Professional Documents

Culture Documents

Design

Uploaded by

korosh750 ratings0% found this document useful (0 votes)

30 views23 pagesReliability facility in design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentReliability facility in design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views23 pagesDesign

Uploaded by

korosh75Reliability facility in design

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 23

A SunCam online continuing education course

Reliability in Facility Design

by

Daniel L. Spradling, P.E.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 2 of 23

Course Description:

The purpose of this training seminar is to familiarize the student with typical RELIABILITY

design criteria and their application to the facilities and buildings system industry. This seminar

provides high level orientation for the architect or engineer with ample references for deeper

study.

The learning objective is to provide the design professional instruction on RELIABILITY design

philosophies within facilities. This seminar has a healthy dose of core multi discipline

information to orient the designer toward thinking holistically about RELIABILITY.

No outside resource materials or prerequisite courses are required. This is not a formulistic

seminar and calculations are not necessary. The technical topic is presented in a narrative manner

and hopefully, in a thought provoking style. Although some facilities and building systems

knowledge is helpful, general definitions and examples are included.

As with any continuing education course, this document is a living document. Any and all

feedback, recommendations and correctional input is greatly appreciated. Updated photographs,

examples and commentary are beneficial to all.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 3 of 23

Course Outline:

Introduction

Definitions and Terms

RELIABILITY Design

RELIABILITY Classification

Class I

Class II

Class III

Facility Design Criteria

Design for Maintenance and Repair

Robust Design versus Over-Design

Design for Access and Handling

Summary and Review

Further Study and Reference

Examination

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 4 of 23

Introduction:

The intent of this seminar is to augment the Federal, State, Regional, and Local Design

Guidelines for facilities with regard to code required minimum standards with thought provoking

ideas concerning RELIABILITY for building systems and their components.

A healthy discussion on definitions and terms common to reliability will be included. This

portion is to aid the diverse architectural and engineering disciplines associated with facilities

and building systems with the terminology of the RELIABILITY design criteria.

One term of high importance is RELIABILITY. RELIABILITY will be defined and its

classifications will be discussed. Examples of each classification will be included. The

RELIABILITY design criteria will then be transposed upon the facilitys design. Items such as

location, expansion, systems, and maintenance will be presented.

The next step is application of the RELIABILITY principles on to the facility design. Specific

topics such as listed below will be presented using a RELIABILITY CENTERED DESIGN

basis.

Design for Maintenance and Repair

Robust Design versus Over-Design

Design for Access and Handling

Finally, an examination on the course content will be included.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 5 of 23

Definitions:

RELIABILITY A measurement of the ability of a component to perform its designated

function without failure. RELIBILITY pertains to system components and the maintainability of

those components.

REDUNDANCY - simply having a backup. The backup can be a component or can also be a

plan. Basically, redundancy gives the facility the ability to operate when any single component

fails without harming the operational function of the facility. A prime example is a power

generator. Typically, the generator is a redundant power source to the local utility.

MARGIN - the difference between the capacity of a building system and the actual usage. An

elevator may have the capacity of 2500 pounds, but may only be used for typically lifting 1000

pounds. The margin is the difference.

HVAC acronym. HVAC is the acronym for Heating Ventilation and Air Conditioning.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 6 of 23

RELIABILITY Design:

RELIABILITY design is a field that designs with the ability of a system or component to

perform its required functions. RELIABILITY is often measured with terms such as probability

of failure, mean time between failures, measure of availability, and maintainability.

RELIABILITY design for complex systems requires a more elaborate systems approach than

RELIABILITY for a simpler system. RELIABILITY designers should have broad skills and

knowledge of the processes within a facility. Most industries do not have specialized

RELIABILITY designers, and the RELIABILITY task becomes a part of the design

architect/engineers responsibility.

Basically, RELIABILITY design is mainly concerned with costs. It relates events that transform

into a particular level of revenue loss for the client. These costs can be due to loss of production,

loss of use, man-hours, etc. Any event that keeps a facility from properly operating is costing the

client and needs to be remediated. It is the function of the RELIABILITY designer to minimize

these events, and thus minimize the costs.

RELIABILITY design is an emerging discipline that refers to the process of including

RELIABILITY into products and systems. One of the most important design techniques is

redundancy or backup. This means that if one part of the system fails, there is an alternate path,

such as a backup system. The reason why this is the preferred choice is related to the fact that to

provide absolute RELIABILITY is often very costly. By creating redundancy, along with a high

level of control and the avoidance of common mode failures, any system can be made reasonably

reliable to the task.

Typically, RELIABILITY is classified into three main categories.

Class I High RELIABILITY

Class II Medium RELIABILITY

Class III Low RELIABILITY

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 7 of 23

RELIABILITY Classification:

Generally, facilities have RELIABILITY classifications within the three following categories.

Class I (High RELIABILITY) Facilities that are necessary for the public health are in this

category. Facilities such as fire stations, police stations, and evacuation shelters are

in this category.

The photos below show typical fire stations. Since first responders have a need for

high RELIABILITY in their facilities, designers of such buildings should take extra

care to accommodate the operational needs.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 8 of 23

RELIABILITY Classification (continued):

Class II (Medium RELIABILITY) Facilities that have defined operating strategies such as

banks, office buildings and schools are in this category. These buildings typically

have laws and rules that require them to operate on certain days or hours. Banks are

controlled by Federal and State laws and rules. Schools have local school boards as

well as State regulators requiring certain operating conditions. These facilities are

no less important than the Class I buildings, but have semi-flexible operations.

The photos below show typical banks and school buildings.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 9 of 23

RELIABILITY Classification (continued):

Class III (Low RELIABILITY) Facilities not otherwise classified as Reliability Class I or II

are in this category. Typically, facilities with very flexible operating schedules are

in this category. Examples are seasonal leisure resorts, hotels, and retail facilities.

These facilities have very flexible operations and are typically not governed by laws

as much as the owners directions. These facilities are very important just like Class

I and II facilities and are the livelihood for millions of employees across many

continents.

The photo below shows a typical retail facility for a small business.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 10 of 23

Facility Design Criteria:

The facility location is of prime concern when considering the RELIABILITY of the building

systems. The potential for damage or interruption of operation due to flooding should be

considered.

Flood levels for ten (10) years, twenty-five (25) years and one hundred (100) years should be

considered. Typically, the facility should remain operational DURING a 10 year or a 25 year

flood event. Additionally, good design practice warrants that the facility be operational AFTER

a 100 year flood event.

The location selection is a primary factor in RELIABILITY.

The photo below demonstrates a facility that has been flooded. It is obvious that this facility is

not operational and probably will require heavy maintenance before being operational. Note that

if the facility had been located across the road, there may have been higher RELIABILITY.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 11 of 23

Design for Maintenance and Repair:

Every vital component (a component may include elevators, air handlers, pumps, controllers,

etc.) in the facility should be designed to enable repair or replacement without interruptions in

facility operations. Minimizing the interruptions is a very good practice and the intent is to

provide a means for maintaining the components without interruptions. To comply with these

criteria, it is typical for facilities to operate under a RELIABILITY CENTERED

MAINTENANCE program developed through a RELIABILITY CENTERED DESIGN

program.

Maintenance was created when mankind first wore animal hide for protection from the weather

and injury and used tools to do work. Since civilization started, the problems of poor

RELIABILITY have been with us. The hides we wore aged and perished and the tools we used

blunted and broke. Along with the benefits of civilization, we also took on the obligation of its

upkeep. Our ancestors determined which hides and tools were the most useful and centered their

hunting and gathering around these commodities. This was the start of RELIABILITY

CENTERED DESIGN.

Maintenance and RELIABILITY protect us. Safety, defense, risk reduction, and quality are

benefits we need from maintenance and RELIABILITY. Our ancestors wanted those benefits too

and labored to get them. They learned what was needed to reduce maintenance and

RELIABILITY problems and passed the fundamental understandings from generation to

generation in wise words.

Across years of experience and experimentation, sound and valuable advice on the best

maintenance and RELIABILITY practices was passed to us from our forbearers and ancestors.

Their advice is priceless and ageless. It is wisdom spoken with the lovingly hope that listeners

will use the learning to improve their life and position. Below are explanations of five of the

most important sayings our forbearers told us about having RELIABILITY and maintenance

success. Designing with these criteria are key to facility RELIABILITY.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 12 of 23

Design for Maintenance and Repair (contd):

An apple a day keeps the doctor away.

This RELIABILITY insight is one of the greatest health and wellness advices of all time. The

wisdom it contains is not about the fitness benefits of eating apples. The understanding shrewdly

conveyed in the saying is of the great worth of prevention rather than cure. Our forefathers tell us

that the wise person adopts those actions and behaviors that extend their health and well-being

and so prevents future illness and loss. This is very important in RELIABILITY centered design.

When this phrase was coined, a visit to the doctor could mean your death. By the time you had

deteriorated to the point a doctor was needed your chances of living had diminished greatly. It is

a warning that maintaining good health is a life and death matter. It is smart maintenance.

In our world and time we know this saying as proactive maintenance and design. Many people

think that it is a new way. It has always been the right way. Somehow we forgot what had been

known for centuries. Do not begrudge the effort and requirements needed to design and keep

your facility in the condition to live a long and healthy life. With healthy design practices you

can find great business success; without reliable design practices certain business failure

eventually awaits.

One of the key items that have been found to aid in the an apple a day keeps the doctor away

design strategies is to specify warranty periods and maintenance periods in the original building

construction documents. In fact, recent trends have most equipment vendors offering up to five

year warranties at no extra cost. Fluorescent lighting is a prime example. Currently if you mate

most manufacturers ballast and lamps, a five year warranty is automatic. Variable frequency

drives and air handlers are another mated example with extended warranty periods.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 13 of 23

Design for Maintenance and Repair (contd):

A stitch in time saves nine.

This is maintenance advice passed down from countless tailors to their apprentices. The message

in the words has nothing to do with stitching and repairing clothes. It is a warning that a budding

problem left unresolved grows into a disaster that sacrifices time and money. Immediate action

taken to correct a problem when it starts prevents great waste and loss. In our world and time we

call this predictive design and maintenance, and condition monitoring. We look for the earliest

evidence of a failure starting and act to prevent it becoming a breakdown. The sayings

remarkable value was rediscovered by the aerospace/aviation industry in the 1980s and termed

RELIABILITY centered maintenance.

This is directly related to the design of Building Automation Systems and Building Information

Modeling. The design of extensive condition monitoring is a critical portion of the predictive

design and maintenance of todays smart facilities. Using real world feedback on systems such

as HVAC into Building Information Modeling simulations can greatly aid in determining duty

cycles of equipment and life cycle cost analysis.

Most major equipment manufacturers have application modules for Building Information

Modeling software packages such as Autodesks REVIT and Bentleys BIM. These sizing and

simulation routines can be very helpful in determining many of the major building systems

within your facility. In addition, simulation routines can also integrate with preventative

maintenance software packages such as IBMs MAXIMO asset management software. This

information can then identify and prompt for routine maintenancethus a stitch in time saves

nine.

At a recent site visit to a municipal building that was suffering from too negative of a building

HVAC pressure (the exterior doors were extremely hard to open), it was discovered that this

axiom was evidently avoided. Somehow, in an effort to fix a leaky flat roof, a designer opted for

a standing seam metal roof. This roof was installed over the existing roof-top HVAC units. Not

only did this cut off the outside air supply (thus causing the negative pressure issue), but the roof

used the frames of the HVAC units as structural support. The redesign effort to clean up the

code violations and the unfortunate situation was extremely costly.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 14 of 23

Design for Maintenance and Repair (contd):

When all you have is a hammer, everything begins to look like a nail.

There is a powerful warning in this saying about the dangers of ignorance and stymied education.

If we know too little, we risk misunderstanding the truth. If we know too little, we limit our

range of decisions and solutions. If we know only a few things we cannot be successful in those

situations where those few things no longer apply. Our loving ancestors must have made many

mistakes and learned this truth at great cost to them to have arrived at advice so profound and

wise to give us. They clearly put high value on learning and understanding. They knew that

ignorance and mistaken beliefs could lead to trouble.

Today the message is still relevant to us in industry. Perhaps it is more important than ever

before. Our future is one of greater complexity. We drive technology to create ever more

complex machines and systems. In an effort to build a sustainable civilization we add machines

with intricate functions to our world. These technologies and machines need people with a deep

knowledge and understanding of what to do and the skills to do it successfully. Smart buildings

are perfect examples.

In your operation, you need people that can use more than a hammer to look after the design of

the facility. What unimaginable trouble we would have if architects, engineers, maintainers, and

operators only know how to use a hammer and they were limited to only hammers in their

toolkits. To be successful you need people with an array of different tools in their toolboxes and

who can use each masterfully. Those toolboxes need to be full of clean, in-perfect-condition,

well-practiced and properly-handled tools. Such skilled people with toolkits will solve problems

and not create them.

A prime example was a recent project where during a design review meeting, the owner

requested the removal of all variable speed drives from the design documents. This startled me

and brought a surprised Why? The owners response was that her facility maintenance staff

was not capable of the intense programming and maintenance of high technology equipment.

Therefore, she wanted to dumb-down the building technology to match the staffs education

level.

Improving education, knowledge and skills is more than a design success strategy; it is a life

success strategy. Ignorance and the bravado it breeds are terribly expensive, wasteful, and a

RELIABILITY killer.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 15 of 23

Design for Maintenance and Repair (contd):

Measure twice; cut once. The Carpenters Creed

The carpenters of the past knew a thing or two about doing great work. I can only guess once a

profession has been around for ten thousand years all the good secrets get discovered. The

Carpenters Creed measure twice; cut once is not about cutting wood. It is about delivering

quality workmanship through the use of failure preventing quality control. The master carpenters

of the past have honored us with this priceless advice to guide us in the right ways. They say to

proof-check our actions before doing them. They advise us that if you want to be sure that what

you do will go right then thoroughly check it before you do it. An example will help you

understand their success secret.

Taken literally the saying means that first you measure a required distance from a datum and put

a mark. Then you check the mark is in the right place by repeating the measurement. The human

error rate in misreading a ruler or tape measure is about 1 in 200 opportunities. If you measured

once and marked the wood it would be in the wrong spot on average 1 in 200 times. If you were

the carpenter and cut the wood before you checked the position of the mark, you have a 1 in 200

chance that the cut is in the wrong place. A carpenter that did 40 to 50 cuts a day and only

measured once before cutting the wood would scrap a job every week. Along with the wood they

waste they also throw-out all the prior time, money and efforts put into it by others. Such a

wasteful and uncaring carpenter would be of little use to an employer and would be given few

career opportunities. With the added proof-check the second measurement the error rate falls to

1 in 5,000. Now work is scrapped only once in every 20 weeks. Those carpenters of the past knew a

thing or two about doing quality work.

Instilling the use of a tiered design review process is critical to design RELIABILITY. To

simply have a second set of eyes review the designs will decrease the error rate. It is a simple

proven fact.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 16 of 23

Design for Maintenance and Repair (contd):

As above, so below; as within, so without.

This is the oldest of the maintenance and RELIABILITY sayings, coming from ancient Egypt of

5,000 years ago. It is about the effects of our habits, inner values, attitudes and deep beliefs on

our behaviors and demeanor. As we are, so we do. Our mindset and spirit shows in our actions

and in our lack of actions. This is true of organizations as much as it is of people. We are

counseled by the ancient Egyptians that our perceptions, inner values and state of mind conjure

the outcomes that we experience. Your organizational knowledge, norms and culture make the

people in your company behave as they do. These behaviors become its performance and then its

results. From mind and heart to a result is a chain that binds our individual and company

destinies.

In the world of RELIABILITY design, the wrong understandings, values and attitudes show-up

as lost production, re-work, unsatisfied facility owners, and failed opportunities. Wrong mind

and wrong heart ingrain wrong actions into business systems, and thus repetitively producing

failures. In such organizations formal and informal leaders build business processes and set work

quality that can never deliver the performance wanted. If you want to understand why an facility

performs badly and its maintenance is costly listen to what the leaders say. What they think

becomes words. The words become decisions. The decisions become actions. And the people

and company must receive the fateful consequences.

RELIABILITY success starts in the minds and souls of the formal and informal leaders in an

organization. The right knowledge, thoughts and attitudes flow into the leaders decisions and

from there into their words. Good words become correct actions and behaviors that reap good

rewards. Wrong thoughts and incorrect behaviors can only reap wrong outcomes. Our ancient

Egyptian cousins warn us that the reflected outcome can only be what is already within. The

reason that a company does not have world-class maintenance and reliability performance is

because the internal values and beliefs of its people are not yet world-class. World-class is first a

mental journey to understanding. Our actions then follow our thoughts to world-class

performance. Only then are world-class results certain to appear.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 17 of 23

Design for Maintenance and Repair (contd):

You can work the saying backward and first change the required outside behavior so the inside

values change in response. It takes dedicated persistence and commitment to continue the change

process until there is nothing left of the old culture and norms. The ancient Egyptians tell us that

you can only change an organization when its leaders have the vision and heart to rebuild it in

the image that produces the required results. Basically, RELIABILITY has to start with everyone

(architect, engineer, owner, maintenance person, etc.) all working together to establish the

common goal.

Outcomes reflect the mind and spirit behind them. If you want a better future, first instill the

values and beliefs that create that future. In todays world of RELIABILITY, as it has been since

ancient times, seek and use the right knowledge and the right performance standards that will

bring sure success. Nothing is new in RELIABILITY, we have only to understand and use the

powerful wisdom of our ancestors.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 18 of 23

Robust Design versus Over-Design:

Robust Design means factoring RELIABILITY into the development of the design itself;

designing for a target RELIABILITY and thereby avoiding either costly over-design or

dangerous under-design in the first place. Such an approach eliminates a deterministic stack-up

of tolerances, worst-case scenarios, safety factors, and margins that have been traditional

approaches for treating uncertainties.

Overdesign is common and expensive. In large scale projects, each discipline (mechanical,

structural, electrical, etc.) communicates worst-case requirements to other disciplines rather than

attempting to couple the design analyses. This leads to designs that are heavier and more costly

than they need to be, and in some cases does not even result in a safer or more reliable design.

For example, it is common for power specialists to require that the nickel-hydrogen batteries for

an uninterruptible power system never exceed 15C. This creates a serious thermal control

challenge, requiring additional structural mass, and technology risk. In fact, nickel-hydrogen

batteries do not fail at 15C, they simply become less reliable and more likely to fail the longer

they operate at elevated temperatures. Occasional exposure temperatures up to as high as 30C

are tolerable but undesirable yet total avoidance of any temperature greater than 15C becomes

the task of the RELIABILITY designer. The designer might even resort to fancier and therefore

more risky thermal control options to achieve this requirement, resulting in a less reliable overall

design than if temperature excursions had been better tolerated in the battery design

requirements. Perhaps nickel-cadmium batteries that have a higher temperature rating, but lesser

power qualities, would have been a better choice for the project team.

Even within one discipline, overdesign exists due to stack-up of margins and worst-case

scenarios until the design case is unrealistic and will likely never occur. A worst-case (unlikely)

attitude is combined with end-of-life expected degradations, estimations of worst-case

dissipations, and predictions of worst-case performance, etc. Additional margin is then added to

cover uncertainties in modeling, environment, and component sizing. Only when meeting an

extreme stack-up of margins and uncertainties becomes impossible, does a renegotiation of

adequate margin begin, and such renegotiations are seldom based on any mathematical rigor or

true knowledge of the underlying risk. A recent conversation with a local utility company is

recalled where the utility company representative explained we generally provide the service at

50% of the connected load on industrial buildings such as this when coordinating the electrical

service to the building.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 19 of 23

Robust Design versus Over-Design (contd):

In the aerospace facility industry, which is heavily influenced by understandably cautious

military and governmental standards, such overdesign compensates for unknowns and

unforeseen problems. Success in such a design environment is a necessity, and cost is a

secondary consideration. In commercial facilities, on the other hand, cost is a primary

consideration. An overall facility reliability of 99% may be desired, but if significant savings

result from a reduced reliability of 98%, the latter option will be seriously considered.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 20 of 23

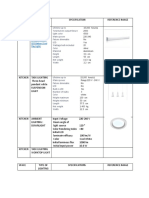

Designing Access and Handling:

Adequate access, handling and removal space should be provided around all components to

facilitate maintenance, removal and replacement. This criterion is applied to components either

inside a building or in an exterior environment. For components in interior spaces, adequate

access for lifting and removing a valve or pump should be planned in the building design. Either

portable or fixed lifting devices need to be planned such that heavy components may be handled.

The structure needs to be designed so that hoists, trolleys and cranes can be used to facilitate

maintenance. For exterior components, typically cooling towers and similar equipment, ample

access for maintenance vehicles and lay-down areas are required for normal disassembly and

removal. Typically, large equipment (such as trucks mounted with jib cranes) may be required.

Proper access planning is strongly recommended.

The objective is to provide the facility operators with a well designed building system which can

be easily be maintained in an orderly and expedient manner. The goal is to get the repair done as

quickly as possible and reduce the outage time. This is a characteristic of good RELIABILITY.

The photo below is an example of the typical equipment used in maintenance. Note the access

space for the maintenance crew.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 21 of 23

Summary and Review:

RELIABILITY A measurement of the ability of a component to perform its designated

function without failure. RELIABILITY pertains to system components and the maintainability

of those components.

RELIABILITY engineering is mainly concerned with minimizing downtime costs.

One of the most important RELIABILITY design techniques is redundancy.

There are three classifications of RELIABILITY.

Class I (High RELIABILITY) Facilities that are necessary for the public health are in this

category. Facilities such as fire stations, police stations, and evacuation shelters are

in this category.

Class II (Medium RELIABILITY) Facilities that have defined operating strategies such as

banks, office buildings and schools are in this category.

Class III (Low RELIABILITY) Facilities not otherwise classified as Reliability Class I or II.

Typically, facilities with flexible operating schedules are in this category. Examples

are seasonal leisure resorts, hotels, and retail facilities.

Location selection is a primary factor in RELIABILITY.

Every vital component in the facility should be designed to enable repair or replacement without

interruptions in facility operations.

An apple a day keeps the doctor away conveys the great worth of prevention rather than

reactive curing any illness.

A stitch in time saves nine is a warning that a budding problem left unresolved can grow into a

disaster that sacrifices time and money.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 22 of 23

Summary and Review (contd):

When all you have is a hammer, everything begins to look like a nail is a powerful warning

about the dangers of ignorance and stymied education.

The Carpenters Creed measure twice; cut once is not about cutting wood. It is about

delivering quality workmanship and the use of failure preventing quality control.

As above, so below; as within, so without is about the effects of our habits, inner values,

attitudes and deep beliefs on our behaviors and demeanor.

Nothing is new in RELIABILITY, we have only to understand and use the powerful wisdom of

our ancestors.

Robust Design means factoring RELIABILITY into the development of the design itself;

designing for a target RELIABILITY and thereby avoiding either costly over-design or

dangerous under-design in the first place.

Adequate access, handling and removal space should be provided around all components to

facilitate maintenance, removal and replacement. For components in interior spaces, adequate

access for lifting and removing a valve or pump should be planned in the building design.

Reliability in Facility Design

A SunCam online continuing education course

www.SunCam.com

Copyright

2011 Daniel L. Spradling, P.E.

Page 23 of 23

Further Study and Reference:

The seminar relies on multiple resources for information. The main white papers used are listed

below.

Ageless Maintenance and Reliability Success Secrets, Mike Sondalini, Lifetime

Reliability, J une 2009

Standards Program Procedures, American Institute of Aeronautics and Astronautics,

October 2005

Reliability Engineering and Robust Design: New Methods for Thermal/Fluid

Engineering, Brent Cullimore, C&R Technologies, Inc., May 2000

Some North American Universities that offer courses in Reliability Engineering are listed. All of

these engineering programs offer reliability courses and some even offer advanced degrees.

University of Tennessee

University of Maryland

Concordia University

In addition, there are many conferences and industry training programs (such as this one)

available for RELIABILITY engineering. Several professional organizations exist for reliability

engineering including IEEE Reliability Society, the American Society for Quality and the amply

named Society for Reliability Engineers.

You might also like

- Final Report Farley PDFDocument41 pagesFinal Report Farley PDFkorosh75No ratings yet

- Wind On Sheds PDFDocument12 pagesWind On Sheds PDFkorosh75100% (1)

- Ductility Factor - Article368966 - Structuraldesigncodesofaustraliaandnewzealand - ManuscriptDocument16 pagesDuctility Factor - Article368966 - Structuraldesigncodesofaustraliaandnewzealand - ManuscriptMacNo ratings yet

- Wind Actions Design Guide PDFDocument12 pagesWind Actions Design Guide PDFkorosh75No ratings yet

- Improving The Resilience of Existing Housing To Severe Wind EventsDocument37 pagesImproving The Resilience of Existing Housing To Severe Wind Eventskorosh75No ratings yet

- Final Report Farley PDFDocument41 pagesFinal Report Farley PDFkorosh75No ratings yet

- Compression MemberDocument3 pagesCompression Memberkorosh75No ratings yet

- Analysing A Two Span Slab Using Structural Toolkit: in This TutorialDocument21 pagesAnalysing A Two Span Slab Using Structural Toolkit: in This Tutorialkorosh75No ratings yet

- Ccaaguide2001 T54 CPH1 4 TBR PDFDocument16 pagesCcaaguide2001 T54 CPH1 4 TBR PDFkorosh75No ratings yet

- PT DetailingDocument52 pagesPT Detailingcuongnguyen100% (4)

- Post Tensioned SlabsDocument44 pagesPost Tensioned SlabsMaad Ahmed Al-Maroof100% (2)

- Code Tiltup PrecastDocument47 pagesCode Tiltup Precastkorosh75No ratings yet

- Asi Tn006v2webDocument5 pagesAsi Tn006v2webkorosh75No ratings yet

- TN009 - Documentation of Structural SteelDocument8 pagesTN009 - Documentation of Structural SteelAndy AcousticNo ratings yet

- Australian Geomechanics: Landslide Risk ManagementDocument27 pagesAustralian Geomechanics: Landslide Risk ManagementChristian SchembriNo ratings yet

- Code Tiltup PrecastDocument89 pagesCode Tiltup PrecastbalgitNo ratings yet

- Steeldoc 31-05-07 PDFDocument67 pagesSteeldoc 31-05-07 PDFkorosh75No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Fundamentals of Post-Tensioned Concrete Design For BuildingsDocument49 pagesFundamentals of Post-Tensioned Concrete Design For Buildingssalaverria0% (1)

- Performance Based Design by Ashraf H.Document86 pagesPerformance Based Design by Ashraf H.korosh75100% (2)

- Australian Geomechanics: Landslide Risk ManagementDocument27 pagesAustralian Geomechanics: Landslide Risk ManagementChristian SchembriNo ratings yet

- SteelDocument33 pagesSteelkorosh75No ratings yet

- SPACE GASS 11.08 Help ManualDocument1,012 pagesSPACE GASS 11.08 Help ManualozbuildNo ratings yet

- Beam ColumnDocument75 pagesBeam ColumnAscanio BarbosaNo ratings yet

- Staad Pro and OffshoreDocument9 pagesStaad Pro and OffshoreAla BazrqanNo ratings yet

- STI12 Cyclic Symmetry at 6.0Document5 pagesSTI12 Cyclic Symmetry at 6.0M. Ceyhun SözbirNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 12 Solutions To ExercisesDocument41 pagesChapter 12 Solutions To ExercisesMuhammad Awais56% (9)

- En 19Document3 pagesEn 19Sanjay GoreNo ratings yet

- 117position Monitor PDFDocument2 pages117position Monitor PDFJacob KalloorNo ratings yet

- Sustainable Production of Acrolein: Investigation of Solid Acid-Base Catalysts For Gas-Phase Dehydration of GlycerolDocument7 pagesSustainable Production of Acrolein: Investigation of Solid Acid-Base Catalysts For Gas-Phase Dehydration of GlycerolnayarapradoNo ratings yet

- Abrasive Cleaning SystemDocument4 pagesAbrasive Cleaning SystemSulfikar SalimNo ratings yet

- GROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Document5 pagesGROUP 7 - Banksia-SD-SE-T1-Hazard-Report-Form-Template-V1.0-ID-200278Samir Mosquera-PalominoNo ratings yet

- Network AssignmentDocument4 pagesNetwork AssignmentOsamah ElaiwahNo ratings yet

- Manual V100-V30-70 ENGDocument38 pagesManual V100-V30-70 ENGAzeddine LANo ratings yet

- hsg47 - Avoiding Danger From Underground Services PDFDocument40 pageshsg47 - Avoiding Danger From Underground Services PDFAchilleas21No ratings yet

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- Astm A722 PDFDocument5 pagesAstm A722 PDFNguyễn ThạnhNo ratings yet

- MUJ - Hostel B8, B9 & B10Document12 pagesMUJ - Hostel B8, B9 & B10GanjaNo ratings yet

- C510WNDocument2 pagesC510WNEdgarDavidDiazCamposNo ratings yet

- S8 PDFDocument184 pagesS8 PDFsrdsosonpurNo ratings yet

- Class 10 Science (Physics) MCQs Chapter 11 QuestionsDocument28 pagesClass 10 Science (Physics) MCQs Chapter 11 QuestionsKSA TEXTILENo ratings yet

- Philips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Document4 pagesPhilips Slimline Compact 20w/2000lm 2ft LED Batten (Cool Day Light)Shrutie PatilNo ratings yet

- 1Document9 pages1MurtadhaNo ratings yet

- Instruction ManualDocument462 pagesInstruction ManualCaraluaNo ratings yet

- 7749289-TheClandestineChemist 'Snotebook PDFDocument28 pages7749289-TheClandestineChemist 'Snotebook PDFTonNo ratings yet

- Fast-Recovery Rectifier Diodes: Ru 4Y Ru 4Z RU4 Ru 4A Ru 4B Ru 4CDocument1 pageFast-Recovery Rectifier Diodes: Ru 4Y Ru 4Z RU4 Ru 4A Ru 4B Ru 4CY. Leonel MolinaNo ratings yet

- SchedulingDocument41 pagesSchedulingBeing VikramNo ratings yet

- Chapter 3 IPCDocument53 pagesChapter 3 IPCkirubelNo ratings yet

- 64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BDocument18 pages64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BChu Thi ThuanNo ratings yet

- Nse Past Questions and AnswersDocument10 pagesNse Past Questions and Answersadesloop85% (13)

- Soil Test Report KolhapurDocument35 pagesSoil Test Report Kolhapuryedida viswanadhNo ratings yet

- Cover Block (8383837083)Document7 pagesCover Block (8383837083)BALAJI ENTERPRISESNo ratings yet

- Datasheet Dc-m9204 & Di-M9204 Manual Call PointDocument4 pagesDatasheet Dc-m9204 & Di-M9204 Manual Call PointHajji MehdiNo ratings yet

- Elements of Roads and Highways by Max Fajardo 2nd EditionDocument6 pagesElements of Roads and Highways by Max Fajardo 2nd EditionJ-Ron Calias0% (1)

- Report Torsion TestDocument27 pagesReport Torsion TestCherif ChokeirNo ratings yet

- 1SDA071192R1 E4 2n 4000 Ekip Dip Lsi 3p F HRDocument3 pages1SDA071192R1 E4 2n 4000 Ekip Dip Lsi 3p F HRjunior_jazzzNo ratings yet