Professional Documents

Culture Documents

Hilltie Post Installed Conc Anchor Test

Uploaded by

jarnebergCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hilltie Post Installed Conc Anchor Test

Uploaded by

jarnebergCopyright:

Available Formats

The Assessment and Design of Adhesive Anchors in Concrete for Sustained Loading

R. Eligehausen

1

, J. Silva

2

7-Jan-08

1.0 Foreword

On July 10, 2007 the National Transportation Board (NTSB) issued its final report on the

partial collapse of the ceiling system in the I-90 Seaport Portal Tunnel on July 10, 2006.

The collapse of the concrete ceiling panels resulted in one fatality and significant traffic

disruption in the Boston Central Artery/Ted Williams Tunnel system over an extended

period. The cause of the collapse was identified as creep failure of adhesive anchors

installed overhead and subjected to sustained tension loading. The NTSB report

3

specified the following safety issues relative to the ongoing use of adhesive anchors in

construction:

Insufficient understanding on the part of designers and builders regarding the

nature of adhesive anchoring systems; and

Lack of standards for the testing of adhesive anchors in sustained tensile load

applications.

The veracity of these statements notwithstanding (standards for the creep testing of

adhesive anchors have existed since 1993), the NTSB report has generated legitimate

concerns in the design and constructions communities regarding the qualification, design

and use of adhesive anchors for safety-related applications in construction. The report

also makes the following recommendation to the Federal Highway Administration:

Prohibit the use of adhesive anchors in sustained tensile-load overhead

highway applications where failure of the adhesive would result in a risk

to the public until testing standards and protocols have been developed

and implemented that ensure the safety of these applications.

4,5

What follows is an overview of the assessment and design of adhesive anchors in the U.S.

The following points are emphasized:

a. Testing of adhesive anchors under sustained loading conditions has been ongoing

for over a quarter of a century.

1

Prof. Dr.-Ing. Rolf Eligehausen, Institut fr Werkstoffe im Bauwesen, University of Stuttgart.

2

John Silva, S.E., Director of Codes & Standards, Hilti North America.

3

National Transportation Safety Board, Accident Report No. NTSB/HAR_07/02 Ceiling Collapse in the

Interstate 90 Connector Tunnel, Boston, Massachusetts, July 10, 2006, Executive Summary July 10, 2007,

p. ix.

4

Ibid., p. 109.

5

This recommendation has as of this writing been adopted by the FHWA and by at least one state highway

agency. The use of adhesive anchors for sustained tensile-load overheadapplications in highway

construction is likely limited in any case. Historically, typical applications include the anchorage of

guardrails, lighting standards and post-installed reinforcing bars.

Page 1

b. Standards for the assessment of adhesive anchors to address this condition have

been in place for over a decade.

c. The use of adhesive anchors overhead to resist tension loads in safety-related

applications is admissible provided that the system has been properly qualified,

designed and installed.

The findings of the aforementioned NTSB report with regard to cause of failure or

responsibility are not discussed, and the information presented herein should not be

construed as an opinion on the part of the authors or Hilti with respect to the NTSB

investigation and subsequent proceedings.

2.0 Background

Adhesive anchors are widely used around the world to address a variety of structural and

non-structural fastening problems in both new construction and structural renovation of

concrete structures. [As used here, the term adhesive anchor refers to anchorages

comprised of a steel anchor element, usually threaded rod or reinforcing bar, installed in a

drilled hole and bonded to the surrounding concrete with a polymer-based adhesive

filling an annular gap of no more than 1-1/2 times the anchor element diameter.

6

Anchorages based on larger annular gaps are typically referred to as grouted anchors and

are generally executed with cementitious grouts. These are not addressed further here.]

The widespread use of adhesive anchors can be attributed to several factors:

Thixotropic adhesives (gels) are generally suitable for all orientations of

installation, provided that issues of void-free installation and creep under sustained

load have been adequately addressed. Cementitious-based grouts are usually

suitable for down-hole applications only.

Adhesive anchors provide the designer with a wide range of possible embedment

depths to accommodate the specific geometry and material parameters of the

anchorage. Most mechanical anchor systems provide only limited options for

varying the embedment depth.

Adhesive anchors accommodate a wide variety of anchor element types (threaded

rod of any grade, reinforcing bar, internally threaded inserts)

Adhesive anchors do not generate the large expansion forces upon installation that

are associated with most mechanical anchor systems. This makes them more

suitable for near-edge applications where splitting of the concrete is a concern.

Similarly, the use of adhesive anchor systems for the installation of reinforcing in

hardened concrete, usually for the purpose of shear transfer between new and existing

concrete elements, but sometimes also for flexural and direct tension applications, is

common practice. Again, the utility, flexibility and reliability of injectable adhesive

anchoring systems makes them preferable to other solutions (drypack, poured grout) for

these applications.

6

The limit of 1-1/2 times the anchor element diameter is based on current practice. Many adhesive anchor

systems specify thin bond lines (on the order of 1/16-inch or 1.5 mm) in order to limit shrinkage and

maximize the value proposition for the system.

Page 2

The use of adhesive anchor systems in construction is predicated on several points:

The availability of systems that provide for consistent mixing of the adhesive

components in the correct proportion and the efficient delivery of the mixed

adhesive into the drilled hole.

Relative insensitivity of the adhesive anchor system to minor variations in the

installation procedure.

Predictable response of the installed adhesive anchor to loading at service and

ultimate load levels.

Stable behavior of the cured adhesive over time frames consistent with the lifespan

of the built environment and under conditions as might be anticipated to occur over

the life of the anchorage (temperature variations, etc.)

The verification of these critical characteristics is the domain of the assessment procedure

used to provide the building official or other authority having jurisdiction with the

requisite assurance of code compliance as well as the information required for design.

Prior to the mid-1990s, assessment of adhesive anchor systems was performed on an ad

hoc basis by the International Conference of Building Officials Evaluation Service

(ICBO-ES) and other evaluation agencies in the U.S. and Canada. The development of

standardized test procedures specifically for adhesive anchor systems was first

incorporated in ASTM 1512-93, and a complete set of testing requirements and

assessment criteria on the basis of that standard was issued by ICBO-ES as AC58,

Acceptance Criteria for Adhesive Anchors in Concrete and Masonry Elements in 1995.

This document has since been revised to address adhesive anchors in masonry only, and

as of January 1, 2007 the assessment of adhesive anchors in concrete is covered

exclusively (in the context of IBC/IRC jurisdictions) by AC308, Acceptance Criteria for

Post-Installed Adhesive Anchors in Concrete Elements.

7

These two criteria, AC58 and

AC308, are briefly compared and contrasted with respect to their treatment of both

service load and suitability assessment procedures in the following.

7

AC308 is based substantially on Part 5 Bonded Anchors, of the European Technical Approval Guideline

(ETAG) 001. As of October of 2007, 73 adhesive anchor systems had been assessed and 140 European

Technical Approvals issued under this guideline.

Page 3

3.0 Assessment of adhesive anchors for service conditions

3.1 Service condition testing under AC58

Under AC58, assessment for service loads was conducted using an allowable stress

design (ASD) format, whereby a global safety factor (see Fig. 1) was applied to the mean

of five replicates to develop allowable loads for comparison with unfactored load

combinations. Group and near-edge effects were assessed on the basis of replicate tests

with groups and near-edge anchors at specific anchor spacings and edge distances, and

these results were then extended to other cases, usually by linear interpolation. Typically,

testing of all diameters was required to establish allowable loads for single anchors

whereas values for edge distances and spacings less than the value required for full

capacity were based on testing of small, intermediate and large diameters. Where

multiple embedment depths were associated with a single diameter, tests were required at

each embedment depth for which recognition was desired. Testing was typically

conducted in three concrete strengths.

Fig. 1 Global factors of safety for various codes and test conditions as reproduced from

AC58

8

3.2 Service condition testing under AC308

AC308 was developed for use in conjunction with the limit state (LRFD) design format

established in ACI 318 Appendix D. It is based largely on procedures developed by the

European Organization for Technical Approvals for the assessment of adhesive anchors.

9

Assessment for service conditions in AC308 primarily consists of testing to establish the

characteristic bond strength associated with the adhesive anchor system.

10

In this context,

8

ICC-ES, AC58 Acceptance Criteria for Adhesive Anchors in Concrete and Masonry Elements, as

approved June 2005, p. 11.

9

See European Organization for Technical Approvals (EOTA), European Technical Approval Guideline

001, Part 5, Bonded Anchors, Brussels, March 2002.

10

AC308, in accordance with ACI 318 Appendix D, makes a general distinction between anchors to be

used in concrete that may develop cracks in the anchor vicinity over the service life of the anchor (cracked

Page 4

the term adhesive anchor system is understood to comprise the adhesive, injection system,

installation procedures and anchor element. The bond strength

k

is suitable for use in a

uniform bond stress equation (see Fig. 2) to predict the anchor resistance as governed by

bond failure

11

for comparison with the calculated strength associated with the other

applicable failure modes. The assessment is potentially valid for embedment depths

ranging from 4 to 20 anchor diameters. This represents a significant departure from past

anchor testing criteria.

4.0 Assessment of adhesive anchors for suitability

4.1 Suitability testing under AC58

In addition to service load testing, AC58 contained suitability tests for in-service

temperature (required), response to sustained tension loading (optional), dampness

(optional), freezing and thawing (optional) and seismic (optional) with a table linking the

successful performance of the creep and seismic tests to the global safety factor (see Fig.

1) and permissible load cases (seismic, sustained loads).

13

For example, a product that

either was not tested for creep or did not satisfy the acceptance criteria for creep testing in

AC58 would be limited to applications involving wind or earthquake loading only (no

dead or live loads), and would carry a safety factor of 5.33 instead of 4. In particular, the

test procedures for response to sustained tension loads (creep testing) have come under

close scrutiny recently, and this is discussed in further detail below.

h

D.5.3.9 The basic strength of a single adhesive anchor in tension in cracked concrete shall not

exceed

, a0 k cr ef

N d =

where

, k cr

= characteristic bond stress in cracked concrete;

d = anchor diameter

ef

h = anchor embedment

Fig. 2 Bond stress equation for cracked concrete as expressed in AC308

12

concrete applications) and those that will not (uncracked concrete applications) and contains test

procedures for both cases. AC58 was originally formulated for testing in uncracked concrete only, and as

such was only suitable to qualify anchors for the uncracked concrete applications. This was clearly stated in

evaluation reports issued by ICC-ES on the basis of AC58 testing for use with IBC/IRC codes.

11

The value of N

a0

corresponds to the resistance of a single anchor far from edges or adjacent loaded

anchors. See Eligehausen, R., Cook, R., and Appl, J., Behavior and Design of Adhesive Bonded

Anchors, ACI Structural Journal Vol. 103, No. 6, December 2006, pp. 822-831 for additional information.

12

ICC-ES, AC308 Acceptance Criteria for Post-installed Adhesive Anchors in Concrete Elements, as

approved February 2007, p. 19. A similar expression addresses uncracked concrete applications.

13

Fire tests were permitted as an option in AC58; however, guidance was lacking with respect to how the

resulting design values should be applied in an ASD design environment.

Page 5

4.2 Suitability testing under AC308

AC308 likewise requires suitability testing. In addition to tests for the conditions covered

in AC58, AC308 specifies tests for sensitivity to reduced cleaning effort in dry, wet and

underwater conditions, sensitivity to installation direction and sensitivity to mixing effort.

In contrast to the requirements of AC58, tests for sensitivity to sustained tension load are

not optional in AC308.

5.0 Assessment for response to sustained tension loading

5.1 Assessment for sustained loading under AC58

Testing for response to sustained tension loads in AC58 (designated as creep testing)

consists of subjecting 1/2-inch diameter anchors installed to an embedment of 4-1/2

inches in concrete blocks at a constant elevated temperature of 110 F (43.3 C) to 40%

of the mean ultimate tension strength in tension as measured in tests at room temperature

(see Fig. 3).

14

The load is maintained over a period of at least 42 days (1,008 hours) with

the displacement measured at roughly 24-hour intervals. The resulting displacement

measurements are then extrapolated to 600 days using a logarithmic function of the form

y = c ln(x) + b and the mean displacement at 600 days is compared with the mean

displacement at peak load as measured on anchors tested in tension to failure at 110 F

(43.3 C) . Criterion for acceptance (passing) is that the mean extrapolated displacement

should not exceed the mean displacement corresponding to peak load in short-term tests

at elevated temperature or 0.12 inches (3 mm), whichever is less. No requirements are set

on the residual strength of the anchor on the assumption that any anchor fulfilling the

displacement criteria will not exhibit appreciable strength loss.

14

AC58 permits the use of either unrestrained tests (in accordance with E 488) or restrained tests (in

accordance with E 1512 Section 7.1.2) for the establishment of the mean ultimate tension strength; however,

where unrestrained tests are used to establish the sustained load (40% of the mean ultimate strength), the

sustained load test is to be performed with wide support spacing as well. The following observations are

relevant: 1) Since the ultimate strength associated with a restrained test, wherein the support spacing is

purposely restricted in order to preclude concrete breakout, is generally elevated (from 10-35% in

uncracked concrete, depending on the bond characteristics of the adhesive) over that associated with

unrestrained testing, the restrained testing option likely represents a more severe standard. It is not known

how many product assessments under AC58 are based on sustained loads determined from restrained vs.

unrestrained testing, however, in the authors experience many creep tests were performed using a semi-

restrained test setup (see Fig. 3a) 2) There is a question regarding the impact of close support spacing (see

Fig. 3b) on the displacements recorded in a sustained test; it is not known to what degree the reduction in

displacements associated with restrained creep testing offset the increased sustained load associated with

restrained reference tests.

Page 6

spring dashpot

LVDT ea. side

temperature-

controlled

chamber

1.5 d

o

d

o

spring dashpot

LVDT ea. side

temperature-

controlled

chamber

1.5 d

o

d

o

spring dashpot

LVDT ea. side

temperature-

controlled

chamber

spring dashpot

LVDT ea. side

temperature-

controlled

chamber

a) Semi-restrained test configuration b) Restrained test configuration

Fig. 3 Typical test setups for sustained loading

Duration of

load t [hours]

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

2000

600

days

1000 4000

1000 Duration of load t

[hours]

2

1

2

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Detail A

Detail A

data points used for extrapolation

log function extrapolation

600

Duration of

load t [hours]

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

2000

600

days

1000 4000

1000 Duration of load t

[hours]

2

1

2

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Detail A

Detail A

data points used for extrapolation

log function extrapolation

600

Fig. 4 Extrapolation of sustained load displacements per AC58

Page 7

5.2 Assessment for sustained loading under AC308

The fundamental premise used for evaluating the long-term performance of adhesive

anchors under AC308 is the same as that used in AC58; namely, that relatively short-term

test results may be extrapolated to predict long-term behavior. However, the parameters

specified in AC308 for the load level, the extrapolation range, displacement limits, and

requirements on residual capacity vary from AC58. While the requirements on the

minimum duration of the test (42 days) and on the number of data points used for the

extrapolation (minimum last twenty) are the same in both criteria, AC308 uses an

extrapolation equation commonly referred to variously as the Findley Power Law or

Findley Creep Law. Originally developed for plastics, it has the general form

where

0 n

t

+

= +

0

,

+

, and are functions of material (plastic). This equation has

been found to provide very satisfactory predictions for plastic laminates, polyethylene

and polyvinylchloride over long time (10+ years) spans.

n

15

It yields superior predictions to

those provided by linear viscoelastic models involving combinations of dashpots and

springs. According to Findley, et al.

This is due in part to the fact that creep of plastics,

concrete and some metals under moderate stresses starts

out at a very rapid rate immediately after loading and

progresses at a continuously decreasing rate.

Furthermore, AC308 requires that sustained load tests be conducted at two concrete

temperatures: standard temperature (essentially room temperature) and the maximum

long-term elevated concrete temperature

16

established for the adhesive anchor system.

The displacements obtained

by extrapolating the data from

these two sets of tests to 50

years (standard temperature)

and 10 years (maximum long-

term elevated temperature) are

not compared with values

corresponding to peak load in

static short-term tests as in

AC58, but rather with the

mean displacement associated

with loss of adhesion in

tension tests conducted at the

respective temperatures (see

Fig. 5).

Displacement

Tension load N

Load at loss of

adhesion N

adh

N

Peak load N

ult

adh

ult

Displacement

Tension load N

Load at loss of

adhesion N

adh

NN

Peak load N

ult

adh

ult

Fig. 5 Establishment of displacement corresponding

to loss of adhesion

The use of the displacement at

loss of adhesion as a marker

15

Findley, W., Lai, J., and Onaran, K., Creep and Relaxation of Nonlinear Viscoelastic Materials, Dover,

N.Y., N.Y., 1976, p. 14.

16

The long-term elevated concrete temperature is assumed to be roughly constant over significant periods

relative to the life of the anchorage. AC308 also defines short-term elevated concrete temperatures as those

that occur over brief intervals, e.g., as a result of diurnal cycling.

Page 8

for creep behavior is well established.

17

The sustained load level used in AC308 is 55% of the mean ultimate load established

from short-term tension tests to failure at standard and maximum long-term temperature,

respectively.

Comparing the sustained load used in AC58 (assuming unrestrained tests

18

) to that

specified in AC308 as a function of the design load:

AC58: = =

sust u

design u

N 0.4N

1.6

N 0.25N

(1)

AC308: =

sust u

design u

N 0.55N

1.6

N 0.65 0.75N

1.4

(2)

whereby in the second instance the ratio of characteristic strength to mean ultimate

strength is assumed to be 0.75, the strength reduction factor is conservatively taken as

0.65 (Category 1 anchor) and the load factor for sustained load is taken as 1.4.

A summary comparison of the creep test parameters defined in AC58 and AC308 is

provided in Table 1.

17

Eligehausen, R., Mallee, R., and Silva, J., Anchorage in Concrete Construction, Ernst & Sohn, Berlin,

2006, p. 201.

18

It should be noted that an additional margin of safety, anywhere from 10 to 25%, would be present if

restrained reference tests were used to establish the sustained load (see Footnote 14).

Page 9

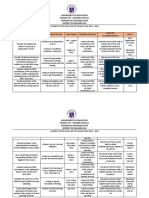

Table 1 Summary comparison of creep test parameters in AC58 and AC308

Test condition AC58 AC308

Static tension

load

u,std temp

0.40 N

u

0.55 N *

Temperature(s)

during creep

test

110F (43.3C) standard (room) temp.

max. long-term elevated temp.

Duration of test min. 42 days min. 42 days

Extrapolation

period

600 days (elevated temp.) 50 years (room temp.)

10 years (elevated temp.)

Extrapolation

method

Logarithmic

( ) = + + ( t ) a ln t b

0

Findley Power Law

( ) = +

b

( t ) a t

0

Residual

capacity

No test required Test anchors in tension to

failure following application of

sustained load

Acceptance

criteria

( )

u,elevated temp

( 600days ) min

0.12in. 3mm

lim,roomtemp

lim,elevated temp

( 50 yrs )

( 10 yrs )

**

Residual load:

req

=0.90

* The mean ultimate loads associated with standard temperature and elevated temperature conditions are

used for the sustained load tests at room temperature and elevated temperature, respectively.

**The calculated estimated displacement service for any one test may not exceed 1.2lim

6.0 Validity of current methods for predicting creep behavior

The methodology used for determining the response to sustained tension load in both

AC58 and AC308 fundamentally assumes that relatively short-term testing (typically in

the range of 1,000 hours) can be extrapolated to long-term behavior. This is an admissible

assumption assuming that the adhesive behaves like a visco-elastic material and it has

been applied to other cases where adhesives are used in thin bond lines (e.g. externally-

applied carbon fiber reinforcing

19

). It further assumes that the behavior of the tested

19

Triantafillou, T., Fardis, M., Strengthening of historic masonry structures with composite materials,

Materials and Structures, Vol. 30, No. 8, Springer Netherlands, November 2006, pp. 486-496.

Page 10

anchor diameter and embedment is representative of the entire anchor diameter and

embedment range, and that all other factors investigated in the assessment of the anchor

system for short-term strength, such as incomplete hole cleaning, affect the long-term

behavior to the same degree. These assumptions are less well supported by systematic

investigation. There is no evidence to indicate that they are incorrect, however.

Current experience with long-term testing of adhesive anchors is extensive owing to the

number of manufacturers engaged in the development and marketing of adhesive anchor

systems over the past 30 years.

20

It may be observed from Fig. 6, Fig. 7, and Fig. 8 that

the displacement curves exhibit increasing stability over time. This is generally true of

systems that exhibit stiff response up to ultimate in short-term testing to failure. However,

systems that exhibit a large ratio between peak load and the load at loss of adhesion (as

evidenced by a sharp change in the load-displacement response) have a greater tendency

to show increased displacements over time when the sustained load exceeds the load

corresponding to loss of adhesion. It has further been noted that sustained loading does

not appear to impair short-term strength provided that long-term failure is not

imminent.

21

Finally, it may be stated that the predicted anchor displacements associated

with sustained tension loading as yielded by the logarithmic function (AC58) are in

accordance with current experience and that those associated with the Findley Power Law

(AC308) are generally conservative.

y = 0.1629Ln(x) - 0.7079

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 50000 100000 150000 200000 250000

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Duration of load [hrs]

AC58 logarithmic projection

Measured displacements

Spring re-tension

27 years

y = 0.1629Ln(x) - 0.7079

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 50000 100000 150000 200000 250000

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Duration of load [hrs]

AC58 logarithmic projection

Measured displacements

Spring re-tension

27 years

Fig. 6 Long-term testing of 16 mm capsule anchors in 2,900 psi (19/20 MPa) concrete

subjected to N

sust

0.36 N

u,m

comparison with logarithmic projection

20

Mszrs, J., Tragverhalten von chemischen Befestigungen unter zentrischer Belastung, doctoral thesis,

University of Stuttgart Institut fr Werkstoffe im Bauwesen, April 2002, p. 18.

21

Eligehausen, R., et al., op. cit., p. 201.

Page 11

6.1 Adequacy of Adhesive Anchoring Systems for Sustained Load

6.1.1 Systems qualified under AC58

Ongoing changes to qualification methods for adhesive anchors with respect to sustained

load naturally raises questions concerning the adequacy of existing installations based on

earlier qualification methods (i.e. AC58). In this regard, the following may be said:

Where adhesive anchor systems qualified under AC58 for sustained loading have been

designed properly and installed correctly (e.g., without voids and with proper hole

cleaning)

22

, the likelihood of premature failure under sustained load is extremely low.

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 20000 40000 60000 80000 100000 120000

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Duration of load [hrs]

AC308 (Findley) projection

AC58 logarithmic projection

Measured displacements

0

0.2

0.4

0.6

0.8

1

1.2

1.4

0 20000 40000 60000 80000 100000 120000

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Duration of load [hrs]

AC308 (Findley) projection

AC58 logarithmic projection

Measured displacements

Fig. 7 Long-term testing of 12 mm injection anchors in 4,200 psi (29 MPa) concrete

subjected to N

sust

0.41 N

u,m

comparison with logarithmic and Findley extrapolations

This is in part due to the relatively large safety factor associated with the ASD design

paradigm. It is also due to the fact that the conditions imposed under AC58 (elevated

temperature) represents an extreme usually not seen in practice, i.e., service conditions

generally do not produce a constant 110F (43.3C) in situ temperature in the concrete.

(The extrapolation to 600 days in the AC58 criteria is based on outdoor field tests and

was intended to represent the number of high temperature days that an anchor might

experience over its service life.) Additionally, experience shows that the practical

22

It should be noted that tests to verify the effectiveness of overhead installation procedures were not

included in AC58, and where specific instruction for overhead installations (either in writing or on the

jobsite) were not provided, the quality of the installation may be questionable.

Page 12

considerations associated with running creep tests dictate that the displacement criteria

established for passing the test (non-exceedence of the lesser of failure displacement or 3

mm) are rarely if ever fulfilled without an additional margin of safety, and design

conditions (group effects, near edges, steel capacity, practical constraints on minimum

bolt diameter) often dictate a lower bond stress than that corresponding to marginal long-

term behavior.

23

Finally, it should also be noted that some manufacturers (e.g. Hilti) have conducted

extensive testing of adhesive anchor systems over many years to verify their performance

under conditions and load levels that exceed the requirements of AC58.

Where there is doubt about the correct installation of adhesive anchors subjected to

sustained tension loading and where the level of sustained load is high relative to the

anchor design bond strength, it is advisable to investigate their behavior via on site proof

load testing, regular displacement monitoring or both. In specific cases, testing to failure

of a sample of the installed anchors may also be warranted to ascertain the quality of the

installation.

y = 0.1629Ln(x) - 0.7079

y = 0.018x

0.4565

0

1

2

3

4

5

6

0 50000 100000 150000 200000 250000

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Duration of load [hrs]

AC308 (Findley) projection

AC58 logarithmic projection

Measured displacements

y = 0.1629Ln(x) - 0.7079

y = 0.018x

0.4565

0

1

2

3

4

5

6

0 50000 100000 150000 200000 250000

D

i

s

p

l

a

c

e

m

e

n

t

[

m

m

]

Duration of load [hrs]

AC308 (Findley) projection

AC58 logarithmic projection

Measured displacements

Fig. 8 Long-term testing of 16 mm capsule anchors in 2,900 psi (19/20 MPa) concrete

subjected to N

sust

0.36 N

u,m

data plotted against AC58 logarithmic projection and

AC308 Findley Power Law (compare to Fig. 6.)

23

As stated earlier, an additional margin of safety would also be present where restrained reference tests

were used to establish the sustained load (see Footnotes 14 and 18).

Page 13

6.1.2 Systems qualified under AC308

Under the LRFD design paradigm associated with AC308, the global safety factor can be

less than that mandated by AC58. Assuming a strength reduction factor on concrete-

related failure modes of 0.65 (optimum anchor reliability) and a relationship of

characteristic to mean strength of 0.75, the global safety factor resulting from ACI 318

Appendix D for a sustained permanent (dead) load would be:

u

design

N 1.4

2.9

N 0.65 0.75

=

(3)

This reduced safety factor (for superior systems as determined through reliability tests) is

justified by the increased robustness of the assessment and design processes embodied in

AC308 and ACI 318 Appendix D. With respect to creep behavior, the reduced safety

factor is partly offset by the fact that anchors qualified under AC308 for sustained load

must meet a substantially stricter standard due to the increased time of extrapolation, the

use of the more conservative Findley expression for predicting creep displacements (see

Fig. 8) and the limitation on displacement corresponding to loss of adhesion vs. peak load

(see Table 1 and Fig. 5).

6.2 Further Considerations

6.2.1 Overhead installation

The installation of adhesive anchors in the overhead position presents particular

challenges.

24

These may be summarized as follows:

a. Void-free injection of adhesive into the hole.

b. Avoidance of adhesive run and attendant fouling of anchor rod

25

.

c. Securing of the anchor rod in the hole prior to cure of the adhesive, particularly

for larger diameters.

Anecdotal evidence indicates that the presence of entrained air bubbles and voids caused

by adhesive run are particularly relevant to long-term behavior and can aggravate the

creep response of anchors subjected to sustained tension. This may be ascribed to two

effects: 1) the effect of the limited oxygen in the voids on the curing process of the

adhesive and 2) the loss of bond area; whereas the impact on cure is dependent on the

adhesive formulation, loss of bond area will always result in a lowering of the load

associated with loss of adhesion. It is therefore particularly important that measures be

taken to prevent adhesive loss and air entrainment. These may include use of specialized

24

AC308 mandates testing of anchors installed in the overhead position for anchors that are intended for

this application.

25

Protective wear appropriate to the hazard level of the adhesive being used should always be used. Refer

to manufacturer instructions and MSDS.

Page 14

injection equipment such as

stoppers fitted to the end of the

injection tube. One method for

assessing the effectiveness of

procedures intended to ensure

void-free installation is to perform

the injection in a Plexiglas tube

of corresponding diameter and

length. This method is particularly

effective when performed blind

by the installer (see Fig. 9).

6.2.2 Long-term strength and

factor of safety

The foregoing discusses methods

for qualifying adhesive anchor

systems for applications involving

sustained tension load. For

practical reasons, these are

conceived as pass-fail tests with

pre-defined levels of acceptable

displacement based on short-term behavior.

Clear plastic tube (e.g.,

Plexiglas)

support

system for

tube

shield to block line of sight

beyond concrete surface

Clear plastic tube (e.g.,

Plexiglas)

support

system for

tube

shield to block line of sight

beyond concrete surface

Fig. 9 Use of a Plexiglas tube to verify the

installation procedures and equipment for an

adhesive anchor system

To extract more complete information regarding the response of an adhesive anchor

system to long-term loading it would be necessary to conduct tests at various levels of

sustained tension load (see Fig. 10). Testing at higher sustained loads (i.e., approaching

the anchor ultimate capacity) would necessarily result in failure after a short time. Lower

levels of load would provide correspondingly longer time periods prior to failure.

Ultimately, sufficient tests could be conducted to develop a sustained load strength

curve with the sustained load plotted against the time to failure. Such a curve would

show, at some level of sustained load, runout behavior whereby failure does not occur

for any reasonably anticipated time duration. (This is analogous to the runout portion of

s-n fatigue curve.)

Page 15

tension

load

time t from onset of loading

sustained load strength curve

N

sust,1

N

sust,2

t

fail,1

t

fail,2

N

permissible

N

u,m

margin

against

failure

under

short-term

load

margin

against

failure under

sustained

load

N

sust,3

mean tension capacity under short-term load

2

scatter

associated

with

sustained

load

behavior

tension

load

time t from onset of loading

sustained load strength curve

N

sust,1

N

sust,2

t

fail,1

t

fail,2

N

permissible

N

u,m

margin

against

failure

under

short-term

load

margin

against

failure under

sustained

load

N

sust,3

mean tension capacity under short-term load

2

scatter

associated

with

sustained

load

behavior

Fig. 10 Concept of a sustained load strength curve

Considering such a process, it can be observed that the margin between the design or

permissible load and the failure load as described by the sustained load strength curve

necessarily decreases over time and that at some load level N

sust

corresponding to runout,

the margin between long-term strength and applied load is defined. Such a curve would

be associated with some scatter, and this is represented in the form of a Gaussian

distribution. Similarly, the applied loading is associated with some uncertainty, and the

usual relationship between load and resistance can be drawn.

This approach is outlined in ASTM D 4680

26,27

which provides guidelines for testing

creep performance of glued wood joints in static shear (see Fig. 11):

To establish a curve of stress versus time to failure, a common practice is

to load specimens at four or more evenly spaced intervals of stress

beginning at 90%. Stress is expressed as a percentage of the average short-

term ultimate shear strength of adhesive bonds. It is desirable that at least

one data set at each stress level fall within each base-10 log of time cycle.

26

ASTM D 4680-98, Standard Test Method for Creep and Time to Failure of Adhesives in Static Shear by

Compression Loading (Wood-to-Wood), Annual Book of ASTM Standards Vol. 15.06, pp. 392-393.

27

ASTM D 2990-01, Standard Test Method for Tensile, Compressive, and Flexural Creep and Creep-

Rupture of Plastics, contains a similar procedure.

Page 16

Fig. 11 Stress versus log of time to failure curve excerpted from ASTM D 4680

Development of a long-term strength curve for an adhesive anchor system would

naturally lead to the application of the safety factor directly to the predicted long-term

strength. While appealing for its simplicity, this approach assumes that the necessary

long-term strength data can be generated in a reliable and consistent manner. This has yet

to be verified experimentally.

The relationship of the methodologies embodied in AC58 and AC308 to such an

approach is unclear at present.

In view of the above, and considering the difficulties associated with overhead

installations and the possibility that the creep behavior could be negatively affected by

poor installation, it is reasonable to perform an additional design check for overhead

installations subjected to sustained tension loading (e.g. hanger installations), whereby a

reduced resistance is compared with only those portions of the load that is sustained. This

supplemental design proof thus takes the form of:

R, S ,

N N

(4)

where

R,

N

is the resistance associated with a reduced bond value

k

where

k

is the bond

strength generated by the AC308 qualification process.

S ,

N

is the tension component of the sustained load (usually, dead load plus some

portion of the live load that is assumed to be sustained)

This supplemental proof has been implemented by ICC-ES in AC308 on an ad hoc basis

for overhead applications involving direct tension whereby a value of 0.75 has been

adopted for

. Extension of this proof to other design conditions such as cantilever

Page 17

beams where anchors may be subject to sustained tension loading is warranted for

specific cases (e.g., where the ratio of live to dead loads is small).

7.0 Conclusions

The use of adhesive anchors for safety-related applications involving sustained tension

loading is supported by extensive experience both in the field and in the laboratory. The

following points are relevant:

1. Standards for the assessment of adhesive anchor systems to address sustained

loading have been in place for over a decade.

2. Assuming proper installation and design in all other respects, allowable stress

designs of adhesive anchors qualified to resist sustained tension loading in safety-

related applications under AC58 provide the requisite level of safety against creep

failure.

28

3. The qualification and design of adhesive anchors for sustained tension load

applications in accordance with the provisions of AC308 and ACI 318 Appendix

D provide a level of safety in accordance with current standards and procedures

for reinforced concrete design. Pending further research on the relationship of

creep testing to long-term strength, the additional check on long-term strength as

discussed in Section 6.2.2 should be included in the design.

4. Particular care should be exercised in the installation of adhesive anchors in

overhead conditions due to the potential for degraded creep response associated

with inadequate hole cleaning and injection techniques.

5. Ongoing research into creep phenomenon in adhesives used to transfer sustained

loads is warranted. This research has applicability to a wide range of applications,

including the use of surface-applied strengthening materials (carbon fiber, other),

repair of reinforced concrete elements with crack injection, etc.

6. In light of the standards now in place for the assessment of adhesive anchor

systems for sustained loading, the authors are of the opinion that the NTSB

recommendation to prohibit the use of adhesive anchors in sustained tensile-

load overhead highway applicationsuntil testing standards and protocols have

been developed and implemented... is excessively broad in scope. A prohibition

on the use of systems that have not been assessed in accordance with AC308

would be appropriate.

28

Where anchors have been installed in the overhead position to resist sustained tension loads and there are

questions regarding the quality of the installation or the procedures used to assure good bond and a void-

free installation, it may be prudent to perform periodic field checks as discussed in Section 6.1.

Page 18

Postscript: Discussion of Federal Highway Administration report

29

on creep behavior of

adhesive anchors in connection with the I-90 Seaport Portal Tunnel partial ceiling

collapse of July 10, 2006.

Background:

The partial collapse of the ceiling system in the I-90 Seaport Portal Tunnel resulted in an

extensive investigation by the National Traffic Safety Board (NTSB) and the Federal

Highway Administration (FHWA). As part of that investigation, tests were conducted at

the FHWAs Turner-Fairbank Highway Research Center on the anchors used in the

tunnel, including tests specifically intended to investigate creep behavior.

The apparent purpose of the FHWA investigation into creep behavior was to establish

whether the products used in that application were subject to creep failure and whether

this could have been anticipated with current screening methodologies. The focus of the

investigation, however, was on realistic re-creation of in-situ conditions in the I-90 tunnel,

not laboratory testing and qualification procedures.

Synopsis of the FHWA testing and analysis:

Twelve anchor specimens were installed in the overhead position and individually loaded

with dead weights placed by forklift. The anchors were installed in cored holes and the

ambient laboratory temperature during the test varied between approximately 75 and 90

degree Fahrenheit

30

. The measured displacements and residual failure loads were

recorded and analyzed. Subsequent inspection revealed the existence of substantial air

voids in at least 8 of the 12 test specimens, particularly in the anchorages executed with

the fast-cure adhesive. A power function was used to extrapolate the displacements out to

various time periods. These were then compared to the predicted displacements using the

natural log function specified in AC58. A limiting displacement of 0.20 in. (5.1 mm) was

taken for predicting the life of the anchors under sustained load, and a conclusion was

reached that the time to failure could best be predicted with the power function developed

using regression analysis and that the log function specified in AC58 is inadequate for

this task.

Analysis:

A preliminary review of the FHWA findings contained in the report indicates the

following:

1. That practical difficulties associated with installing the anchors overhead (as

reported in their findings) resulted in significant voids in the adhesive mass with

attendant significant decreases in the bond strength of the anchors.

29

Federal Highway Administration Turner-Fairbanks Highway Research Center, Report I-90 Seaport

Portal Tunnel Partial Ceiling Collapse Investigation: Sustained Load Behavior of Powers Fasteners Power-

Fast

+

Adhesive Anchors, July 2006, as made available on the Boston Globe website

www.bostonglobe.com.

30

Ibid., p. 16, p. 74, The report notes that the increase in ambient temperature towards the end of the testing

correlated with increased anchor displacements.

Page 19

2. That the fast-cure product in question, had it been subjected to the complete

criteria contained in AC58 for creep testing (constant elevated temperature of 110

degrees Fahrenheit, displacement limit derived from static tests with maximum

displacement 0.12 inches, etc.), would not have been qualified for long-term

loading, not even at the reduced design capacity associated with the application in

question (2.6 kips per anchor corresponding to a mean ultimate of 10.4 kips and a

sustained load requirement of 4.2 kips.

31

).

Conclusion:

In several respects, the FHWA testing of the subject product did not correspond to an

AC58 assessment. Had such an assessment been conducted by the FHWA, they would

have found that the fast-cure adhesive in question would be precluded for long-term

loading and, in fact, it was not rated for such loading in the ICBO-ES evaluation report

32

issued for the product after the anchors had been installed. That evaluation report was

based on an assessment using AC58 criteria.

AC308, the current ICC-ES acceptance criteria for assessing adhesive anchors, requires

extrapolation of measured displacements under sustained loading to 50 years at room

temperature and 10 years at elevated temperature (mandatory requirement). The

establishment of a time window of 75 to 100 years for highway construction (as opposed

to 50 years for buildings) does not materially affect the outcome since the incremental

increase in displacement at these long time frames is marginal.

It is therefore the opinion of the authors that the conclusion stated in the FHWA report

that the continued use of adhesive anchors subject to sustained tension loads should

be very limited if not eliminated for life safety applications

33

is not supported by these

tests and is unwarranted.

31

National Transportation Safety Board, op cit., p. 37.

32

ER-4514, Chem-Stud and Power-Fast Adhesive Anchor Systems, ICBO Evaluation Service, Inc.,

Whittier, CA, re-issued February 1, 2000, p. 2.

33

Federal Highway Administration Turner-Fairbanks Highway Research Center, op cit., p. 48.

Page 20

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Familiarization With Apparatus and Equipment Used in Testing of MaterialsDocument5 pagesFamiliarization With Apparatus and Equipment Used in Testing of MaterialsEmanoAce33% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The SNR Expert Diagnosis:: Analysis and Recommendations For Optimizing Bearing LifeDocument36 pagesThe SNR Expert Diagnosis:: Analysis and Recommendations For Optimizing Bearing Lifejarneberg100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Belleville Disk Washer FormulaDocument2 pagesBelleville Disk Washer FormulajarnebergNo ratings yet

- Designing HSS ConnectionsDocument8 pagesDesigning HSS Connectionsjarneberg100% (1)

- Wire Rope Sling Hand BookDocument28 pagesWire Rope Sling Hand BookJogi Oscar SinagaNo ratings yet

- Aluminum Bronze OverviewDocument7 pagesAluminum Bronze OverviewjarnebergNo ratings yet

- Lockbox Br100 v1.22Document36 pagesLockbox Br100 v1.22Manoj BhogaleNo ratings yet

- 450i User ManualDocument54 pages450i User ManualThượng Lê Văn0% (2)

- Food and Beverage Department Job DescriptionDocument21 pagesFood and Beverage Department Job DescriptionShergie Rivera71% (7)

- Guide To Growing MangoDocument8 pagesGuide To Growing MangoRhenn Las100% (2)

- HSBC in A Nut ShellDocument190 pagesHSBC in A Nut Shelllanpham19842003No ratings yet

- Hotel Reservation SystemDocument36 pagesHotel Reservation SystemSowmi DaaluNo ratings yet

- Horizontal LifeLine InstructionsDocument8 pagesHorizontal LifeLine InstructionsjarnebergNo ratings yet

- AISI 8620 Case HardeningDocument2 pagesAISI 8620 Case HardeningjarnebergNo ratings yet

- Metallurgical Investigation of "Tiger Stripes" On A Carburized High Speed PinionDocument3 pagesMetallurgical Investigation of "Tiger Stripes" On A Carburized High Speed PinionjarnebergNo ratings yet

- Test Report: IMR KHA Report Number 201416232Document1 pageTest Report: IMR KHA Report Number 201416232jarnebergNo ratings yet

- Case Studies in Engineering Failure Analysis: Michael K. BudinskiDocument11 pagesCase Studies in Engineering Failure Analysis: Michael K. BudinskijarnebergNo ratings yet

- Special Inspection Guidelines Rev 6-6-11Document13 pagesSpecial Inspection Guidelines Rev 6-6-11jarnebergNo ratings yet

- Simpson XT Anchor ICBO CertDocument16 pagesSimpson XT Anchor ICBO CertjarnebergNo ratings yet

- Crosby Clips PG 40Document2 pagesCrosby Clips PG 40jarnebergNo ratings yet

- Standard Gear Couplings 24330Document52 pagesStandard Gear Couplings 24330jarnebergNo ratings yet

- Selection and Performance: Criteria For Power Transmission CouplingsDocument10 pagesSelection and Performance: Criteria For Power Transmission CouplingsjarnebergNo ratings yet

- Rofi Operation and Maintenance ManualDocument3 pagesRofi Operation and Maintenance ManualSteve NewmanNo ratings yet

- Specialty Arc Fusion Splicer: FSM-100 SeriesDocument193 pagesSpecialty Arc Fusion Splicer: FSM-100 SeriesSFTB SoundsFromTheBirdsNo ratings yet

- Delta AFC1212D-SP19Document9 pagesDelta AFC1212D-SP19Brent SmithNo ratings yet

- Departmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedDocument37 pagesDepartmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedGeorgina AlpertNo ratings yet

- Avalon LF GB CTP MachineDocument2 pagesAvalon LF GB CTP Machinekojo0% (1)

- Action Plan Lis 2021-2022Document3 pagesAction Plan Lis 2021-2022Vervie BingalogNo ratings yet

- QUIZ Group 1 Answer KeyDocument3 pagesQUIZ Group 1 Answer KeyJames MercadoNo ratings yet

- Guide For Overseas Applicants IRELAND PDFDocument29 pagesGuide For Overseas Applicants IRELAND PDFJasonLeeNo ratings yet

- HRD DilemmaDocument4 pagesHRD DilemmaAjay KumarNo ratings yet

- Audit On ERP Implementation UN PWCDocument28 pagesAudit On ERP Implementation UN PWCSamina InkandellaNo ratings yet

- Rebar Coupler: Barlock S/CA-Series CouplersDocument1 pageRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefNo ratings yet

- Agfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Document3 pagesAgfa CR 85-X: Specification Fuji FCR Xg5000 Kodak CR 975Youness Ben TibariNo ratings yet

- How To Control A DC Motor With An ArduinoDocument7 pagesHow To Control A DC Motor With An Arduinothatchaphan norkhamNo ratings yet

- PVAI VPO - Membership FormDocument8 pagesPVAI VPO - Membership FormRajeevSangamNo ratings yet

- Newsletter 289Document10 pagesNewsletter 289Henry CitizenNo ratings yet

- Chapter 5Document3 pagesChapter 5Showki WaniNo ratings yet

- Oem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Document43 pagesOem Functional Specifications For DVAS-2810 (810MB) 2.5-Inch Hard Disk Drive With SCSI Interface Rev. (1.0)Farhad FarajyanNo ratings yet

- Cryo EnginesDocument6 pagesCryo EnginesgdoninaNo ratings yet

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDocument13 pagesThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6No ratings yet

- PeopleSoft Application Engine Program PDFDocument17 pagesPeopleSoft Application Engine Program PDFSaurabh MehtaNo ratings yet

- GR L-38338Document3 pagesGR L-38338James PerezNo ratings yet

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamNo ratings yet

- Material Safety Data Sheet (According To 91/155 EC)Document4 pagesMaterial Safety Data Sheet (According To 91/155 EC)Jaymit PatelNo ratings yet