Professional Documents

Culture Documents

92 - 07 02 14 - Paper Loss Model

Uploaded by

apoorvs75Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

92 - 07 02 14 - Paper Loss Model

Uploaded by

apoorvs75Copyright:

Available Formats

Proceedings of the 8th International Symposium

on Experimental and Computational

Aerothermodynamics of Internal Flows

Lyon, July 2007

Paper reference : ISAIF8-0053

Modeling of 3-D Losses and Deviations

in a Throughow Analysis Tool

Jean-Francois Simon

Techspace Aero - Aerodynamic Group

jsimon@techspace-aero.be

Alain Nicks

University of Li` ege - Turbomachinery Group

alainnicks@hotmail.com

Nicolas Paris

University of Li` ege - Turbomachinery Group

Nicolas.Paris@student.ulg.ac.be

Olivier L eonard

University of Li` ege - Turbomachinery Group

o.leonard@ulg.ac.be

This contribution is dedicated to the modeling of the end-wall ows in a throughow model for turbomachinery applications.

The throughow model is based on the Euler or Navier-Stokes equations solved by a Finite-Volume technique. Two approaches are

presented for the end-wall modeling. The rst one is based on an inviscid formulation with dedicated 3-Ddistributions of loss coefcient

and deviation in the end-wall regions. The second approach is directly based on a viscous formulation with no-slip boundary condition

along the annular end-walls and blade force modication in the region close to the end-walls. The throughow results are compared

to a series of 3-D Navier-Stokes calculations averaged in the circumferential direction. These 3-D calculations were performed on the

three rotors of a low pressure axial compressor, for a series of tip clearance values.

Keywords: throughow, losses, deviations, axial compressors

Introduction

The throughow level of approximation still remains

an important tool for designing turbomachines [2] even

though 3-D calculations are used more and more early in

the design process. The throughow models heavily rely

on empirical inputs such as 2-D correlations or end-wall

loss models. This feature has shown to be efcient but

lacks of generality.

Two-dimensional empirical correlations are available

in the literature but they have generally been designed for

classical families of blade proles such as C4 or NACA-

65 and are not directly applicable to the custom-based pro-

les nowadays used in the industry. However, it is possi-

ble to adapt existing loss correlations to modern blade pro-

les [5] or to derive correlations for an arbitrary proles

with the help of blade-to-blade codes [6].

Concerning the 3-D losses, very few results are avail-

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 2

able in the open literature. The main contribution on the

compressor side is from Roberts et al. [7,8]. They pro-

posed correlations based on collected empirical data to

build up 3-D distributions of loss coefcient and devia-

tion in the end-wall regions. A throughow analysis tool

based on an inviscid model, supplemented with these 3-

D correlations for the end-wall losses is the rst approach

studied here.

The second approach presented in this contribution is

directly based on the Navier-Stokes equations with blade

force modications close to the end-walls to capture the

end-wall ows. By including more physics in the model,

less empiricism is needed and a more general method can

therefore be devised.

The objective of the present work is to test both ap-

proaches for the modeling of the end-wall ows within

a throughow model. The results are compared to a se-

ries of 3-D Navier-Stokes calculations performed on axial

compressor rotors.

Nomenclature

AR

c

channel aspect ratio, h/s

m

c mean blade chord

h mean span or mean blade height

s blade spacing [mm]

S

3D

extent of 3-D loss, in fraction of span

(S

3D

)

max

location of maximum 3-D loss, in

fraction of span

TC rotor blade tip clearance, in fraction

of span

Greek letters

ow deviation angle

displacement thickness

solidity, c/s

blade camber angle

loss coefcient

ow deection

R = W

2

/W

1

velocity ratio

Subscripts

1 inlet

5 5% of span from tip at the blade outlet

95 95% of span from tip at the blade outlet

2D relative to a two-dimensional ow

3D relative to a three-dimensional ow

h hub

max maximum location

mo maximum overturning location

rt rotor tip

Throughow analysis tool

The throughowanalysis tool used in the present work

is based on the Euler equations [1,11] and the Navier-

Stokes equations [9]. Such models allow to calculate the

ow eld whatever the ow regime is, they are able to

perform transient simulations and they can cope with 2-D

ow recirculations. These approaches offer alternatives to

the classical streamline curvature method.

Details on the present solver are available in [9]. In

short, the equations are solved by a nite volume tech-

nique. The inviscid uxes are computed thanks to the Roe

scheme and the viscous ux by the diamond path scheme.

The time integration is performed by an explicit multistep

Runge-Kutta scheme.

The turbulence model is of the mixing length type and

a radial mixing model based on a turbulent diffusion as-

sumption is used. The inviscid blade force is computed by

an additional time-dependent equation [1], while the vis-

cous blade force is calculated by a distributed loss model

and empirical correlations. In order to avoid loss gener-

ation by the inviscid blade force, its direction is chosen

orthogonal to the ow eld. An adaptation of the inviscid

blade force in the end-wall regions is therefore required.

More details on these modications are available in a fol-

lowing section.

3-D database

The test-case used in the present work is composed

of 3 rotors of a low pressure compressor designed by

Techspace Aero. For each rotor, four different tip clear-

ance values were considered: 0.4, 0.8, 1 and 1.2 percents

of the mean blade height. The database is composed of 3-

D Navier-Stokes calculation results. For each congura-

tion, two computations were run, one with ow conditions

and blade incidence representative of an on-design con-

guration, a second one representative of near-stall condi-

tions. The mesh is made of about 1.2 million grid points

and the turbulence model is algebraic.

These 3-D Navier-Stokes computations, after a cir-

cumferential averaging, provide the boundary conditions

for the throughow calculations. Rotor blades were dis-

cretized in ten sections at different blade heights to trans-

fer the blade camber and thickness to the throughow

analysis tool in a rather complete way. The radial blade

forces were neglected.

Inviscid annulus end-walls formulation

The rst approach for modeling the end-wall ows is

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 3

based on an inviscid treatment of the hub and shroud with

a slip condition. The effect of the viscous ow develop-

ing along the end-walls is (partly) reintroduced by adding

a 3-D distribution of deviation and loss coefcient on the

top of the 2-D distributions:

=

2D

+

3D

(1)

=

2D

+

3D

(2)

The gure 1 illustrates the 3-D distributions obtained

with Roberts correlations [7,8] for a rotor. The usual evo-

lution of the deviation with an overturning at the hub and

an overturning followed by an underturning at the tip is

observed. The loss coefcient distribution also shows a

classical shape at both end-walls.

The expression of Roberts correlations is reproduced

hereafter in order to highlight the main parameters driving

the loss and deviation generation.

0 20 40 60 80 100

0

0.02

0.04

0.06

0.08

0.1

(a) Loss coefcient vs blade height

0 20 40 60 80 100

6

4

2

0

2

4

(b) Deviation vs blade height

Figure 1 : Original 3-D correlations of Roberts

Correlations for 3D losses at shroud :

(

3D

)

max,rt

= 0.25 tanh

10

3

1

TC (3)

(S

3D

)

max,rt

=

(

3D

)

max,rt

2

(4)

(S

3D

)

rt

= 2.5(S

3D

)

max,rt

(5)

Correlations for 3D losses at hub :

(

3D

)

max

= 0.2 tanh

15(

2

1

ARc

) (6)

(S

3D

)

max

= 0.1 (7)

S

3D

= 2.5 (S

3D

)

max

= 0.25 (8)

Correlations for 3D deviations at hub :

95

= 2 (9)

h

h

= 0.85 (10)

Correlations for 3D deviations at shroud :

5

= 30 tanh(10

3

1

TC) (11)

mo

= 1.25 (12)

h

mo

= 0.15 (13)

These correlations allow to describe the distributions

of the 3-D loss coefcients and deviations using only a

few parameters, the latter being obtained from the ow-

path geometry, the blade geometry and the inlet boundary

layer displacement thickness. These parameters however

do not allow to obtain the whole distributions along the

span but only some typical points of these distributions.

Additional information must be provided. The following

curves (Gaussian law, 1-D damped oscillator equation and

parabola) have been used to connect the points provided

by the correlation of Roberts:

f(x) =

1

2

exp

(x )

2

2

2

(14)

f(x) = exp

[f

0

cos(

d

x) + sin(

d

x)] (15)

f(x) = ax

2

+bx +c (16)

A last remark has to be added before presenting the re-

sults obtained with this approach. The loss coefcient in

the tip region obtained from the 3-D Navier-Stokes com-

putations does not always follow the classical distribution

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 4

shown on gure 1(a). Distributions with no peak are ob-

tained when the value of the tip clearance is low com-

pared to the boundary layer thickness, as shown on gure

2, which gives the loss coefcient distribution for differ-

ent tip clearance values, for one of the rotors considered in

this work. These distributions with no peak have not been

included in the database. Clearly, another way to charac-

terize the loss coefcient distribution for low tip clearance

values is needed.

Applying the original correlations provided by

Roberts to the rotors considered in the present work failed

to reproduce the averaged 3-D Navier-Stokes results. A

calibration procedure was performed on the parameters

of Roberts correlations so as to t the 3-D Navier-Stokes

database corresponding to the rst rotor blade. The g-

ure 3 compares the loss coefcient distributions in the tip

region obtained with the original correlation, with the cal-

ibrated one and with the 3-D averaged one.

Unfortunately applying this calibrated correlation to

the two other rotor geometries failed to reproduce the ow

characteristics for these rotors, as shown on gure 4. This

gure shows one of the parameters of Roberts correlation,

(

3D

)

max,rt

, i.e. the peak in the 3-D loss coefcient, ver-

sus a combination of the clearance gap and the boundary

layer thickness. These results are related to on-design op-

erating points only.

The above results demonstrate the need for including

extra parameters in the Roberts correlation in order to take

into account additional effects such as the blade loading.

Indeed the main drawback of Roberts correlations is that

they do not rely on quantities representative of the aero-

dynamic loading (to the exception of the blade camber for

the maximum loss at hub).

From that observation, it was decided to test several

functions depending on the loading, the velocity ratio or

the ow deection in order to derive the sought correla-

tions. This was performed systematically for each variable

to be modeled by the correlations. The obtained results are

presented hereafter.

The gure 5 illustrates the results obtained for the peak

of the loss coefcient distribution in the tip region, for sev-

eral rotors and several clearance values. The function used

to approximate it is of the following form :

(

3D

)

max,rt

= Atanh

R

a

b

1000

1

TC

(17)

where A, a and b are the parameters determined by the

calibration process. The results are thought to be good.

The 3-D Navier-Stokes distributions for which no peaks

are observed have also been added on the same gure. For

these distributions the maximumof the loss coefcient has

been used instead of the (non-existing) peak. These values

have however not been used to build the correlations.

0.8 0.85 0.9 0.95 1

L

o

s

s

c

o

e

f

f

i

c

i

e

n

t

Normed radii

TC=0,42%

TC=0,84%

TC=1,05%

TC=1,26%

Figure 2 : Radial distribution of loss coefcient obtained

from 3D calculations

Figure 3 : Loss coefcient distribution at rotor tip

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

10

3

1

*

TC/h

2

(

3

D

)

m

a

x

,

r

t

1st rotor

2nd rotor

3rd rotor

1st rotor calibrated correlation

original correlation

Figure 4 : Clearance effect tted on 1st rotor data

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 5

f(R,,AR

c

,

1

*

,TC)

(

3

D

)

m

a

x

correlation

NS 3D simulation with no peak

NS 3D simulation

Figure 5 : Loss coefcient peak at tip

f(R,,AR

c

,

1

*

,)

(

3

D

)

m

a

x

correlation

NS 3D simulation

Figure 6 : Loss coefcient peak at hub

The gure 6 illustrates the same quantity for the hub

region and again illustrates the quality of the results.

It is recognized that the database used here is far to

be sufciently dense to allow drawing general correla-

tions such as those devised by Roberts. More operat-

ing points and more geometries should be considered and

tested. However, the proposed procedure, based on load-

ing criterions and on 3-D numerical simulations seems to

be promising and should be easily extended to a larger

database.

Viscous annulus end-walls formulation

However, it must be recognized that the previous

method essentially based on empirical correlations lacks

of generality. An improved method for capturing the 3-

D ows, inspired from Gallimore [4], is proposed here-

after. In the frame of its viscous Streamline Curvature

method, Gallimore proposed to modify the blade force

(its circumferential component more exactly) in the end-

wall regions. The modication he proposed for the blade

force is based on experimental observations of the blade

wall static pressure eld, noteworthy the observations of

Dring [3]. These results show that the circumferential

component of the blade force varies smoothly across the

span and does not exhibit rapid changes as one approaches

the end-walls contrary to the circumferential momentum

jump across the blade row. This is an illustration of the

well known fact that the pressure eld does not vary much

across a boundary layer in the direction orthogonal to the

wall.

From that observation it seems possible to extrapolate

some information across the span to model the blade force

in the end-wall regions. A simple model for the evolution

of the circumferential blade force in these regions is pro-

posed hereafter for a rotor:

for the hub ow, the circumferential component of

the blade force is kept constant over a given portion

of the span, starting from the hub,

for the tip ow, the blade force is set to zero in the

gap. The blade force is also kept constant from a

given spanwise position to the tip gap. It was found

that this last modication is necessary in order to

obtain the correct level of underturning in the tip

region. It is in agreement with the experimental ob-

servations of Gallimore [4] and Dring [3].

This is a rather simple model and more elaborated

prediction of the evolution of the blade force inside the

boundary layer can be devised (see the model of Gal-

limore [4] for example). The purpose here is to evaluate

the benet that such a method could bring on the 3-D loss

and deviation predictions.

In the regions where the inviscid blade force is mod-

ied, the ow does not follow any more the camber sur-

face. In order to avoid the generation of numerical losses,

it is important that the blade force remains orthogonal to

the ow. For this reason, it is not possible to work directly

on the modulus of the blade force. To avoid imposing a

constrain on the modulus of the force, the modication

is performed on its circumferential component only. The

other components are computed so that the resulting blade

force is still orthogonal to the ow eld.

The modication of the blade force is tested hereafter

on the rst rotor studied in the previous section. The ow

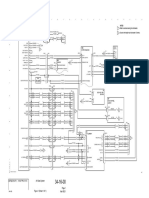

path is shown on the gure 7, together with the mesh used

in the present study.

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 6

Figure 7 : Typical mesh used

0 0.05 0.1 0.15 0.2 0.25 0.3

3D data

TF NS 2D

TF NS 3D

(a) deviation at hub vs normed radii

0.7 0.75 0.8 0.85 0.9 0.95 1

3D data

TF NS 2D

TF NS 3D

(b) deviation at tip vs normed radii

Figure 8 : Impact on the deviation of the blade force

modications in the end-wall regions

The modication of the blade force has been per-

formed over about 15 % of the span. This extent has been

chosen more or less arbitrarily in order to inuence the

ow eld over the correct fraction of the span. This extent

could be determined automatically with a criterion based

on the boundary layer thickness for example.

The gures 8 and 9 present the results obtained in

terms of deviation and loss coefcient distributions. For

both quantities, two calculations are presented: one with

the blade force modication (TF NS 3-D) and the other

one without (TF NS 2-D). These two calculations are

compared with the distribution obtained from the 3-D

Navier-Stokes calculation which represents the reference

solution.

The gure 8(a) shows the deviation in the hub region.

Thanks to the constant blade force through the bound-

ary layer, the overturning is predicted both in location

and magnitude. At the tip, the underturning is also pre-

dicted but with less precision, as shown on gure 8(b).

It is globally underestimated except very close to the tip

gap. A way to improve the result would be to decrease the

blade force in that region instead of keeping it constant.

This would be in agreement with the experimental results

obtained by Storer and Cumpsty [10]. The improvement

brought by the modication of the blade force compared

to the 2-D solution is clearly demonstrated.

Concerning the loss coefcient, the blade force modi-

cation has only a slight effect on the ow development at

the hub (gure 9(a)). Indeed the proposed modication of

the inviscid blade force does not model the loss generated

by the interaction of the blade and the annulus end-wall.

For the tip region (gure 9(b)), the situation is different,

as canceling the blade force in the tip gap induces some

friction forces at the tip of the blade. The resulting loss

coefcient is more similar to the one obtained by the 3-D

Navier-Stokes simulation but with a lower intensity: some

ow features such as the loss generated by the tip vortex

ow is not modeled in the throughow.

In conclusion, the 3-D deviation is relatively well pre-

dicted by the blade force modication model. This is not

the case for the 3-D losses as the mechanisms that gener-

ate those losses is not modeled (at the exception of some

parts for the tip region). A way to model these losses

would be to rely on the characteristics of the captured 3-D

deviation. Indeed, as it is (partly) the same phenomena

that are responsible for the generation of the 3-D losses

and the 3-D deviation, it should be possible to determine

the 3-D loss coefcient from the captured 3-D deviation.

For example, the maximumunderturning at the tip is prob-

ably well correlated with the maximum loss coefcient at

the tip. This is also true for the spanwise extent of the 3-D

deviation and 3-D losses effects.

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 7

0 0.05 0.1 0.15 0.2 0.25 0.3

3D data

TF NS 2D

TF NS 3D

(a) loss coefcient at hub vs normed radii

0.75 0.8 0.85 0.9 0.95 1

3D data

TF NS 2D

TF NS 3D

(b) loss coefcient at tip vs normed radii

Figure 9 : Impact on the loss coefcient of the blade

force modications in the end-wall regions

This approach for the 3-D loss correlation has been

developed and the results are illustrated by the gure 10.

It gives the maximum of the loss coefcient distribution

at the shroud in function of the maximum deviation ob-

served at the same location. The obtained relation is of

the following form:

(

3D

)

max,rt

= Atanh

5

a

R

b

1

ARc

c

(18)

Here again A, a, b, c are the parameters of the dis-

tribution. These parameters have been determined in the

previous section to t the parameters in the database. The

prediction is considered to be sufciently accurate.

f(

2

)

(

3

D

)

m

a

x

correlation

NS 3D simulation with no peak

NS 3D simulation

Figure 10 : Maximum loss coefcient in function of the

maximum deviation

0 0.05 0.1 0.15 0.2

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

normed radii

V

a

x

Throughflow NS approach

Throughflow Euler approach

Figure 11 : Comparison of non-dimensionalized axial

velocity distributions

Conclusions

The rst approach solving the Euler equations does

not need any renement of the mesh in the vicinity of the

hub and the shroud, resulting in moderate calculation ef-

forts. However this rst approach does not capture the

complexity of the ow physics in the end-wall regions as

the no-slip condition cannot be imposed, and therefore re-

lies on empirical inputs that must be tuned or may suffer

from a lack of generality.

The second approach solving the Navier-Stokes equa-

tions is less dependent on empirical inputs as more physics

is included in the model, but at the price of a denser mesh

Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows 8

and higher computational efforts. The gure 11 shows

the improvement brought by the Navier-Stokes formula-

tion over the Euler one for the radial distribution of the

axial velocity at the outlet of the rst rotor. More realis-

tic distributions are indeed found with the Navier-Stokes

model.

It is believed that the combination of both approaches,

i.e. the Navier-Stokes approach with captured devia-

tion and 3-D losses coefcient computed through cali-

brated functions (equation (18) for example) is a promis-

ing way to remove a part of the empiricism included in the

throughow model.

References

[1] S. Baralon, L.-E. Erikson and U. Hall. Viscous

Throughow Modelling of Transonic Compressors Using

a Time-Marching Finite-Volume Solver. Proceedings of

the 13th International Symposium on Airbreathing En-

gines (ISABE), Chattanooga, 1997.

[2] J.D. Denton and W.N. Dawes. Computational Fluid

Dynamics for Turbomachinery Design. In Developments

in Turbomachinery Design, John Denton editor, Profes-

sional Engineering Publishing, 1999.

[3] R.P. Dring. Radial Transport and Momentum Ex-

change in an Axial Compressor. Transactions of the

ASME Journal of Turbomachinery, 115:477486, 1993.

[4] S.J. Gallimore. Viscous Throughow Modelling of

Axial Compressor Bladerows using a Tangential Blade

Force Hypothesis. ASME Paper 97-GT-415, 1997.

[5] W.M. K onig, D.K. Hennecke, and L. Fottner. Im-

proved Blade Prole Loss and Deviation Angle Models

for Advanced Transonic Compressor Blading : Part I - A

Model for Subsonic Flow, Part II - A Model for Super-

sonic Flow. Transactions of the ASME Journal of Turbo-

machinery, 118:7380, 1996.

[6] E.W. Ptzinger and W. Reiss. ANewConcept for Loss

and Deviation Prediction in Throughow Calculations of

Axial Flow Compressors. Proceedings of the 2nd Euro-

pean Turbomachinery Conference, Antwerpen, 1997.

[7] W.B. Roberts, G.K. Serovy and D.M. Sandercock.

Modeling the 3-D Flow Effects on Deviation Angle for

Axial Compressor Middle Stages. Journal of Engineering

for Gas Turbines and Power, 108, 1986.

[8] W.B. Roberts, G.K. Serovy and D.M. Sandercock. De-

sign Point Variation of 3-D Loss and Deviation for Ax-

ial Compressor Middle Stages. ASME Paper 88-GT-57,

1988.

[9] J. Simon and O. L eonard. A Throughow Analysis

Tool Based on the Navier-Stokes Equations. Proceedings

of the 6th European Turbomachinery Conference, Lille,

2005.

[10] J.A. Storer and N.A. Cumpsty. Tip Leakage Flow in

Axial Compressors. Transactions of the ASME Journal of

Turbomachinery, 113:252, 1991.

[11] A. Sturmayr and C. Hirsch. Shock Representa-

tion by Euler Throughow Models and Comparison with

Pitch-Averaged Navier-Stokes Solutions. ISABE 99-

7281, 1999.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Coupled Pressure Based All Speed SolverDocument50 pagesCoupled Pressure Based All Speed Solverapoorvs75No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Turbulence ModelDocument19 pagesTurbulence Modelapoorvs75No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Computer Graphics - OpenglDocument150 pagesComputer Graphics - Openglapoorvs75No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- T FMF A Coupled Finite Volume SolverDocument21 pagesT FMF A Coupled Finite Volume Solverapoorvs75No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Paper by Gang and DavidsonDocument12 pagesPaper by Gang and Davidsonapoorvs75No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Moving Boundary Problems For The BGK Model of Rarefied Gas DynamicsDocument3 pagesMoving Boundary Problems For The BGK Model of Rarefied Gas Dynamicsapoorvs75No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Various Turbulence ModelDocument15 pagesVarious Turbulence Modelapoorvs75No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- CFDMSH - Python Module For Meshing of AirfoilDocument132 pagesCFDMSH - Python Module For Meshing of Airfoilapoorvs75No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Implicit Turbine Cascade CFD SOlverDocument13 pagesImplicit Turbine Cascade CFD SOlverapoorvs75No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Sheet Caviation CFD ModellingDocument13 pagesSheet Caviation CFD Modellingapoorvs75No ratings yet

- Orthogonal Algebraic Elliptic Structured Grid GenerationDocument13 pagesOrthogonal Algebraic Elliptic Structured Grid Generationapoorvs75No ratings yet

- Collocated FVMDocument17 pagesCollocated FVMapoorvs75No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Implicit Euler MethodDocument29 pagesImplicit Euler Methodapoorvs75No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Gas Power CyclesDocument76 pagesGas Power CyclesJuan JoseNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Potential FlowDocument27 pagesPotential Flowapoorvs75No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elementary Cascade Theory ExplainedDocument3 pagesElementary Cascade Theory Explainedapoorvs75100% (1)

- AIAA 2013 2567 CharestDocument21 pagesAIAA 2013 2567 Charestapoorvs75No ratings yet

- Measure Mean & Fluctuating Fluid Flow VelocitiesDocument86 pagesMeasure Mean & Fluctuating Fluid Flow VelocitiesRajashree Ravi100% (1)

- Low Pressure Turbine Blade DesignDocument10 pagesLow Pressure Turbine Blade Designapoorvs75No ratings yet

- High Lift LPT DesignDocument10 pagesHigh Lift LPT Designapoorvs75No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Disk in Flight EulerDocument169 pagesDisk in Flight Eulerapoorvs75No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- 19980017196Document70 pages19980017196apoorvs75No ratings yet

- Design For Radial EquilibriumDocument4 pagesDesign For Radial EquilibriummihailmiNo ratings yet

- Convection SchemeDocument49 pagesConvection Schemeapoorvs75No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Aiaa 1998 969 820Document10 pagesAiaa 1998 969 820apoorvs75No ratings yet

- Cliping Triangular MeshDocument10 pagesCliping Triangular Meshapoorvs75No ratings yet

- Aiaa 2001 2609Document6 pagesAiaa 2001 2609apoorvs75No ratings yet

- NPSH MarginDocument32 pagesNPSH MarginminhphuongphamNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Livrable-Maillage-nsmb - Ovetset Grid TheoryDocument18 pagesLivrable-Maillage-nsmb - Ovetset Grid Theoryapoorvs75No ratings yet

- CHP SopDocument26 pagesCHP Sopkalyanm20351550% (2)

- Pipe Stress AnalysisDocument23 pagesPipe Stress AnalysisAlberto Garcia100% (1)

- Emirates - Manage A BookingDocument2 pagesEmirates - Manage A BookingdedynovandiNo ratings yet

- Oceanic Navigation Using Advanced GPS by A HaiderDocument11 pagesOceanic Navigation Using Advanced GPS by A Haideradnanscientist33No ratings yet

- Carbon Fiber Reinforced Plastics in Aircraft Construction: C. SoutisDocument6 pagesCarbon Fiber Reinforced Plastics in Aircraft Construction: C. SoutisMizanNo ratings yet

- Thermal Flying Burkhard MartensDocument2 pagesThermal Flying Burkhard Martensggbb91814% (7)

- Metrology CH 3Document52 pagesMetrology CH 3Eng Islam Kamal ElDin100% (1)

- Keyword SuggestionsTG LiebherrDocument13 pagesKeyword SuggestionsTG LiebherrDEEPAK GOYALNo ratings yet

- Air Data SystemDocument20 pagesAir Data SystemBiblioteca Brasil AviationNo ratings yet

- Syllabus Aero RTUDocument13 pagesSyllabus Aero RTUAnubhav JoshiNo ratings yet

- Purlins: Rails Eaves Beams AccessoriesDocument48 pagesPurlins: Rails Eaves Beams AccessoriesRam AravindNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ata 52 53 56Document10 pagesAta 52 53 56anilmathew244No ratings yet

- Azure Resources Md82 Specs MSN 49221 1jun2010Document5 pagesAzure Resources Md82 Specs MSN 49221 1jun2010Francesco OrlandoNo ratings yet

- CH 12 SolDocument20 pagesCH 12 Solaoeu1234No ratings yet

- Chapter 2Document9 pagesChapter 2Ryugi KamasakiNo ratings yet

- Bruce M. Bailey - We See All - A Pictorial History of The 55th Stategic Reconnaissance Wing, 1947-1967-55th ELINT Association Historian (1982)Document327 pagesBruce M. Bailey - We See All - A Pictorial History of The 55th Stategic Reconnaissance Wing, 1947-1967-55th ELINT Association Historian (1982)SergeNo ratings yet

- GNSS Principles and Comparison: GPS, GLONASS, Galileo and CompassDocument10 pagesGNSS Principles and Comparison: GPS, GLONASS, Galileo and CompassAndrei SimionNo ratings yet

- Air Bus 380Document24 pagesAir Bus 380lulu3232No ratings yet

- 2010 Catalogueen LbiDocument48 pages2010 Catalogueen LbipashaulNo ratings yet

- Soroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0Document54 pagesSoroosh and Nowrooz Integrated Development Project: SO EST AN Spp1 55000 D0AnjuNo ratings yet

- Financial Planning: (In Aerodrome)Document21 pagesFinancial Planning: (In Aerodrome)Joseph LlegueNo ratings yet

- Sae J2656 2003 (En)Document10 pagesSae J2656 2003 (En)Georgiana RosulescuNo ratings yet

- Modular Fuel SystemDocument2 pagesModular Fuel Systemwildfire142No ratings yet

- Bav b747 QRHDocument127 pagesBav b747 QRHJoel vitorNo ratings yet

- Transmission and DistributionDocument4 pagesTransmission and DistributionMuthamizhan ThiyagarajanNo ratings yet

- Svcet: Ce6501-Structural Analysis - Classical MethodDocument22 pagesSvcet: Ce6501-Structural Analysis - Classical MethodrangaNo ratings yet

- Kinematics Experiment 102: Velocity and AccelerationDocument1 pageKinematics Experiment 102: Velocity and AccelerationChristopherHiladoNo ratings yet

- TFE 731 Chap 77Document12 pagesTFE 731 Chap 77Egor85No ratings yet

- FAARFIELD Rigid Incl 3D FEMDocument50 pagesFAARFIELD Rigid Incl 3D FEMTim LinNo ratings yet

- 1 MCM PDFDocument88 pages1 MCM PDFKingsely.shuNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)