Professional Documents

Culture Documents

111

Uploaded by

Kaya Emanuel0%(1)0% found this document useful (1 vote)

184 views11 pagesfengda

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfengda

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

184 views11 pages111

Uploaded by

Kaya Emanuelfengda

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

PROFESSIONAL

FENG HUA BIDA MACHINERY MANUFACTURE CO.,LTD

AIRBRUSH KIT

ASSEMBLY & INSTRUCTION MANUAL

Please read through this manual very carefully before using it! CAUTION:

!

Air Brush Assembly & Instruction Manual

SAVE THIS MANUAL

You will need this manual for safety warnings, precautions, operation, inspection,

maintenance, cleaning procedures, parts mbly diagram. Keep your invoice with

this manual. Write the invoice number on the inside of the front cover. Keep this

manual and invoice in a safe and dry place for future reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. Do not exceed the maximum pressure rating of 50 PSI.

2. Keep work area clean and dry. Cluttered, damp, or wet work areas invite injuries.

3. Keep children away from work area. Do not allow children to handle this product.

4. Store idle equipment. When not in use, tools and equipment should bestored in

a dry location to inhibit rust. Always lock up tools and equipment, and keep out

of reach of children.

5. Do not use products if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired

while taking drugs. If there is any doubt, do not attempt to use products.

6. Use eye and breathing protection. Wear ANSI approved safely impact eye

goggles and an ANSI approved dust mask or respirator when using products.

7. Industrial applications must follow OSHA requirements.

8. Stay alert. Watch what you are doing at all times. Use common sense. Do not

use products when you are tired or distracted from the job at hand.

9. Check for damaged parts. Before using this product, carefully check that it will

operate properly and perform its intended function. Check for damaged parts

and any other conditions that may affect the operation of products. Replace or

repair damaged or worn parts immediately.

10. Replacement parts and accessories: When servicing, use only identical replac-

ements parts. Only use accessories intended for use with specific product.

11. Maintain this product with care.keep this product clean and dry for better and

safer performance. For your safety, service and maintenance should be perfor-

med regularly by a qualified technician.

-2-

-3-

12. Use the right tool for the job. Do not attempt to force a small tool to do the

work of a larger industrial tool. There are certain applications for which this

was designed. It will do the job better and more safely at the capacity for

which it was intended. Do not modify this tool and do not use this tool for a

purpose for which it was not intended.

13. Maintain a safe working environment. Keep the work area well lit. Make sure

there is adequate surrounding work space. Use products only in a ell ventilated

area.

14. Before each use, always check all connections and joints to make sure no air

leaks are present. Also check air hoses for cracks or excessive wear. Always

replace a damaged hose.

15. The Air Brush is designed only to spray paint. Never spray gasoline, kerosene,

or any flammable solvent.

16. If paint is accidentally swallowed or inhaled, immediately contact a physician

for emergency medical attention.

17. Always disconnect the Air Brush from its air supply source before changing

accessories or performing any maintenance on the Air Brush Kit.

18. Always read and adhere to all safety warnings and instructions provided in the

instruction manual of the spray paint being used.

19. WARNING! The warnings, precautions, and instructions discussed in this

manual cannot cover all possible conditions and situations that may occur. The

operator must understand that common sense and caution are factors, which

cannot be built into this product, but must be supplied by the operator.

PRODUCT DESCRIPTION

Air Brush is a professional tool for high precision spray painting works. The major

parts of a complete air brush include head, nozzle, Air Brush body, valve body, ne-

edle, O-Rings, spring, etc. The professional use of an Air Brush includes temporar-

ily tattoo, tanning, automobile art works, nail, model, chinaware, house decorating,

cake decorating, T-shirt and other fine art works and projects.

-4-

A. Product Type

Double Action Air Brush is the most practical type. It is applicable for all projects from

beginners to professionals. Air comes out as soon as the trigger is pressed. Pull back trigg-

er, ink will be sprayed out with a 0.8 mm. straight line to a mist circle.

Double-Action AirBrush

BD-130

BD-134 BD-135 BD-136

BD-137 BD-139 BD-180

BD-182 BD-182A BD-105

BD-116 BD-116A BD-128

BD-128P BD-800 BD-200

BD-132 BD-133

BD-201 BD-202 BD-203

BD-205 BD-186 BD-168

BD-181 BD-181A BD-183

BD-207 BD-184 BD-208

BD-158S BD-158 BD-206

BD-138P BD-138 BD-148

Single-Action AirBrush

Single-Action AirBrush

Air controllable Single Action AirBrush is applicable for basic painting.

-5-

Elementary type is applicable for large area basic painting.

AS-16

AS-18(A)

AS-186(A)

AS-18

AS-19

AS-189

AS-18(2)

AS-186

AS-189(A)

AS-196

AS-09 AS-06K

BD-15 BD-16 BD-17

AS-196(A) AS-06

Mini Air-compressor(Oil-free)

Airbrush Holder

-6-

BD-22 BD-21 BD-23

BD-25 BD-24

BD-117

BD-13 BD13-4 BD13-6

BD-777 BD-118 MOD472P

BD-119 BD-12

BD-26

BD-18

Air Hose

Accessories

-7-

-8-

Fittings

B. Color Cup Type

C. Nozzle Size

D. Various Shape of Air Cap

Fixed Cup Removable Cup Removable Side Cup Removable Jar

Regular nozzle size ranges from 0.20mm to 0.50mm. Large area painting requires nozzle

size from 0.80mm to 1.0mm. The smaller nozzle size is suitable for exquisite painting pr-

ojects;larger size nozzle is required for thick ink so it would not be easily jammed during

spraying 0.30mm is the most popular nozzle size.

1. Concentrate Cap 2. Spread Cap 3. Flower Cap

1. Concentrate Cap: spray head concentrates the paint to the center of focus.

2. Spread Cap: spread the paint so to cover a large area.

3. Flower Cap: spray head is in shape of a flower that expels air thats reflected from the

object.

BD35

BD37

BD39

BD38

BD45

BD47

BD48

BD49

(for BD-138)

BD49

(for BD-158)

BD52

BD53

BD46

BD41

BD42

BD36(Only For BD-128)

BD44

BD42

(For BD-182)

BD43 BD50 BD51

-9-

OPERATION INSTRUCTIONS

Note: Use proper solvent for thinning. Use lacquer for all lacquers,

paint thinner or all oil based paints and clean water for all latex

based paints. Read the labels of the paint you are using carefully

for correct thinning and cleaning up of Air Brushes.

Mixing and Thinning Paints:

Generally new paint is thick and must be diluted before attempting to spray with Air

Brush. The following rules apply when mixing and diluting paint;

1. When mixing colors, it is recommended to mix only paints of the same type;

2. Enamel and lacquer paints should be diluted with thinner at one to one (1:1) ratio.

Make sure to read the paint manufacturers recommendations for using with Air

Brush;

3. Before spraying, make sure that the diluted paint is thoroughly mixed;

3. Easy Assemble Hose Nut

Apply Easy Assemble Hose on Air Brush makes the connection

to air hose a lot easier.

4. Air Adjustor Lever

Air Adjustor Lever enables non air pressure adjust capable Air

Brush with air adjust function.

1. Air Adjustor Nut

Air Adjustor Nut helps control air pressure directly from the

Adjustor instead of from compressor.

2. Mini Separator

Mini oil-water Separator on Air Brush helps block moisturized

air from coming into the Air Brush.

E. Accessories

-10-

INSPECTION, MAINTENANCE AND CLEANING

1. WARNING!! Make sure the Air Brush is disconnected from its air supply before perfo-

rming any inspection, maintenance or cleaning procedures.

2. BEFORE EACH USE, inspect the general condition of the Air Brush. Check for loose

connections and condition that may affect its operation. Do not use damaged equipment.

3. Cleansing after short term use: after using the Air Brush, always spray thinner or water

(depending upon the type of paint used) through the Air Brush until it is completely cl-

ean. Make sure the Air Brush Cup and Jar are thoroughly cleaned (see fig 1).

4. Cleansing after long term use: certain amount of paint residues after long term use, it is

recommended to disassemble and clean the Air Brush to avoid degrading the accuracy

and damage the Air Brush. When disassembling, make sure not to collide the needle.

Use brush washes the needle with detergent (see fig 2 & 3). When assembling, make

sure not to touch the head of the needle (see fig 4). Finally assemble all parts back to

the Air Brush and spray with detergent. Then clean up the Air Brush (see fig 5).

4). When cleaning, spray into a large bucket or other metal container to avoid spraying

into the environment.

FIG 1 FIG 2 FIG 3 FIG 4 FIG 5

Painting:

1. Proper oil free compressor is needed for operating an Air Brush. Attach the hose to

Air Brush and compressor. Turn on the compressor and adjust the output air pressure

from 15 to 50 PSI. Normal operating pressure is 20 PSI. (AS-18A and AS-186 com-

pressor made by our factory is recommended.)

2. If the Air Brush comes with a built-in air regulator valve, adjust the air regulator va-

lve. The air regulator valve can be adjusted from 15 to 50 PSI. Since there is no pre-

ssure gauge, you will have to test the Air Brush until the desired pressure is reached.

3. Remove the protective cap on the Air Brush.

4. On the Air Brush, gently pull the trigger back to start spraying paint. Pull the trigger

back more to increase paint flow, less to decrease paint flow. You can also adjust the

flow using the adjusting screw, tighten it to increase flow, loosen it to decrease or

shut off flow.

5. Always do a test spray before starting on your project.

-11-

PARTS LIST AND ASSEMBLY DIAGRAM

1. Protective Cap 2. Air Cap 3. Nozzle

4. Air Brush Housing 5. Hose Connector Nut 6. Valve Screw

7. Needle Adjust Screw 8. Trigger 9. Back Lever

10. Handle 11. Needle 12. Cup Lid

13. Tube Shank 14. Needle Tube 15. Needle Stop Screw

Notice: Each Air Brush may not come with all equipment or accessories listed above.

TROUBLESHOOTING

Air leaking Valve lever stuck

Problem Possible Causes Probable Solutions

Paint leaking

Head of needle bent or distorted

Repair or replace parts

Nozzle and needle not fully contacted

Loosen screw, make sure nozzle

and needle fully contacted and

then screw tightly.

Poor paint atomization

Air bubble in the cup

Paint leaks from back

Air Brush nozzle is partially plugged Wash nozzle with detergent

Needle screw loosen Make sure screw is tighten

Faulty nozzle seal ring causes air

reflux

Replace nozzle seal ring or use

seal glue on whorl

The gap between needle and its seal is

enlarged

Take off parts on the back, fasten

screw or replace the seal.

Take trigger off; apply lube after

cleaning and put trigger back.

You might also like

- Exercise 1 Language of AnatomyDocument4 pagesExercise 1 Language of Anatomymaniz44285% (27)

- MBLEx Practice Exams PDFDocument268 pagesMBLEx Practice Exams PDFVani100% (4)

- Balcrank 1130-001 Tiger PumpDocument8 pagesBalcrank 1130-001 Tiger PumpJoseph GeraciNo ratings yet

- Um 32 150S Eng 0119901Document28 pagesUm 32 150S Eng 0119901Gediminas LinkusNo ratings yet

- Hamstring Rehabilitation in Elite Track and FieldDocument13 pagesHamstring Rehabilitation in Elite Track and FieldBarry DoeNo ratings yet

- Compliance Policy Guides - CPG Sec. 555Document2 pagesCompliance Policy Guides - CPG Sec. 555diggerexeNo ratings yet

- Gravity Feed Refinishing Gun S701G: 1. Safety InstructionsDocument3 pagesGravity Feed Refinishing Gun S701G: 1. Safety InstructionsAlexsandro CenteioNo ratings yet

- Pipecoater IIIDocument8 pagesPipecoater IIIEngTamerNo ratings yet

- Gravity Feed and HVLP Air Spray Guns: FX100 FX200Document18 pagesGravity Feed and HVLP Air Spray Guns: FX100 FX200Fabian MedranoNo ratings yet

- Clarke Impact Wrench Cat131Document16 pagesClarke Impact Wrench Cat131rubbishNo ratings yet

- TPB90 ManualDocument8 pagesTPB90 ManualAmaury LeonNo ratings yet

- Earlex Hv1900 ManualDocument12 pagesEarlex Hv1900 ManualPaul CollinsNo ratings yet

- Pes Gun Manual - A5 Printable 2Document20 pagesPes Gun Manual - A5 Printable 2Ruban GeorgeNo ratings yet

- Model: Air Concrete BreakerDocument12 pagesModel: Air Concrete BreakerING MANTENIMIENTO CONINTEL S.ANo ratings yet

- Heavy-Duty Air-Operated Oil Pump: Owner's ManualDocument17 pagesHeavy-Duty Air-Operated Oil Pump: Owner's ManualCarlosNo ratings yet

- A110 210 Ä Éaëpò 201117Document1 pageA110 210 Ä Éaëpò 201117Phan Trong ThucNo ratings yet

- Manual Toku TPB 90Document9 pagesManual Toku TPB 90Toño Rodriguez LopezNo ratings yet

- Air Operated Barrel Pump: Model 93755Document9 pagesAir Operated Barrel Pump: Model 93755SIVARAMANJAGANATHANNo ratings yet

- Airbrush User ManualDocument2 pagesAirbrush User ManualStefan PetcuNo ratings yet

- Spray Fine ManualDocument19 pagesSpray Fine ManualAndres GaitanNo ratings yet

- Manual Aeropulidor AP H WoodpeckerDocument29 pagesManual Aeropulidor AP H WoodpeckerVadim GribinceaNo ratings yet

- Viair 87 ManualDocument4 pagesViair 87 Manualjuanpablito6183No ratings yet

- Neo Series ManualDocument11 pagesNeo Series ManualJavier MañaricúaNo ratings yet

- Operation Manual of Silent Air CompressorDocument12 pagesOperation Manual of Silent Air CompressorBebby DhimasNo ratings yet

- Speeflo: Hydra M / Hydra Pro SuperDocument39 pagesSpeeflo: Hydra M / Hydra Pro Superalvaro yepes oviedoNo ratings yet

- Deluxe: Please Read The Manual & Safety Instructions Before Use. Please Retain For Future ReferenceDocument14 pagesDeluxe: Please Read The Manual & Safety Instructions Before Use. Please Retain For Future ReferenceMeenakshi ShekhawatNo ratings yet

- Spray Painting, WHSPRO-018 CMDocument6 pagesSpray Painting, WHSPRO-018 CMsanthoshNo ratings yet

- FLG5 ManualDocument8 pagesFLG5 Manualasdfghjkl234No ratings yet

- Air Grease Gun Model 00219Document10 pagesAir Grease Gun Model 00219renspurNo ratings yet

- Kobalt Spray Gun ManualDocument39 pagesKobalt Spray Gun ManualChris ReddersenNo ratings yet

- Manual - Belt Air Compressor Series - ENDocument26 pagesManual - Belt Air Compressor Series - ENknjigebook1 knjigebook1No ratings yet

- Solo 433 ManualDocument19 pagesSolo 433 ManualSantiago UrgilesNo ratings yet

- AEROPRO R500 InstructionDocument7 pagesAEROPRO R500 InstructionAlejandro EnriquezNo ratings yet

- Grease Pump YamadaDocument15 pagesGrease Pump Yamadasugiyono81No ratings yet

- Fuel Injection Canister Cleaner Model 95834Document11 pagesFuel Injection Canister Cleaner Model 95834renspurNo ratings yet

- Bnac 658 HBDocument56 pagesBnac 658 HBmatejprdloNo ratings yet

- Instruction ManualDocument14 pagesInstruction ManualSIVARAMANJAGANATHANNo ratings yet

- Twister Manual 2108Document16 pagesTwister Manual 2108Proveedora de servicios y suministros PSSNo ratings yet

- Rebel30 60Document14 pagesRebel30 60McnaughtonFT17No ratings yet

- Owner's Manual: Air CompressorDocument32 pagesOwner's Manual: Air CompressorPratyay Kumar BasuNo ratings yet

- Minijet - 3000 - B - HVLP ExtractedDocument24 pagesMinijet - 3000 - B - HVLP ExtractedMark SimcoeNo ratings yet

- High Pressure Washer Owner's Manual: Problems? Questions?Document20 pagesHigh Pressure Washer Owner's Manual: Problems? Questions?Greggo1010No ratings yet

- Titan Campbell HousfeldDocument24 pagesTitan Campbell HousfeldairmacmexNo ratings yet

- Air Ratchet Wrenches: GSA20, GSA20KIT, GSA21, GSA21KITDocument4 pagesAir Ratchet Wrenches: GSA20, GSA20KIT, GSA21, GSA21KITAntonio DimaculanganNo ratings yet

- HEMPEL's Shop Primer ZS 15890Document3 pagesHEMPEL's Shop Primer ZS 15890NestramiNo ratings yet

- Spray KitsDocument1 pageSpray KitsEliasNo ratings yet

- Manual Instruction For Hygienic Pumps Ver. 5.12Document25 pagesManual Instruction For Hygienic Pumps Ver. 5.12Dmitry DauhalNo ratings yet

- DH-B Serials Air Compressor PDFDocument15 pagesDH-B Serials Air Compressor PDFYusuf HungundNo ratings yet

- Puzzi 100 User ManualDocument17 pagesPuzzi 100 User ManualSunshadespainNo ratings yet

- 7399 Instruction-SheetDocument36 pages7399 Instruction-SheetHector DiazNo ratings yet

- Compressor PartsDocument24 pagesCompressor Partsjohnnyboy111No ratings yet

- The B2 Air Hand-Held De-Burring System: Manual For Operating The EquipmentDocument15 pagesThe B2 Air Hand-Held De-Burring System: Manual For Operating The EquipmentbulentNo ratings yet

- Internal Pipe Coater (Ipc900) Operation-Part List Manual 0281-001rev140720 1594718407Document9 pagesInternal Pipe Coater (Ipc900) Operation-Part List Manual 0281-001rev140720 15947184078fjk8hp5c2No ratings yet

- Oil Less Mtoii Single Stage Manual If3266Document93 pagesOil Less Mtoii Single Stage Manual If3266andsanleaNo ratings yet

- Sprayit Gravity Feed Spray Gun SPRAYITDocument8 pagesSprayit Gravity Feed Spray Gun SPRAYITLuís GuerreiroNo ratings yet

- Hydrovane HV01-02.2013 PartsDocument64 pagesHydrovane HV01-02.2013 PartsMark Carter100% (1)

- PowrLiner 1800M 2800MDocument64 pagesPowrLiner 1800M 2800MRAUL CAVITANo ratings yet

- Honda WT20X Water Pump Shop Manual (Serial No GX140-1000001 To 9999999 & GC02-2000001 To 8669999, WAAJ-1000001 To 9999999)Document105 pagesHonda WT20X Water Pump Shop Manual (Serial No GX140-1000001 To 9999999 & GC02-2000001 To 8669999, WAAJ-1000001 To 9999999)Tomás CappaNo ratings yet

- Dux Automatic ManualDocument17 pagesDux Automatic Manualcav4444No ratings yet

- APC4028 ManualDocument32 pagesAPC4028 Manualvaibhavgitevaibhav_9No ratings yet

- G 2500 VH 1.194-402.0 Sams - PDF Manual Hidro KacherDocument46 pagesG 2500 VH 1.194-402.0 Sams - PDF Manual Hidro KacherClaudia Lizeth Maciel RamirezNo ratings yet

- FLG5 Spraygun InstructionsDocument8 pagesFLG5 Spraygun Instructionsianrichards121No ratings yet

- Learn How to Airbrush Reptiles and Amphibians For the BeginnersFrom EverandLearn How to Airbrush Reptiles and Amphibians For the BeginnersRating: 5 out of 5 stars5/5 (1)

- 7 - Hammerite - 2.3 - Prep - Directtorust Metal Paint 2018 Rev3Document7 pages7 - Hammerite - 2.3 - Prep - Directtorust Metal Paint 2018 Rev3Kaya EmanuelNo ratings yet

- Unutarnje PVC Prozorske Klupice: Ýhs39&NoxslfhDocument7 pagesUnutarnje PVC Prozorske Klupice: Ýhs39&NoxslfhKaya EmanuelNo ratings yet

- S606 OmDocument15 pagesS606 OmKaya EmanuelNo ratings yet

- Tehnical Data Sheet ApriliaDocument1 pageTehnical Data Sheet ApriliaNarcisDanielPetreaNo ratings yet

- Sikahyflex 220 Window - Pds en PDFDocument4 pagesSikahyflex 220 Window - Pds en PDFKaya EmanuelNo ratings yet

- Bag Spin PocketDocument1 pageBag Spin PocketKaya EmanuelNo ratings yet

- Sikahyflex 220 Window - Pds en PDFDocument4 pagesSikahyflex 220 Window - Pds en PDFKaya EmanuelNo ratings yet

- Clothing Protection: OverallsDocument1 pageClothing Protection: OverallsKaya EmanuelNo ratings yet

- Unutarnje PVC Prozorske Klupice: Ýhs39&NoxslfhDocument7 pagesUnutarnje PVC Prozorske Klupice: Ýhs39&NoxslfhKaya EmanuelNo ratings yet

- Tehnical Data Sheet ApriliaDocument1 pageTehnical Data Sheet ApriliaNarcisDanielPetreaNo ratings yet

- RotaryWatches InstructionManual AquaspeedDocument8 pagesRotaryWatches InstructionManual AquaspeedKaya EmanuelNo ratings yet

- 2013 ABA Paint Buyers GuideDocument6 pages2013 ABA Paint Buyers GuideKaya EmanuelNo ratings yet

- Shift+Left/Right Skip Next/Prev ChapDocument1 pageShift+Left/Right Skip Next/Prev ChapKaya EmanuelNo ratings yet

- DKVM-4K DsDocument2 pagesDKVM-4K DsKaya EmanuelNo ratings yet

- Raspored Total TV KolovozDocument1 pageRaspored Total TV KolovozKaya EmanuelNo ratings yet

- Scooter IzeDocument25 pagesScooter IzeKaya EmanuelNo ratings yet

- DKVM-4K DsDocument2 pagesDKVM-4K DsKaya EmanuelNo ratings yet

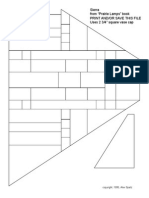

- Sierra From "Prairie Lamps" Book Print And/Or Save This File Uses 2 3/4" Square Vase CapDocument1 pageSierra From "Prairie Lamps" Book Print And/Or Save This File Uses 2 3/4" Square Vase CapKaya EmanuelNo ratings yet

- Slim Smart Full HD LED TV: With Ambilight 2-SidedDocument3 pagesSlim Smart Full HD LED TV: With Ambilight 2-SidedKaya EmanuelNo ratings yet

- Tehnical Data Sheet ApriliaDocument1 pageTehnical Data Sheet ApriliaNarcisDanielPetreaNo ratings yet

- Cisco Model EPC2425Document110 pagesCisco Model EPC2425apmihaiNo ratings yet

- Hempel's Custom Marine Polish 67445 67445 En-GbDocument1 pageHempel's Custom Marine Polish 67445 67445 En-GbKaya EmanuelNo ratings yet

- 41 2129 0712Document20 pages41 2129 0712imam116No ratings yet

- 41 2129 0712Document20 pages41 2129 0712imam116No ratings yet

- Lab 2 ElectronicsDocument3 pagesLab 2 ElectronicsKaya EmanuelNo ratings yet

- 4uc Ae1Document267 pages4uc Ae1Kaya EmanuelNo ratings yet

- Hardware Maintenance Manual - ThinkPad R61, R61i and T61 14.1inch WidescreenDocument256 pagesHardware Maintenance Manual - ThinkPad R61, R61i and T61 14.1inch WidescreenSetyo Nugroho100% (10)

- Panasonic ES-RT31 - ES-RT51 Operating InstructionsDocument7 pagesPanasonic ES-RT31 - ES-RT51 Operating InstructionsKaya EmanuelNo ratings yet

- Drill Perceuse Taladro: Instruction Manual Manuel D'Instruction Manual de InstruccionesDocument16 pagesDrill Perceuse Taladro: Instruction Manual Manuel D'Instruction Manual de InstruccionesKaya EmanuelNo ratings yet

- Ani Full AnswerDocument7 pagesAni Full AnswerIshu & Gattu's Toy ReviewNo ratings yet

- Fraktur KlavikulaDocument10 pagesFraktur KlavikulaEricsen T.P.No ratings yet

- Post-Operative Complications of Craniotomy and CraniectomyDocument9 pagesPost-Operative Complications of Craniotomy and CraniectomyLusy Octavia SaputriNo ratings yet

- The Atlantic Refining Company, Owner of The Tankship Atlantic Trader v. Matson Navigation Company, Owner of The Steamship Hawaiian Retailer, 253 F.2d 777, 3rd Cir. (1958)Document5 pagesThe Atlantic Refining Company, Owner of The Tankship Atlantic Trader v. Matson Navigation Company, Owner of The Steamship Hawaiian Retailer, 253 F.2d 777, 3rd Cir. (1958)Scribd Government DocsNo ratings yet

- Atlas of Approaches in Neurosurgery - J.FischerDocument7 pagesAtlas of Approaches in Neurosurgery - J.FischerZdravko HeinrichNo ratings yet

- Autopsy: Prepared By: Christian RaveinaDocument24 pagesAutopsy: Prepared By: Christian RaveinaRoman MamunNo ratings yet

- 44 - Imaging in Neuroemergency DR - Rohadi SP - BsDocument51 pages44 - Imaging in Neuroemergency DR - Rohadi SP - BsEriekafebriayana RNo ratings yet

- Diving Acciden TS: Presented By: Arcemie AguavivaDocument40 pagesDiving Acciden TS: Presented By: Arcemie AguavivaArcemie AguavivaNo ratings yet

- Bleeding and Wounds: Dan Olesnicky, MD Tactical PhysicianDocument37 pagesBleeding and Wounds: Dan Olesnicky, MD Tactical PhysicianHari KoneruNo ratings yet

- Ai Di X Chen YiDocument323 pagesAi Di X Chen YiMrDeviNo ratings yet

- 04 039 PDFDocument56 pages04 039 PDFBruno AfoncelNo ratings yet

- Clean Premises & Equipment PDFDocument11 pagesClean Premises & Equipment PDFGiabell100% (2)

- S17 BL Shoulder and Brachial Plexus 21Document39 pagesS17 BL Shoulder and Brachial Plexus 212110052 BRYAN RICARDO HANDOKONo ratings yet

- Virtual Shoulder and Knee ExaminationDocument10 pagesVirtual Shoulder and Knee ExaminationAdmirNo ratings yet

- Path NotesDocument111 pagesPath NotesNirav Patel100% (1)

- H&S Quiz AnswersDocument4 pagesH&S Quiz AnswersHashir Badar50% (2)

- Antegrade Versus Retrograde Nailing TechniquesDocument11 pagesAntegrade Versus Retrograde Nailing TechniquesJian Wei LowNo ratings yet

- MVP-50T Ii 1211061DDocument79 pagesMVP-50T Ii 1211061DvnNo ratings yet

- Six Family Members Die in Road AccidentDocument3 pagesSix Family Members Die in Road AccidentHanan HasmiNo ratings yet

- Approach To The Adult With Unspecified Knee Pain - UpToDateDocument55 pagesApproach To The Adult With Unspecified Knee Pain - UpToDateCamila Gomes Santos MoraesNo ratings yet

- The Lucky One ChordsDocument3 pagesThe Lucky One ChordshardiangkaNo ratings yet

- Surgery MCQDocument33 pagesSurgery MCQFan EliNo ratings yet

- Muhammad Aditya Alfarizki 71.2017.007: Pembimbing: Dr. Rizal Daulay, SP - OT, MARSDocument25 pagesMuhammad Aditya Alfarizki 71.2017.007: Pembimbing: Dr. Rizal Daulay, SP - OT, MARSaditNo ratings yet

- OADocument27 pagesOADarkKnighthere100% (1)

- Gamma3: Long Nail R2.0Document52 pagesGamma3: Long Nail R2.0Aravind DesaiNo ratings yet

- Hydrocele Complications Are Largely Avoided With Meticulous Dissection and Gentle Tissue Handling. inDocument2 pagesHydrocele Complications Are Largely Avoided With Meticulous Dissection and Gentle Tissue Handling. inYoga AninditaNo ratings yet