Professional Documents

Culture Documents

SPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate Reservoirs

Uploaded by

Jose Miguel Gonzalez0 ratings0% found this document useful (0 votes)

60 views21 pagesThis paper was prepared for presentation at the Abu Dhabi International Petroleum Exhibition &Conferenceheld Abu Dhabi, UAE, 11-14 November 2012. Paper will outline a novel process for non-conventional batch chemical applications where bullhead stimulation treatments have been displaced deep into the formation.

Original Description:

Original Title

SPE-160703-MS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis paper was prepared for presentation at the Abu Dhabi International Petroleum Exhibition &Conferenceheld Abu Dhabi, UAE, 11-14 November 2012. Paper will outline a novel process for non-conventional batch chemical applications where bullhead stimulation treatments have been displaced deep into the formation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

60 views21 pagesSPE 160703 Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate Reservoirs

Uploaded by

Jose Miguel GonzalezThis paper was prepared for presentation at the Abu Dhabi International Petroleum Exhibition &Conferenceheld Abu Dhabi, UAE, 11-14 November 2012. Paper will outline a novel process for non-conventional batch chemical applications where bullhead stimulation treatments have been displaced deep into the formation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 21

SPE 160703

Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone

and Carbonate Reservoirs

Jordan, M.M. Nalco Ltd

Copyright 2012, Society of Petroleum Engineers

This paper was prepared for presentation at the Abu Dhabi International Petroleum Exhibition &Conferenceheld Abu Dhabi, UAE, 11-14 November 2012.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

In many oilfields the relatively small number of high-cost, highly productive wells, coupled with a carbonate and or sulfate

scaling tendency (upon waterflood breakthrough of injected seawater) requires effective scale management along with removal

of near-wellbore damage in order to achieve high hydrocarbon recovery.

The nature of the well completion strategy in new fields such as frac packs for sand control and acid stimulation for carbonate

reservoirs had resulted in some wells with higher than expected skin values due to drilling fluid losses, residual frac gel, fluid

loss agents, and fines mobilization within the frac packs where applied.

The paper will present how the challenges of managing impaired completions and inorganic scale forced innovation in terms

of when to apply both stimulation and scale inhibitor packages to sandstone and carbonate reservoirs. This paper will outline a

novel process for non-conventional batch chemical applications where bullhead stimulation treatments have been displaced

deep into the formation (>20ft) using a scale inhibitor overflush. Not only does this benefit the stimulation by displacing the

spent acid and reagents away from the immediate wellbore area, but the combined treatment provides cost savings with a

single mobilization for the combined treatment. The paper will describe the laboratory testing that was performed to qualify

the treatments for both sandstone and an HP/HT gas condensate carbonate reservoir. The lessons learned fromcarbonate

corefloodevaluationunder HT/HP conditions when appling stimulation fluids with and without scale inhibitor present in the

treatment stageswill be presented.

Many similar fields are currently being developed in offshore Brazil, West Africa and Middle East, and this paper is a good

example of best-practice sharing from another oil basin.

Introduction

The combining of scale squeeze treatments with matrix stimulations has the potential to bring cost saving to wells that have a

need for stimulation due to either generation of primary production or removal of completion/production related damage and

have a positive scale tendency that cannot be effectively treated by downhole chemical injection if installed. The following

section outlines the mechanism of scale formation and formation damage these treatments are designed to control and remove.

Nature of the Inorganic Scale Problem

Oilfield scales are inorganic crystalline deposits that form as a result of the precipitation of solids from brines present in the

reservoir and production flow system. The precipitation of these solids occurs as the result of changes in the ionic

composition, pH, pressure and temperature of the brine. There are three principal mechanisms by which scales form in oilfield

systems:

1) Decrease in pressure and/or increase in temperature of a brine, leading to a reduction in the solubility of the salt (most

commonly these lead to precipitation of carbonate scales, such as CaCO

3

);

2) Mixing of two incompatible brines (most commonly formation water rich in cations such as barium, calcium and/or

strontium, mixing with sulphate-rich seawater, leading to the precipitation of sulphate scales, such as BaSO

4

);

2 SPE 160703

3) Brine evaporation, resulting in the salt concentration increasing above the solubility limit and leading to salt

precipitation (as may occur in HP/HT gas wells where a dry gas stream may mix with a low rate brine stream resulting in

dehydration and most commonly the precipitation of NaCl).

Details of these mechanisms are given elsewhere

1-5

, as are the reasons why they pose problems in the production well,

near-well areas and surface facilities

6-8

, much less commonly in injection wells

9

, and never deep within the reservoir

10-13

. The

various techniques that may be adopted to meet the challenges of scale control may be divided into four principal categories,

as follows:

1) Selection of injection fluid source

2) Chemical inhibition

3) Chemical/mechanical remediation

4) Flow conformance

Stimulation Treatments

Stimulation treatments can be divided into two groups for the purpose of this paper; (1) treatments applied to ensure

production is possible via stimulation of the rock both carbonate and sandstones via acids or chelant formulations. (2)

treatments applied to regain production decline due to a range of mechanisms from completion induced damage, fines

mobilization, scale formation etc.

Combined Stimulation Squeeze Treatments in Sandstone Reservoirs

Sandstone Acid Plus Inhibitor

The author has already published work

14

on the inclusion of scale inhibitor (acid phosphonate) within a hydrochloric acid

formulation applied to clean perforation tunnels of perforation charge debris (zinc metal). This treatment stage was

overflushed with potassium chloride solution, again treated with the same scale inhibitor, prior to frac packing of the well.

Results from over 20 of these treatments show very effective treatment lifetimes were possible.

14

Sandstone Acid Stage Displaced by Inhibitor Squeeze Stage (Squimulation)

Following the success of the inclusion of acid phosphonate scale inhibitor into the well completion fluids it was decided to see

if it was possible to improve the economics of treatments to wells within the same field.

15

These required stand-alone squeeze

treatments and overtime were showing signs of production decline associated with completion induced damage that could be

removed via matrix acid stimulation treatments.

Six treatments have been applied to date following qualification of the chemicals as outlined in a previous publication.

15

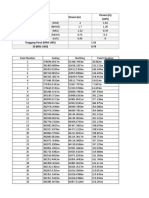

Table

1 shows the treatment programs deployed to four of the wells and Table 2 shows the improvement in oil production observed

following the deployment of the acid stimulation stage displaced by the scale squeeze treatment stage.

Table 1. Stimulation and squeeze treatment volumes applied

Well No

Treatment stage P4 P6 P5 P20

Acid

treatment Preflush 24 bbls SW 100 bbls of mutual solvent 50 bbls mutual solvent 71 bbls of mutual solvent

Preflush II 140 bbls Mutual solvent Not applied 102 bbls of solvent Not applied

Preflush acid 380 preflush acid 435 bbls of preflush acid 481 bbls preflush acid 524 bbls perflush acid

Mud acid Not Applied 100 bbls of mud acid 136 bbls of mud acid 95 bbls of mud acid

Spacer Not Applied 390 of preflush acid 323 bbls of preflush acid 321 bbls of preflush acid

Squeeze

treatment Preflush

300 bb s 0% u ua

solvent, 0.5% scale inibitor

in SW

350 bb s 0% u ua

solvent, 0.5% scale inibitor

in SW

80 bb s 0% u ua

solvent, 0.5% scale inibitor

in SW

50 bb s 0% u ua

solvent, 0.5% scale inibitor

in SW

Main treatment

1250 bbls of 10% scale

inhibitor in SW

650 bbls of 10% scale

inhibitor in SW

1800 bbls of 10% scale

inhibitor in SW

750 bbls of 10% scale

inhibitor in SW

Overflush

3000 bbls 0.1% scale

inhibitor in SW

1600 bbls 0.1% scale

inhibitor in SW

2850 bbls 0.1% scale

inhibitor in SW

1950 bbls 0.1% scale

inhibitor in SW

Design life days 365 days 180 days 365 days 365 days

design life bbls

water to MIC 1,880,000 bbls 785,610 bbls 3,200,000 bbls 1,600,000 bbls

SPE 160703 3

Table 2. Production gains observed for the stimulated/squeezed wells

Well Gain

BOPD

Year Comments

P4 no HF 2000 2010 Doubled PI, some production impaired by G/L valve plugging

P6 1600 2010 First HF treatment, lowered skin 40% and increased KH

P5 1000 2010 20% increase in oil and water production

P20 1200 2010 10% oil increase from squimulation. Prior stimulation (without

scale squeeze) doubled production.

Total 5800

The principle observation from these combined stimulation/squeeze treatments to sandstone reservoirs has been as follows:-

The squeeze treatments displacing the acid stimulation stage of the programs appear to have controlled scale

formation even after acid reflow over adsorbed chemical.

Scale inhibitor retention properties from the combined treatments compare favorably with retention properties from

prior scale squeeze treatments that did not include an acid package. And in some cases the acid appears to have

displaced scale inhibitor from prior squeezes deeper into the reservoir extending squeeze life.

This approach of combining the stimulation and the squeeze (Squimulation) not only benefits the stimulation by

displacing the spent acid and reagents away from the immediate wellbore area, but the combined treatment provides a

cost saving with a single mobilization for the combined treatment.

Based on the above findings for sandstone reservoirs

15

the next logical step is to assess if the inclusion of scale inhibitor within

acid or an acid displacement by inhibitor treatment stage would be effective in carbonate reservoirs given that acid stimulation

are a very common operation in such reservoirs to start production and to enhance production during the life of a well.

Qualification of Scale Inhibitor for Inclusion in Stimulation Treatments for and HP/HT Carbonate Reservoir

As outlined for sandstone reservoirs two possible application environment were identified for the treatment of carbonate

reservoirs in a previous publication.

16

Scale inhibitor (low molecular weight phosphonate

17

) within the stimulation fluid

(organic acid) or applied as in the Squimulation programs for the sandstone reservoirs with the stimulation fluid being

displaced by the inhibitor squeeze stage.

Test Program

Three coreflood studies were carried out within the qualification, (1) acid formulation plus the scale inhibitor (2) Stimulation

fluid only and a (3) conventional scale squeeze treatmentto confirm that if the stimulation fluid was applied and then displaced

by the conventional squeeze treatment there would be no formation damage.

Full details of the coreflood program is presented in Appendices A and B. The core material used was taken from an HP/HT

field (155C) reservoir producing from carbonate (Photographs 1 and 2) with a very low permeability of < 0.5mD, flow regime

was via the matrix to the natural fractures within the rock, filtered field condensate was used, synthetic produced water (Table

3) which appears to be a mixture of formation water and water of condensation, with oxygen free nitrogen as the gas phasewas

also utilized in the study.

The stimulation system was a very mild acid (pH 4 organic acid chelant, neutralized aliphatic amine acid) formulated with the

correct percentage of corrosion inhibitor, non-emulsifier, anti-slugging chemical. This formulation had been applied to

stimulate other wells within the candidate field. The scale inhibitor was a very calcium compatible thermally stable scale

inhibitor applied in many HP/HT sandstone reservoirs to control carbonate and mild sulphate scales.

17,18,19

4 SPE 160703

Photograph 1 Preserved reservoir core body Photograph 2 1.5 inch diameter plug before

trimming

Table 3. Produced water composition used in HT carbonate coreflood study

Ion in mg/l

Typical Produced

Water

Na 2560

Ca 41

Mg 6

K 16

Sr 6

Cl 3779

HCO3 200

SO4 90

pH 6

Coreflood Results

Three tests were carried and assessment was madeof the differential pressure during condensate, gas and produced water

injection (permeability) prior to and after chemical injection along with the differential pressure values recorded during the

injection of the chemical treatment stages. The critical cations (calcium, magnesium, lithium tracer) concentration within the

inhibitor return profile from the production stages was also evaluated.

Test 1Carbonate Stimulation Fluid PlusScale Inhibitor

In order to evaluate applying scale inhibitor within stimulation treatments a coreflood test was conducted using the full test

program is presented in Appendix A. The application of the scale inhibitor within the stimulation acid would eliminate the

need to scale squeeze the well for an extended period of time as any produced water would be treated with scale inhibitor.

Conventional scale squeezes would still be required in the future once stimulation/squeeze treatment chemical has been

exhausted. The following section provides the results from the formation damage/inhibitor retention coreflood giving the

effects of using an organic acid package with 10% low molecular weight phosphonate (LMWP) scale inhibitor blended into it.

Fig. 1 shows the condensate saturation (stages 2.11) this will be used to determine whether there is any impact on condensate

permeability following the inhibitor/acid treatment, Appendix A. Fig. 2 shows the gas saturation (stage 2.13) carried out prior

to injection for the combined organic acid/scale inhibitor treatment stage.

SPE 160703 5

Fig. 1 - Condensate saturation prior to stimulation/scale inhibitor injection, stage 2.11, see appendix A

0

100

200

300

400

500

600

700

800

900

1000

0 10 20 30 40 50 60 70 80 90 100 110 120

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour

Q = 60ml/hour

Fig. 2 Gas (Nitrogen) saturation prior to stimulation/scale inhibitor injection, stage 2.13, see appendix A

In Fig. 3 the differential pressure observed when the 0.5 pore volume (pv) of chemical package 10% Low molecular weight

phosphonate (LMWP) within the organic acid stimulation fluid is injected. Half a pore volume of the combined scale

inhibitor/acid package was injected in order to create a worm hole within the core that would not penetrate the full length of

the core, this allows for further condensate, gas and water permeability to be carried out after chemical treatment. The rise in

differential pressure as the combined acid and LMWP formulation hit the core is likely to be due to the excessive precipitation

of the scale inhibitor with the released calcium from the acid digestion of the core. However the slightly higher viscosity of

the stimulation fluid (double that of the synthetic produced water) could also account for a slight rise in pressure but not to the

extent observed in Fig. 3. Compatibility evaluation of the acid formulation with 10% of the LMWP was also conducted to

ensure that the rise in differential pressure was not due to incompatibility between the scale inhibitor and some of the additives

within the organic acid formulation. These tests carried out at 155C showed no incompatibility and hence the theory of

excessive calcium release from the core is the most likely mechanism of the profile present in Fig. 3 during the

stimulation/inhibitor formulation injection.

6 SPE 160703

Fig. 3 - Scale inhibitor plus Stimulation Fluid injection, stage 3.1, see appendix A

0

100

200

300

400

500

600

700

800

900

1000

0 1 2 3 4 5

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (mins)

Differential Pressure (psi)

Stage 3.1:

10% LMWP + 100ppm Li in organic acid,

pH = 4.02,

Q = 60ml/hour,

T = 155C

Fig. 4 shows the differential pressure observed during the gas saturation of the core post the stimulation fluid/scale inhibitor

injection. The profile post the stimulation treatment looks very similar to that prior to the chemical application (Fig.2).

Condensate was injected into the core following the gas injection (Fig. 5), while the initial period of injection is slightly more

spiky possibly due to displacement of the gas phase rather than brine phase as was present in the conditioning stage (Fig. 1)

the differential pressure appears to steady at a lower value than was measured prior to the stimulation/scale inhibitor

application.

Fig. 4 - Gas (Nitrogen) saturation post inhibitor plus acid chemical treatment, stage 5.1, see appendix A

SPE 160703 7

Fig. 5 Condensate saturation post inhibitor plus acid chemical treatment, stage 5.3, see appendix A

0

100

200

300

400

500

600

700

800

900

1000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour

Q = 60ml/hour

Fig. 6 shows the differential pressure observed during the produced water saturation of the core post the stimulation fluid/scale

inhibitor injection and gas followed by condensate saturations. It is clear that the differential pressure steadily falls from an

initial value of 600 Psi to 300 psi over the 72 hour flowback period. The differential pressure profile would suggest that after

initial condensate displacement the steadily declining pressure may be due to dissolution or displacement of the precipitation

phase suggested to have formed during initial stimulation/scale inhibitor stage injection (Fig. 3).

Fig. 6 Produced water saturation post inhibitor plus acid chemical treatment, stage 6.1, see appendix A

0

100

200

300

400

500

600

700

800

900

1000

0 6 12 18 24 30 36 42 48 54 60 66 72

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (hours)

Differential Pressure (psi)

Q = 60ml/hour

Coreflood 1, stimulation fluid plus scale inhibitor treatment permeability data assessment. The following table (Table 4)

shows the permeability data calculated at different stages of the coreflood conditioning and chemical injection.

The brine, condensate and gas permeability measured during stages 2.10, 2.12 and 2.14 respectivelywere used to compare the

fluid permeabilies following stimulation/inhibitor chemical injection and produced water flowback. The condensate

permeability post chemical treatment was measured at 0.13mD, this is an increase 18% and after 600PV of produced water

flowback this has further increased to 0.15mD.

The gas permeability showed no initial change following stimulation/inhibitor chemical application staying at 0.13mD but

following a further 600pv of produced water injection it has increased to 0.52mD (400% increase).

8 SPE 160703

Produced water permeability reduced from 0.18mD to 0.11mD (decline of 39%) following stimulation/inhibitor application

but following 600pv of injection rose to 0.19mD (increase of 6% from initial pre chemical application value). The initial

decline in brine permeability following the chemical application and its recovery post produced water injection would suggest

that a brine soluble compound was removed during the extended (600pv) brine injection period.

Table 4. Coreflood 1, permeability date pre and post combined stimulation fluid/scale inhibitor application

!"#$% '() *%+,-./".(0 (1 "2% +"#$% 32%-% 4%#+5-%4%0" "#6%0 7%-4%#8.9.": ;-#,".(0 7%-4%#8.9.": <2#0$%

=)>? 7-% ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" >@@< ?)>A4*

=)>= 7-% ,2%4.,#9 "-%#"4%0" ,(0B%0+#"% /%-4%#8.9.": #" >@@< ?)>>4*

=)>C 7-% ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" >@@< ?)>D4*

In[ect|on, shut-|n and backf|ow of St|mu|at|on f|u|d]Low Mo|. hosphonate Sca|e Inh|b|tor

@)= 7(+" ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" >@@< ?)>D4* >)??

E)C 7(+" ,2%4.,#9 "-%#"4%0" ,(0B%0+#"% /%-4%#8.9.": #" >@@< ?)>D4* >)>A

E)= 7(+" ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" >@@< ?)>>4* ?)E>

I|ood core w|th format|on water for 600 V

F)C 7(+" ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" >@@< ?)@=4* C)??

F)= 7(+" ,2%4.,#9 "-%#"4%0" ,(0B%0+#"% /%-4%#8.9.": #" >@@< ?)>@4* >)DE

A)= 7(+" ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" >@@< ?)>G4* >)?E

There is clear evidence of formation damage if the organic acid stimulation fluid with 10% LMWP is applied as a blended

stage to the core. The damage will recover with water production as the suspended damaging solid a precipitated inhibitor

calcium complex, re-dissolves.

Scale Inhibitor desorption profiles during combined acid and scale inhibitor treatment injection and back-flow stages. Fig.

7presentes the critical concentration of ions within the flood effluent during produced water displacement of the

stimulation/scale inhibitor fluid and Fig. 8 presents the concentration of phosphonate within the synthetic produced water

during the back production stage of the coreflood test.

Fig. 7shows aninitial spike in calcium and magnesium ion concentration during the injection of the produced water.

Magnesium concentration declines rapidly to injected brine concentration (6ppm, see Table 3)but calcium ion concentration

takes 100pv to decline below 100ppm, the injection brinecontains only 40ppm. This steady decline in calciumfollows the

same trend as the declining inhibitor concentration profile. The higher than input values are most likely due to the release of

precipitated calcium from a calcium phosphonate inhibitor complex formed during injection of the stimulation/scale inhibitor

stage.

SPE 160703 9

Fig. 7 - Combined inhibitor/stimulation fluidsproduced water desorption profile, stage 6.1, see appendix A

!"#!!

#"!!!

#!"!!!

#!!"!!!

#!!!"!!!

#!!!!"!!!

!"!!! $!"!!! %!"!!! &!"!!! '!"!!! #!!"!!! #$!"!!! #%!"!!! #&!"!!! #'!"!!! $!!"!!!

!

"

#

$

%

#

&

'

(

&

)

"

#

+

,

,

-

.

!/--/0(&)1% 2"'% 3"0/-%4

() *+ ,- ./

The effluent during the three days of brine flowback was collected and analyzed for the concentration of scale inhibitor, Fig.8.

This stage of the program was carried out to assess if the inhibitor within the stimulation fluid would be released from the core

surface. The return profile observed during this simulated production stage clearly shows that if produced wateris flowing

over rock treated with the stimulation/scale inhibitor blend than the inhibitor is released from the rock and returned to surface

within the flowing brine stream. In terms of return profile given the very small volume of inhibitor applied (0.5pv) relative to

a typical coreflood program (5 to 10pv) the return profile shows excellent retention and release characteristics and one that if

reproduced in the field would protect many months of produced water.

Fig. 8 - Combined inhibitor/stimulation acid produced water desorption profile, stage 6.1, see appendix A

0

1

10

100

1000

10000

0 100 200 300 400 500 600

l

o

g

S

I

C

o

n

c

e

n

t

r

a

t

i

o

n

(

p

p

m

)

Cumulative Pore Volumes

!"# $%&'(()

10 SPE 160703

Test 2 Carbonate Stimulation Fluid Displaced by Inhibitor

A coreflood was conducted using the stimulation fluids alone without the addition of scale inhibitor. This test was intended to

confirm that the stimulation fluid alone did not negatively impact the core and so implies that if the acid formulation could be

separated from the low molecular weight phosphonate squeeze chemical via a spacer stage it would be safe to apply in the

field.

As with corefloodtest 1 this coreflood was conducted using reservoir conditioned carbonate core from the same core body but

a newly cut 1.5 inch diameter plug. Fig. 9 shows the condensate saturation conducted (stage 2.11, Appendix B) and Fig. 10

shows the gas saturation conducted (stage 2.13, Appendix B); thesevalues will be compared to the measurements made

following injection of the organic acid stage.

Fig. 9 - Condensate saturation prior to stimulation treatment, stage 2.11, Appendix B.

0

100

200

300

400

500

600

700

800

900

1000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour Q = 60ml/hour

Fig. 10Gas (nitrogen) saturation prior to stimulation treatment, stage 2.13, Appendix B.

Fig. 11 shows the differential pressure observed as the 0.5 PV of stimulation fluid is injected at 60ml/h. The rise in differential

pressure with stimulation fluid injection is very similar to that observed when the stimulation fluid combined with the scale

SPE 160703 11

inhibitor was injected, Figure 3.

Fig. 11 - Stimulation fluid injection, stage 3, Appendix B

0

100

200

300

400

500

600

700

800

900

1000

0 1 2 3 4 5 6 7 8 9 10

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (mins)

Differential Pressure (psi)

Stage 3.1

Stimulation fluid only,

Q = 60ml/hour,

T = 155C

Figs. 12, 13 and 14 shows the differential pressure observed as gas, condensate and produced brine respectively are injected

into the core after injection of the stimulation fluid treatment.

Fig. 12 -Gas saturation post stimulation fluid injection, stage 5.1, see appendix B

12 SPE 160703

Fig. 13 Condensate saturation post stimulation injection, stage 5.3, see appendix B

0

100

200

300

400

500

600

700

800

900

1000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour

Q = 60ml/hour

Fig. 14 Produced water saturation post stimulation injection, stage 5.5, see appendix B

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour

Q = 60ml/hour

Coreflood 2, stimulation acid permeability data assessment. The following table (Table 5) shows the permeability data

calculated at different stages of the coreflood conditioning prior to and following stimulation fluid injection.

The condensate permeability post chemical treatment was measured at 0.15mD, this is an increase of 7% and after 15PV of

produced water flowback it had declined slightly to 0.14mD (decline of 7%).

The gas permeability showed an initial change following stimulation chemical application from 0.11mD to 0.12mD (increase

of 9%) with no change following a further 15pv of produced water injection.

Produced water permeability reduced from 0.13mD to 0.04mD (decline of 69%) following stimulation application and

following 15pv of injection remained unchanged at 0.04mD. The initial decline in brine permeability following the chemical

application and lack of recovery post produced water injection would suggest that the core has become more oil and less brine

wet and that no brine soluble compounds were present in the core.

SPE 160703 13

Table 5. Coreflood 2, permeability data pre and post stimulation fluid application

!"#$% '() *%+,-./".(0 (1 "2% +"#$% 32%-% 4%#+5-%4%0" "#6%0 7%-4%#8.9.": ;-#,".(0 7%-4%#8.9.": <2#0$%

=)>? 7-% ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" >@@< ?)>A4*

=)>= 7-% ,2%4.,#9 "-%#"4%0" ,(0B%0+#"% /%-4%#8.9.": #" >@@< ?)>@4*

=)>C 7-% ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" >@@< ?)>>4*

!"#$%&'(") +,-&.'" /"0 1/%234(5 (3 6&'7-4/&'(" 34-'0

@)= 7(+" ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" >@@< ?)>=4* >)?D

@)C 7(+" ,2%4.,#9 "-%#"4%0" ,(0B%0+#"% /%-4%#8.9.": #" >@@< ?)>E4* >)?F

@)E 7(+" ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" >@@< ?)?C4* ?)A>

84((0 %(9$ 5'&, 3(97/&'(" 5/&$9 3(9 :; <=

7(+" ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" >@@< ?)>=4* >)??

7(+" ,2%4.,#9 "-%#"4%0" ,(0B%0+#"% /%-4%#8.9.": #" >@@< ?)>C4* ?)DA

7(+" ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" >@@< ?)?C4* ?)A>

It is clear that the stimulation fluid alone increased the permeability of the core to gas and condensate so confirms the findings

in Coreflood test 1 which showed the mixed stimulation fluid and low molecular weight phosphonate would cause damage

due to inhibitor reaction with spent acid and calcium released from the core. It is expected that if the spent organic acid

stimulation fluid and the scale inhibitor were separated by a brine spacer stage then no formation damage would occur within

the core or reservoir.

Test 3 Conventional scale squeeze

Prior to injection of the conventional squeeze treatment chemical (low molecular weight phosphonate) condensate and gas

saturation cycles were conducted with permeability measured at three flow ratesusing the same core that was treated with the

Test 2 stimulation flood only. The differential pressure data recorded during the condensate and gas saturation step is

presented in Figs. 15 and 16 respectively. The pre treatment saturation stages should be compared and contrasted with those

post the squeeze treatment presented in Figs. 18 and 19.

Fig. 15- Condensate saturation prior to chemical injection, stage 5.7, see appendix B

0

100

200

300

400

500

600

700

800

900

1000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour

Q = 60ml/hour

14 SPE 160703

Fig. 16- Gas (nitrogen) saturation prior to chemical injection, stage 5.9, see appendix B

Fig. 17 shows the differential pressure recorded when the conventional squeeze treatment stage (10% low molecular weight

phosphonate scale inhibitor) is injected. A shut in at 155C overnight followed this stage. It is clear that the differential

pressure steadily rises as the main inhibitor stage is injected into the core. The rise in differential pressure is a similar shape of

profile to that observed for the stimulation fluids alone, Coreflood 2, Fig.11. Inhibitor chemical compatibility assessments

were also conducted prior to the coreflood study to show that the inhibitor and the synthetic produced water were compatible

over a range of mixing ratios up to reservoir temperature of 155C. This inhibitor has application history within reservoir up to

170C and in reservoirs of up to 35,000ppm calcium within the produced water

16,17,18

so bulk precipitation was not expected to

be an issue.

Fig. 17 - Preflush and 10% Low Mol. Wt. phosphonate scale inhibitor injection, stage 6, see appendix B

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 1 2 3 4 5 6 7 8

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (mins)

Differential Pressure (psi)

Stage 3.1

10% Low Mol. Wt. Phosphonate + 100ppm Li in 2% KCl

pH = 3.90,

Q = 60ml/hour,

T = 155C

Displacement of the main treatment stage by gas followed by condensate followed by synthetic produced water is presented in

Figs. 18, 19 and 20 respectively It is clear that the pressure profile for these fluid types recorded before squeeze treatment

application and after are very similar suggesting no significant formation damage was observed with respect to the fluids.

SPE 160703 15

Fig. 18 Gas (nitrogen)saturation post the conventional scale squeeze treatment, stage 8.1, see appendix

B

Fig. 19 Condensate saturation post the conventional scale squeeze treatment, stage 8.3, see appendix B

0

100

200

300

400

500

600

700

800

900

1000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differential Pressure (psi)

Q = 30ml/hour

Q = 60ml/hour

16 SPE 160703

Fig. 20 Produced water saturation post the conventional scale squeeze treatment, stage 8.5, see appendix B

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150

D

i

f

f

e

r

e

n

t

i

a

l

P

r

e

s

s

u

r

e

(

p

s

i

)

Time (minutes)

Differntial Pressure (bar)

Q = 30ml/hour

Q = 60ml/hour

Coreflood 3, Squeeze treatment permeability data assessment.The following table (Table 6) shows the permeability data

calculated at different stages of the coreflood conditioning prior to and following squeeze chemical injection.

The condensate permeability post chemical treatment was measured at 0.15mD, this is an increaseof 7% over the pre squeeze

measured permeability.

The gas permeability showed an initial change following the squeeze chemical application from 0.12mD to 0.10mD (decrease

of 17%).

Produced water permeability remained unchanged at 0.04mD following squeeze chemical application

The fact that the brine permeability is not reduced by the squeeze chemical a feature that was observed in the

stimulation/squeeze treatment (Table 4) and the stimulation fluid alone (Table 5) would suggest that the stimulation fluid is

reducing the ability of water to pass through the core possibly due to a wettability effect. The squeeze treatment and

stimulation fluid alone and in combination increased the condensate permeability. The gas permeability shows only a slight

negative impact when the squeeze treatment was applied (not observed with the stimulation and stimulation/squeeze

combined) but this slight reduction is expected to be removed rapidly on brine production as was observed in the

stimulation/scale inhibitor coreflood but this stage was not carried out on the squeeze only coreflood.

Table 6. Coreflood 3, permeability data pre and post conventional scale squeeze application

!"#$% '() *%+,-./".(0 (1 "2% +"#$% 32%-% 4%#+5-%4%0" "#6%0 7%-4%#8.9.": ;-#,".(0 7%-4%#8.9.": <2#0$%

7-% ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" =>>< ?)?@4*

7-% ,2%4.,#9 "-%#"4%0" ,(0A%0+#"% /%-4%#8.9.": #" =>>< ?)=@4*

7-% ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" =>>< ?)=B4*

In[ect|on, shut-|n and backf|ow of Low Mo|. hosphonate Sca|e Inh|b|tor

7(+" ,2%4.,#9 "-%#"4%0" $#+ /%-4%#8.9.": #" =>>< ?)=?4* ?)CD

7(+" ,2%4.,#9 "-%#"4%0" ,(0A%0+#"% /%-4%#8.9.": #" =>>< ?)=>4* =)?E

7(+" ,2%4.,#9 "-%#"4%0" 8-.0% /%-4%#8.9.": #" =>>< ?)?@4* =)??

SPE 160703 17

Conclusions

There are clear differences between the interaction observed between scale inhibitor within acid stimulation fluids based on the

rock type being treated and for this reason the conclusions are split into those for a sandstone reservoir

14,15

and those for a

carbonate reservoir reported here and in previous publications.

19

Sandstone (<5% carbonate grains present) conclusions

For sandstone reservoirs scale inhibitor deployed within the existing perforation wash acid and displacement fluid

program under matrix, radial flow allows effective protection during early water production

Perforation wash acid and overflush fluid treated with phosphonate scale inhibitor has been shown to protect between

190,000 to 2,100,000bbls of produced water, allowing between 210 to 650 days of production. This protection

allowed the water cut to increase without scale formation, reducing/eliminating the risk of squeezing low water cut

wells

The development for sandstone reservoirs of a novel process for non-conventional batch chemical applications where

bullhead stimulation treatments (HCl & HCl/HF) have been displaced deep into the formation (>20ft) using a scale

inhibitor overflush has been proved to be effective in the four wells treated to date.

The squeeze treatments displacing the acid stimulation stage of the programs appear to have controlled scale

formation even after acid reflow over adsorbed chemical within sandstone reservoirs.

Scale inhibitor retention properties from the combined treatments to sandstone reservoirs compare favorably with

retention properties from prior scale squeeze treatments that did not include an acid package. And in some cases the

acid appears to have displaced scale inhibitor from prior squeezes deeper into the reservoir extending squeeze life.

Carbonate conclusions

Based on the carbonate coreflood results presented in this study and in a previous publication

19

it is not advised to

blend phosphonate scale inhibitor with acid or organic chelant stimulation fluids as there is a risk of formation

damage potential under matrix flow conditions. This damage is believed to be due to excessive precipitation of the

scale inhibitor with calcium released from the rock by the action of the acid or organic chelant and the increased pH

at the rock/fluid interface associated with the carbonate dissolution process

Application of the acid or organic chelant stimulation treatment displaced by the scale squeeze with a suitable spacer

volume would give the stimulation required and effective squeeze life without formation damage risk for carbonate

reservoirs.

Scale inhibitor return profiles look excellent for phosphonate scale inhibitors in carbonate reservoirs applied as

conventional squeeze or as part of Squimulation type treatment.

General statement

This approach of deploying the stimulation step and the squeeze step (Squimulation) into one pumping operation

not only benefits the stimulation by displacing the spent acid and reagents away from the immediate wellbore area,

but pumping of the treatments stages provides a cost saving with only a single mobilization now being required for

the combined treatment.

Acknowledgments

The authors wish to thank the Nalco, for permission to publish this work. We also greatly appreciate support and assistance

from Nalcos Aberdeen based laboratory staff and members of Scaled Solutions Ltd who carried out the corefloodapplications

outlined in this paper.

18 SPE 160703

References

1 Oddo, J.E. and Tomson, M.T.: Why Scale Forms in the Oil Field and Methods to Prevent It, SPE Production and Facilities

(Feb. 1994) 47-54.

2 Ramstad, K., Tydal, T., Ellersten, E. and Jakobsen, T.: Precipitation and Deposition of CaCO

3

. Laboratory Studies and Field

Experience, presented at the 1999 NIF Tenth International Oil Field Chemicals Symposium, Fagernes, Norway, Mar. 1-3.

3 Vetter, O.J., Kandarpa, V. and Harouaka, A.: Prediction of Scale Problems due to Injection of Incompatible Waters, JPT (Feb.

1982) 273-284.

4 Jacques, D.F. and Bourland, B.I.: A Study of Solubility of Strontium Sulfate, SPEJ (Apr. 1983) 292-300.

5 Vetter, O.J., Kandarpa, and Phillips, R.C.: Prediction of Deposition of Calcium Sulfate Scale under Down-Hole Conditions, JPT

(Oct. 1970) 273-2841299-1308.

6 White, R., Brookley, J. and Menzies, N.: Practical Experiences of Gel Diversion Technique and an Overview of Scale

Management for the Alba Field, SPE Symposium on Oilfield Scale: Field Applications and Novel Solutions, Aberdeen, Scotland,

27 - 28 January 1999.

7 Mackay, E.J. and Sorbie, K.S.: Brine Mixing in Waterflooded Reservoirs and the Implications for Scale Prevention paper SPE

60193 presented at the SPE 2nd International Symposium on Oilfield Scale, Aberdeen, Scotland, 26-27 January 2000.

8 Sorbie, K.S. and Mackay, E.J.: Mixing of Injected, Connate and Aquifer Brines in Waterflooding and its Relevance to Oilfield

Scaling Journal of Petroleum Science and Engineering (July 2000) 27 (1-2) 85-106

9 Mackay, E.J., Collins, I.R., Jordan, M.M. and Feasey, N.: PWRI: Scale Formation Risk Assessment and Management paper SPE

80385, presented at the SPE 5th International Symposium on Oilfield Scale, Aberdeen, Scotland, 29-30 January 2003.

10 Bertero, L, Chierici, G L, Gottardi, G, Mesini, E. and Mormino, G: Chemical Equilibrium Models: Their Use in Simulation the

Injection of Incompatible Waters, SPE Reservoir Engineering, (February 1988) 288-294.

11 Paulo, J. and Mackay, E.J.: Modelling of In-Situ Scale Deposition presented at the 12

th

International Oil Field Chemical

Symposium, Geilo, Norway, 1-4 April 2001.

12 Mackay, E.J.: Predicting In-Situ Sulphate Scale Deposition and the Impact on Produced Ion Concentrations, Trans IChemE

(March 2003) 81 (A) 326-332.

13 Mackay, E.J., Jordan, M.M., Feasey, N., Shah, D., Kumar, P. and Ali, S.: Integrated Risk Analysis for Scale Management in

Deepwater Developments paper SPE 87459, presented at the SPE 6

th

International Symposium on Oilfield Scale, Aberdeen,

Scotland, 26-27 May 2004.

14 Patterson, D., Kendrick, M., Thurston, K., Malondan, J., Riordan, H., Jordan, H., Witort, M. and Morrow, B. Sulfate Scale

Inhibition Via Stimulation Program Carried out During Well Completion, Deepwater, West Africa, presented at NACE 2011,

March 14

th

to 17

th

, Houston USA

15 Patterson, D., Kendrick, M. William, W. and Jordan M.: Squimulation Simultaneous Well Stimulation and Scale Squeeze

Treatments in Deep-Water, West Africa, SPE 151863, presented as the SPE International Symposium and Exhibition on

Formation Damage Control, Lafayette, USA, 15

th

-17

th

February 2012.

16 Jordan, M.M., Simultaneous Well Stimulation and Scale Squeeze Treatments in Sandstone and Carbonate Reservoirs Part 1

SPE 156804, presented atSPE International Production and Operations Conference and Exhibition in Doha, Qatar, 14-16

th

May

2012.

17 Brockmann, R, Bache, O., Asheim, T.I, Feasey, N.D and Jordan, M.M. CaCO3 Inhibition Efficiency and Thermal Stability of

Generically Different Scale Inhibitors for High Temperature Conditions. Presented at 9

th

International Oilfield Chemicals

Symposium, Geilo 22-25

th

March 1998.

18 Jordan, M.M, Feasey, N., Johnston, C, Marlow, D, and Elrick, M. Biodegradable Scale Inhibitors. Laboratory to Field Evaluation

of Green Carbonate and Sulphate Scale Inhibitors with Deployment Histories in the North Sea. Presented at the Royal Society

of Chemistry, Chemistry in the Oil Industry, Manchester 5-6

th

November 2007.

19 Dyre, S. Orski, K. Menezes, C., Heath, S., MacPherson, C., Simpson, C. and Graham, G. Development of Appropriate Test

Methodologies for the Selection and Application of Lead and Zinc Sulphide Inhibitors for Elgin/Franklin Field SPE 100627,

presented at SPE International Oilfield Scale Symposium, Aberdeen, UK, 30

th

May 1

st

June 2006.

SPE 160703 19

Appendix A Coreflood procedure 1

The procedures used are intended to simulate as closely as is practically possible a real field squeeze treatment, broadly the

same squeeze conditions which would be present in the field for the well to be treated.

To maximize the limited core available for testing two reservoir core plugs (8cm long by 3.75cm diameter) was used for the

three chemical tests. Core plug 1 was used for stimulation fluid/scale inhibitor and core plug 2 was used for the stimulation

fluid and then re used for the stand alone squeeze treatment.

Outline Procedure: Inhibitor Application, Formation Damage and Inhibitor Return

NOTE: Forward Flow (FW) = Formation to Wellbore Direction

Reverse Flow (WF) = Wellbore to Formation Direction

1. Ambient Stages

1. Run dead volume in rig, 45 x 1ml samples with Li and 45 x 1ml samples without Li (per direction).

2. Assemble reservoir core plug in core holder & pressure test overburden to 1500psi

3. Mild solvent cleaning with cyclic saturations of methanol, toluene and methanol

4. Short FW Formation Water Saturation at low rate

5. FW Formation Water Saturation at ambient conditions at 100% Swi

6. FW & WF Formation Water Permeability at ambient conditions at 100% Swi

7. FW Formation Water Saturation to reservoir temperature (T = 155C)

2. Pre-treatment Stages at T = 155C

1. FW Pre-treatment Formation Water Saturation (1) at 100% Sw

2. FW Pore Volume / Porosity (by Li tracer) at 100% Sw

3. FW & WF Pre-treatment Formation Water Multi-rate Permeability (1) at 100% Sw

4. FW Pre-treatment Condensate Oil Saturation (1) to Swr

5. FW & WF Pre-treatment Condensate Oil Multi-rate Permeability (1) at Swr

6. FW Pre-treatment Gas (OFN) Saturation (1) to Swor

7. FW & WF Pre-treatment Gas (OFN) Multi-rate Permeability (1) at Swor

8. FW Pre-treatment Formation Water Saturation (2) to Sgor

9. FW Pore Volume / Porosity (by Li tracer) at Sgor

10. FW & WF Pre-treatment Formation Water Multi-rate Permeability (2) at Sgor

11. FW Pre-treatment Condensate Oil Saturation (2) to Sgwr

12. FW & WF Pre-treatment Condensate Oil Multi-rate Permeability (2) at Sgwr

13. FW Pre-treatment Gas (OFN) Saturation (2) to Swor

14. FW & WF Pre-treatment Gas (OFN) Multi-rate Permeability (2) at Swor

3. Main Treatment Application Sequence, WF direction at T = 155C

Acid Application, WF Direction: 0.5 pore volume Organic Acid (as supplied) + 10% LMWP

4. Shut in over 16 hours at T = 155C

5. Flow Back Saturation Stages (Formation Damage)at T = 155C

1. FW Flow Back Gas (OFN) Saturation to Swor

chem

2. FW & WF Flow Back Effective Gas (OFN) Multi-rate Permeability at Swor

chem.

3. FW Flow Back Condensate Oil Saturation to Sgwr

4. FW & WF Flow Back Condensate Oil Multi-rate Permeability at Sgwr

6. Short Post-flush to Sor at T = 155C

1. FW Post-flush Brine Saturation to Sgor over five days

Test Stages

1 Stimulation fluid/Scale Inhibitor Appendix A Stages 1 to 8

2 Stimulation fluid Appendix B Stages 1 to 5.10

3 Squeeze Appendix B stages 5.11 to 6.8

20 SPE 160703

2. FW & WF Post-flush Brine Multi-rate Permeability at Sgor

7. Post-treatment Stages at T = 155C

1. FW Post-treatment Condensate Oil Saturation to Sgwr

2. FW & WF Post-treatment Condensate Oil Multi-rate Permeability at Sgwr

3. FW Post-treatment Gas (OFN) Saturation to Swor

4. FW & WF Post-treatment Gas (OFN) Multi-rate Permeability at Swor

8. Post-treatment Stages at T = 155C

1. FW Post-treatment Formation Water Saturation to Sgor

2. FW & WF Post-treatment Brine Multi-rate Permeability at Sgor

Temperature and confining pressure carefully lowered to ambient. Core removed, wrapped and stored prior to CAT

scanning of the core to assess wormhole generation/propagation.

Stage 5 and Stage 7 why repeat the saturation cycles ? Stage 5 cycle of fluid saturation established the permeability after the

main treatment stage has been swept back by the gas and condensate. This is what is believed to be happing during initial

flowback of the well post treatment. With time water production starts (Stage6) and the produced brine flushes and dissolves

water soluble chemical from the mineral surfaces. Stage 7 evaluates the gas and condensate permeability after the onset of

brine production following the treatment. The test determines if the production of brine will improve the permeability to gas

and condensate due to removal of water soluble compounds from the core.

Appendix B Coreflood procedures 2 & 3

NOTE: Forward Flow (FW) = Formation to Wellbore Direction

Reverse Flow (WF) = Wellbore to Formation Direction

1. Ambient Stages

1. Run dead volume in rig, 45 x 1ml samples with Li and 45 x 1ml samples without Li (per direction).

2. Assemble reservoir core plug in core holder & pressure test overburden to 1500psi

3. Mild solvent cleaning with cyclic saturation of methanol

4. Short FW Formation Water Saturation at low rate

5. FW Formation Water Saturation at ambient conditions at 100% Swi

6. FW & WF Formation Water Permeability at ambient conditions at 100% Swi

7. FW Formation Water Saturation to reservoir temperature (T = 155C)

2. Pre-treatment Stages at T = 155C

1. FW Pre-treatment Formation Water Saturation (1) at 100% Sw

2. FW Pore Volume / Porosity (by Li tracer) at 100% Sw

3. FW & WF Pre-treatment Formation Water Multi-rate Permeability (1) at 100% Sw

4. FW Pre-treatment Condensate Oil Saturation (1) to Swr

5. FW & WF Pre-treatment Condensate Oil Multi-rate Permeability (1) at Swr

6. FW Pre-treatment Gas (OFN) Saturation (1) to Sgor

7. FW & WF Pre-treatment Gas (OFN) Multi-rate Permeability (1) at Sgor

8. FW Pre-treatment Formation Water Saturation (2) at Sor

9. FW Pore Volume / Porosity (by Li tracer) at Sor

10. FW & WF Pre-treatment Formation Water Multi-rate Permeability (2) at Sor

11. FW Pre-treatment Condensate Oil Saturation (2) to Swr

12. FW & WF Pre-treatment Condensate Oil Multi-rate Permeability (2) at Swr

13. FW Pre-treatment Gas (OFN) Saturation (2) to Sgwor

14. FW & WF Pre-treatment Gas (OFN) Multi-rate Permeability (2) at Sgwor

SPE 160703 21

Stimulation fluid Injection

3. Main Treatment Application Sequence, WF direction at T = 155C

Organic Acid Application, WF Direction: 0.5 pore volume Organic acid (applied as supplied)

4. Shut in over 16 hours at T = 155C

5. Flow Back Saturation Stages (Formation Damage)at T = 155C

1. FW Flow Back Gas (OFN) Saturation (1) to Sgwor

chem

2. FW & WF Flow Back Effective Gas (OFN) Multi-rate Permeability (1) at Sgwor

chem.

3. FW Flow Back Condensate Oil Saturation (1) to Sgwr

4. FW & WF Flow Back Condensate Oil Multi-rate Permeability (1) at Sgwr

5. FW Brine Saturation to Sgor

6. FW & WF Brine Multi-rate Permeability at Sgor

7. FW Flow Back Condensate Oil Saturation (2) to Sgwr

8. FW & WF Flow Back Condensate Oil Multi-rate Permeability (2) at Sgwr

9. FW Flow Back Gas (OFN) Saturation (2) to Swor

10. FW & WF Flow Back Effective Gas (OFN) Multi-rate Permeability (2) at Swor

.

Scale Squeeze Injection

6. Main Treatment Application Sequence, WF direction at T = 155C

Squeeze Application, WF Direction: 0.5 pore volume 10% LMWP in 2% KCl

7. Shut in over 16 hours at T = 155C

8. Flow Back Saturation Stages (Formation Damage)at T = 155C

1. FW Flow Back Gas (OFN) Saturation to Sgwor

chem

2. FW & WF Flow Back Effective Gas (OFN) Multi-rate Permeability at Sgwor

chem.

3. FW Flow Back Condensate Oil Saturation to Sgwr

4. FW & WF Flow Back Condensate Oil Multi-rate Permeability at Sgwr

5. FW Brine Saturation to Sgor

6. FW & WF Brine Multi-rate Permeability at Sgor

You might also like

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceFrom EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNo ratings yet

- Modelling LSWFDocument13 pagesModelling LSWFChun YanNo ratings yet

- HASIL - Bottle Test Queen FixDocument3 pagesHASIL - Bottle Test Queen Fixjannes_pratamaNo ratings yet

- Chemical FloodingDocument26 pagesChemical FloodingFranklyn FrankNo ratings yet

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsFrom EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo ratings yet

- 10.1007 - s13202 013 0051 4Document4 pages10.1007 - s13202 013 0051 4Luis FloresNo ratings yet

- SPE-124799-PA-Determining Wax Type Paraffin or NaphtheneDocument6 pagesSPE-124799-PA-Determining Wax Type Paraffin or NaphtheneJohn HastingNo ratings yet

- Spe 123072Document13 pagesSpe 123072Jose Gregorio Fariñas GagoNo ratings yet

- Control of Paraffin Deposition in Production Operations: SPE, Conoco Inc. SPE, Conoco IncDocument6 pagesControl of Paraffin Deposition in Production Operations: SPE, Conoco Inc. SPE, Conoco IncAlesa Acosta JaraNo ratings yet

- Spe 17140 Pa PDFDocument5 pagesSpe 17140 Pa PDFJose RamirezNo ratings yet

- Collection and Preservation of Water SamplesDocument24 pagesCollection and Preservation of Water SamplesSyed Talha AhmedNo ratings yet

- Surfactant Flooding 2020MSPET103Document49 pagesSurfactant Flooding 2020MSPET103Sunny BbaNo ratings yet

- Microbial Enhanced Oil Recovery (MEOR)Document26 pagesMicrobial Enhanced Oil Recovery (MEOR)MilaNo ratings yet

- Chemical Sand Consolidation Trials (Shell)Document33 pagesChemical Sand Consolidation Trials (Shell)Nur Syaffiqa Mohamad RuzlanNo ratings yet

- Ranking Oil Viscosity in Heavy Oil ReservoirsDocument12 pagesRanking Oil Viscosity in Heavy Oil ReservoirsJORGE SALINAS SALCEDONo ratings yet

- EOR Final ReportDocument60 pagesEOR Final Reportvalay_k07No ratings yet

- SPE-172549-MS Tandem ESP-Packer Dumpflood Completion - A Successful Alternative To Conventional Encapsulated ESP Systems - Field Case StudyDocument7 pagesSPE-172549-MS Tandem ESP-Packer Dumpflood Completion - A Successful Alternative To Conventional Encapsulated ESP Systems - Field Case StudyAhmed Ali AlsubaihNo ratings yet

- Test Procedure Ot Oil in Water by NDocument1 pageTest Procedure Ot Oil in Water by NSarbast H. SaeedNo ratings yet

- Spe 56772Document7 pagesSpe 56772curumnNo ratings yet

- Spe 143550 MS PDFDocument16 pagesSpe 143550 MS PDFLija BinuNo ratings yet

- Larry W. Lake - Russell Johns - Bill Rossen - Fundamentals of Enhanced Oil Recovery-SPE (2014)Document784 pagesLarry W. Lake - Russell Johns - Bill Rossen - Fundamentals of Enhanced Oil Recovery-SPE (2014)Minh LeNo ratings yet

- SPE-195039-MS Compositional Modeling and Calibration of ASP Carbonate CorefloodsDocument19 pagesSPE-195039-MS Compositional Modeling and Calibration of ASP Carbonate CorefloodsMohamed CHIKHAOUINo ratings yet

- An Introduction To EORDocument4 pagesAn Introduction To EORMnesNo ratings yet

- SPE-174699-MS Dalia/Camelia Polymer Injection in Deep Offshore Field Angola Learnings and in Situ Polymer Sampling ResultsDocument18 pagesSPE-174699-MS Dalia/Camelia Polymer Injection in Deep Offshore Field Angola Learnings and in Situ Polymer Sampling ResultslimbergNo ratings yet

- Spe 0101 0057 JPT PDFDocument2 pagesSpe 0101 0057 JPT PDFSahib QafarsoyNo ratings yet

- Recovery ImprovementFrom EverandRecovery ImprovementQiwei WangNo ratings yet

- Asphaltene Deposit Removal Long-Lasting Treatment With A CO-SOLVENTDocument8 pagesAsphaltene Deposit Removal Long-Lasting Treatment With A CO-SOLVENTRamanamurthy PalliNo ratings yet

- Wax RemediationDocument3 pagesWax RemediationDonna GrayNo ratings yet

- SPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingDocument11 pagesSPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingMarcelo Ayllón RiberaNo ratings yet

- SPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldDocument13 pagesSPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldJosé Manuel UsuriagaNo ratings yet

- Laboratory Report On The Constituents of WastewaterDocument15 pagesLaboratory Report On The Constituents of WastewaterGarfield SmithNo ratings yet

- SPE-57390-Underbalance or Extreme OverbalanceDocument10 pagesSPE-57390-Underbalance or Extreme Overbalancecv sabiraNo ratings yet

- SRB & TCB Tests EvaluationDocument25 pagesSRB & TCB Tests EvaluationEmad BehdadNo ratings yet

- Progressive Cavity Pump Manual: Version 07/03Document23 pagesProgressive Cavity Pump Manual: Version 07/03Jose Miguel GonzalezNo ratings yet

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeFrom EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeRating: 4 out of 5 stars4/5 (2)

- Petroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi BehbahaniDocument7 pagesPetroleum: Mahdi Zeinali Hasanvand, Mohammad Ali Ahmadi, Reza Mosayebi Behbahanimarcoesteban97No ratings yet

- RapidCheck SRB KitDocument2 pagesRapidCheck SRB KitsksghNo ratings yet

- Reservoir Engineering-: Primary Recovery MechanismsDocument16 pagesReservoir Engineering-: Primary Recovery Mechanismsعلي حسين جميل100% (1)

- Low Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsFrom EverandLow Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsNo ratings yet

- Formation DamageDocument26 pagesFormation DamagerajneeshgogoiNo ratings yet

- 4d - Reservoir Fluid Sampling and PVT Analysis and Rs CorrelationsDocument23 pages4d - Reservoir Fluid Sampling and PVT Analysis and Rs CorrelationsTHE TERMINATORNo ratings yet

- Mechanism of An Asphaltene Inhibitor PDFDocument50 pagesMechanism of An Asphaltene Inhibitor PDFTEXOPED Parsian KishNo ratings yet

- Spe 143287 MS PDocument11 pagesSpe 143287 MS PbvkvijaiNo ratings yet

- CV Example PHD PostdocDocument2 pagesCV Example PHD PostdocDhileepan Kumarasamy100% (1)

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Phosphonate Scale Inhibitor Adsorption/Desorption and The Potential For Formation Damage in Reconditioned Field CoreDocument14 pagesPhosphonate Scale Inhibitor Adsorption/Desorption and The Potential For Formation Damage in Reconditioned Field CoreLaura Natalia SalcedoNo ratings yet

- Surfactant EORDocument43 pagesSurfactant EORLê Công100% (1)

- SPE 53715 Microbial Enhanced Oil Recovery Pilot Test in Piedras Coloradas Field, ArgentinaDocument29 pagesSPE 53715 Microbial Enhanced Oil Recovery Pilot Test in Piedras Coloradas Field, Argentinajpsi6No ratings yet

- GEOG TI2012 Flow Assurance Aspects of Intrusive Erosion ProbesDocument10 pagesGEOG TI2012 Flow Assurance Aspects of Intrusive Erosion ProbesIsmail SayutiNo ratings yet

- Treatment of EmulsionDocument7 pagesTreatment of EmulsionSaurab DevanandanNo ratings yet

- 25 One Year Experience With The Injection of Nitrate To Control Souring in Bonga Deepwater Development Offshore NigeriaDocument9 pages25 One Year Experience With The Injection of Nitrate To Control Souring in Bonga Deepwater Development Offshore NigeriaCatalinaManjarresNo ratings yet

- SPE 89391 Development of A Novel Waterflood Conformance Control SystemDocument9 pagesSPE 89391 Development of A Novel Waterflood Conformance Control SystemLeo Rojas DomNo ratings yet

- SUEZ Upstream OG Chemicals PDFDocument9 pagesSUEZ Upstream OG Chemicals PDFMoujahed FarésNo ratings yet

- C (I-1B) Reservoir Fundam Fluid FlowDocument97 pagesC (I-1B) Reservoir Fundam Fluid FlowAndrei HorhoianuNo ratings yet

- 56 - Remedial Cleanup, Sand Control and Other Stimulation TreatmensDocument9 pages56 - Remedial Cleanup, Sand Control and Other Stimulation Treatmensrizal tri susiloNo ratings yet

- Angsi K StoneDocument9 pagesAngsi K StonerishitharanNo ratings yet

- Spe 39437 MSDocument14 pagesSpe 39437 MSAndrés Bojacá MatizNo ratings yet

- Enhanced Oil RecoveryDocument3 pagesEnhanced Oil Recoverys33d_2010No ratings yet

- Chloride and SalinityDocument8 pagesChloride and SalinitysalahudinNo ratings yet

- (Aptitude) Percentage - Percentage To Fraction & Fraction To Percentage Conversion - RAVI MOHAN MISHRADocument1 page(Aptitude) Percentage - Percentage To Fraction & Fraction To Percentage Conversion - RAVI MOHAN MISHRAPeterGomesNo ratings yet

- Production Enhancement From Sand Control ManagementDocument14 pagesProduction Enhancement From Sand Control Managementabdulsalam alssafi94No ratings yet

- Active Co2Document18 pagesActive Co2Jose Miguel GonzalezNo ratings yet

- SPE 94604 One-Step Acid Removal of An Invert EmulsionDocument9 pagesSPE 94604 One-Step Acid Removal of An Invert EmulsionJose Miguel GonzalezNo ratings yet

- Onestep: Simplified Sandstone Stimulation SystemDocument1 pageOnestep: Simplified Sandstone Stimulation SystemJose Miguel GonzalezNo ratings yet

- SPE 126719 Matrix Acid Systems For Formations With High Clay ContentDocument15 pagesSPE 126719 Matrix Acid Systems For Formations With High Clay ContentJose Miguel GonzalezNo ratings yet

- SPE 143301 Novel Environmentally Friendly Fluids To Remove Carbonate Minerals From Deep Sandstone FormationsDocument16 pagesSPE 143301 Novel Environmentally Friendly Fluids To Remove Carbonate Minerals From Deep Sandstone FormationsJose Miguel GonzalezNo ratings yet

- HUAWEI G510-0251 V100R001C76B185a Upgrade GuidelineDocument7 pagesHUAWEI G510-0251 V100R001C76B185a Upgrade GuidelineJose Miguel GonzalezNo ratings yet

- Use of Single-Step 9% HF in Geothermal Well StimulationDocument3 pagesUse of Single-Step 9% HF in Geothermal Well StimulationJose Miguel GonzalezNo ratings yet

- GasolineDocument17 pagesGasolineJose Miguel GonzalezNo ratings yet

- IPTC 10693 Recent Advances in Carbonate Stimulation: Fig. 1-Normalized and Averaged Reactivity of CarbonatesDocument8 pagesIPTC 10693 Recent Advances in Carbonate Stimulation: Fig. 1-Normalized and Averaged Reactivity of CarbonatesJose Miguel GonzalezNo ratings yet

- Cetano Norma D4737 10Document5 pagesCetano Norma D4737 10Jose Miguel GonzalezNo ratings yet

- Clase 2Document15 pagesClase 2Jose Miguel GonzalezNo ratings yet

- PCP TdaDocument25 pagesPCP TdaJose Miguel GonzalezNo ratings yet

- Jurnal Online Agroekoteknologi Vol.1, No.3, Juni 2013 ISSN No. 2337-6597Document11 pagesJurnal Online Agroekoteknologi Vol.1, No.3, Juni 2013 ISSN No. 2337-6597Anjar SulistyoNo ratings yet

- Quaker Chemical PresentationDocument23 pagesQuaker Chemical Presentationnpskier205No ratings yet

- Exam3 Problems SolDocument36 pagesExam3 Problems Solnancy maganaNo ratings yet

- Scirce All ChaptersDocument20 pagesScirce All ChaptersshirinNo ratings yet

- Engineeringexperv 00000 I 00146Document60 pagesEngineeringexperv 00000 I 00146LALENo ratings yet

- Reduction of Organic Compounds With Sodium Borohydride-Transition Metal Salt Systems - Reduction of Organic Nitrile, Nitro and Amide Compounds To Primary AminesDocument4 pagesReduction of Organic Compounds With Sodium Borohydride-Transition Metal Salt Systems - Reduction of Organic Nitrile, Nitro and Amide Compounds To Primary AminesjavasoloNo ratings yet

- 13C and 1H NMR (RMN 1H y 13C)Document1 page13C and 1H NMR (RMN 1H y 13C)veromendoNo ratings yet

- Polimers PDFDocument71 pagesPolimers PDFomer faruqeNo ratings yet

- Chapter - 1 .. Electric Charges and Fields: Coulomb's LawDocument8 pagesChapter - 1 .. Electric Charges and Fields: Coulomb's LawAshok PradhanNo ratings yet

- 6.review and Example On Combustion TheoryDocument6 pages6.review and Example On Combustion TheoryVan Nguyen Huu VanNo ratings yet

- 3.1 Mass Transfer Equipment Design: H O CH Cooh CHDocument61 pages3.1 Mass Transfer Equipment Design: H O CH Cooh CHZAINOR SYAHIRA BINTI ZAINAL STUDENTNo ratings yet

- Annex 2 Drawings and CatalogueDocument8 pagesAnnex 2 Drawings and CatalogueShaun DavidsNo ratings yet

- Appendix 7 - 4: Weather of Dalbandin, Baluchistan PakistanDocument4 pagesAppendix 7 - 4: Weather of Dalbandin, Baluchistan PakistanZia JanNo ratings yet

- UG-2f-B.Tech PolymersTechnologyDocument47 pagesUG-2f-B.Tech PolymersTechnologysuranjana26No ratings yet

- Chapter 1Document55 pagesChapter 1truongngvNo ratings yet

- Baking Soda LabDocument6 pagesBaking Soda LabAubrey KemberNo ratings yet

- Welded Nickel and Nickel-Cobalt Alloy Pipe: Standard Specification ForDocument5 pagesWelded Nickel and Nickel-Cobalt Alloy Pipe: Standard Specification ForZouhair BoukriNo ratings yet

- Possible Hazards and Contributing Factors Associated With Medical Devices (ISO 14971:2000, Annex D)Document3 pagesPossible Hazards and Contributing Factors Associated With Medical Devices (ISO 14971:2000, Annex D)hamed IranpourNo ratings yet

- MSDS Boric Ecid Etimaden TurkeyDocument14 pagesMSDS Boric Ecid Etimaden TurkeyalkanfilesalesNo ratings yet

- A.4.b. Naoh Liquid (Cv. Kurnia Jaya) - Coa & MsdsDocument10 pagesA.4.b. Naoh Liquid (Cv. Kurnia Jaya) - Coa & MsdsLailaNo ratings yet

- QM 1 HW 4 AnswersDocument5 pagesQM 1 HW 4 Answerselius2138726No ratings yet

- To Estimate Charge On Pith Ball Class XIIDocument17 pagesTo Estimate Charge On Pith Ball Class XIIHollow GamingNo ratings yet

- LunaGrid Considerations For Developing An Expandable & Distributed Lunar Power GridDocument1 pageLunaGrid Considerations For Developing An Expandable & Distributed Lunar Power Gridewillia13No ratings yet

- HOPPY: An Open-Source and Low-Cost Kit For Dynamic Robotics EducationDocument8 pagesHOPPY: An Open-Source and Low-Cost Kit For Dynamic Robotics Educationchoco bananaNo ratings yet

- Utkarsh Paper Class XI 17.10.2022Document11 pagesUtkarsh Paper Class XI 17.10.2022HarshNo ratings yet

- State of Matter Teacher's Guide/chemistry Form 4 / Simulation Scientific ConceptDocument6 pagesState of Matter Teacher's Guide/chemistry Form 4 / Simulation Scientific ConceptHannanNashruddinNo ratings yet

- Appendix A Appendix A Standard Solutions and Reference Materials PDFDocument8 pagesAppendix A Appendix A Standard Solutions and Reference Materials PDFFiorella MeoñoNo ratings yet

- Koord 17042019Document688 pagesKoord 17042019Totok GapuradianNo ratings yet