Professional Documents

Culture Documents

Innovation in Long Span Concrete Bridges

Uploaded by

monolith80Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innovation in Long Span Concrete Bridges

Uploaded by

monolith80Copyright:

Available Formats

Innovation in Long Span Concrete Bridges

Akio KASUGA

Technical Director

Sumitomo Mitsui Construction

Tokyo, JAPAN

akasuga@smcon.co.jp

Space for a portrait

32 x 48 mm

Akio Kasuga, born in 1957, received

his civil engineering degree from the

Kyushu University, Japan. He has

been working for Sumitomo Mitsui

Construction as a bridge designer

since 1980. He is a deputy president

of the Japan Prestressed Concrete

Institute and the invited member of

fib Technical Council.

1. Introduction

There has already been a great deal of innovation in long span concrete bridges, but is there still

scope for further innovation? Today, most of the obvious solutions have already been tried, and

concrete long span bridges typically take the form of cable-stayed bridges or arch bridges. In Japan,

where 75% of the terrain is mountainous, long arch bridges have an extensive history. This paper

includes a new conceptual approach for half-through arch bridges, and proposes a solution that can

produce economic and easy-to-build arch bridges.

Japan was also the location for the worlds first extradosed bridge, the Odawara Blueway Bridge

constructed in 1994, which marked the debut of a structural form that could cover span lengths for

which cable-stayed bridges are uneconomic. This represented a major innovation in thinking about

the design of stays. Cable-stayed bridges and external-cable structures could be conceived as points

on the same continuum when determining the maximum allowable stress for stays. Taking this

approach enables the use of stays with allowable stress in a continuous range between 0.4f

pu

and

0.6f

pu

. Moreover, the allowable stress can be determined according to the range of live load stresses

in the cables. Instead of the conventional approach of stipulating a single value of allowable stress

for the whole structure, the structure could be designed with different values for each stays. This

design method was formalized in Japans specifications for highway bridges, enabling engineers to

produce more rational designs for stays.

Innovation in cable-stayed bridges and extradosed bridges consists of finding ways to make the

main girders lighter. Recently, there has been remarkable progress in composite structures that

permit lighter main girders, including the successful construction of many corrugated steel web

bridges and composite truss bridges. Further progress is now being made in Japan with the

construction of bridges using a new form of composite structure, the butterfly web. Butterfly web

structures use panels of steel or fiber reinforced concrete as an alternative to a double warren truss,

and make it possible to achieve a similar level of lightness to corrugated steel web bridges. This

paper presents a number of initiatives to reduce the weight of cable supported bridges, focusing

mainly on Japan, in the hope of providing ideas for further innovation.

2. Long Span Half-through Arch Bridges

The half-through arch bridge is an extremely attractive structure, but it has tended to be avoided due

to the difficulty of construction. In the new concept for half-through arch bridges introduced in this

paper, the deck is used as one part of the arch structure, and this resolves several issues. Connecting

the deck to the arch causes the axial force of the arch to pass to this section. In such cases, the lower

section arch and deck are constructed first, allowing the upper section arch to then be constructed

on top of the deck. In the case of a single plane arch, a certain portion of the axial force is passed to

the deck, enabling the arch placed between the outbound and inbound lanes to be reduced in size

and simplifying the suspension details. Out of consideration for erection, a corrugated steel web

design is suitable for the deck structure in such cases.

3. Long Span Cable Supported Bridges

Reducing the weight of the superstructure is the key to innovation in long span bridges supported

by cables. The reason is that this approach enables stiffness to be increased without increasing

girder weight. Lighter weights are enabled by using stronger concrete or designing composite

structures. In pursuing such designs, it is important to explore how to attain an optimum overall

solution for the whole composite structure when determining the extent of use and strength of steel

members and costly high-strength materials. Some examples of composite girder construction are

given in this paper.

Extradosed bridges have become popular structures for spans of 150m-250m, taking a place

between conventional girder bridges and longer cable-stayed bridges. However, it is useful to

consider whether using extradosed bridges for longer spans would be structurally and economically

feasible. Consequently, we will investigate whether the technologies for producing lighter main

girders described above have the potential to enable the construction of longer spans.

We consider a cable-stayed bridge with a central span of 435m, and compare it with an extradosed

bridge having the same span length but with shorter main towers, about 60% of the height of the

towers for the cable-stayed bridge. The girder cross-section is 3.5m high in the cable-stayed type

bridge, and 5.5m in the extradosed type, using a single plane of stay cables and struts inside the box

girder. The cable-stayed bridge uses a conventional box girder, but the extradosed bridge uses a

butterfly web to counter the increase in weight due to the larger girder height. Consequently, the

superstructure weight is unchanged, but the stiffness of the main girder is doubled. Japanese

standards permit a maximum allowable stress of 0.6f

pu

for stay cables, even for this sort of long

span extradosed bridge. The number of cables required is about 20% more than for the cable-stayed

bridge, but because the weight reduction technology has produced a stiffer main girder without an

increase in weight, the main towers can be shorter, which makes this structure very competitive in

earthquake-prone Japan. This demonstrates that a long span extradosed bridge with reduced weight

main girder is feasible.

4. Conclusions

This paper examined the scope for further innovation in long span concrete bridges. It has

introduced an innovative long span half-through arch bridge concept, and demonstrated the

feasibility of long span cable supported structures, particularly extradosed bridges. The half-through

arch bridge is structurally elegant, and can be easily constructed by ensuring that arch action also

acts on the main girder in the central section. This structure enables a design with a large arch rise,

making it more economical than conventional arch bridges.

It is clear that there is still potential for innovation in long span cable-stayed bridges and extradosed

bridges by using composite structures to reduce the weight of the main girder. A number of cable

supported structures using a composite structure have already been realized. The paper has also

shown that efficient composite truss designs can be constructed by using an optimized mix of

concrete and steel in combination with a cable supported structure. Furthermore, use of the butterfly

web, an innovative structure, provides many benefits for maintenance as well as weight reduction. It

can produce sustainable structures that are more durable than other composite structures and

provide substantial reduction of maintenance costs. In mechanical terms, a composite bridge can be

an extremely rational structure.

This sort of emergence of new materials is another major driver of innovation. I firmly believe that

girder weight reduction from concrete bridges and structural challenges will lead to a new

generation of innovation.

Fig.29: Bending Moment Diagram

You might also like

- Recent Technology of Prestressed Concrete Bridges in Japan PDFDocument10 pagesRecent Technology of Prestressed Concrete Bridges in Japan PDFYuli Ana Fransisca SantanaNo ratings yet

- Historical View of Bridge AerodynamicsDocument18 pagesHistorical View of Bridge Aerodynamicsmahe32maheNo ratings yet

- Y-Shaped Pylon Extradosed Bridge with High-Strength ConcreteDocument4 pagesY-Shaped Pylon Extradosed Bridge with High-Strength ConcreteSimone Bertola100% (1)

- Segmental Post-Tensioned BridgesDocument7 pagesSegmental Post-Tensioned BridgesAnonymous Gd0PTUQNo ratings yet

- Approach For Steel BridgesDocument51 pagesApproach For Steel BridgesRuri NguyenNo ratings yet

- Construction Process of Segmental BridgesDocument47 pagesConstruction Process of Segmental BridgesmnsawantNo ratings yet

- Finite Element Analysis of Segmental BridgesDocument7 pagesFinite Element Analysis of Segmental BridgesAbu Bidu100% (1)

- Segmental ConstructionDocument9 pagesSegmental Constructionmanoj_mousamNo ratings yet

- Shear Performance Analysis Tapered Beam-Resal PDFDocument11 pagesShear Performance Analysis Tapered Beam-Resal PDFp rNo ratings yet

- Aerial Structure Design Guide for Light Rail SystemsDocument90 pagesAerial Structure Design Guide for Light Rail SystemsTony SiNo ratings yet

- First Prs EditedDocument38 pagesFirst Prs EditedMathew SebastianNo ratings yet

- Effect of Torsion On Externally Prestressed Segmental Concrete Bridge With Shear Key PDFDocument7 pagesEffect of Torsion On Externally Prestressed Segmental Concrete Bridge With Shear Key PDFVinothAyyasamyNo ratings yet

- Genuine Concrete Bridges Mega Projects?Document9 pagesGenuine Concrete Bridges Mega Projects?harsha_civilNo ratings yet

- Effect of Torsion On Externally Prestressed Segmental Concrete BridgeDocument7 pagesEffect of Torsion On Externally Prestressed Segmental Concrete Bridgepmullins_11No ratings yet

- EPF Building Fire: Did The Grenfell Tragedy Nearly Happen Here?Document2 pagesEPF Building Fire: Did The Grenfell Tragedy Nearly Happen Here?Sopi Labu100% (1)

- A Critical Analysis of The Donghai Bridge, ShanghaiDocument10 pagesA Critical Analysis of The Donghai Bridge, ShanghaiPunithan PunithanNo ratings yet

- CPCI PCI Bridge Design Manual PresentationDocument81 pagesCPCI PCI Bridge Design Manual PresentationmikefaraNo ratings yet

- Comparative Study of Seismic Analysis of Bridge Substructure in Different Seismic Zones As Per IRC GuidelinesDocument9 pagesComparative Study of Seismic Analysis of Bridge Substructure in Different Seismic Zones As Per IRC GuidelinesIJRASETPublicationsNo ratings yet

- Text 2010-10-28 Millau ViaductDocument132 pagesText 2010-10-28 Millau Viaductfuafuafua100% (1)

- Study On Economic Partnership Projects in Developing Countries in FY2007Document22 pagesStudy On Economic Partnership Projects in Developing Countries in FY2007ras_deepNo ratings yet

- Bai Chay 2Document3 pagesBai Chay 2Anh NguyenNo ratings yet

- Evolution of Bridge TechnologyDocument17 pagesEvolution of Bridge TechnologyPaniraju Narayanappa BellurNo ratings yet

- Bridge Design Guide Eurocode ImplementationDocument30 pagesBridge Design Guide Eurocode ImplementationPaul Hardin100% (1)

- Simply Supported Composite Railway Bridge: A Comparison of Ballasted and Ballastless Track AlternativesDocument175 pagesSimply Supported Composite Railway Bridge: A Comparison of Ballasted and Ballastless Track AlternativesdeathesNo ratings yet

- Bridge Construction Practices Using Incremental Launching PDFDocument14 pagesBridge Construction Practices Using Incremental Launching PDFFia Putri100% (1)

- The Causes of Shear Cracking in Prestressed Concrete Box Girder BridgesDocument10 pagesThe Causes of Shear Cracking in Prestressed Concrete Box Girder Bridgesw1000000No ratings yet

- SB6.1 Guideline STR PDFDocument137 pagesSB6.1 Guideline STR PDFBianca ZahariaNo ratings yet

- Taller, Longer, Lighter: Meeting Growing Demand with Limited ResourcesDocument6 pagesTaller, Longer, Lighter: Meeting Growing Demand with Limited ResourcesAmuana RalteNo ratings yet

- Øresund Bridge, Sweden and Denmark: Case Study 49Document5 pagesØresund Bridge, Sweden and Denmark: Case Study 49Hermann LoweNo ratings yet

- Horizontal Construction JointsDocument18 pagesHorizontal Construction JointsPremasiri KarunarathnaNo ratings yet

- Design and Construction of Frank Gehry Bridge. First Access To The New Island of Zorrotzaurre in Bilbao, SpainDocument9 pagesDesign and Construction of Frank Gehry Bridge. First Access To The New Island of Zorrotzaurre in Bilbao, SpainMiguel Sacristán100% (1)

- Bridge Design in FinlandDocument10 pagesBridge Design in Finlandअरुण कुमार सोनीNo ratings yet

- A Critical Analysis of Kylesku BridgeDocument10 pagesA Critical Analysis of Kylesku BridgeVeenoy DabeeNo ratings yet

- Pwi Journal 0120 Vol138 pt1 Rail Stress Track-Bridge InteractionDocument4 pagesPwi Journal 0120 Vol138 pt1 Rail Stress Track-Bridge InteractionGanesh PrasannaNo ratings yet

- 03 12 General Design Design of Integral Bridges PDFDocument15 pages03 12 General Design Design of Integral Bridges PDFshardasiddhNo ratings yet

- Cable Stays of Cable-Stayed Bridges (T 5140.25)Document9 pagesCable Stays of Cable-Stayed Bridges (T 5140.25)Mohamed BahgatNo ratings yet

- Third Karnaphuli Bridge: David AstinDocument32 pagesThird Karnaphuli Bridge: David AstinJoy ChowdhuryNo ratings yet

- Long Span Bridge Health Monitoring System in Japan PDFDocument8 pagesLong Span Bridge Health Monitoring System in Japan PDFblukututNo ratings yet

- Staggered Truss System - Wikipedia, The Free EncyclopediaDocument3 pagesStaggered Truss System - Wikipedia, The Free EncyclopediashawnideaNo ratings yet

- Large-Scale Testing of Steel Reinforced Concrete (SRC) Coupling BeamsDocument21 pagesLarge-Scale Testing of Steel Reinforced Concrete (SRC) Coupling BeamsMREFAATNo ratings yet

- Example Plate Girder - Example 2Document11 pagesExample Plate Girder - Example 2kumutha100% (1)

- Austroads - AP-R445-13 - Standardised Bridge Barrier Design PDFDocument239 pagesAustroads - AP-R445-13 - Standardised Bridge Barrier Design PDFdjay101No ratings yet

- 2011 Bridge SarkadyDocument17 pages2011 Bridge SarkadyTan Duy LeNo ratings yet

- BridgesDocument3 pagesBridgesShah KhanNo ratings yet

- New Trends in Prestressed Concrete BridgesDocument35 pagesNew Trends in Prestressed Concrete BridgesdrozgurbezginNo ratings yet

- Extradosed BangladeshDocument16 pagesExtradosed BangladeshSimone BertolaNo ratings yet

- Chapter05 - Plane Frame and Grid EqDocument63 pagesChapter05 - Plane Frame and Grid EqAgus BaeNo ratings yet

- 0 6729 1Document192 pages0 6729 1lamkinpark3373No ratings yet

- Means and Methods Analysis of A Cast in Place Balanced Cantilever Segmental BridgeDocument302 pagesMeans and Methods Analysis of A Cast in Place Balanced Cantilever Segmental BridgeEnocHernandez0% (1)

- 3rd Bosphorus Bridge. Michel Virlogeux.Document66 pages3rd Bosphorus Bridge. Michel Virlogeux.Muhammad Umar RiazNo ratings yet

- 03.03 - General Design - Design Rules For Aerodynamic Effects On Bridges - BD 49-01Document34 pages03.03 - General Design - Design Rules For Aerodynamic Effects On Bridges - BD 49-01Oscar Mendoza100% (1)

- Ba3993 Assesment of Reinforced Concrete Half-JointedDocument22 pagesBa3993 Assesment of Reinforced Concrete Half-JointedvaleNo ratings yet

- WARREN Hulme Bridge, ManchesterDocument10 pagesWARREN Hulme Bridge, ManchesterJay KennedyNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Prestressed Concrete Bridges PDFDocument8 pagesPrestressed Concrete Bridges PDFedisonmalahitoNo ratings yet

- Analyzing cable-stayed bridges using STAAD Pro softwareDocument5 pagesAnalyzing cable-stayed bridges using STAAD Pro softwareMananNo ratings yet

- Cable Stayed Bridges ExplainedDocument31 pagesCable Stayed Bridges ExplainedArmus MarsNo ratings yet

- Shrinkage Effect On Beams Strengthened With Additional Concrete LayersDocument2 pagesShrinkage Effect On Beams Strengthened With Additional Concrete Layersmonolith80No ratings yet

- Shear Behaviour of Reinforced Concrete Members Without Stirrups and SubjectedDocument2 pagesShear Behaviour of Reinforced Concrete Members Without Stirrups and Subjectedmonolith80No ratings yet

- PE Registration Document in Oregon U.SDocument18 pagesPE Registration Document in Oregon U.Smonolith80No ratings yet

- New football stadium roof in Saint-Petersburg analyzed using superelements and incremental launchingDocument2 pagesNew football stadium roof in Saint-Petersburg analyzed using superelements and incremental launchingmonolith80No ratings yet

- High-Rise Buildings With Transfer Floors: Drift CalculationsDocument2 pagesHigh-Rise Buildings With Transfer Floors: Drift Calculationsmonolith80100% (1)

- Long-Term Monitoring of White Rhino, Building With Tensegrity SkeletonsDocument9 pagesLong-Term Monitoring of White Rhino, Building With Tensegrity Skeletonsmonolith80No ratings yet

- Rehabilitation and Upgrading of Major Dhyan Chand National StadiumDocument2 pagesRehabilitation and Upgrading of Major Dhyan Chand National Stadiummonolith80No ratings yet

- Metropol Parasol, Plaza de La Encarnación - Adventures in EngineeringDocument2 pagesMetropol Parasol, Plaza de La Encarnación - Adventures in Engineeringmonolith80No ratings yet

- Challenges in Implementing Urban Transport Projects in MumbaiDocument2 pagesChallenges in Implementing Urban Transport Projects in Mumbaimonolith80No ratings yet

- Poverty Alleviation Through Bridge BuildingDocument2 pagesPoverty Alleviation Through Bridge Buildingmonolith80No ratings yet

- Evaluation of Damage Equivalent Factor For Roadway BridgesDocument8 pagesEvaluation of Damage Equivalent Factor For Roadway Bridgesmonolith80No ratings yet

- Fifty Years of Bridge HistoryDocument10 pagesFifty Years of Bridge Historymonolith80No ratings yet

- A Fast Incremental-Iterative Procedure For Ultimate Strength Analysis of Composite Cross-Sections With Arbitrary ShapeDocument8 pagesA Fast Incremental-Iterative Procedure For Ultimate Strength Analysis of Composite Cross-Sections With Arbitrary Shapemonolith80No ratings yet

- Prestressed Concrete Girder Bridges Using Large 0.7 Inch StrandsDocument8 pagesPrestressed Concrete Girder Bridges Using Large 0.7 Inch Strandsmonolith80No ratings yet

- An Analysis of Binary Flutter of Bridge Deck SectionDocument12 pagesAn Analysis of Binary Flutter of Bridge Deck Sectionmonolith80No ratings yet

- Suppression of Wind Induced Instabilities of A Long Span Bridge by A Passive Deck Flaps Control System - Part 1 Formulation - 2000Document19 pagesSuppression of Wind Induced Instabilities of A Long Span Bridge by A Passive Deck Flaps Control System - Part 1 Formulation - 2000monolith80No ratings yet

- Construction of The La Plata Twinstar DomeDocument7 pagesConstruction of The La Plata Twinstar Domemonolith80No ratings yet

- SS1 - 1 Chakraborty - LONG PDFDocument7 pagesSS1 - 1 Chakraborty - LONG PDFmonolith80No ratings yet

- Nonliner Dynamics of Cable Stays - Part 1 - Sinusoidal Cable Support Excitation - 2005Document28 pagesNonliner Dynamics of Cable Stays - Part 1 - Sinusoidal Cable Support Excitation - 2005monolith80No ratings yet

- Hurricane Wind Power Spectra, Cospectra, and Integral Length ScalesDocument20 pagesHurricane Wind Power Spectra, Cospectra, and Integral Length Scalesmonolith80No ratings yet

- Computational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011Document11 pagesComputational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011monolith80No ratings yet

- Aerodynamic Problems of S Super-Long Span Cable-Stayed Bridge - IABSE 2005Document8 pagesAerodynamic Problems of S Super-Long Span Cable-Stayed Bridge - IABSE 2005monolith80No ratings yet

- Bridge Design Manual M 23-50.06 July 2011Document1,316 pagesBridge Design Manual M 23-50.06 July 2011monolith80No ratings yet

- Computational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011Document11 pagesComputational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011monolith80No ratings yet

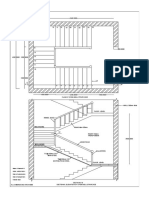

- Stair Detail PlanDocument1 pageStair Detail PlanJohn Rhey Almojallas BenedictoNo ratings yet

- Time Table of Night Bus ServicesDocument9 pagesTime Table of Night Bus ServicesmingdiNo ratings yet

- Installation and safety devices of escalatorsDocument2 pagesInstallation and safety devices of escalatorsRuchira Anand PimpalkhuteNo ratings yet

- (Asce) 1084 0702 (1999) 4 3 (151) - 2Document6 pages(Asce) 1084 0702 (1999) 4 3 (151) - 2Hamdi Yoga PratamaNo ratings yet

- Stair tread, riser, and rail implementation detailsDocument10 pagesStair tread, riser, and rail implementation detailsjohnNo ratings yet

- UNIT-2 (Lecture-3) Types of BridgesDocument41 pagesUNIT-2 (Lecture-3) Types of BridgesMd Sabbir HossainNo ratings yet

- Jeppview For Windows: General Information General InformationDocument22 pagesJeppview For Windows: General Information General InformationAfner OtnielNo ratings yet

- DLR Route MapDocument1 pageDLR Route MapStefcsik GáborNo ratings yet

- Pages From LSL - Stair Stringers and TreadsDocument1 pagePages From LSL - Stair Stringers and TreadsViNo ratings yet

- Ms Takrish Sajrini MeghaDocument2 pagesMs Takrish Sajrini Meghatakrish sajrini meghaNo ratings yet

- VSL - Puente Unidad MexicoDocument2 pagesVSL - Puente Unidad MexicohedyNo ratings yet

- Wass (Soq) - Domine Eduard OsokDocument10 pagesWass (Soq) - Domine Eduard OsokAbang FayyadNo ratings yet

- Types of BridgesDocument5 pagesTypes of BridgesNavanee LakshmiNo ratings yet

- Baseline Projections 2021-2024Document1 pageBaseline Projections 2021-2024NAVEEN SNo ratings yet

- LidoDocument8 pagesLidofgffgfgNo ratings yet

- English DictDocument19 pagesEnglish DictFernando LimaNo ratings yet

- Composite Steel-Concrete Cable-Stayed Bridges - SEMC2013Document7 pagesComposite Steel-Concrete Cable-Stayed Bridges - SEMC2013Miguel PerezNo ratings yet

- Judgement On FunicularDocument9 pagesJudgement On FunicularAnirudh JaswalNo ratings yet

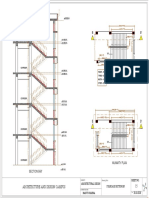

- Architecture and Design Campus 15: Architectural Design Sheet NoDocument1 pageArchitecture and Design Campus 15: Architectural Design Sheet NoManvi SharmaNo ratings yet

- Perencanaan Jembatan Gantung 100 MeterDocument10 pagesPerencanaan Jembatan Gantung 100 MeterOkta Candra GunawanNo ratings yet

- Completed: Name Length Main Span Completed Traffic Country M FT M FTDocument2 pagesCompleted: Name Length Main Span Completed Traffic Country M FT M FTSuresh g.s.No ratings yet

- Oka River On The Bypass of Murom City - TransmostDocument1 pageOka River On The Bypass of Murom City - TransmostAyman ShamaNo ratings yet

- Evidence of Failures of Bridges and Viaducts RIDDocument73 pagesEvidence of Failures of Bridges and Viaducts RIDFranco BontempiNo ratings yet

- LTR No.137 Water ReportDocument2 pagesLTR No.137 Water ReportLACHMOLI BRIDGE NO. 8No ratings yet

- 2023.05.24 - Magway Win Fertilizer - Stair Handrail DetailsDocument1 page2023.05.24 - Magway Win Fertilizer - Stair Handrail DetailsKyaw Pyae ThanNo ratings yet

- Internship Log Sheet Kwasi BempongDocument9 pagesInternship Log Sheet Kwasi BempongKwasi BempongNo ratings yet

- Open Well Staircase Plan and SectionDocument1 pageOpen Well Staircase Plan and SectionDhanush RNo ratings yet

- Truss BridgeDocument13 pagesTruss BridgeRahul ChandraNo ratings yet

- Staircase II Full Tread BifurcatedDocument1 pageStaircase II Full Tread BifurcatedStuti ParikhNo ratings yet

- Baseline S CurveDocument6 pagesBaseline S CurveGodfrey EmilioNo ratings yet