocument9 pagesCSWP Sample Exam Solid Modeling SpecialistJose Luis AtaullucoNo ratings yet

- Segment 1 - CSWP-CORE ExamDocument9 pagesSegment 1 - CSWP-CORE ExammengodNo ratings yet

- Advanced PartDocument6 pagesAdvanced PartMatnSambu100% (1)

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document62 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)bontrager1306100% (1)

- Solidwize: Online Solidworks TrainingDocument9 pagesSolidwize: Online Solidworks Trainingjuanito pipas0% (1)

- To Create Drawing View B' It Is Necessary To Sketch A Spline (As Shown) On Drawing View A' and Insert Which SOLIDWORKS View Type?Document7 pagesTo Create Drawing View B' It Is Necessary To Sketch A Spline (As Shown) On Drawing View A' and Insert Which SOLIDWORKS View Type?Javier McleonNo ratings yet

- CSWP Guide For Solidworks TestDocument5 pagesCSWP Guide For Solidworks TestMario Valdes86% (7)

- CsWa Sample Exam QuestionsDocument6 pagesCsWa Sample Exam QuestionsgurisNo ratings yet

- CSWP Advanced Sheet Metal Sample ExamDocument7 pagesCSWP Advanced Sheet Metal Sample Examroberto1793No ratings yet

- CSWP Practice Test #1 Segment 1Document6 pagesCSWP Practice Test #1 Segment 1Juan David LizardoNo ratings yet

- Part Modeling: The Following Images Are To Be Used To Answer Questions #3 - 4Document8 pagesPart Modeling: The Following Images Are To Be Used To Answer Questions #3 - 4AliNo ratings yet

- CSWP Examen de EjemploDocument3 pagesCSWP Examen de EjemploJoa Molina100% (8)

- CSWP Book - Segment3 - SamplesDocument30 pagesCSWP Book - Segment3 - SamplesMohamed ShafeekNo ratings yet

- Examen1 CSWPDocument16 pagesExamen1 CSWPDaniel Ruiz100% (2)

- CSWP Sample Exam 2 (2012) Segment 2Document10 pagesCSWP Sample Exam 2 (2012) Segment 2rafaelNo ratings yet

- SolidWize CSWP Sample Exam 2 Segment 3 PDFDocument16 pagesSolidWize CSWP Sample Exam 2 Segment 3 PDFparin advani100% (3)

- CSWP1803 Segment 1Document10 pagesCSWP1803 Segment 1PaoloDeMatteisNo ratings yet

- SolidWize CSWP Sample Exam 2 Segment 1Document9 pagesSolidWize CSWP Sample Exam 2 Segment 1Arif Ahmed100% (2)

- CSWPDocument1 pageCSWPNeo NMNNo ratings yet

- SolidWize CSWP Sample Exam 2 Segment 3Document16 pagesSolidWize CSWP Sample Exam 2 Segment 3Kamel BousninaNo ratings yet

- CSWP SOLIDWORKS Certification Exam GuideDocument3 pagesCSWP SOLIDWORKS Certification Exam GuidesravanNo ratings yet

- CSWP Book - Segment1 - SamplesDocument19 pagesCSWP Book - Segment1 - SamplesNics Valbuena80% (5)

- UIDAHO Exam 1.1Document6 pagesUIDAHO Exam 1.1dgm929No ratings yet

- CSWP Sample Exam 1 (2012) Segment 2 QuestionsDocument10 pagesCSWP Sample Exam 1 (2012) Segment 2 QuestionsRommel Leal67% (3)

- CSWP Practice Test Book: Certified Solidworks ProfessionalsDocument20 pagesCSWP Practice Test Book: Certified Solidworks ProfessionalsmohamedNo ratings yet

- CSWP Segment - 1Document1 pageCSWP Segment - 1maulikNo ratings yet

- Q1 11Document5 pagesQ1 11SeymurH-vNo ratings yet

- The Third Sector and Welfare State Modernisation: Inputs, Activities and Comparative PerformanceDocument18 pagesThe Third Sector and Welfare State Modernisation: Inputs, Activities and Comparative PerformanceLukasz GablerNo ratings yet

- CSWP1801 Segment 1Document10 pagesCSWP1801 Segment 1Hassan Attan100% (1)

- SolidWize CSWP Sample Exam 2 Segment 3Document16 pagesSolidWize CSWP Sample Exam 2 Segment 3bontrager1306No ratings yet

- SolidWize CSWP Sample Exam 2 Segment 3 PDFDocument16 pagesSolidWize CSWP Sample Exam 2 Segment 3 PDFMiguel Angel Munguia FloresNo ratings yet

- CSWP Seg.2Document4 pagesCSWP Seg.2Emad Bassem60% (5)

- SolidWize CSWP Sample Exam 1 Segment 3Document17 pagesSolidWize CSWP Sample Exam 1 Segment 3gordansim100% (2)

- Solid Works Flow Simulation 2012Document8 pagesSolid Works Flow Simulation 2012drbaneNo ratings yet

- CSWP Practice Exam - Segment 2Document10 pagesCSWP Practice Exam - Segment 2DH Afnan100% (1)

- Practice Exam QuestionsDocument22 pagesPractice Exam QuestionsWahyu Adi PrayogaNo ratings yet

- Edu Cswa Sample Exam 2013 EngDocument10 pagesEdu Cswa Sample Exam 2013 Engtigerman_nr10% (1)

- Cert Cswpcdessample2008Document7 pagesCert Cswpcdessample2008Gustavo Reaño PulacheNo ratings yet

- CSWA-Sustainability Exam GuideDocument1 pageCSWA-Sustainability Exam GuideHarshi BavishiNo ratings yet

- CSWP Sample Exam: Solid Modeling Specialist (CSWP-COREDocument9 pagesCSWP Sample Exam: Solid Modeling Specialist (CSWP-CORElachhelNo ratings yet

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document8 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Klever MoralesNo ratings yet

- Pieza AvanzadaDocument9 pagesPieza AvanzadaLuis PNo ratings yet

- CSWP-WLDM Sample ExamDocument12 pagesCSWP-WLDM Sample Examtito36bcnNo ratings yet

- Exercício 9 - Cálculo de MassaDocument2 pagesExercício 9 - Cálculo de MassaTiago OliveiraNo ratings yet

- Ejercicio1 CSWADocument2 pagesEjercicio1 CSWAjorgeriver7No ratings yet

- CSWP-WLDM Sample ExamDocument12 pagesCSWP-WLDM Sample ExamJose CuevasNo ratings yet

- CSW ExerciceDocument7 pagesCSW ExercicePermaflex Route Bekalta TeboulbaNo ratings yet

- Solidworks Corporation: Cswa Sample ExamDocument14 pagesSolidworks Corporation: Cswa Sample ExamReena MoisesNo ratings yet

- Cs Was Ample Exam 2010Document14 pagesCs Was Ample Exam 2010El FilyNo ratings yet

- CSWASample Exam 2010Document14 pagesCSWASample Exam 2010Rich Mack100% (1)

- CSWA Practice 2013Document24 pagesCSWA Practice 2013pacomermela69No ratings yet

- CSWA Sample Exam TipsDocument11 pagesCSWA Sample Exam TipsElmika TrầnNo ratings yet

- Solidworks Corporation: Cswa Sample ExamDocument12 pagesSolidworks Corporation: Cswa Sample Examboussaid nejlaNo ratings yet

- Solidworks Corporation: CSWP Advanced Sheet Metal Sample ExamDocument7 pagesSolidworks Corporation: CSWP Advanced Sheet Metal Sample ExamKamal GifariNo ratings yet

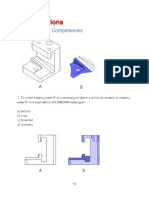

- Test Questions: Part 1: Drafting CompetenciesDocument11 pagesTest Questions: Part 1: Drafting Competencies4112 - Subhash NNo ratings yet

- CAD Contest QuestionDocument37 pagesCAD Contest QuestionFahad AbdullahtNo ratings yet

- Certified Solidworks Associate (Cswa) : Sample Exam QuestionsDocument7 pagesCertified Solidworks Associate (Cswa) : Sample Exam Questionsagus fikri rosjadi100% (10)

- A Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormFrom EverandA Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormRating: 5 out of 5 stars5/5 (5)

- Quantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsFrom EverandQuantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsRating: 5 out of 5 stars5/5 (2)

- Mental Math Secrets - How To Be a Human CalculatorFrom EverandMental Math Secrets - How To Be a Human CalculatorRating: 5 out of 5 stars5/5 (3)

- Mathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingFrom EverandMathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingRating: 4.5 out of 5 stars4.5/5 (21)

- Build a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.From EverandBuild a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Rating: 5 out of 5 stars5/5 (1)

- Making and Tinkering With STEM: Solving Design Challenges With Young ChildrenFrom EverandMaking and Tinkering With STEM: Solving Design Challenges With Young ChildrenNo ratings yet

- Strategies for Problem Solving: Equip Kids to Solve Math Problems With ConfidenceFrom EverandStrategies for Problem Solving: Equip Kids to Solve Math Problems With ConfidenceNo ratings yet

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeFrom EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticeRating: 4 out of 5 stars4/5 (2)

- Calculus Made Easy: Being a Very-Simplest Introduction to Those Beautiful Methods of Reckoning Which are Generally Called by the Terrifying Names of the Differential Calculus and the Integral CalculusFrom EverandCalculus Made Easy: Being a Very-Simplest Introduction to Those Beautiful Methods of Reckoning Which are Generally Called by the Terrifying Names of the Differential Calculus and the Integral CalculusRating: 4.5 out of 5 stars4.5/5 (2)

- A-level Maths Revision: Cheeky Revision ShortcutsFrom EverandA-level Maths Revision: Cheeky Revision ShortcutsRating: 3.5 out of 5 stars3.5/5 (8)

- Math Magic: How To Master Everyday Math ProblemsFrom EverandMath Magic: How To Master Everyday Math ProblemsRating: 3.5 out of 5 stars3.5/5 (15)

- Psychology Behind Mathematics - The Comprehensive GuideFrom EverandPsychology Behind Mathematics - The Comprehensive GuideNo ratings yet

- Mental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)From EverandMental Math: How to Develop a Mind for Numbers, Rapid Calculations and Creative Math Tricks (Including Special Speed Math for SAT, GMAT and GRE Students)No ratings yet

- Conceptual Calculus: A Grand Review Guide for the Ap® Calculus ExamFrom EverandConceptual Calculus: A Grand Review Guide for the Ap® Calculus ExamNo ratings yet

- A Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormFrom EverandA Mathematician's Lament: How School Cheats Us Out of Our Most Fascinating and Imaginative Art FormRating: 4.5 out of 5 stars4.5/5 (20)