Professional Documents

Culture Documents

(Lathe Series) 0iTD, 18i - 21iTB

Uploaded by

avalente112Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(Lathe Series) 0iTD, 18i - 21iTB

Uploaded by

avalente112Copyright:

Available Formats

OPERATION MANUAL

OPERATION MANUAL

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

1

Operation Procedure

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

2

POWER ON ...................................................................................................................................................................... 4

MAIN POWER SWITCH ON ................................................................................................................................................ 4

MACHINE READY ............................................................................................................................................................ 4

AXES REFERENCE ............................................................................................................................................................ 4

WARMING UP .................................................................................................................................................................. 5

WARMING UP PROCEDURE ............................................................................................................................................... 5

MAIN OPERATION PANEL .......................................................................................................................................... 6

POWER ON / POWER OFF .................................................................................................................................................. 7

EMERGENCY STOP ........................................................................................................................................................... 7

SPINDLE LOAD METER ..................................................................................................................................................... 7

MODE SELECTION ........................................................................................................................................................... 8

SPINDLE CW & SPINDLE J OG ................................................................................................................................... 11

SPINDLE STOP ................................................................................................................................................................ 11

SPINDLE CCW .............................................................................................................................................................. 12

SPINDLE ORIENTATION .................................................................................................................................................. 12

AUTO. ZRN ................................................................................................................................................................... 13

DRY RUN ....................................................................................................................................................................... 13

MACHINE LOCK ............................................................................................................................................................. 14

M.S.T. LOCK ................................................................................................................................................................. 14

SINGLE BLOCK FUNCTION ............................................................................................................................................. 15

OPTIONAL STOP FUNCTION ............................................................................................................................................ 15

BLOCK SKIP FUNCTION .................................................................................................................................................. 15

TURRET CW/CCW........................................................................................................................................................ 16

WORKING LIGHT ........................................................................................................................................................... 16

COOLANT SWITCH ......................................................................................................................................................... 16

OVER TRAVEL RELEASE ................................................................................................................................................. 17

CYCLE START ................................................................................................................................................................ 17

FEED HOLD .................................................................................................................................................................... 18

FEED RATE OVERRIDE & J OG FEED RATE ........................................................................................................................ 18

RAPID OVERRIDE ........................................................................................................................................................... 19

SPINDLE OVERRIDE ....................................................................................................................................................... 19

ALARM SIGNAL ............................................................................................................................................................. 20

PROGRAM STOP (M00, M01) ......................................................................................................................................... 20

OD/ID KEY SWITCH (OPTION)-ONLY WHEN HYDRAULIC CHUCK SUPPLIED .................................................................... 20

PENDING FUNCTION ...................................................................................................................................................... 21

MEMORY PROTECT KEY ................................................................................................................................................. 21

OPTION ........................................................................................................................................................................... 22

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

3

CHIP CONVEYOR CW/STOP/CCW (OPTION) ................................................................................................................ 22

CHIP WASH DOWN DEVICE (OPTION) .............................................................................................................................. 22

PROGRAM RESTART (OPTION) ........................................................................................................................................ 23

MANUAL ABSOLUTE (OPTION) ....................................................................................................................................... 23

AUTO POWER OFF (OPTION) ........................................................................................................................................... 23

FIX TYPE MPG SELECT (OPTION) ................................................................................................................................... 24

2

ND

TURRET CW/CCW (OPTION) ................................................................................................................................... 24

TOOL SETTER - MANUAL AND AUTOMATIC (OPTION) ..................................................................................................... 25

BAR FEEDER & DESCRIPTION (OPTION) ......................................................................................................................... 29

PROGRAMMABLE TAILSTOCK BODY DESCRIPTION (OPTION) .......................................................................................... 32

C-AXIS DESCRIPTION (OPTION) ..................................................................................................................................... 33

TOOL LIFE MANAGEMENT DESCRIPTION (OPTION) ......................................................................................................... 37

M CODE LIST & DESCRIPTION ............................................................................................................................... 39

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

4

Power on

Main power switch on

Item Operation Location

1 Check the machine condition and interface - Machine panel & all

switches plugs connection

2 Main power switch on - Electric cabinet

3 CNC power on - Main operation panel

Machine ready

Item Operation Location

1 Release EMG stop switch - main operation panel

- Hand-wheel operation panel

- Chip conveyor panel

Axes reference

+ Mode selection

Item Operation Location

1 Select Mode - Control panel

2 Push function key - Control panel

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

5

Warming up

It is necessary to warm up the machine after it has been stopped for hours, especially over

night. Please ensure to let the machine running free for at least 30-45 minutes before

you do accurate cutting.

Warming up

1. Load free operation more than 30 minutes (longer in winter time)

2. Check spindle rotation and orientation function

3. Check tool change function

4. Check lubrication and coolant device function

5. Make sure all these are working properly.

Warming up procedure

3

Item Operation Location

1 Check machine condition and interface - Machine

2 Select automatic mode and search a program - Refer to Fanuc operation

manual

3 Push cycle start button

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

6

Main operation panel

T

S

O

P

Y

E

R

E

M

N

E G

C

10

20

30

40

50

60

70 80

90

100

110

120

130

140

150 0

%

F0

25 50

100

%

LM

50

60

70

80 90

100

110

120

SP LOAD METER

?

X

%

%

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

7

Power on / Power off

Item Operation Remark

1 Push this button to switch on CNC power - Main power switch needs

switch on

Item Operation Location

1 Push this button to switch off CNC power

Emergency stop

Item Operation Location

1 Push this button can stop any function

Spindle load meter

SP LOAD METER

LM %

Item Description Location

1 To check the load condition of spindle motor

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

8

Mode selection

1. The machine has 8 types of selection mode.

8 modes (from right to left, down to up)

a. ZRN uses for the three axes for returning to the MECHANICAL REFERENCE

POINT.

b. RAPID

In this mode, the specify axis will be moved as per the feed rate of the rapid

override rate (please refer to the rapid override rate for detail)

When execute this mode,

a. choose a rapid override rate

b. choose a axis

c. press [AXIS/DIRECTION] key, keep the finger on the key. (the

movement will stop while un-press). The specify axis will be moving

according to the rapid rate.

c. JOG

This mode is for using the feed rate selection toggle to set a axiss feed rate.

Please refer to feed rate selection toggle for detail.

When execute this mode,

choose a feed rate from the feed rate toggle.

Choose a moving axis, press [AXIS/DIRECTION] key, keep the finger on

the key (the movement will stopped while un-press), the specify axis will

be move accordingly.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

9

d. MPG

In this mode, uses of MPG to control the moving speed of the 3 axes.

When executes this mode

Choose a moving axis.

Choose a feed rate

After finishing of above steps, this can be used MPG to control movement

When using handle, please refer to the description of the sub control panel

for MPG.

e. MDI

In this mode, a simple program can be input directly and execution.

In this mode, a simple program can not be memorized. It will be

disappeared after execution.

In this mode, input a simple program.

f. AUTO (MEM)

Program execution mode

CNC program only can be run under this mode.

Please refer to the detail of feed rate override toggle for feed rate override of

this mode.

g. EDIT

By editing, alter, inset or delete for the program

This mode is only use for editing, can not be used for execution.

For editing a new program, must be turned to AUTO.

After finishing the editing, the control will automatically keep it and thus no

need for doing any saving.

h. TAPE (DNC)

For uses of connection program through computer with software.

Note : Please make sure of the operation mode before operating, after the toggle and work

continued to be done.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

10

Axis direction

Item

Operation Remark

1 To move an axis in the JOG and RAPID

mode. Use these buttons, select the axis to

be moved and the direction of movement.

The indicated lamp ON the push button of

moving axes will light on.

-Z

X

X

+Z

-C

+C

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

11

Spindle CW & Spindle jog

Item Operation Remark

1 Only be used during manual mode - Spindle rotate in clockwise

direction

2 It will not be effective during Auto. mode

3 During effective condition, the built-in bulb will

be light on, and it will be off when SPINDLE

STOP or SPINDLE CCW effective.

Spindle stop

Item Operation Remark

1 Under normal condition, it will be effective

while spindle stop.

- The spindle will be stopped

by pressing of this key no

matter of spindle CW or

CCW.

2 It will be only effective during manual mode.

3 It will not be effective during Auto. mode

4 During effective condition, the built-in bulb will

be light on, and it will be off when SPINDLE

CW or SPINDLE CCW is effective

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

12

Spindle CCW

Item Operation Remark

1 Only be used during manual mode. - Spindle rotate in counter

clockwise direction

2 It will not be effective during Auto. mode

3 During effective condition, the built-in bulb will

be light on, and it will be OFF when SPINDLE

STOP or SPINDLE CW is effective.

Spindle orientation

Item Operation Remark

1 It will be effective during manual

mode.

- Before too change, spindle indexing key

unit is turned to a specify degree. The

spindle will be turned to a specify

indexing place by pressing of this key.

2 When this key is effective,

spindle bulb will be light on.

3 The indexing function and bulb

will be cancelled by pressing the

RESET key on the NC control

panel.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

13

Auto. ZRN

Item Operation Remark

1 Turn the model selection toggle to ZRN

mode

- Manual operation key for

zero return of the three

axes

2 Press this key

3 The bulb of ZRN indicated lamp on the

display panel will be light on while reaching

the reference point.

4 The built-in bulb of key will be also light on.

Dry run

Item Function Remark

1 Program can be only executed by CYCLE

START when this function is on. During the

thread canned cycle ON is useless. Each

axis will be moved as per the setting of the

program

- F setting on the program is

useless, each axis will be

moved according to the

specified feed rate of the jog

feed rate.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

14

Machine lock

Item Function Remark

1 When it is on, to execute a program or handle. The coordination

point keep on showing , machine will hold on unmoved.

2 When execute G28, G29, G30 machine will not be moved to zero

point if execute the zero return. Each axis return bulb still will not

be light on.

3 Push this key is not merely machine lock, nor M.S.T. and B code

can be executed. It wont be effective by the machine lock.

M.S.T. lock

M.S.T

Item Function Remark

1 When the M.S.T. lock switch is set to on (the indicated lamp on this

push-button will light on), M,S, and T function operations are locked.

Push this key does not affect machine lock function.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

15

Single block function

Item Function Remark

1 Program can be only executed by CYCLE START. One

single block can only be executed by pressing CYCLE

START

Optional stop function

Item Function Remark

1 While execute a single block, a program will be stopped at

specify block where mention a M01 command in order.

To start the program, CYCLE START key have to be

pressed.

Block skip function

Item Function Remark

1 Program will not be executed any single block while

meeting a / symbol

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

16

Turret CW/CCW

Item Operation Remark

1 Push this button CW turret one position - Working only when front

door is closed

2 Push this button to CCW turret one position - Work only when front door

is closed

Working light

Item Operation Location

1 Push this button to switch on - Under any mode

2 Push again then switch off

Coolant switch

Item Operation Location

1 Push this button to start - The pump will stop if the

main door is opened.

2 Push again then stop

3 Use M8 to start - Use M9 to stop

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

17

Over travel release

Item Operation Remark

1 When X Y or Z axes are over travel which dog

touches the limit switch, the O.T. release

indicated lamp is ON and alarm appears on

CRT. Press continuously this button and use

the MPG to move axis into safety area.

- This button must be

pressed till axes move to

correct position, and then

can be released.

Cycle start

Item Function Condition

1 Program will be executed

in Auto. model

- It will be only effective during auto. mode.

- The built-in bulb will be light on when pressing

this key.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

18

Feed hold

Item Function Condition

1 The three axes will be

stopped during execution

by pressing of this key.

- It will only be effective during auto mode.

- It will not be effective during auto. mode.

- It will not be effective during the operation of

canned cycle. The three axes will be only

stopped until the end of the canned cycle

operation.

Remark : during effective condition

The built-in bulb will be light on.

The spindle will be continuous rotating.

By pressing the CYCLE START key, the program will be re-operated.

Feed rate override & jog feed rate

100

60

50

0

40

20

10

30

150

140

130

120

110

80 70

%

90

1. This switch determines the feed rate by the scales.

2. Each scale has two readings.

a. the below reading represents the original programs set feed rate (F) percentage.

I.E. when the switch is set at 60% F300 means that the feed rate is

300x60%-180mm/min.

b. The one upper represents the jog fee rate per minute. I.E. if the switch is set at

20, the feed rate displayed in screen.

3. The meaning of scales will very by the mode selection.

a. When the mode selection is set at auto. mode, the below reading represents the

feed rate override of G01 execution.

b. When using DRY RUN in JOG or auto mode, the reading upper represents the

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

19

jog feed rate (mm/min.)

c. This switch is no effective during tapping cycle.

Rapid override

50 25

F0 100

%

1. In parameters, the high set feed rate of rapid override is set for G00 command. Also

the low set feed rate of rapid override is set to be F0=400mm/min. (only for FANUC)

2. When in auto. mode, the actual feed rate of G00 command is the feed rate of this

switch multiply the G00 feed rate.

3. When RAPID mode, the feed rate is the feed rate of this switch multiply the G00 feed

rate.

4. Example : original G00 feed rate is 18000mm/min. when this switch is set at 50%, then

the actual feed rate is 9000mm/min.

5. This switch has four steps (100%, 50%, 25%, F0) to be selected. F0 is set at

1000mm/min.

6. This switch is not effective during tapping cycle.

Spindle override

%

During spindle is running, speed can be adjusted by the switch (50% -120%)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

20

Alarm signal

1. When it is light on, control has trouble or machine can not be operated.

2. Warning lamp activated.

Program stop (M00, M01)

When program is executed M00, M01 feed hold.

OD/ID key switch (option)-only when hydraulic chuck supplied

Select chuck direction for workpieces clamping by this key switch

Select chuck in CLAMP direction (for normal 3 jaw chuck),

Note :for some type of hydraulic collect, because clamp/unclamp mechanical

construction is opposite ,the key will make collect UNCLAMPING.

Select chuck in UNCLAMP direction(for normal 3 jaw chuck)

Note :for some type of hydraulic collect, due to clamp/unclamp mechanical

construction is opposite, the key will make collect CLMAPING.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

21

Pending function

Function to be declared when it is ready.

Memory protect key

1. This key switch is used to prevent the programs from being edited, deleted, or

modified.

2. Under normal circumstances, this switch should be at ON position to prevent the

programs from being modified or deleted.

3. In case there are need to edit, delete, or modify the programs, set the switch at OFF

position.

4. (Only for FANUC system) when the switch is at OFF position, the mode selection

must be set at EDIT position, otherwise the programs are still protected.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

22

OPTION

Chip conveyor CW/STOP/CCW (option)

Item Operation Remark

1 Push CW button to execute function M24 chip conveyor ON

M25 chip conveyor OFF

2 Push STOP button to stop CW action

3 Push CCW button to execute CCW. It is

JOG movement.

- Function is effective only

when button is push.

- Function fails to work when

button is released.

Chip wash down device (option)

Item Operation Location

1 Push this button to start - When door is open, it will

not be working

2 Push again then stop -

3 Use M12 to start - Use M9 to stop

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

23

Program restart (option)

RESTART

PROGRAM

Please refer to the operators manual of the CNC control.

Manual absolute (option)

MANNAL ABS

Item Operation Remark

1 ON The move amount by manual operation

is not counted to the present position ON.

2 OFF The move amount by manual

operation is not counted to the present

position on the work coordinate system.

Auto power off (option)

POWER OFF

AUTO

Item Operation Remark

1 When this switch is on (the indicated lamp will

light on), the power supply circuit will be

automatically cut off after a M30 command

being read during the memory operation.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

24

Fix type MPG select (option)

Item Operation Remark

1 ON The Fix type MPG select.

2 OFF The Portable MPG select.

2

nd

Turret CW/CCW (option)

+

Item Operation Remark

1 Push this CW turret and center of jog key to

turn 2

nd

turret one position

- Working only when front

door is closed

2 Push this button to CCW turret and center of

joy key to turn 2

ND

turret one position

- Work only when front door

is closed

-Z

X

X

+Z

-C

+C

Fix type

MPG select

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

25

Tool setter - Manual and Automatic (option)

Tool setter operation procedure:

Note: Not suggest alternately using manual and auto. Tool setter, it may have 30~60u

tolerance. (Reason 1- acceleration and deceleration for manual and automatic is different. 2-

the measurement position is different.)

1. Manual tool setter operation procedure:

(1) Put the arm down, and under Manual JOG mode, comply with direction button to

make X and Z axis moved to positive or negative. And confirm the traveling feed is

F=32/mm/min. After tool touched the probe, the compensation value is created

automatically into the tool data, then move X and X in opposite movement.

(2) Move the arm back, install a work piece on the chuck, move the tool which has

completed above compensation to work piece end surface,, and press Work Shift

Setting, After light on, press it again, check the content of Work Shift is correct or not.

The way to check:

After executing Work Shift Z=-600000+100000=-500000u(-500mm)

(3) After doing cutting by program ,check the diameter ,if its incorrect, please follow any

one of below to modify:

By increasing or decreasing value into wear offset of relative tool data. If the

external diameter cutting is bigger than the program, set the value up to positive (+).

And if the internal diameter cutting is smaller than the program, set the value up to

positive (+).

By increasing or decreasing value into work coordination(G54~G59)value. If the

external diameter cutting is bigger than the program, set the value up to negative (-).

And if the internal diameter cutting is smaller than the program, set the value up to

positive (+).

Tool

Turret

Chuck

Work Piece

Z= 600mm

100mm

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

26

2. Program to operate manual tool setter for setting tool offset compensation

procedure:

Explanation of format of Automatic tool setter: G65 P9011 H** T**

G65 : code for call macro.

P9011: macro program no. for tool measurement

K1 : For setting probe one direction position of X or Z axis.

(Note: the setting is done manually before shipment from factory, please

do not use this function to set automatically)

K2 : Setting both direction (+/-) position automatically simultaneously

according to #530 and #531.

(Note: the setting is done manually before shipment from factory, please

do not use this function to set automatically)

H**: direction for tool nose.

T**: offset number for tool geometry

Rear

mounted

Turret

+X

Front

mounted

+Z

H5 H7

H8

H6

H1

H3

H2

H4

H5 H7

H6

H8

H4

H2

H3

H1

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

27

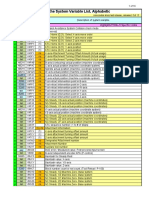

RELATIVE VARIABLE DESCRIPTION

#509: Offset type setting ,(Standard setting 1).

0 geometric and wear offset not separately

1 geometric and wear offset separately

#522: X+ cube position

#523: X- cube position

#524: Z+ cube position

#525: Z- cube position

#530: Diameter cube for X (30=15*2, diameter) (Use K2 for emending)

#531: Diameter cube for Z (15, diameter) (Use K2 for emending)

Program to operate for setting tool offset compensation procedure:

(1) Before measuring, move tool to 6 mm away from cube.

(2) Execute G65 P9011 H** T** to set every single compensation value for each tool.

(3) Use the reference tool to set the part program zero position of cutting program by

conducting WORK SHIFT SETTING function button or WORK SHIFT function

on control panel.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

28

3.Automatic tool setting execution:

Its available to use M code to control Automatic tool setter Are up and down. (M74 for Arm

down ,M75 for Arm up) Besides, you have automatic tool offset and wear detect

Explanation of code function:

G65 :code for call macro

P9012: macro program no. for auto tool measurement and detect

H**: direction for tool nose

M**: wear detect alarm distance(mm)

(Note: Before sing this format, it is essential the value of tool length compensation is

completed or execution of G65 P911 H** T** is done. )

EXAMPLE: O3000

G28 U0.

M74 (TOOL SETTER DOWN)

T0202 (O.D. TOOL)

G65 P9012 H3 (AUTO TOOL OFFSET)

G28 U0.

T0303 (DRILL TOOL)

G65 P9012 H7 (AUTO TOOL OFFSET)

G28 U0.

T0404 (O.D. TOOL)

G65 P9012 H3 M0.1 (When wear over +- 0.1 MM THAN get alarm)

M75 (TOOL SETTER UP)

M30

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

29

Bar feeder & Description (option)

1. NC setup for BAR feeder procedure

(1) Check bar feeder connection and I/O signal

(2) Check parameter 6083=70 (for use M70 code call O9023 macro)

(3) Check O9023 PROGRAM (M70-BAR-FEEDER-MACRO)

O9033 PROGRAM (REMAIN-BAR-EJECT-SUBROUTINE)

O7000 PROGRAM (NEW-BAR-FACE-SUBROUTINE)

(4) Check KEEP RELAY

K21.0 =1 (AUTO BAR FEEDER VALID)

K21.1 =0 (spindle jog for new bar)

K21.2= 0 For short bar of bar feeder

1 Bar start for new bar only (normal select for long bar of bar feeder)

K22.0 =1 (PARTS CATCHER VALID)

K22.1 =0 (NO IN SWITCH-PARTS CATCHER)

K22.2 =0 (USE 2 VALVE-PARTS CATCHER)

2. Bar feeder setup procedure (refer to bar feeder manual)

(1) Assemble all accessories.

(2) adjust same level to spindle center of chuck.

(3) Select correct push bar and set bar diameter from hand wheel and bar stop dog.

(4) Select correct spindle chuck and sleeve.

(5) Set work-piece length/return stroke, bar end point, remain bar out point,

push bar position limit, safety length, shortest length, and longest length.

(6) Push first bar through chuck to stopper position by manual mode and check if the

bar moves smoothly.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

30

3. Bar feeder operation procedure

(1) Set macro variable:

#580: Normal & new bar X obstruct point (machine coordinate)

#581: Normal bar Z Obstruct point (machine coordinate)

#582: Obstruct tool number (SET 100 means T0100)

#583: New bar Z obstruct point (machine coordinate)

(not valid for long bar of bar feeder. To set from bar feeder side)

#585: SET 1 with face cutting by subroutine

(2) Set chuck direction key switch at operation panel (CLAMP:for normal 3 jaw chuck)

Note :for some type of hydraulic collect, because clamp/unclamp mechanical

construction is opposite (UNCLAMP:for hydraulic collect )

(3) Write program then press cycle start use M70 code to communication bar feeder

example: O5000

M70 (Bar feeder enable & call O9023 push bar in position)

G28 U0.

T0101 (parts programming start area)

.

M99

O7000 (New-bar-face-subroutine) (when set macro variable #585=1)

G28 U0.

T0303 (for new bar face programming start area)

..

..

M99

(4) Press auto mode and auto start from bar feeder panel

Obstruct Tool

#582

Turret

Chuck

Work Piece

#581

#580

#583

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

31

4. Bar feeder trouble shooting

(1) Remove alarm from bar feeder panel by manual mode, then push bar into position.

(2) Refer to machine operation manual to reset alarm and then chuck close and press

cycle start again.

(3) After NC wait at stop position, press auto mode and auto start from bar feeder

panel.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

32

Programmable tailstock body Description (option)

1.NC setup for programmable tailstock body procedure

(1) Check parameter 6076=76 (for use M76 code call O9006 macro)

Check parameter 6077=77 (for use M77 code call O9007 macro)

Check parameter 6078=78 (for use M78 code call O9008 macro)

(2) Check O9006 PROGRAM (M76-TAILSTOCK-POSITION-RECORD)

O9007 PROGRAM (M77-TAILSTOCK-GOTO-POSITION)

O9008 PROGRAM (M78-TAILSTOCK-PIN-BACKWARD)

(3) Check KEEP RELAY K20.2 =1 (PROGRAM TAILSTOCK PIN VALID)

K20.0 =0 (no tailstock quill)

(4) Set programmable tailstock Stored stroke limit (positive direction)

Parameter 1326 :X-axis set same as parameter1320, Z-axis set about -10000

Set programmable tailstock Stored stroke limit (negative direction)

Parameter 1327 :X-axis set same as parameter1321, Z-axis depend on machine

2.M code description:

M77: Tailstock body search position and Tailstock body unlock

M78: Tailstock body lock

M76: Tailstock body pin position memory (for maintenance only)

M79: Tailstock body unlock (for maintenance only)

3.example: O300

G28 U0.

M77

G01 W-90. F1440

M78

M03S500

G00 Z3.0 X50.

G01X48.

Z-50.

.

.

M05

M30

Programmable Tailstock body position miss adjustment procedure::

1. In MPG mode, look at the tailstock body pin and move Z axis let it approach the

position of carriage hooker.

2. In MDI mode, execute M79 Tailstock body unlock. Pin is out and use handlewheel to move Z

axis. Then let the pin plug into the hole for carriage hooker.

3. In MDI mode, execute M76 Tailstock body pin position memory to record the Z axis

position for programmable tailstock.

4. In MDI mode, execute M78 Tailstock body lock. After that, the setting is finish.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

33

C-Axis Description (option)

C-Axis button and M cod description

1. Button description

Rotary tool spindle select

Item Function Remark

1 When the Rotary tool spindle switch is set to on (the indicated lamp

on this push-button will light on), life tool spindle on turret function.

Push the button again first spindle function.

2. M code description

M45: First C axis ON M46: First C axis OFF

M68: C axis high brake ON M69: C axis high brake OFF

M113: Rotary tool forward M114: Rotary tool reverse

M119: Rotary tool orientation M5: Spindle stop /rotary tool rotation stop

M29: Rigid tapping for live tool spindle(only available M45 execution)

3.C-Axis operation notes:

(1) Instruction for adjust C axis braking pressure

Rotary tool

Spindle

Breaking pressure gauge

Solenoid valve of high pressure (left)

Solenoid valve of low pressure (right)

Adjusting valve for low pressure braking (top)

Adjusting valve for high pressure braking (bottom)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

34

.Sol enoi d acti on expl anati on :

When high pressure solenoid is not electrified , but low pressure

solenoid is electrified and the light is on---C-axis low braking is active.

When both high pressure solenoid and low pressure solenoid are

electrified and light is on-----C-axis high braking is active.

To adj ust the hi gh &l owpressure i nstructi on :

Select MDI mode, execute below program and confirm the action of

low pressure solenoid. After that, adjust the low pressure:

M45 ;

M114 S2000 ;

Adjust low pressure valve, confirm the pressure is between 0.5-1.5kg/cm2.

Select MDI mode, execute below program and confirm the action of

high pressure solenoid. After that, adjust the high pressure:

M45;

M114 S200

M68;

Adjust the valve of high pressure, then confirm the pressure is 30kg/cm.

After adjustment, select MDI mode, execute M69. Then finish adjustment.

Attention:

(1) For some model, we design the high braking system by use in totally pressure, so you

dont need adjustment. And the pressure gauge is only display when it is in low

pressure. So, please only check the high pressure solenoid if it is active or braking

plate is completely stop

(2) Some model, the braking system of high/low pressure was design in same set, so

please only check braking pressure gauge is matching the pressure requirement.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

35

(2) When use C-Axis in program by M 45 CODE, after M code finish the next block,

you need make zero return by G28 C0. for C-axis otherwise it will get alarm.

4.example: O317 (polar coordinate contours cutting with C axis low pressure braking)

G28U0.

T0202

G54

G98

G18

M45

G28C0.

M113S4500

N1

G0X200.

N2G12.1

G01X190.F1440

G01C95.

G01X-190.

G01C-95.

G01X190.

G01C95.

G01X300.F10000

G13.1

Braking system:

There is one set braking system

for low and high braking on this

photo. (But for some model, the

braking system is separated, you

will find two sets)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

36

M46

M30

example: O316 (drilling hole with C axis high pressure braking)

G28U0.

G98

M45

G28C0.

G00X200Z2M113S1500

G83X200C0Z-8.R0Q5000F150M68

C45.

C90.

C135.

C180.

C225.

C270.

C315.

G80

M69

M46

M30

example: O318 (Rigid tapping by live tool with C axis high braking)

G99

M68

M45

G28C0.

M113 S400 (Select direction for Rigid tapping)

G0X70.Z0.

M29S400

G84Z-15.R5 F1.25

C45.

C90.

M69;

G80;

M05;

M46;

M30

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

37

Tool life management Description (option)

I. NC setup for tool life management procedure

Set parameter 8132#0 =1 tool life management is used(for 0iTB/C controller only)

If set parameter 6800#2 =0 tool life specified by the number of times

=1 tool life specified by the time(unit :minute)

2.M cod description

M27: Tool Skip ON

(When use tool group to call tools in tool life management, if the current tool is

broken before the tool life arrival, you can use the M code to skip it and use next tool)

3. operation procedure

Program of tool life data:

Tape format Meaning

O_ _ _ _;

G10L3;:

P_ _ _ _L_ _ _ _;

T_ _ _ _;

T_ _ _ _;

.

.

P_ _ _ _L_ _ _ _;

T_ _ _ _;

T_ _ _ _;

.

.

G11;

M30;

Program number

G10L3: Start of setting tool life data

P___: Group number(1 to 128)

L___: Tool life (1 to 9999)

T____ :Tool number

Tool are select from

(1) to (2) to ..to(n)

Data for the next group

G11: End of setting tool life data

End of program

example: O3000 for setting tool life data

O3000 ;

G10L3 ;

P1L2 ; (Set Group 1 ,Tool life 2 times or 2 minutes)

T0404;

T0505;

P2L2 ; (Set Group 2 ,Tool life 2 times or 2 minutes)

T0606;

T0707;

G11;

M30;

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

38

Specifying a tool group in a machine program

Tape format Meaning

.

.

T99

.

.

T88

.

.

M30;

Ends the tool used by now ,and start to use the tool of the

01 group. 99 distinguishes this specification from

ordinary specification

Cancel the offset of the tool of the 01 group. 88

distinguishes this distinguishes this specification from

ordinary specification

End of program

example: O3001 for tool life use

O3001;

G28U0.;

T0199; Ends the previous tool ,and start to use the tool of the 01 group.

.

.

T0188; Cancels the offset of the tool of the 01 group.

.

T0508; Ends the tool of the 01 group. Selects tool number 05 and offset number 08

.

.

T0500; Cancels the offset of the tool number 05.

.

.

T0299; Ends the tool number05,and start to use the tool of the 02 group.

.

.

T0299; Ends the tool number05,and start to use the tool of the 02 group.

.

.

T0199; Ends the tool of the 02 group ,and start to use the tool of the 01 group.

.

if more than one offset number is specified for the tool, the second offset numbers is select.

Otherwise ,the previous offset number is used

M30;

NOTE: Please refer controller operation or program manual for details operation.

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

39

M CODE LIST & DESCRIPTION

S:STANDARD O:OPTION

NO. FUNCTION S/ NO. FUNCTION S/

M00

Program stop

S M24

Chip conveyor ON

O

M01

Optional stop

S M25

Chip Conveyor OFF

O

M02

End of program

S M26

M03

Spindle forward

S M27

Tool Skip ON

O

M04

Spindle reverse

S M28

M05

Spindle stop /rotary tool rotation

stop

S M29

Rigid tapping(Fanuc only)

O

M06

M30

Program end &Rewind

S

M07

M31

X AXIS Mirror IMAGE ON

S

M08

Coolant ON

S M32

Z AXIS Mirror IMAGE ON

S

M09

Coolant/M07/M50 OFF

S M33

X,Z, AXIS MIRROR IMAGE OFF

S

M10

Chuck clamp

O M34 O

M11

Chuck unclamp

O M35 O

M12

Chip wash down coolant ON

O M36 O

M13

Spindle forward &Coolant ON

S M37 O

M14

Spindle reverse &Coolant ON

S M38

M15

Work door close

O M39

M16

Work door open

O M40

M17

M41

Spindle gear 1

O

M18

M42

Spindle gear 2

O

M19

Spindle orientation

S M43

Spindle gear 3

O

M20

Quill advance

O M44

Spindle gear 4

O

M21

Quill retract

O M45

First C axis ON

O

M22

M46

First C axis OFF

O

M23

M47

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

40

S: STANDARD O: OPTION

NO. FUNCTION S/ NO. FUNCTION S/

M48

Override ON

S M71

Turret change at any position

an position

S

M49

Override cancel ( = 100 % )

S M72

Parts catcher in(*)

O

M50

Oil mist/External air blower

O M73

Parts catcher out (*)

O

M51

M74

Tool setter down(*)

O

M52

M75

Tool setter up (*)

O

M53

M76

Tailstock body pin position memory

(for maintenance only)

M54

M77

Tailstock body search position and

Tailstock body unlock

O

M55

M78 Tailstock body lock O

M56

Chamfering on

S M79

Tailstock body unlock

(for maintenance only)

M57

Chamfering on

S M80

Spare function 1 ON

O

M58

IN Position check ON

S M81

Spare function 1 OFF

O

M59

IN Position check OFF

S M82

Spare function 2 ON

O

M60

M83

Spare function 2 OFF

O

M61

M84

Spare function 3 ON

O

M62

M85

Spare function 3 OFF

O

M63

M86

Spare function 4 ON

O

M64

M87

Spare function 4 OFF

O

M65

M88

Spare function 5 ON

O

M66

Steady rest clamp

O M89

Spare function 5 OFF

O

M67 Steady rest unclamp O M90

Spare function 6 ON

O

M68

C axis high brake ON (*)

O M91

Spare function 6 OFF

O

M69

C axis high brake OFF (*)

O M92

M70 Bar feeder enable O M93

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

41

S: STANDARD O: OPTION

NO. FUNCTION S/ NO. FUNCTION S/

M94

Cutting off detection

O

M95

Parts count

S

M96 Work piece probe select O

M97 Tool setting probe select O M1008

M98

Call Sub-program

S M1009

M99

Sub-program stop

S

M1011

M100

M1012

M101

M1015 Built-in spindle warm-up O

M102

M1016Built-in spindle system reserve(dont O

M103

M113

Rotary tool forward

O

M114

Rotary tool reverse

O

M115

M116

M119

Rotary tool orientation

O

M180

Feed hold when spindle stop

O

M181

Feed ON when spindle stop

O

M201

O

M202

o

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM/OPERATION MESSAGE.

NC ALARM

Please refer to MELDAS or FANUC Instruction/Operation Manual if NC screen

displayed NC alarm.

The NC alarm including

1. Servo alarms

2. Over-travel alarms

3. Overheat alarms

4. System alarm

5. Background edit alarm (BP/S)

6. Program error (P##alarm)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM LIST

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1000

F0

AL1001 SPINDLE DRIVER FAULT(A0.1) THE SPINDLE ALARM

F1

AL1002 SAFETY GUARD SWITCH FAULT(A0.2)

F2

AL1003 NC BATTERY ALARM (A0.3) REPLACE BATTERY FROM NC CONTROLLER

F3

AL1004 DOOR OPEN (A0.4) MACHINE DOOR IS OPEN

F4

AL1005 SPINDLE WITHOUT S CODE (A0.5) WHEN SPINDLE ROTATION S CODE MISS

F5

AL1006 HEAD STOCK LUBE MOTOR O.L (A0.6) HEAD STOCK LUBE SYSTEM UNIT ALARM

F6

AL1007 ZERO RETURN MISSED (A0.7) AXIS NOT RETURN TO ZERO POINT, AFTER POWER

F7 OR MACHINE LOCK

AL1008 COOLANT MOTOR OVER LOAD COOLANT PUMP OVER RELAY ALARM

F8

AL1009 LUBE LEVEL LOW (A1.1) THERE IS LEVEL LOW IN LUBRICATION OIL.

F9

AL1010

F10

AL1011 CHUCK CLAMP FAULT (A1.3) CHUCK CLAMP OVER TIME OR SWITCH FAULT

F11

AL1012 CHUCK UNCLAMP FAULT (A1.4) CHUCK UNCLAMP OVER TIME OR SWITCH FAULT

F12

AL1013 SPINDLE ORIENTATION FAULT(A1.5) SPINDLE ORIENTATION OVERTIME

F13

AL1014 PROBE BATTERY LOW (A1.6) REPLACE BATTERY FROM RENISHAW PROBE

F14

AL1015 PROBE SYSTEM ERROR (A1.7) CHECK RENISHAW PROBE SETTING AND WIREING

F15

AL1016 CHUCK SWITCH SETTING ERROR (A2.0) CHUCK SWITCH DISCONNECT

F16 OR NC DATA SETTING ERROR

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1017 EMG. STOP/ O.T(A2.1) EMERGENCY STOP BUTTON PRESS

F17 OR STROKE LIMIT HARDWARE OVER TRAVEL

AL1018 AIR PRESSURE LOW (A2.2) AIR PRESSURE LOW

F18

AL1019 CHIP CONVEYOR OVER LOAD (A2.3) CHIP CONVEYOR MOTOR OVER RELAY ALARM

F19

AL1020 WASH DOWN/COOLANT GUN CHIP WASH DOWN /COOLANT GUN

F20 OVER LOAD (A2.4) OVER RELAY ALARM

AL1021 GEAR NOT POSITION (A2.5) GEAR NOT IN POSITION ALARM

F21

AL1022 BELT OF SPD WAS LOOSING (A2.6)

F22

AL1023 TAILSTOCK BODY OT. (A2.7)

F23

AL1024 CHUCK MUST BE CLAMP (A3.0) CHUCK NOT CLAMP BEFORE SPINDLE RUNNING

F24 CYCLE START

AL1025 X AXIS NEAR HOME (A3.1) AFTER MACHINE LOCKED, X AXIS IS NEAR HOME

F25 POSITION. PLEASE REMOVE X AXIS OUT OF

HOME POSITION TERRITORY.

AL1026 Z AXIS NEAR HOME (A3.2) AFTER MACHINE LOCKED, Z AXIS IS NEAR HOME

F26 POSITION. PLEASE REMOVE Z AXIS OUT OF

HOME POSITION TERRITORY.

AL1027 C AXIS NEAR HOME (A3.3) AFTER MACHINE LOCKED, C AXIS IS NEAR HOME

F27 POSITION. PLEASE REMOVE C AXIS OUT OF

HOME POSITION TERRITORY.

AL1028

F28

AL1029

F29

AL1030 HYD-PRE.SW. SETTING ERROR(A3.6) PRESSURE SWITCH DISCONNECT

F30 OR NC DATA SETTING ERROR

AL1031

F31

AL1032 HYDRUALIC MOTOR OVER LOAD (A4.0) HYDRUALIC MOTOR OVER RELAY ALARM

F32

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1033 HYDRUALIC PRESSURE LOW (A4.1) HYDRUALIC PRESSURE UNDER NORMAL

F33

AL1034 LUBE PRESSURE MISS (A4.2) LUBE PRESSURE UNDER NORMEL

F34

AL1035 MAIN POWER PHASE SEQUENCE MAINE POWER PHASE NOT CONNECT COORECT

F35 WRONG (A4.3)

AL1036 CHECK OP PANEL AXES PB. (A4.4) AXIS OF J OG SELECTING SWITCH IS

F36 SHORT OR BREAK DOWN

AL1037

F37

AL1038 COOLANT TANK LEVEL LOW (A4.6) COOLANT UNIT TANK LEVEL LOW

F38

AL1039 RECYCLE PUMP OVER LOAD (A4.7) RECYCLE PUMP OVER RELAY ALARM

F39

AL1040

F40

AL1041 X ZRN STROKE SWITCH FAULT (A5.1) X AXIS HOME SWITCH DISCONNECTED OR

F41 ABNORMAL

AL1042 Z ZRN STROKE SWITCH FAULT (A5.2) Z AXIS HOME SWITCH DISCONNECTED OR

F42 ABNORMAL

AL1043 C ZRN STROKE SWITCH FAULT (A5.3) C AXIS HOME SWITCH DISCONNECTED OR

F43 ABNORMAL

AL1044 WORK AREA SETTING ERROR (A5.4)

F44

AL1045 POSITION SWITCH SETTING ERROR WORK AREA STROKE-POSITION SWITCH IS SET

F45 (A5.5) ERROR OR NEGLECTED SETTING.

AL1046 NOT IN WORKING AREA (A5.6)

F46

AL1047 COOLANT WATER OVERFLOW (A5.7)

F47

AL1048

F48

AL1049

F49

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1050 LUBE PRESSURE SETTING ERROR PRESSURE SWITCH DISCONNECT

F50 (A6.2) OR NC DATA SETTING ERROR

AL1051 TOOL SETTER SETTING ERROR NC DATA SETTING ERROR

F51 (A6.3)

AL1052 TAILSTOCK QUILL MOTOR CHECK TAILSTOCK QUILL MOTOR

F52 OVERLOAD (A6.4) OVER RELAY ALARM

AL1053 TAILSTOCK BODY MOTOR CHECK TAILSTOCK BODY MOTOR

F53 OVERLOAD (A6.5) OVER RELAY ALARM

AL1054 TAILSTOCK SETTING ERROR (A6.6) TAILSTOCK SWITCH DISCONNECT

F54 OR NC DATA SETTING ERROR

AL1055 TAILSTOCK FORWARD FAULT(A6.7) TAILSTOCK FORWARD OVER TIME

F55 OR SWITCH FAULT

AL1056 TAILSTOCK BACKWARD TAILSTOCK BACKWARD OVER TIME

F56 OR SWITCH FAULT

AL1057 TAILSTOCK BODY LOCK TAILSTOCK BODY LOCK OVER TIME

F57 OR SWITCH FAULT

AL1058 TAILSTOCK BODY UNLOCK FAULT(A7.2) TAILSTOCK BODY UNLOCK OVER TIME

F58 OR SWITCH FAULT

AL1059 TAILSTOCK BODY PIN FAULT(A7.3) TAILSTOCK BODY PIN OVER TIME

F59 OR SWITCH FAULT

AL1060 PARTS CATCHER NOT IN POSITION PARTS CATCHER NOT AT UP OR DOWN POSITION

F60

AL1061 PARTS CATCHER TIME OUT(A7.5) PARTS CATCHER UP/DOWN OVER TIME

F61 OR SWITCH FAULT

AL1062 TOOL SETTER NOT IN POSITION(A7.6) TOOL SETTER NOT AT UP OR DOWN POSITION

F62

AL1063 TOOL SETTER TIME OUT(A7.7) TOOL SETTER UP/DOWN OVER TIME

F63 OR SWITCH FAULT

AL1064 BAR FEEDER ALARM(A8.0)

F64

AL1065 X/Z NOT IN NEW START POINT(A8.1) BEFORE SENDING NEW BAR, X&Z POSITION NOT

F65 IN NEW START POINT

AL1066 CUT OFF INCOMPELETE (A8.2) BAR IS NOT CUT OFF COMPLETELY OR CUTTING

F66 OFF DETECTOR NOT IN POSITION

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1067 C AXIS ZERO RETURN MISSED (A8.3)

F67

AL1068 C AXIS ON SPINDLE DISABLE(A8.4)

F68

AL1069 SPINDLE/ROTARY TOOL ROTATION(A8.5)

F69

AL1070 ROTARY TOOL SPINDLE FAULT(A8.6)

F70

AL1071 AUTO DOOR OVERTIME (A8.7)

F71

AL1100 TURRET TYPE SELECT ERROR(A9.0) CHECK CABLE CONNECTION

F100 AND KEEP RELAY SETTING

AL1101 K1.1 SETTING ERROR (A9.1)

AL1102 CHUCK GUARD IS OPEN (A9.2)

AL1103 X NOT AT ATC CHANG POSITION TURRET TOOL CHANGE NOT AT X HOME POSITION

(A9.3)

AL1104 Y AXIS NEED ZERO RETURN(A9.4)

AL1105 TURRET NOT IN POSITION (A9.5)

AL1106

AL1107 TURRET INDEX TIMEOUT(A9.7) TURRET ROTATION OVER TIME

OR SWITCH FAULT

AL1108 TURRET MOTOR OVER LOAD

(A10.0)

AL1109

AL1110 TURRET OVER TEMPERATURE TURRET OVER TEMPERATURE

(A10.2) OR THERMAL SWITCH FAULT

ALl111 TURRET SIGNAL FAULT (A10.3)

AL1113 CABINET AIR CONDITIONER ALARM

F113 (A10.5)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1114 FOOT ON MAT WHILE DOOR CLOSE

F114 (A10.6)

AL1115

F115

AL1116 TURRET POWER FAULT (A11.0) Power is no connected or voltage low

AL1117 TURRET MAX. VOLTAGE (A11.1) Power voltage not normal

Check voltage within (220 +%10/-%15)

AL1118 TURRET EXTRACURRENT (A11.2) Motor coil temperature gauge signal on

or check gauge wiring

AL1119 TURRET UNLOCKING ERROR(A11.3) Check pneumatic circuit integrity Ascertain that solenoid

Valve receives command or check proximity sensor

AL1120 TURRET LOCKING ERROR(A11.4) Check pneumatic circuit integrity Ascertain that solenoid

Valve receives command or check proximity sensor

AL1121 TURRET ZERO SEARCH ERROR(A11.5) Check that turret setting (turret blt)corresponds to size

And number of position foreseen by you turret

AL1122 TURRET SEARCH TIME OUT (A11.6) Check correct operation of ZERO proximity sensor

Check wiring of power cable

AL1123 TURRET RESOLVER ALARM (A11.7) Check that resolver connector is well connection ,

AL1124 TURRET PARITY ALARM (A12.0) Check correct setting of position code(position bit and

)with connection

AL1125

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

ALARM ALARM MESSAGE REMARK

ADDRESS

AL1132 HV4 TURRET UNCLAMP FAULT(A13.0) HV4 TURRET UNCLAMP SWITCH DISCONNECTED OR

ABNORMAL

AL1133 HV4 TURRET CLAMP FAULT(A13.1) HV4 TURRET CLAMP SWITCH DISCONNECTED OR

ABNORMAL

AL1134 HV4 TURRET CW FAULT(A13.2) HV4 TURRET CW SWITCH DISCONNECTED OR

ABNORMAL

AL1135 HV4 TURRET CCW FAULT(A13.3) HV4 TURRET CCW SWITCH DISCONNECTED OR

ABNORMAL

AL1136 TOOL POST INTERFERENCE

ALARM(A13.4)

AL1137

AL1138

AL1139 PARTS CATCHER DRIVE

ERROR(A13.7)

AL1140 PARTS CATCHER BATTERY

ALARM(A14.0)

AL1141

AL1142

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

OPERATION MESSAGE LIST.

MESSAGE NO. OPERATION MESSAGE REMARK

ADDRESS

OP2000 WORKS COUNT OVER (A15.0)

OP2001 DOOR NOT OPEN WHEN

SPINDLE CHUCK UNCLAMP

OPERATION (A15.1)

OP2002 MODE SELECT ERROR (A15.2)

OP2003 FEED OVERRIDE=0 (A15.3)

OP2004 OT-RELEASE PUSH BUTTON ON RAPID OFF & PROGRAM FEED HOLD

(A15.4)

OP2005 MAKE SURE DRY RUN IN USED

(A15.5)

OP2006 M00/M01 PROGRAM FEED HOLD

(A15.6)

OP2007 AXES STOP WITHOUT SPINDLE

(A15.7)

OP2008 MACHINE LOCK (A16.0)

OP2009 M.S.T. LOCK (A16.1)

OP2010 PROGRAM IS RUNNING (A16.2)

OP2011 TURRET ZERO SEARCH (A16.3)

OP2012 WAIT X ZERO RETURN FIRST

(A16.4)

OP2016 LUBE/COOLANT LEVEL LOW/PROGRAM BECOME SINGLE BLOCK(A17.0)

OP2017 CHECK WORK AREA AND PRESS LIGHT GUARD RESET BUTTON(A17.1)

OP2018 SPINDLE OIL COOLER SETTING ERROR K0.0 (A17.2)

OP2019 CABINET AIR CONDITIONER SETTING ERROR K3.3 (A17.3)

OP2020 NOT ALLOW OPERATION BECAUSE SPINDLE ROTATION (A17.4)

OP2021

OP2022 FOOT ON SAFETY MAT WHILE DOOR OPERATING(A17.6)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

MESSAGE NO. OPERATION MESSAGE REMARK

ADDRESS

OP2032 MAG. OPERATION ERR. (A19.0)

OP2033 T CODE ERROR WHEN T CODE USED NOT IN MAGAZINE TABLE

(A19.1)

OP2034 CHECK TOOL TABLE BY PRESS SPINDLE STOP OR PMCRPM DATA

(A19.2)

OP2035 CHUCK UNCLAMP OR CHUCK

DIRECTION SELECT ERROR(A19.3)

OP2036

OP2037 OPERATION ERROR (A19.5) PRESS RESET KEY

OP2038 TOOL LIFE OVER (A19.6) CHANGE NEW TOOL AND RESETTING TOOL

LIFE

OP2039 TURRET ALARM/ PRESS EMERGENCY STOP FOR RESET ALARM (A19.7)

OP2040 TAILSTOCK BODY PIN OUT/ RAPID&ZRN MODE INVALID (A20.0)

OP2042 HANDWHEEL SETTING ERROR K7.0/K7.2/K7.7/X24.0(A20.2)

OP2048 WRONG DIRECTION KEY IN J OG, PRESS RIGHT KEY OR USE HANDWHEEL(A21.0)

OP2049 SUB PANEL HANDLE RATE ON NOT CONNECTED(A21.1)

OP2050 PARTS CATCHER IN/ REDUCE RAPID AND TAILSTOCK QUILL INHIBIT (A21.2)

OP2051 TOOL SETTER DOWN/ REDUCE RAPID AND TAILSTOCK QUILL INHIBIT (A21.3)

OP2052 CHECK BAR FEEDER IS CONNECTION AND READY (A21.4)

OP2053 CHECK BAR POSITION&CHUCK CLAMP/THAN PRESS RESET KEY(A21.5)

OP2054 RESET/SELECT MDI FOR NEW M CODE OR USE BUTTON ON PANEL(A21.6)

OP2055 MANUAL MODE INVALID WHEN C AXIS HIGH BRAKE ON(A21.7)

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

MESSAGE NO. OPERATION MESSAGE REMARK

ADDRESS

OP2056 BARFEEDER NOT AT MANUAL MODE-CHECK

MODE SELECT OF BARFEEDER(A22.0)

OP2065

OP2066

OP2067

OP2068

OP2069

OP2070 SECOUND TURRET IS DISABLED(A23.6)

OP2071 ONLY ALLOW SINGLE AXIS ZERO

WHEN TWIN TURRET (A23.7)

OP2100 TURRET TOOL NO./D0= DISPLAY TURRET TOOL NO.

(AFTER PRESS SPINDLE STOP)

OP2101 SECOUND TURRET TOOL NO./D200=

OP2102

OP2103 SELECT T** AND THAN PRESS CYCLE START

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

MACRO ALARM LIST.

MESSAGE NO. ALARM MESSAGE REMARK

ADDRESS

AL3001

Tapping W=0 (Renashaw RP3 O9014 )

AL3002

Tapping F=0 (Renashaw RP3 O9014 )

AL3003 W over (Renashaw RP3 O9014 )

AL3004 F over (Renashaw RP3 O9014 )

AL3005

AL3006

AL3007

AL3008

AL3030

AL3040

CATCHER&T-SETTER&CHUCK-ERR

AL3041

OBSTRUCT-POSITION-ERROR

AL3042 OBSTRUCT-TOOL-NUMBER-ERROR

AL3043 NEW-BAR-Z-POSITION-ERROR

OPERATION MANUAL

BNC/LT/T/HT SERIES

Version: 04 Date: April.16, 2012

MESSAGE NO. ALARM MESSAGE REMARK

ADDRESS

AL3050

TAILSTOCK PIN POSITION LOST

AL3051

TAILSTOCK GO TO POSITION

FAULT

AL3081

Illegal tool offset number

(FOR O9011,O9012)

AL3082

Illegal tool nose vector H

(FOR O9011,O9012)

AL3083 Input C and H1-H4 mixed

(FOR O9011,O9012)

AL3092

Probe open

Early touch on Tool setter Probe error

(FOR O9011,O9012)

AL3093

Probe FAUL

No touch on Tool setter Probe in stroke

(FOR O9011 ONLY)

AL3099 Broken tool

(FOR O9011 ONLY)

MICROCUT

BNC& LT SERIES

ELECTRICAL MANUAL

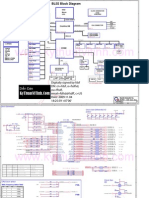

(FOR FANUC 0iTD/32iT/31iT)

SERIAL NO.:....

BUFFALO MACHINERY CO., LTD.

ADDRESS: No. 56, LANE 38, DER SHENG ROAD, TA YA,

TAICHUNG COUNTY, TAIWAN, R.O.C.

TEL : 886-4-25603759

FAX : 886-4-25603769

Manual Number :L00-5037-01-2

Date :04/30/2009

REV : 01

18IT-LE-00-01.DOC 10/8/2012 I I

CONTENTS

1. Announcement.1-1

2. Power supply of control system..2-1

2.1 Selection of power supply unit

2.2 Selection of power supply capacity

2.3 Selection of wire size

2.4 Selection of AC reactor

3. Design requirement.3-1

4. List of main power & protection parts ......4-1

5. Connection of main power..5-1

6. Wire diagrams.6-1

6-00 contents-overview

6-01 id. Code and graphical symbols description of item electric cabinet layout

6-04 electrical system connection diagram

6-05 three-phase main-power and motor circuit

6-07 power supply,spindle,servo module circuit

6-10 power supply for control circuit

6-11 AC single phase load circuit

DC loader circuit

6-19 NC I/O output circuit

6-25 NC I/O input circuit

6-31 emergency stop circuit

6-32 operators panel input circuit

6-41 operators panel output circuit

6-46 NC I/O power circuit

6-51` safety guard interlock switch circuit

6-52 NC power and power supply module interface

6-53 spindle drive interface

6-54 CRT interface

6-55 RS232 and I/O unit MPG interface

18IT-LE-00-01.DOC 10/8/2012 I I I

6-56 servo drive interface

6-57 servo turret motor and liner scale interface

6-59 grounding system diagram (for DC control circuit)

6-60 grounding system diagram (for AC control circuit)

6-61 electrical cabinet layout

6-62 terminal board layout

6-63 BARUFFALIDI TB turret connection

6-66 DUPLOMATIC TB turret connection

6-69 E4 type turret connection

6-71 HV8 type turret connection

6-73 portable MPG connection

6-74 tool probe/work piece probe connection

6-76 operation panel layout diagram

6-81 BAR FEEDER connection

7. Parts list...7-1

8. I/0 address scheme interpolation.8-1

9. EN 60204-1 : 2000 check list..9-1

18IT-LE-01-01.DOC 10/8/2012

1-1

1. Announcement

The specification and design of the electrical system of this machine complies

with EN60204-1: 2000

18IT-LE-02-01.DOC 10/8/2012

2-1

2. Power Supply of Controller System

2.1 Selection of Power Supply Unit

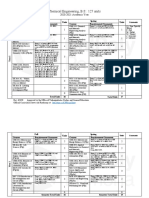

1. SPINDLE AND 2 AXES SERVO MOTOR SPECIFICATION FOR SERIES

FANUC 0iTC / 21iT /18iT - SERIES

MOTOR AMPLIFIER

MODEL

SPINDLE X&Z-AXIS (option)

POWER-

TURRET

SPINDLE X AND Y AXIS POWER

SUPPLY

(option)

POWER-

TURRET

AC

REACTOR

BNC-16/18

12i

/7000

12i /3000(X)

22i/2000(Z)

SVPM2-15i/A A81L - 0001

0156

BNC-30/35 A22i

/7000

12/3000i(X)

22/3000i(Z)

SPM-26i SVM2-

80/80i

PSM

30i

A81L - 0001

0158

A22i

/7000

12/3000i(X)

22/3000i(Z)

A3i

/10000

SPM-26i SVM2-

80/80i

PSM

37i

SPM 5.5i

B

A81L - 0001

0159

46T/LT42/L

T52/LT65

12i

/7000

12iB/3000(X)

12i/3000(Z)

SVPM2-15i/A A81L - 0001

0156

18IT-LE-02-01.DOC 10/8/2012

2-2

2. POWER SUPPLY MODULE (PSM)

TABLE 1

PSM

5.5i

PSM

11i

PSM

15i

PSM

26i

PSM

30i

PSM

37i

PSM

55i

PSM

11HV

i

PSM

18HV

i

PSM

30HV

i

PSM

45HV

i

PSM

75HV

i

PSM

100HVi

POWER SOURCE AC200/220V/230V, +10% -15% ,50 / 60Hz 1Hz 400~480VAC, +10% -15%, 50 / 60Hz 1Hz

POWER SOURCE

CAPACITY(KVA)

9 17 22 37 44 54 79 17 26 44 64

107 143

CONTROL

POWER

CAPACITY(KVA)

0.7

RATED

OUTPUT( KW)

5.5 11 15 26 30 37 55 11 18 30 45 75 100

MAX OUTPUT

(KW)

11 20 28 40 53 70 104 20 35 60 85 120 150

PEAK OUTPUT

(KW)

20 34 46 66 77 96 174 34 58 87 124 175 200

3.SPINDLE AMPLIFIER MODULS

TABLE 2

MODEL

ITEM

SPM - 2.2i SPM - 5.5i SPM 11i

SPM 15i SPM 22i SPM 26i

RATED OUTPUT (A) 13 27 48 63 95

111

RATED OUTPUT (KW) 2.2 5.5 11 15 22

26

MAX OUTPUT (KW) 2.64 6.6 13.2 18 26.4

31.2

APPLIED MOTOR

(EXAMPLE)

0.5/10000i

1/10000i

1.5/1000i

2/10000i

3/10000i

3/12000i

6/1000i&12000i

P12/6000i&8000i

8/8000i&1000i

1.5/15000i

12/7000i&10000i

P15/6000i&8000i

P18/6000i&8000i

2/15000i

P22/6000i&8000i

15/7000i&10000i

P30/6000i

18/7000i&10000i

T15/10000i

P40/6000i

22/7000i&

10000i

P50/6000i

T8/15000i

T22/10000i

OUTER DIMENSION

(H*W*D) mm

380*60*272

(OUTER DIMENSION II)

380*90*272 (OUTER DIMENSION III) 380*150*272

(OUTER DIMENSION IV)

MODEL

ITEM

SPM 30i SPM

45i

SPM

55i

SPM -

5.5HVi

SPM

11HVi

SPM

15HVi

SPM

30HVi

SPM

45HVi

SPM

75HVi

SPM

100HVi

RATED OUTPUT (A) 133 198 250 14 23 32 70 100 170 200

RATED

OUTPUT( KW)

30 45 55 5.5 11 15 30 45 75 100

MAX OUTPUT( KW) 36 54 66 6.6 13.2 18 36 54 90 120

APPLIED MOTOR

(EXAMPLE)

P60/4500i

T15/12000i

30i

40i

50i

0.5 HVi

1HVi

2HVi

3HVi

6HVi

8HVi

P15

HVi

15HVi

22HVi

P40HVi

P50HVi

30HVi

40HVi

P60HVi

60HVi 100HVi

OUTER DIMENSION

(H*W*D) mm

380*150*272

(OUTER

DIMENSION

IV)

380*300*272

(OUTER

DIMENSION V)

(OUTE

R

DIMEN

SION I)

380*60*272

(OUTER

DIMENSION

II)

380*90*272

(OUTER

DIMENSION IV)

380*150*272

(OUTER

DIMENSION V)

18IT-LE-02-01.DOC 10/8/2012

2-3

4. rated output and acceleration maximum output (kw) of spindle motors.

TABLE 3

Motor model Continuons rating 30 - minute rating Accelerating maximum

0.5/10000i 0.55 1.1(15-minute) 1.32

1/10000i 1.5 2.2(15-minute) 2.64

1/15000i 1.5 2.2(15-minute) 5.6

1.5/10000i 1.1 3.7(15-minute) 4.44

1.5/15000i 1.5 2.2(15-minute) 13.0

2/10000i 2.2 3.7(15-minute) 4.44

2/15000i 2.2 3.7(15-minute) 20.0

3/10000i 3.7 5.5 6.6

3/12000i 3.7 5.5 13.0

6/10000i&12000i 5.5 7.5 9.0

8/8000i&10000i 7.5 11.0 13.2

12/7000i&10000i 11.0 15.0 18.0

15/7000i&10000i 15.0 18.5 22.2

18/7000i&10000i 18.5 22.0 26.4

22/7000i&10000i 22.0 26.0 31.2

30/6000i 30.0 37.0 44.4

40/6000i 37.0 45.0 54.0

50/6000i 45.0 55.0 66.0

P12/6000i&8000i 5.5 7.5 12.3

P15/6000i&8000i 7.5 9.0 13.5

P18/6000i&8000i 9.0 11.0 15.1

P22/6000i&8000i 11.0 15.0 20.0

P30/6000i 15.0 18.5 25.0

P40/6000i 18.5 22.0 29.0

P50/6000i 22.0 30.0 35.4

P60/4500i 22.0 30.0 36.0

T8/15000i 11.0 15.0 28.0

T15/10000i 15.0 18.5 22.2

T15/12000i 15.0 18.5 38.0

T22/10000i 22.0 26.0 31.2

Notes

The values given for the accelerating maximum outputs are for reference only and are not

guaranteed values.

18IT-LE-02-01.DOC 10/8/2012

2-4

5. CONTINUOUS RATED OUTPUT AND ACCELERATING MAXIMUM OUTPUT (KW)

OF SERVO MOTORS

TABLE 4

Motor model Continuous rating Accelerating maximum

1 / 5000i 0.5 2.0

2 / 5000i 0.75 2.9

4 / 4000i 1.4 4.5

8 / 3000i 1.6 5.7

12 / 3000i 3.0 7.6

22 / 3000i 4.0 9.6

30 / 3000i 7.0 21

40 / 3000i 6.0 18.0

40 / 3000i (with fan) 9.0 18.0

M2 / 5000i 0.75 2.8

M3 / 5000i 1.0 3.1

M8 / 4000i 2.5 8.0

M12 / 4000i 2.7 12.0

M22 / 4000i 4.5 17.0

M30 / 4000i 5.5 22.0

M40/ 4000i 5.5 24.0

M50/ 3000i+FAN 14 39

M100/ 2500i 11 38

M2000/ 2500i 20 48

M300/ 2000i 37 96

M500/ 2000i 50 104

C4 / 3000i 1.0 2.3

C8 / 2000i 1.2 3.2

C12 / 2000i 1.8 2.6

C22 / 2000i 3.0 6.2

C30 / 1500i 4.2 8.7

Notes

The values given for the accelerating maximum outputs are for reference only and are not

guaranteed values.

18IT-LE-02-01.DOC 10/8/2012

2-5

6. SELECTION OF POWER SUPPLY MODULE

Please calculate rated output capacity and maximum output capacity of power supply

module according to following method. And please select power supply model as they

satisfy following conditions.

(1) CALCULATION OF RATED OUTPUT CAPACITY OF POWER SUPPLY MODULE

Rated output capacity of power supply module is fixed by following expression.

(2) CALCULATION OF MAXIMUM OUTPUT CAPACITY OF POWER SUPPLY

MODULE

If rated output capacity is less than 11KW, then please calculate maximym output capacity of

power supply module according to item (2.1) More than 12KW, then calculate according to

item (2.2).

Please refer to table1 for rated output capacity of power supply module, refer to table2 for

continuous rated output capacity of spindle motor and refer to table3 for continuous rated

output capacity of servo motor.

(2.1) For A Rated ouutput capacity of 11KW or less

If calculate is more than 20KW, then calculate according to item again.

(2.2) For A Rated output capacity of 12KW or more.

Please refer to table1 for maximum output capacity of power supply module, refer to

table2 for maximum output of spindle motor and refer to one power supply module.

Connectable number of module are fixed by following table.

SPM

SVM

SVM1 SVM2 SVM3

2 6

4

3

Connectable number of module

(This is the example when two

SPMs are connected.)

An occasion when only one SPM is connected to SPM.

Rated output capacity (Continuous rated output of spindle motors) 1.15

of

power supply module (Continuous rated output of servo motors) 0.6

Maximum output capacity (Accelerating Maximum output of spindle motor) 1.15

of + (Accelerating Maximum output of servo motor) 0.6

power supply module ( for simultaneous acceleration/decceleration axis)

Maximum output capacity (Accelerating Maximum output of spindle motor)

of + (Accelerating Maximum output of servo motor)

power supply module ( for simultaneous acceleration/decceleration axis)

When various axis type SVMs are connected,

connectable number of SVM fixed by following

number of SVM11

number of SVM21.5 6

number of SVM32

18IT-LE-02-01.DOC 10/8/2012

2-6

Rated output capacity of power supply module is fixed following inequality.

(3) BNC-16/18 CASE : SPINDLE MOTOR 6i, SERVO MOTOR 8 / 3000i *1

12/ 3000i *1,POWER MOTOR 2i

Spindle motor 6/7000i conte. rated output : 7.5KW

maximum output : 13.2KW

Servo motor 8 / 3000i conte. rated output : 1.6KW

maximum output : 5.7KW

Servo motor 12 / 3000i conte. rated output : 3.0KW

maximum output : 7.6KW

POWER motor 2/10000i conte. rated output : 2.2KW

maximum output : 4.44KW

Rated output capacity of power supply module

cont. rated output of spindle motor1.15 + cont. rated output of servo motor0.6

=((7.5+2.2)*1.15) +[(1.6+3)*0.6]=13.43--------------- (1)

Maximum output capacity of power supply module

maximum output of spindle motor +

maximum output of servo motor (which accelerate / decelerate at the same time)

=(13.2+4.44) +(5.7+7.6) =30.94--------------- (2)

PSM 15i is selected by condition (1) and (2)

Rated output capacity of PSM 30 min. rated output of spindle motor

18IT-LE-02-01.DOC 10/8/2012

2-7

7. SELECTION OF POWER SUPPLY MODULE for SVPM*-5.5i~15i

(1)[How to obtain a power supply capacity]

-output capacity-

-output capacity-

(2)-power supply capacity-

SVPM*-5.5i

Power supply capacity(KVA)=output capacity (KW)*1.64

SVPM*-11i

Power supply capacity(KVA)=output capacity (KW)*1.55

SVPM*-15i

Power supply capacity(KVA)=output capacity (KW)*1.47

(3) LT42 CASE : SPINDLE MOTOR 12i/7000, SERVO MOTOR 12 / 3000i *1

12/ 3000i *1,

Spindle motor 6/7000i conte. rated output : 11KW

Servo motor 12 / 3000i conte. rated output : 1.8KW

Servo motor 12 / 3000i conte. rated output : 1.8KW

Rated output capacity of power supply module

cont. rated output of spindle motor1.15 + cont. rated output of servo motor0.6

=(11*1.15) +[(1.8+1.8)*0.6]=14.8--------------- (1)

Maximum output capacity of power supply module

SVPM*-15i

Power supply capacity(KVA)=(14.8KW)*1.47=21.7(KVA)

Maximum output capacity (Accelerating Maximum output of spindle motor) 1.15

of + (Accelerating Maximum output of servo motor) 0.6

power supply module ( for simultaneous acceleration/decceleration axis)

18IT-LE-02-01.DOC 10/8/2012

2-8

:standard package

MODEL

SPINDLE (KW) POWER

-AXIS

(KW)

X-AXIS (KW) Z-AXIS

(KW)

BNC-16/18

/22/26

12i/7000 11(Con.) 12iB/3000 1.8(Con.) 12i/3000 1.8(Con.)

=(11*1.15) +((1.8+1.8)*0.6)=14.8-- (1)

SVPM2 15i is selected by condition (1)

BNC-30/35 A22i/7000 22(Con.)

31.2(30MIN)

12/3000i

3(Con.)

7.6(max.)

22/3000i

4(Con.)

9.6(max.)

=[22*1.15) +(3+4)*0.6])=29.5-- (1) =31.2+7.6+9.6 =48.4---- (2)

PSM 30i is selected by condition (1) and (2)

BNC-30/35

WITH

POWER

TURRET

A22i/7000 22(Con.)

31.2(30MIN)

3/10000i 3.7(Con.)

6.6(max.)

12/3000i

3(Con.)

7.6(max.)

22/3000i

4(Con.)

9.6(max.)

=((22+3.7)*1.15) +((3+4)*0.6])=33.75-- (1) =31.2+6.6+7.6+9.6 =55---- (2)

PSM 37i is selected by condition (1) and (2)

46T/LT42

/LT52/LT65

12i/7000 11(Con.) 12i/3000 1.8(Con.) 22i/2000 1.8(Con.)

=(11*1.15) +((1.8+2.5)*0.6)=15.2-- (1)

SVPM2 15i is selected by condition (1)

18IT-LE-02-01.DOC 10/8/2012

2-9

2.2 Selection of Power Supply Capacity

The power supply capacity reference values for the power supply unit selected in section 3.1 are

as follow :

2.2.1.

Power Supply Module

Table 2.2.1 Power Supply Module

PSM

5.5i

PSM

11i

PSM

15i

PSM

26i

PSM

30i

PSM

37i

PSM

55i

PSM

11HV

i

PSM

18HV

i

PSM

30HV

i

PSM

45HV

i

PSM

75HV

i

PSM

100HVi

POWER SOURCE AC200/220V/230V, +10% -15% ,50 / 60Hz 1Hz 400~480VAC, +10% -15%, 50 / 60Hz 1Hz

POWER SOURCE

CAPACITY(KVA)

9 17 22 37 44 54 79 17 26 44 64

107 143