Professional Documents

Culture Documents

42 46

Uploaded by

San Deep Sharma0 ratings0% found this document useful (0 votes)

25 views5 pagesJIT

Original Title

42-46

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJIT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views5 pages42 46

Uploaded by

San Deep SharmaJIT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

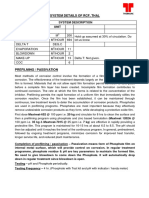

International Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering (October 5-7, 2012)

Punjab Technical University, Jalandhar-Kapurthala Highway, Kapurthala, Punjab-144601 (INDIA) 42

A REVIEW PAPER ON HARDFACING

*

Vineet Shibe,

1

Vikas Chawla

*

Ph.D. Research Scholar, Deptt. of Mech. Engg., Punjab Technical University, Jalandhar, India.

2

Bhai Maha Singh College of Engineering, Muktsar, Punjab, India.

shibevineet@gmail.com, vikkydmt@gmail.com

ABSTRACT

Wear is a process of removal of material from one or both of two solid surfaces in solid state contact, occurring

when two solid surfaces are in sliding or rolling motion together. Different modes of wear are abrasion, impact,

metallic, heat, corrosion etc. Mostly the worn out components fail due to combination of modes of wear, such as

abrasion and impact etc. Wear can be reduced either in the form of using a new wear resistant material or by

improving the wear resistance of the existing material by addition of any wear resistant alloying element etc. Many

methods to reduce wear are in practice. In the last years hardfacing processes have been developed and used for

most of the wear resistant applications. Research is carried out for studying the wear characterization, as the basic

aim of hardfacing is to improve or extend the life of various components used across the industry owing to the high

cost of replacement of original part. In this paper an attempt has been made to review few hardfacing processes,

base materials used, the current research being done and the advantages of hardfacing.

Key Words: Hardfacing, Wear resistance, Welding, Shield manual arc welding (SMAW) process

1. Introduction

Degradation of materials by wear results in very

high losses in several industries such as agricultural,

automobiles, constructional, metal working etc.

Individuals and industry tend to focus on the wearing

surface that has the greatest impact on their own

economic situation. Wear is a surface phenomenon

and occurs mostly at outer surfaces. Every part that is

moving in service will be subject to wear at the

contact point with other parts. The consequence of

this wear is that the parts need to be replaced, which

costs money and causes downtime on the equipment.

Common Methods to control wear are hardfacing, use

of surface coatings and lubrication. Hardfacing is the

application of build-up of deposits of specialized

alloys by means of welding process to resist abrasion,

corrosion, high temperature, or impact. Surface

coating may be defined as a layer of material, formed

naturally or deposited artificially on the surface of an

object made of another material, with an aim of

obtaining required technical or decorative properties.

Lubrication is done to separate the sliding/mating

surfaces with a lubricating film.

Surface Engineering is defined as the branch of

science that deals with methods for achieving the

desired surface requirements and their behavior in

service for engineering components. The surface

characteristics of engineering materials have a

significant effect on the serviceability and life of a

component thus cannot be neglected in design.

Hardfacing is a surface modification technique

used to rebuild the surface of a work piece and is the

most common process to improve the wear resistance

of the components. It is a technique in which a

superior material is deposited on the substrate having

a sufficient mechanical strength but of less cost and to

achieve the desired properties in an economical way.

Such an alloy may be deposited on the surface, an

edge, or merely the point of a part subject to wear.

Welding is a key technology to fulfil these

requirements and to apply hardfacing alloys [1].

Hardfacing may be applied to a new part during its

production, or it may be used to restore a worn-down

surface. Hard-facing increases the service life of a part

and there by extend the lifetime of machinery

equipment efficiently [1].

In the last years hardfacing became an issue of

intense development related to wear resistant

applications. Economic success of this process

depends on selective application of hardfacing

material & its chemical composition.

2. Welding Processes Used for

Hardfacing

The different welding processes used for

hardfacing are Arc Welding, Gas Welding,

combination of Arc and Gas Welding, etc. Mostly

MMAW process is used for hardfacing because it is

the most common and versatile process. It has low

cost of equipment, portable, inexpensive; flexible in

use, ideal for repair and all position welding can be

performed easily.

The different welding processes used for

Hardfacing can be classified as under:

International Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering (October 5-7, 2012)

Punjab Technical University, Jalandhar-Kapurthala Highway, Kapurthala, Punjab-144601 (INDIA) 43

Hardfacing by Arc Welding

Shielded Metal Arc Welding [2], Flux Cored Arc

Welding [3], Submerged Arc Welding [4].

Hardfacing by Gas Welding

Deposition by Oxy-Acetylene Gas Welding [5].

Hardfacing by combination of Arc and Gas

Welding

Tungsten Inert Gas Welding [6], Gas Metal Arc

Welding [7].

Powder Spraying

Flame Spraying [8], High Velocity Oxy-Fuel Process

[9], Electric Arc Spraying, Plasma Transferred Arc

[10], etc.

Laser Hardfacing or Cladding [11].

The various factors that should be considered for

selecting of the most suitable welding process for a

given job and application are: Base metal (substrate)

composition, Nature of Work to be hardfaced,

Function of the component, Size and shape of

component, Accessibility of welding equipment, State

of repair of worn component and Number of same or

similar items to be hardfaced, etc.

3. Types of Hardfacing Alloys

The different hard-facing alloys available can be

classified as under:

Low alloy iron-base alloys

High alloy iron-base alloys

The cobalt-base and nickel-base alloys

Tungsten carbide materials

Low alloy iron-base alloys

Materials containing up to 12% alloy components,

usually chromium [12], molybdenum [13], and

manganese [14].

High alloy iron-base alloys

Materials with 12-50% alloy content, in addition to

the chromium found in all iron- base hard-facing

alloys, some of these alloys may also contain nickel

[15] or cobalt [7].

The cobalt-base [7] and nickel-base alloys

[15]

Contain relatively small amounts of iron (1.3 to

12.5%). Of these, the most costly, but also the most

versatile, are the cobalt-chromium-tungsten alloys

[16]. All the cobalt- base and nickel-base alloys have

high resistance to corrosion and oxidation; they

possess low coefficients of friction, making them

especially suitable for applications involving metal-to-

metal wear; and they are almost always selected for

applications involving temperatures of 5500C or

higher. The cobalt-base alloys retain much of their

original hardness at red heat (8000C).

Tungsten carbide materials [17]

Tungsten carbide is one of the hardest materials

available for industrial use. It cannot be melted by any

flame and is also rather brittle. For hard-facing

purposes, it is crushed and applied in conjunction with

a binding metal.

4. Types of Base Materials

The base or substrate material on which

hardfacing alloys are deposited by different welding

processes is steel. Steel comprises of different types of

metals and is made principally of iron. The various

types of steels used in the industry for making

different components or parts for different

applications are classified in to the following types:

Low Carbon Steels and Low alloy Steels

Medium Carbon Steels

High Carbon Steels

Other steels

Low Carbon Steels and Low alloy Steels:

These steels include those in the AISI series C-1008

to C-1020 [18]. Carbon ranges from 0.10 to 0.25%,

manganese ranges from 0.25 to 1.5%, phosphorous is

0.4% maximum, and sulfur is 0.5% maximum. Steels

in this range are most widely used for industrial

fabrication and construction. These steels can be

easily welded with any of the arc, gas, and resistance

welding processes. These steels include the low-

manganese steels, the low-to-medium nickel steels,

the low nickel-chromium steels, the molybdenum

steels, the chromium-molybdenum steels, and the

nickel-chromium-molybdenum steels. These alloys

are included in AISI series 2315, 2515, and 2517.

Carbon ranges from 0.12-0.30%, manganese from

0.40-0.60%, silicon from 0.20-0.45% & nickel from

3.25-5.25%.

Medium Carbon Steels:

These steels include those in the AISI series C-1025

to C-1050 [19]. The composition is similar to low-

carbon steels, except that the carbon ranges from 0.25

to 0.50% and manganese from 0.60 to 1.65%.

Medium carbon steels are readily weld able provided

some precautions are observed. These steels can be

easily welded with any welding processes discussed

above.

International Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering (October 5-7, 2012)

Punjab Technical University, Jalandhar-Kapurthala Highway, Kapurthala, Punjab-144601 (INDIA) 44

High Carbon Steels:

These steels include those in the AISI series from C-

1050 to C-1095[20]. The composition is similar to

medium-carbon steels, except that carbon ranges from

0.30 to 1.00%. Special precautions must be taken

when welding steels in these classes. These steels can

be easily welded with any of the processes discussed

above.

Other steels:

These are Low Nickel Chrome Steels (AISI 3120,

3135, 3140, 3310, and 3316), Low Manganese Steels

(AISI 1320, 1330, 1335, 1340, and 1345), Low Alloy

Chromium Steels (AISI 5015 to 5160) and the electric

furnace steels 50100, 51100, and 52100) which can be

welded without special precautions when carbon is at

low end of the range.

5. Hardfacing Applications

Hard facing technique is widely used in

Agriculture: Plowshare points, Soil-tamper points,

Harrower teeth, Tiller blades; Automotive: Trucks,

automobiles, highway construction and agricultural

vehicles, cam actuators and shafts, Exhaust

manifolds, Pumps, Mufflers, Brakes, Clutches, Cones;

Building construction: Brick moulds, Wear plates,

Mixing machine blades, Fuller screws, Crushing

cylinders, Punches and dies for ceramic materials;

Chemical: Pump shafts and sleeves, Rotating joints,

Valves, Mixer blades, Homogenizer blades,

Agitator blades; Food processing: Extruder screws

for vegetables oils, Grain mill equipments, Corn and

sugar cane cutting equipments; Glass & Ceramics:

Moulds, Screws, Mixing blades, Agitator blades;

Leather goods; Cutting tools and equipment;

Metal Working: Shear blades, Conveyor rollers,

Surface cleaning rollers, Straightening rollers, Draw

die equipment, Moulds; Mining Ore: Crusher blades,

Power-shovel teeth, Conveyor chains, Scraper blades,

Cut-off blades; Naval works: Rod ends, Blower

turbines, Piston rods, Transmission shafts, Screw

shafts; Paper: Roll cylinders for continuous

machines, Drying cylinders, Mixers; Petroleum:

Blowers and ventilators, Pumps, Heat exchangers;

Power generation: Turbines; Public works:

Steam shovel teeth and edges, Excavator teeth,

Bulldozer blades and teeth, Dredge rollers, Tractor

rollers; Rubber Tire moulds; Shop Machinery:

Tool machinery, Carriage guides, Mandrels and

spindles, Tail stocks, Bushings; Steel & Foundry:

Ventilator and blower parts, Coke wagons, Blower

nozzles, Feed rollers, Gaskets, Speed reducer, Ore

and earth handling equipment, De-flashing dies, Shear

blades, Punches, Forging moulds and punches, Sheet

metal conveyor guide; Textiles: Filament guides,

Diagonal cutter, Rollers, Heating plates.

6. Results and Discussion from

Current Research

Current Research on hardfacing focuses on using

various hardfacing/ welding techniques, different

weld consumables and different base materials. Most

of the research is carried out in studying the wear

characterization, as the basic aim of hardfacing is to

extend the service life of components used in the

industry owing to the high cost of replacement of

original component.

The different hardfacing layers produced by

shield manual arc welding (SMAW) process with a

bare electrode coated with fluxes and to which

different measures of ferrotitanium (FeTi),

ferrovanadium (FeV), ferromolybdenum (FeMo)

and graphite had been added showed good resistance

to cracking and wear when the amounts of graphite,

FeTi, FeV and FeMo were controlled within a

range of 810%, 1215%, 1012% and 24%,

respectively [21]. The coated tubular electrodes

presented a favorable performance in comparison to

the conventional coated electrode, making possible to

reach lower dilutions yet keeping the same deposition

rates. These results encourage further researches

aiming the exploitation of this fabrication conception

of SMAW electrodes [2]. FCAW welds presented

higher abrasive wear resistance than the SMAW

deposits [3]. Fe-based hardfacing alloys containing

molybdenum compound have been deposited on AISI

1020 steel substrates by shield manual arc welding

(SMAW) process. The hardfacing layer with good

cracking resistance and wear resistance could be

obtained when the amounts of FeMo was controlled

within a range of 34 wt. %. The improvement of

hardness and wear resistance of the hardfacing layers

attributed to the formation of Mo2C carbide and the

solution strengthening of Mo [13].

Gas welding is often a convenient and relatively

inexpensive method of applying wear-resistant surface

coatings [22]. In the analysis of microstructure and

properties of TiC particles reinforced Fe-based surface

composite coatings produced by gas tungsten arc

welding (GTAW), the results showed that in situ

synthesized TiC particle reinforced composite

coatings can be achieved under suitable welding

parameters. The wear resistance of multi-layers

composite coatings is about three to four times higher

than that of 1045 steel substrate [23].

A series of high chromium FeCrC hardfacing

alloys were produced by gas tungsten arc welding

(GTAW). Chromium and graphite alloy fillers were

used to deposit coatings on ASTM A36 steel

substrates. X-ray diffraction analysis and

microstructure characteristics showed CrFe solid

solution (), (Cr,Fe)23C6 and trace amounts of

(Cr,Fe)7C3. Massive (Cr,Fe)23C6 contain (Cr,Fe)7C3

in the center, and causes high hardness value up to

International Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering (October 5-7, 2012)

Punjab Technical University, Jalandhar-Kapurthala Highway, Kapurthala, Punjab-144601 (INDIA) 45

HRC 70 [24]. A series of high carbon FeCrC

hardfacing alloys were produced by gas tungsten arc

welding (GTAW). Chromium and graphite alloy

fillers were used to deposit hardfacing alloys on

ASTM A36 steel substrates. Depending on the four

different graphite additions in these alloy fillers, this

research produced hypereutectic microstructures of

FeCr phase and (Cr,Fe)7C3 carbides on hard-facing

alloys. The microstructural results indicated that

primary (Cr,Fe)7C3 carbides and eutectic colonies of

[CrFe+(Cr,Fe)7C3] existed in hardfacing alloys.

With increasing the C contents of the hardfacing

alloys, the fraction of primary (Cr,Fe)7C3 carbides

increased and their size decreased. The hardness of

hardfacing alloys increased with fraction of primary

(Cr.Fe)7C3 carbides [25].

The FE-based hardfacing alloy has excellent wear

resistance, excellent cavitation erosion resistance, and

excellent corrosion resistance, thereby being

substituted for a cobalt-based satellite alloy, which

has been used for the hardfacing of a nuclear power

plant valve. When the provided Fe-based hardfacing

alloy is used for the hardfacing of the nuclear power

plant valve, inexpensive Fe can be substituted for

expensive Co and radiation fields formed by 58Co

and 60Co radioactive isotopes can be efficiently

reduced [26].

7. Conclusions

Hardfacing is a low cost, most versatile method

of depositing wear resistant surfaces on components

to extend their life and it provides the following

benefits: Longer service life, higher productivity, less

downtime - greater availability of machine and

reduced cost.

Hardfacing improves the life of the worn out

component and reduces the cost of replacement. It

reduces downtime by extending the service life and

hence few shutdowns are required to replace them.

Hardfacing can be done on any steel material

using a suitable welding technique for a given job and

application. Different alloying elements can be

deposited on the substrate or base metal to achieve the

desired properties such as hardness, wear resistance,

abrasive resistance and impact resistance etc.

References

1. Kirchganer M., Badisch E., Franek F. (2008), Behaviour of

Iron-based hardfacing alloys under abrasion & impact, Wear

Journal, Vol. 265(5-6), pp. 772-777.

2. Crespo Amado Cruz, Scotti Amrico, Prez Manuel Rodriguez

(2008), Operational Behavior Assessment of coated tubular

electrodes for SMAW hardfacing, Journal of Materials

Processing Technology, Vol. 199(1-3), pp. 265-273.

3. Coronado John J., Caicedo Holman F., Gmez Adolfo L. (2009),

The effects of Welding Processes on abrasive wear resistance

for hardfacing deposits, Tribology International, Vol. 42, Issue

5, pp. 745-749.

4. Chang Kyu Kim, Sunghak Lee, Jae-Young Jung, Sangho Ahn

(2003), Effects of Complex Carbide fraction on high-

temperature wear properties of hardfacing alloys reinforced with

complex carbides, Materials Science and Engineering: A, Vol.

349, Issues 1-2, pp. 1-11.

5. Buchely M.F., Gutierrez J.C., Len L.M. and Toro A. (2005),

The effect of Microstructure on abrasive wear of hardfacing

alloys, Wear, Vol. 259, Issues 1-6, pp. 52-61.

6. Kashani H., Amadeh A., Ghasemi H.M. (2007), Room and

High Temperature wear behaviors of nickel and cobalt base

weld overlay coatings on hot forging dies, Wear, Vol. 262,

Issues 7-8, pp. 800-806.

7. Fouilland L., El Mansori M., Massaq A. (2009), Friction-

induced Work hardening of cobalt-base hardfacing deposits for

hot forging tools, Journal of Materials Processing Technology,

Vol. 209, Issue 7, pp. 3366-3373.

8. Navas C., Colao R., De Damborenea J., Vilar R. (2006),

Abrasive wear behaviour of laser clad and flame sprayed-

melted NiCrBSi coatings, Surface and Coatings Technology,

Vol. 200, Issue 24, pp. 6854-6862.

9. Lin M.C., Chang L.S., Lin H.C., Yang C.H., Lin K.M. (2006), A

study of high-speed slurry erosion of NiCrBSi thermal sprayed

coating, Surface and Coatings Technology, Vol. 201, Issue 6,

pp. 3193-3198.

10. DOliveira A. S. C. M., Vilar R., Feder C. G. (2002), High

temperature behaviour of Plasma transferred arc and Laser Co-

based alloy coatings, Applied Surface Science, Vol. 201, Issues

1-4, pp. 154-160.

11. Ming Qian, Lim L. C., Chen Z. D. (1998), Laser Cladding of

nickel-based hardfacing alloys, Surface and Coatings

Technology, Vol. 106, Issues 2-3, pp. 174-182.

12. Berns H., Fischer A. (1997), Microstructure of Fe-Cr-C

Hardfacing Alloys with additions of Nb, Ti &, B, Materials

Characterization, Vol. 39, pp. 499-527.

13.Wang Xin-hong, Han Fang, Qu Shi-yao, Zou Zeng-da (2008),

Microstructure of the Fe-based hardfacing layers reinforced by

TiC-VC-Mo2C particles, Surface and Coatings Technology,

Vol. 202, Issue 8, pp. 1502-1509.

14. Kim Jun-ki, Kim Geun-mo, Kim Seon-Jin (2001), The effect of

manganese on the strain-induced martensitic transformation and

high temperature wear resistance of Fe20Cr1C1Si

hardfacing alloy, Journal of Nuclear Materials, Vol. 289, Issue

3, pp.263-269.

15.El Mansori M., Nouari M. (2007), Dry machinability of nickel-

based weld-hardfacing layers for hot tooling, International

Journal of Machine Tools and Manufacture, Vol. 47, Issue 11,

pp. 1715-1727.

16.Riddihough M. (1970), Stellite (Cobalt-Chromium-Tungsten

alloy) as a wear-resistant material, Tribology, Vol. 3, Issue 4,

pp. 211-215.

17.Blombery R.I., Perrott C.M. (1974), Wear of Sprayed Tungsten

carbide hardfacing deposits, Wear, Vol. 29, Issue 1, pp. 95-109.

18.Wang X.H., Han F., Liu X.M., Qu S.Y., Zou Z.D. (2008), Effect

of Molybdenum on the microstructure and wear resistance of Fe-

based hardfacing coatings, Materials Science and

Engineering: A, Vol. 489, Issues 1-2, pp. 193-200.

International Conference on Advancements and Futuristic Trends in Mechanical and Materials Engineering (October 5-7, 2012)

Punjab Technical University, Jalandhar-Kapurthala Highway, Kapurthala, Punjab-144601 (INDIA) 46

19.Wang X.H., Zou Z.D., Qu S.Y. , Song S.L. (2005),

Microstructure and Wear properties of Fe-based hardfacing

coating reinforced by TiC particles, Journal of Materials

Processing Technology, Vol. 168, Issue 1, pp. 89-94.

20.Kwok C. T., Man H. C., Cheng F. T. (2001), Cavitation

erosioncorrosion behaviour of laser surface alloyed AISI 1050

steel using NiCrSiB, Materials Science and Engineering: A,

Volume 303, Issues 1-2, pp. 250-261.

21.Wang Xin-hong, Han Fang, Liu Xuemei, Qu Shiyao, Zou Zengda

(2008), Microstructure and Wear properties of the FeTiV

MoC hardfacing alloy, Wear, Vol. 265, Issues 5-6, pp. 583-

589.

22.Bell G.R. (1972, Surface coatings 3-Gas-welded coatings,

Tribology, Vol. 5, Issue 5, pp. 215-219.

23.Wang X.H., Song S.L., Zou Z.D., Qu S.Y. (2006), Fabricating

TiC particles reinforced Fe-based composite coatings produced

by GTAW multi-layers melting process, Materials Science and

Engineering: A, Vol. 441(1-2), pp. 60-67.

24.Fan Chieh, Chen Ming-Che, Chang Chia-Ming, Wu Weite

(2006), Microstructure change caused by (Cr,Fe)23C6

carbides in high chromium FeCrC hardfacing alloys, Surface

and Coatings Technology, Vol. 201, Issues 3-4, pp. 908-912.

25.Chang Chia-Ming, Chen Yen-Chun, Wu Weite (2010),

Microstructural and Abrasive characteristics of high carbon

FeCrC hardfacing alloy, Tribology International, Vol. 43,

Issues 5-6, pp. 929-934.

26.Kim Seon-Jin, Oh Young-Min, Kim Jun-Gi (2005), Fe-Based

Hardfacing Alloy, United States Patent Publication, Pub. No.:

US 2005/0139294 A1.

You might also like

- 1 PH.D Associate Professor Dr. Vandna ChhabraDocument2 pages1 PH.D Associate Professor Dr. Vandna ChhabraSan Deep SharmaNo ratings yet

- Capital MarketDocument57 pagesCapital MarketSan Deep SharmaNo ratings yet

- Employment certificate for COVID vaccinationDocument2 pagesEmployment certificate for COVID vaccinationcool_spNo ratings yet

- RamanDocument4 pagesRamanSan Deep SharmaNo ratings yet

- PRODUCTION Planning and ControlDocument14 pagesPRODUCTION Planning and ControlLyn EscanoNo ratings yet

- CBSE Class XII Computer Science Syllabus GuideDocument4 pagesCBSE Class XII Computer Science Syllabus GuideSan Deep SharmaNo ratings yet

- 8502Document19 pages8502San Deep SharmaNo ratings yet

- Cca India 2014Document1 pageCca India 2014San Deep SharmaNo ratings yet

- Technical Specification WPS JNNSM PDFDocument8 pagesTechnical Specification WPS JNNSM PDFSan Deep SharmaNo ratings yet

- Example Assignment 2009 PDFDocument15 pagesExample Assignment 2009 PDFSan Deep SharmaNo ratings yet

- Narmaha 222Document74 pagesNarmaha 222San Deep SharmaNo ratings yet

- Reevaluation Form ReportDocument1 pageReevaluation Form ReportSan Deep SharmaNo ratings yet

- XX XxiiiDocument4 pagesXX XxiiiSan Deep SharmaNo ratings yet

- More Than 100 Keyboard Shortcuts Must ReadDocument3 pagesMore Than 100 Keyboard Shortcuts Must ReadChenna Keshav100% (1)

- Converse: Cash On Account P.O # Qty. Description AmountDocument1 pageConverse: Cash On Account P.O # Qty. Description AmountSan Deep SharmaNo ratings yet

- Space Radiations and Its Effect On Ultra High Temperature Resistant Polymeric Nano CompositeDocument4 pagesSpace Radiations and Its Effect On Ultra High Temperature Resistant Polymeric Nano CompositeSan Deep SharmaNo ratings yet

- 09 - Chapter 4 - More Effective Innovation and Entrepreneurship Will Boost Productivity - SBRA Draft ReportDocument28 pages09 - Chapter 4 - More Effective Innovation and Entrepreneurship Will Boost Productivity - SBRA Draft ReportSan Deep SharmaNo ratings yet

- Group NamesDocument6 pagesGroup NamesSan Deep SharmaNo ratings yet

- More Than 100 Keyboard Shortcuts Must ReadDocument3 pagesMore Than 100 Keyboard Shortcuts Must ReadChenna Keshav100% (1)

- Inventory ControlDocument23 pagesInventory ControlSan Deep SharmaNo ratings yet

- V XiiDocument8 pagesV XiiSan Deep SharmaNo ratings yet

- Theoretical Studies of Electronic Properties of Graphene Using Atk SimulationDocument5 pagesTheoretical Studies of Electronic Properties of Graphene Using Atk SimulationSan Deep SharmaNo ratings yet

- 192 198Document7 pages192 198San Deep SharmaNo ratings yet

- 244 251Document8 pages244 251San Deep SharmaNo ratings yet

- 244 251Document8 pages244 251San Deep SharmaNo ratings yet

- 216 221Document6 pages216 221San Deep SharmaNo ratings yet

- 209 215Document7 pages209 215San Deep SharmaNo ratings yet

- 209 215Document7 pages209 215San Deep SharmaNo ratings yet

- 180 182Document3 pages180 182San Deep SharmaNo ratings yet

- 180 182Document3 pages180 182San Deep SharmaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- M2 Machine Gun Technical ManualDocument348 pagesM2 Machine Gun Technical ManualskylarNo ratings yet

- Critical Service Catalog en 08 2016Document72 pagesCritical Service Catalog en 08 2016Mukiara LuffyNo ratings yet

- TFP 3153Document6 pagesTFP 3153Diego PinedaNo ratings yet

- Joost Van Bennekom - Glycerol 1Document221 pagesJoost Van Bennekom - Glycerol 1russell_mahmoodNo ratings yet

- Steelwork Framing C2Document26 pagesSteelwork Framing C2Luwalhati TomilasNo ratings yet

- Maintaining Subsea Petroleum Production SystemsDocument16 pagesMaintaining Subsea Petroleum Production SystemsNaresh NarineNo ratings yet

- Merus Ring - Water Booklet PDFDocument14 pagesMerus Ring - Water Booklet PDFAmey Dhaygude100% (1)

- Corrosion Testing and MeasurementsDocument9 pagesCorrosion Testing and MeasurementsVaish NaviNo ratings yet

- Precautions For Loading, Unloading, Transport and Storage of MethanolDocument3 pagesPrecautions For Loading, Unloading, Transport and Storage of MethanolShashi KumarNo ratings yet

- No.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDocument38 pagesNo.: HURL-G-ED-C00-STA-SPC-000-D102 Engineering Specification For Pressure VesselsDarshan PanchalNo ratings yet

- Flow Serve PDFDocument16 pagesFlow Serve PDFtaher100% (1)

- Potential Measurement To Determine The Chloride Threshold Concentration That Initiates Corrosion of Reinforcing Steel Bar in Slag ConcretesDocument17 pagesPotential Measurement To Determine The Chloride Threshold Concentration That Initiates Corrosion of Reinforcing Steel Bar in Slag ConcretesTarek ChikerNo ratings yet

- Vegetable cutting fluid for grindingDocument5 pagesVegetable cutting fluid for grindingRLNo ratings yet

- PaintDocument35 pagesPaintMahendraAnanthNo ratings yet

- FMDS0706 Plasitc TanksDocument10 pagesFMDS0706 Plasitc Tanksdaniela hritucNo ratings yet

- Materials 12 01325 PDFDocument21 pagesMaterials 12 01325 PDFRodolfoMarínNo ratings yet

- 0170 PDFDocument7 pages0170 PDFMANNANo ratings yet

- Pass I VationDocument1 pagePass I VationSankar100% (1)

- MG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionDocument11 pagesMG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionAbdelrahman Hosny100% (1)

- Failure Analysis of Weld Neck Flange in A RefineryDocument10 pagesFailure Analysis of Weld Neck Flange in A RefineryVenkat RanganNo ratings yet

- COPPERDocument16 pagesCOPPERk lightNo ratings yet

- Sample ThesisDocument8 pagesSample ThesisAkshay Iyer0% (1)

- 18 Fisher-Regulators CatalogDocument110 pages18 Fisher-Regulators CatalogEnrique MurgiaNo ratings yet

- Biological Corrosion FailuresDocument10 pagesBiological Corrosion FailuresJose QuiinteroNo ratings yet

- Boiler PRESERVATION PROCEDUREDocument18 pagesBoiler PRESERVATION PROCEDUREasirul_meNo ratings yet

- 42) API 653 DAY 5 BOOK (1 To 58)Document58 pages42) API 653 DAY 5 BOOK (1 To 58)SHAHIDALI100% (2)

- Quality Audit of Bogie OverhaulDocument24 pagesQuality Audit of Bogie OverhaulEnd End100% (1)

- Bridge Works - MiscellaneousDocument26 pagesBridge Works - MiscellaneousamitjustamitNo ratings yet

- Chemical Cleaning ProcessDocument7 pagesChemical Cleaning ProcessmechanikyNo ratings yet

- Def STAN 03-2 Surface PreparationDocument71 pagesDef STAN 03-2 Surface Preparationsai0% (1)