Professional Documents

Culture Documents

Baker EXP4000 Specifications

Uploaded by

Eduardo_77Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baker EXP4000 Specifications

Uploaded by

Eduardo_77Copyright:

Available Formats

Integrated testing

capabilities

The SKF Dynamic Motor Analyzer -

EXP4000 integrates a wide range of

monitoring capabilities which meet

high quality standards. Designed for

in-service monitoring of power circuit

issues, overall motor health, load, and

performance, it gives the user a

comprehensive look at overall motor

integrity. This instrument was

designed for remote monitoring from

the Motor Control Center (MCC) or

through the EP1000 connection. It is

a non-hazardous, low voltage,

battery operated unit, which makes it

highly portable and durable for use in

tight and rugged locations.

Continuous innovation

Continual design breakthroughs

demonstrate our on going

commitment to quality, reliability,

Specifications and electrical requirements

SKF Dynamic Motor Analyzer -

EXP4000

and competitive advantage. This

instrument provides data on degradation

of motor performance and the effects of

overheating on motor operation. Survey

plant wide efficiency, determine load

mismatches, oscillating load and transient

peak energy. Results are immediate,

showing operating efficiencies, thereby

allowing the user to determine the true

cost of wasted energy.

Comprehensive analysis

The SKF Dynamic Motor Analyzer -

EXP4000 performs seven major

functions to enhance a P/PM program.

Within these functions evaluate the

incoming power, motor and load utilizing a

system wide approach to predictive

maintenance, troubleshooting and quality

assurance. This motor analyzer offers a

wide variety of capabilities for the

maintenance professional to understand

the condition of the rotating system. It is

programmed to supply information on

voltage level, voltage balance, harmonic

and total distortion, rotor cage condition,

motor efficiency, effective service factor,

overcurrent, operating condition, torque

ripple, load history among others. This

wide range of tests allows exploration of

the true condition of motor integrity and

conditions related to motor performance.

Advanced data collection

and organization

Once testing is completed, results can be

saved and stored for each motor. This type

of documentation is critical for any mainte-

nance program. It allows the recalling of

information for true trending capabilities.

Test results are managed using standard

MS Access relational database file formats.

Reports can be quickly generated through

the main print console, allowing operators

visual confirmation of motor integrity.

The software and data transfer package

enables the creation of multiple databases

to organize collected data to specifications

set by users. This eases communication

channels by handling data in a manner

that is useful, complete and accessible.

Test domains

Power quality

This domain identifies non-optimal power

quality problems, which cause additional

motor stress. Flag frequent problems with

voltage level, voltage unbalance, harmonic

distortion, total distortion, power and

harmonics tests. These issues identify

improper tap settings on supply trans-

formers, poorly distributed single phase

loads, overloading (saturating) supply

transformers, excessive VFDs on low

voltage busses, excessing non-harmonic

frequencies on a VFD, missing line

inductors on VFD applications, missing or

open power factor correction capacitors

along with high resistance connections.

Machine performance

Conclusively evaluate the operation of the

motor, identifying stressful operation and

its source with this domain. It looks at

Effective Service Factor, Load, Operation

Condition, Efficiency, and calculates

Payback Period. Commonly found

problems include: thermal overloading of

the motor, machine deterioration

recognition among other items that are

directly related to the motors health and

the energy wasted with inefficiencies.

Current

Currrent level and current unbalance are

utilized to determine overall electrical

machine health. These parameters are

used to determine the following issues

overloading, connection issues, miss

connections, iron saturation and

improperly wound motors.

Spectrum

This domain has the rotor bar test along

with V/I spectrum, Demodulated

Spectrum, and Harmonics. It shows

current and voltage relationships with

regards to frequency. Electrically it will

find saturation problems, broken rotor

2

bars, excessive VFD drives on low voltage

busses and mechanical problems.

Torque (Optional)

The torque domain is a substantial break-

through by Baker Instrument Company,

an SKF Group Company. Torque Ripple and

Torque Spectrum enable the user to find

numerous problems quickly and

accurately. It specializes in diagnosing

mechanical issues, shows transient

overloading, finds mechanical imbalances

along with bearing problems, and

cavitation, among others.

Connections

This portion of the SKF Dynamic Motor

Analyzer - EXP4000 software offers

additional tools including phasor diagrams,

three currents and voltages, instantane-

ous voltage, and symmetrical components.

This data provides the operator with valu-

able power data as well as a way to make

sure the EXP4000 is correctly connected.

VFD monitoring (Optional)

Along with any three phase induction

motor and generator, the SKF Dynamic

Motor Analyzer - EXP4000 will monitor

the activities of VFD applications and AC

servo motors using the VFD4000 software

module. These types of drives have always

created problems for maintenance

professionals and for the first time

comprehensive diagnosis of motor

problems are facilitated even under the

most demanding VFD operation.

Continuous monitoring (Optional)

The continuous monitoring software

(CM4000) enables the user to monitor

41 data points real time. This real time and

continuous data gathering capability will

give immediate impact in finding

intermittent problems with motors such as

electrical tripping. This user customized

software enables the operator to collect

real time data on whatever is deemed the

most important to their operation. This

software will also act as a power analyzer

to determine actual power quality.

Transient Analysis

The SKF Dynamic Motor Analyzer -

EXP4000 also performs a start up analysis

using the transient analysis tool. The traces

are the rms currents and voltages of all

three phases. This data can be zoomed,

panned, and the cursors allow reading of

levels and time within the graphs. Along

with this powerful analysis capability,

startup Torque versus Time can also be

evaluated. These tools allow the user to

visually see the amplitude of voltage,

current and torque at startup, along with

motor startup time. Only by monitoring all

three phases of the current, voltage and

torque can the maintenance professional

separate between a power, motor or load

issue on start up.

Efficiency

Efficiency assessment, pay-back period

and Motor Master+ identify motors

performing under par, and calculates the

pay-back period if replaced by a new motor.

The SKF Dynamic Motor Analyzer -

EXP4000 exceeds the performance of

other instrumentation in both accuracy of

efficiency estimation and in ease of use for

field environments.

3

Bearings

and units

Seals

Lubrication

systems

Mechatronics Services

Baker Instrument Company, an SKF Group Company

4812 McMurry Avenue, Fort Collins, CO 80525

T: 970/282-1200 - 800/752-8272 F: 970/282-1010

www.bakerinst.com

The Power of Knowledge Engineering

Drawing on five areas of competence and application-specific expertise amassed over 100 years,

SKF brings innovative solutions to OEMs and production facilities in every major industry worldwide.

These five competence areas include bearings and units, seals, lubrication systems, mechatronics

(combining mechanics and electro nics into intelligent systems), and a wide range of services, from 3-D

computer modelling to advanced condition monitoring and reliability and asset management systems.

A global presence provides SKF customers uniform quality standards and universal product availability.

SKF is a registered trademark of the SKF Group.

Baker is a registered trademark of the SKF Group.

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

SKF Group 2010

The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless permission is

granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be

accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein.

Publication 6769 EN July 2010

Printed in USA on environmentally friendly paper.

skf.com bakerinst.com

Technical specifications Benefits

Voltage Unbalance Power Quality

Voltage THD Poorly performing transformers

Current THD Connection issues

Negative Sequence Impedance Rotor

Speed calculation -Cracked bars

% Load & % Efficiency -Poor welds

Spectrum Voltage -Broken bars

Spectrum Current -Eccentricity

Current Level Load Issues

Effective Service Factor -Over load

Power details -Process

Continuous acquisition Mechanical

O-Scope -Bearing faults

Auto Phasing -Miss alignment

Auto testing including timer function -Fan unbalances

One button testing -Belt frequencies

Bearing check -Worn Impellars

Startup Transient Voltage -Gear mesh frequencies

Startup Current VFD

Startup Torque

Torque Spectrum

Torque Time Waveform

Efficiency Estimation

-Power quality

-Shorted IGBTs

-Feedback loop

-Process information

-Tuning/Setup

Soft Start

-Tuning/Setup

-Troubleshooting

Energy Assesment

Specifications

Input Power 110-250 VAC, 50/60 Hz integrated power

supply

Maximum Rated

Measurement/Testing

Voltage

1,000 V AC, 500 V DC

Current Transformers

(all portable)

0-10 A, 0-150 A, 1-1,000 A, 0-3,000 A

Connections Amphenol

military spec twist type

Power entry module (1)

Portable voltage connection (1)

Portable current connection (1)

EP Port (1)

Vibration sensor connection (1)

Computer specifications 40 GB 4,200 rpm or better

512 MB - 2GB installed RAM

Battery or AC power operated

Software Platform: Microsoft Windows XP,

Professional, Windows 7 or better

USB 2.0

Weight 15 lbs

Industrial standards NEMA MG-1

IEEE 519

EN61000-2-2

EN 61000-2-7

VDE 839-2-2

VDE 839 -2-2

You might also like

- Diccionario Tecnico en Ingles PDFDocument953 pagesDiccionario Tecnico en Ingles PDFDAVID FAJARDO PUERTO100% (10)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- EXP3000-EXP3000R ExplorerDocument4 pagesEXP3000-EXP3000R ExplorerkarthimeenaNo ratings yet

- Pantone Colour ChartDocument10 pagesPantone Colour ChartCT0011100% (1)

- Pantone Colour ChartDocument10 pagesPantone Colour ChartCT0011100% (1)

- PLC ProjectDocument69 pagesPLC Projectsovon adhikaryNo ratings yet

- EXP4000 Brochure V6 PDFDocument4 pagesEXP4000 Brochure V6 PDFZul AtfiNo ratings yet

- AC Motor Analysis (SKF)Document2 pagesAC Motor Analysis (SKF)gpramuhandokoNo ratings yet

- Motor Management and Condition AssessmentDocument4 pagesMotor Management and Condition AssessmentEngr Irfan AkhtarNo ratings yet

- Megger Baker EXP4000 Brochure en A4 OnlineDocument8 pagesMegger Baker EXP4000 Brochure en A4 OnlinePaulo CLNo ratings yet

- Motor TestingDocument26 pagesMotor TestingGas Gas DucatiNo ratings yet

- Ijecv8n1 03Document6 pagesIjecv8n1 03fakhriNo ratings yet

- Mtekpro Service ProfileDocument13 pagesMtekpro Service ProfilepriyankadasguptaNo ratings yet

- Whitelegg Motortest BrochureDocument8 pagesWhitelegg Motortest BrochureselvamuthukumarNo ratings yet

- All-Test Iv Pro: Motor Circuit AnalyzerDocument6 pagesAll-Test Iv Pro: Motor Circuit AnalyzerJorge Luis Torrico CalatayudNo ratings yet

- EEMDocument17 pagesEEMSandaruwan සුජීවNo ratings yet

- Fluke MDA-510 and MDA-550 Motor Drive Analyzer: Technical DataDocument10 pagesFluke MDA-510 and MDA-550 Motor Drive Analyzer: Technical Datasyed Mujtaba hassanNo ratings yet

- Modern Online Testing of Induction Motors For Predictive Maintenance and MonitoringDocument7 pagesModern Online Testing of Induction Motors For Predictive Maintenance and MonitoringJonas BorgesNo ratings yet

- Motor PDM PrimerDocument4 pagesMotor PDM PrimerBoby100% (1)

- Whitelegg Motatest Dynamic (1) FDocument2 pagesWhitelegg Motatest Dynamic (1) FHenry CruzNo ratings yet

- Power Transformer Frequency Response Analysis Test Set Model Fra-100Document4 pagesPower Transformer Frequency Response Analysis Test Set Model Fra-100Mohamed BoughalNo ratings yet

- Power Flow Analysis: Determine Voltage, Current & Power FlowDocument5 pagesPower Flow Analysis: Determine Voltage, Current & Power FlowK.RamachandranNo ratings yet

- 4 Motor Testing PhilosophyDocument4 pages4 Motor Testing PhilosophyLuis GonzalezNo ratings yet

- Baker d65r HIPOTDocument2 pagesBaker d65r HIPOTjon1224100% (1)

- How VFDs Can Help Reduce Maintenance CostsDocument3 pagesHow VFDs Can Help Reduce Maintenance CostsMenaNo ratings yet

- Procedure For AnalysisDocument22 pagesProcedure For AnalysisOmodibo Oghenekevwe KevinNo ratings yet

- Baker EXP4000 Dynamic Motor AnalyzerDocument8 pagesBaker EXP4000 Dynamic Motor AnalyzerAshishrock SinghNo ratings yet

- Thesis On Switched Reluctance MotorDocument4 pagesThesis On Switched Reluctance Motorbsqxd5g1100% (2)

- Schaffner Nsg5000 DatasheetDocument27 pagesSchaffner Nsg5000 DatasheetLigia RomanNo ratings yet

- Motor Data: IMAGE 2: PDIV ChartDocument2 pagesMotor Data: IMAGE 2: PDIV ChartAMITAVA RAYNo ratings yet

- The - Multi - Technology - Approach Rev 1Document8 pagesThe - Multi - Technology - Approach Rev 1RM HaroonNo ratings yet

- Condition Assessment - HT MachineDocument20 pagesCondition Assessment - HT MachineFerozMujawar0% (1)

- Electrical Troubleshooting in Seven StepsDocument3 pagesElectrical Troubleshooting in Seven StepsilyNo ratings yet

- Detect Induction Motor Faults Without Process ShutdownsDocument65 pagesDetect Induction Motor Faults Without Process ShutdownsSiva RajNo ratings yet

- Portland, OR, USA: Dick Roche FPS, IncDocument3 pagesPortland, OR, USA: Dick Roche FPS, IncJesus DavVelandia MuñozNo ratings yet

- MCSA Identifying Faults JanuaryDocument11 pagesMCSA Identifying Faults Januaryiap35vbNo ratings yet

- Why StudiesDocument4 pagesWhy StudiesRavindra GoyalNo ratings yet

- Electrical System Motor MaintenanceDocument7 pagesElectrical System Motor MaintenanceoritasNo ratings yet

- 1.5 Executive SummaryDocument3 pages1.5 Executive SummaryBernie BuanghugNo ratings yet

- Electrical Power Steering Design Guide TEXASDocument18 pagesElectrical Power Steering Design Guide TEXASacmilan4eva1899100% (1)

- SKF Dynamic Motor Analyzer - EXP4000Document4 pagesSKF Dynamic Motor Analyzer - EXP4000lblancoingNo ratings yet

- Impact of Nonlinear Loads On Motor Generator SetsDocument86 pagesImpact of Nonlinear Loads On Motor Generator Setssierra67_lee3476No ratings yet

- Baker EXP4000 BR EN V02Document8 pagesBaker EXP4000 BR EN V02Mostafa AnwarNo ratings yet

- Brake & Friction Test Systems - enDocument13 pagesBrake & Friction Test Systems - enDivya ShahNo ratings yet

- PHD Thesis On Vector Control of Induction MotorDocument7 pagesPHD Thesis On Vector Control of Induction Motorsarahmichalakwarren100% (1)

- Trabajar A 87hzDocument24 pagesTrabajar A 87hzLuis Fernando CuaspudNo ratings yet

- Chapter 1: Introduction: D P M T PDocument8 pagesChapter 1: Introduction: D P M T PNoé Rafael Colorado SósolNo ratings yet

- 60-070 Datasheet Powerframes Core System 12 2013Document22 pages60-070 Datasheet Powerframes Core System 12 2013Daniel ToapantaNo ratings yet

- Study and Analysis of Systems For Monitoring in Power SubstationsDocument3 pagesStudy and Analysis of Systems For Monitoring in Power SubstationsIsrael DanielNo ratings yet

- FRAX 150: Sweep Frequency Response AnalyzerDocument6 pagesFRAX 150: Sweep Frequency Response AnalyzeroedisNo ratings yet

- Active Magnetic Bearings (AMB) : Submitted To: Submitted byDocument12 pagesActive Magnetic Bearings (AMB) : Submitted To: Submitted byHod of ME PRRMNo ratings yet

- FRAnalyzer Brochure ENUDocument12 pagesFRAnalyzer Brochure ENUJohar ShamNo ratings yet

- Netherlands Hospital EnglishDocument3 pagesNetherlands Hospital EnglishENRIQUENo ratings yet

- Why StudiesDocument4 pagesWhy StudiesDheeraj YadavNo ratings yet

- DBR CalculatorDocument69 pagesDBR CalculatorSURJIT SINGHNo ratings yet

- Motor Current Signature Analysis and InterpretationDocument6 pagesMotor Current Signature Analysis and InterpretationJayant KumarNo ratings yet

- Online Fault Diagnosis of MotorDocument6 pagesOnline Fault Diagnosis of MotorSundar Kumar Vasantha GovindarajuluNo ratings yet

- Literature Review of Speed Control of Induction MotorDocument4 pagesLiterature Review of Speed Control of Induction MotoraflsmperkNo ratings yet

- Servo Motor Literature ReviewDocument8 pagesServo Motor Literature Reviewc5swkkcn100% (1)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- UL & IEC Enclosure Standards Comparison: Type CBG 30Document1 pageUL & IEC Enclosure Standards Comparison: Type CBG 30Eduardo_77No ratings yet

- Current Loop TutorialDocument13 pagesCurrent Loop TutorialNAVEED100% (2)

- NFPA 72 Emergency Communications White Paper FinalDocument5 pagesNFPA 72 Emergency Communications White Paper FinalEduardo_77No ratings yet

- Ral Chart PDFDocument3 pagesRal Chart PDFErunerNo ratings yet

- NFPA 70E Compliance GuideDocument1 pageNFPA 70E Compliance GuidejesusbarajasNo ratings yet

- Control Fundamentals: Terminology and SymbolsDocument28 pagesControl Fundamentals: Terminology and Symbolsm_holbornNo ratings yet

- Current Loop TutorialDocument13 pagesCurrent Loop TutorialNAVEED100% (2)

- Nfpa 72 FaqsDocument2 pagesNfpa 72 Faqssharif339No ratings yet

- SMoke Alarm Detection TechnologyDocument54 pagesSMoke Alarm Detection TechnologyEduardo_77No ratings yet

- Causa RaizDocument10 pagesCausa RaizEduardo_77No ratings yet

- What Your Fellow Professionals Are Saying About NFPA On-Site SeminarsDocument2 pagesWhat Your Fellow Professionals Are Saying About NFPA On-Site SeminarsEduardo_77No ratings yet

- ISO 10816-1 Normativa VibracionesDocument10 pagesISO 10816-1 Normativa Vibracionesumendibil100% (1)

- ISO 10816-1 Normativa VibracionesDocument10 pagesISO 10816-1 Normativa Vibracionesumendibil100% (1)

- 2007 AGA 9.pdf AGA 9 - 2007 PDFDocument9 pages2007 AGA 9.pdf AGA 9 - 2007 PDFadactivatorNo ratings yet

- Standards E PDFDocument31 pagesStandards E PDFHittakarimaNo ratings yet

- Seccion 2. Revision de AGA 9Document25 pagesSeccion 2. Revision de AGA 9Eduardo_77No ratings yet

- Seccion 2. Revision de AGA 9Document25 pagesSeccion 2. Revision de AGA 9Eduardo_77No ratings yet

- Ultrasound Condition Monitoring Ue v7Document7 pagesUltrasound Condition Monitoring Ue v7Eduardo_77100% (1)

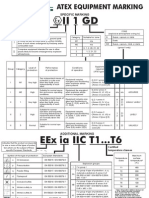

- Atex MarkingDocument1 pageAtex Markinggangotri05No ratings yet

- Atexdirective 94 9 ECDocument1 pageAtexdirective 94 9 ECacornejomNo ratings yet

- Approval Standard For Explosionproof Electrical Equipment General RequirementsDocument33 pagesApproval Standard For Explosionproof Electrical Equipment General RequirementsEduardo_77No ratings yet

- Approval Standard For Repair Service For Communication Equipment Used in Hazardous (Classified) LocationsDocument10 pagesApproval Standard For Repair Service For Communication Equipment Used in Hazardous (Classified) LocationsEduardo_77No ratings yet

- Approval Standard For Intrinsically Safe Apparatus and Associated Apparatus For Use in Class I, II, and III, Division 1, Hazardous (Classified) LocationsDocument15 pagesApproval Standard For Intrinsically Safe Apparatus and Associated Apparatus For Use in Class I, II, and III, Division 1, Hazardous (Classified) LocationsEduardo_77No ratings yet

- Atex Ref GuideDocument2 pagesAtex Ref Guidejim-doyle973No ratings yet

- Atexdirective 94 9 ECDocument1 pageAtexdirective 94 9 ECacornejomNo ratings yet

- Approval Standard For Dust-Ignitionproof Electrical Equipment General RequirementsDocument12 pagesApproval Standard For Dust-Ignitionproof Electrical Equipment General RequirementsEduardo_77No ratings yet

- Applying the commutator transformation C2 for synchronous machinesDocument8 pagesApplying the commutator transformation C2 for synchronous machinesAli AldesogeNo ratings yet

- Quidway S3900 Series Ethernet Switches Installation ManualDocument102 pagesQuidway S3900 Series Ethernet Switches Installation Manualcharliil100% (1)

- Electrical Resistance: Edexcel Igcse / Certificate in Physics 2-4Document21 pagesElectrical Resistance: Edexcel Igcse / Certificate in Physics 2-4Sam JordanNo ratings yet

- Tiger TO-92 Plastic Transistor SpecsDocument3 pagesTiger TO-92 Plastic Transistor SpecsVinod kumarNo ratings yet

- Trane Condensing UnitDocument16 pagesTrane Condensing Unitahmed abdelghanyNo ratings yet

- Microwave Link Design - Nueva EcijaDocument79 pagesMicrowave Link Design - Nueva EcijaMark Vincent Fortaleza55% (11)

- Carrier PARTS 4 2010Document16 pagesCarrier PARTS 4 2010ricodavidNo ratings yet

- 5 Pen PC Technology PDFDocument8 pages5 Pen PC Technology PDFNikitha ReddyNo ratings yet

- Chapter 8 State Space AnalysisDocument22 pagesChapter 8 State Space AnalysisAli AhmadNo ratings yet

- PROFIBUS Standard for Fieldbus Communication in AutomationDocument1 pagePROFIBUS Standard for Fieldbus Communication in AutomationhenrytolentinoNo ratings yet

- Fundamentals of Control SystemsDocument18 pagesFundamentals of Control SystemsShiva Sai BuraNo ratings yet

- D MicroTronDocument2 pagesD MicroTronLh KooNo ratings yet

- Data Aire Brochure Web Version v4Document4 pagesData Aire Brochure Web Version v4dnps2011No ratings yet

- ECE216Document2 pagesECE216Aryan GourNo ratings yet

- Marsh Brown Clr-BrochureDocument4 pagesMarsh Brown Clr-BrochureأبوإسلامNo ratings yet

- LAPORAN PRAKTIKUM ELEKTRONIKA DASAR 1Document25 pagesLAPORAN PRAKTIKUM ELEKTRONIKA DASAR 1assaNo ratings yet

- Assignment - 4Document2 pagesAssignment - 4Hardeep SinghNo ratings yet

- GSM Frequency Bands Table ExplainedDocument2 pagesGSM Frequency Bands Table Explainedamits_aumNo ratings yet

- Lab 5 Series and Parallel CircuitsDocument3 pagesLab 5 Series and Parallel CircuitsJimmyPowellNo ratings yet

- CEPT Novice 1Document26 pagesCEPT Novice 1Ster RncNo ratings yet

- Exp. 2 - Study of Miniature Circuit Breakers (MCB) and Earth Leakage Circuit Breakers (ELCB)Document14 pagesExp. 2 - Study of Miniature Circuit Breakers (MCB) and Earth Leakage Circuit Breakers (ELCB)rishika chhibberNo ratings yet

- Low-Power CODEC With Audio/Voice DSP: 1. General DescriptionDocument4 pagesLow-Power CODEC With Audio/Voice DSP: 1. General Descriptionwicka3No ratings yet

- Arduino 4 Relays Shield Drives High Power LoadsDocument2 pagesArduino 4 Relays Shield Drives High Power LoadsBinNo ratings yet

- Catalogo Numatics 554SA400K046T30Document25 pagesCatalogo Numatics 554SA400K046T30Jair Mata Cuenca100% (1)

- Basic Radio HandlingDocument26 pagesBasic Radio HandlingVlademir Geb Dubouzet100% (1)

- Samsung Bn94-06301v Ue32f5000ak Main SCHDocument18 pagesSamsung Bn94-06301v Ue32f5000ak Main SCHSinorne50% (2)

- Basic Electronics PowerpointDocument16 pagesBasic Electronics PowerpointEarle Sean MendozaNo ratings yet

- DSP Simulation Assignment Using OctaveDocument33 pagesDSP Simulation Assignment Using Octaveapi-19320842No ratings yet

- Meanwell SMPS CATLOGUE.Document1 pageMeanwell SMPS CATLOGUE.rajstarNo ratings yet