Professional Documents

Culture Documents

9 C 96051 D 1 Adcf 70150

Uploaded by

خالد بنسالمOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9 C 96051 D 1 Adcf 70150

Uploaded by

خالد بنسالمCopyright:

Available Formats

Short communication

Study of a new solar adsorption refrigerator powered by a parabolic trough collector

A. El Fadar

a

, A. Mimet

a,

*

, A. Azzabakh

a

, M. Prez-Garca

b

, J. Castaing

c

a

Energetic Laboratory, Sciences Faculty, BP 2121, 93000 Tetouan, Abdelmalek Essaadi University, Morocco

b

Dpto. de Fisica Aplicada Universidad de Almeria, Espaa

c

Laboratoire Thermique, Energtique et Procds (LaTEP), Avenue de lUniversit, BP 1155, 64013 Pau Cedex, France

a r t i c l e i n f o

Article history:

Received 11 July 2007

Accepted 10 June 2008

Available online xxxx

Keywords:

Solar energy

Adsorption

Simulation

Refrigeration

Heat pipe

Parabolic trough collector

a b s t r a c t

This paper presents the study of solar adsorption cooling machine, where the reactor is heated by a par-

abolic trough collector (PTC) and is coupled with a heat pipe (HP). This reactor contains a porous medium

constituted of activated carbon, reacting by adsorption with ammonia.

We have developed a model, based on the equilibrium equations of the refrigerant, adsorption isotherms,

heat and mass transfer within the adsorbent bed and energy balance in the hybrid system components.

From real climatic data, the model computes the performances of the machine. In comparison with other

systems powered by at plate or evacuated tube collectors, the predicted results, have illustrated the

ability of the proposed system to achieve a high performance due to high efciency of PTC, and high ux

density of heat pipe.

2008 Elsevier Ltd. All rights reserved.

1. Introduction

The negative environmental consequences related to conven-

tional vapor compression refrigeration machines, have renewed

interest in adsorption refrigeration systems whose refrigerants

present the advantages of being absolutely benign for the environ-

ment, i.e., these refrigerants satisfy the Montreal protocol on ozone

layer depletion and the Kyoto protocol on global warming [1].

Additionally, solar adsorption refrigeration systems are attrac-

tive, mostly in remote areas without grid-connected electricity,

since solar radiation is freely available, and the demand of refriger-

ation increases particularly in the sunny regions.

Some units of solar adsorption refrigerators have been commer-

cialized using activated carbonmethanol system manufactured by

BLM Co. of France and zeolitewater system manufactured by

Zeopower Co. of USA. These units were technically successful, but

their costs are not competitive with the conventional vapor com-

pression system [2].

In addition to their high costs, adsorption systems have some

other drawbacks, such low specic cooling power and low coef-

cient of performance, due to the weak heat transfer within the

adsorbers. In order to overcome these disadvantages, several works

have been carried out.

To contribute to these researches, this paper presents a study of

an activated carbon-ammonia adsorption system powered by solar

energy, using the coupling of a water-stainless steel heat pipe and

a parabolic trough collector.

The solar power technology using the PTC has been used in var-

ious applications, such as electricity generation, desalination, heat-

ing, etc. Parabolic trough solar technology is the most-veried solar

technology trough deployment and construction testing [3]. Also

Bird and Drost [4] have recommended that the PTC concept should

receive the highest priority for commercial development for low

temperature (65177 C) solar process heat applications.

Even so, solar adsorption cooling systems are usually carried

out with at plate and evacuated tube collectors, whereas little

attention has been paid to concentrating collectors.

Besides, the use of heat pipe in solar collector is attractive, be-

cause it presents some advantages, such as construction simplicity,

perfect adjustability, easier control and high heat transfer ability in

low temperature differences, ability to operate as a thermal diode

and as a thermal switch [5]. In addition, it does not need moving

parts or external pumping.

2. System description

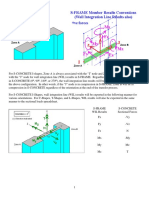

As shown in Fig. 1, the proposed refrigerator comprises a solar

collector, a condenser, an evaporator, refrigerant valves and a

cylindrical adsorber containing the activated carbon-ammonia.

The adsorption and desorption of the refrigerant are generated

by alternate cooling and heating of the reactor.

The evaporator end of the heat pipe is placed at the focused line

of the PTC, and the condenser is inserted in the adsorbent bed. The

1359-4311/$ - see front matter 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.applthermaleng.2008.06.012

* Corresponding author. Tel.: +212 39 97 24 23; fax: +212 39 99 45 00.

E-mail address: mimet@fst.ac.ma (A. Mimet).

Applied Thermal Engineering xxx (2008) xxxxxx

Contents lists available at ScienceDirect

Applied Thermal Engineering

j our nal homepage: www. el sevi er . com/ l ocat e/ apt her meng

ARTICLE IN PRESS

Please cite this article in press as: A. El Fadar et al., Study of a new solar adsorption refrigerator powered by a parabolic trough collector,

Appl. Therm. Eng. (2008), doi:10.1016/j.applthermaleng.2008.06.012

reective surface of PTC focuses the solar direct radiation on the

linear absorber. Then, solar radiation is converted to thermal en-

ergy, which is absorbed at the HP evaporator section. This heat

vaporizes the working uid (water) in this section. The resulting

difference in pressure drives vapour from the evaporator to the

condenser where it is condensed, and then the latent heat of vapor-

ization is released to the heat sink (adsorbent bed). The capillary

pressure, generated by the wick, drives the condensed liquid to

the evaporator for re-evaporation.

3. Mathematical modelling

Under some reasonable assumptions, the energy balance equa-

tions per unit length of the aperture, conned to the concentrator

components, can be written as follows:

3.1. Glass tube

q

g

C

g

A

g

oT

g

ot

ca

g

bWI

b

t pD

gi

U

ab-g

T

ab

T

g

pD

go

U

gamb

T

g

T

amb

1

3.2. Absorber/heat pipe

q

ab

C

ab

A

ab

oT

ab

ot

csa

ab

bWI

b

tpD

o

U

ab-g

T

ab

T

g

pD

o

hT

ab

T

hp

2

where U

g-amb

and U

ab-g

are the heat transfer coefcients between

the glazing envelope and the ambient air, and between the glazing

envelope and the absorber, respectively. The convective and radia-

tive heat transfer coefcients are obtained from correlations given

in the literature [68]. h is the heat transfer coefcient between

the outer surface of absorber and the liquid-vapour interface. The

corresponding thermal resistance, R, is given by:

R 1=2pL

c

lnD

o

=D

i

k

wa

lnD

i

=D

wi

k

eff

3

Under the assumption of the metal screen wick, which is as-

sumed to be saturated with the working uid, the effective wick

thermal conductivity is evaluated by the following equation [9].

k

eff

k

l

k

l

k

w

1 e

w

k

l

k

w

k

l

k

w

1 e

w

k

l

k

w

4

Nomenclature

A cross-sectional area (m

2

)

C specic heat (J/kg K)

D

gi

inner diameter of glass tube (m)

D

go

outer diameter of glass tube (m)

D

i

container inner diameter of absorber (m)

D

o

container outer diameter of absorber (m)

D

wi

wick inner diameter of heat pipe (m)

H heat transfer coefcient (W/m

2

K)

I

b

direct component of solar radiation (W/m

2

)

L

c

collector length/evaporator section length of heat pipe

(m)

L

r

reactor length/condenser section length of heat pipe (m)

m mass (kg)

t time (h)

T temperature (K)

W aperture width of collector (m)

Greek symbols

a Absorptivity

b collector optical factor

c reectivity of the reecting surface

w

porosity of wick

q density (kg/m

3

)

s Transmitivity

Dx adsorption capacity difference between adsorption and

desorption phases (kg/kg)

k thermal conductivity (W/m K)

Subscripts

ab Absorber

AC activated carbon

amb Ambient

Con condensation

Ev Evaporation

G glass tube

Hp heat pipe

L Liquid (water)

w Wick

wa wall (stainless steel)

Abbreviations

COPs solar coefcient of performance

HP heat pipe

PTC parabolic trough collector

3

9

10

11 12

5

1

2

4

7

8

6 6

a

b

Fig. 1. Simplied scheme of the hybrid system: 1, PTC; 2, heat pipe; 3, adsorber; 4, evaporator; 5, condenser; 6, valves; 7, tank; 8, expansion valve. (b) Cross section of the

receiver assembly: 9, reective surface; 10, glazing; 11, absorber; 12, wick.

2 A. El Fadar et al. / Applied Thermal Engineering xxx (2008) xxxxxx

ARTICLE IN PRESS

Please cite this article in press as: A. El Fadar et al., Study of a new solar adsorption refrigerator powered by a parabolic trough collector,

Appl. Therm. Eng. (2008), doi:10.1016/j.applthermaleng.2008.06.012

4. Results and discussion

The assessment parameter of the performance of the adsorption

refrigerating system considered in this study is the solar coefcient

of performance (COPs). This parameter is dened by the following

formula:

COP

s

Q

c

R

sunset

sunrise

A

c

I

b

t dt

5

where A

c

is the collector aperture area and Q

c

is the cooling effect

produced in the evaporator, which it is equal to the refrigerant la-

tent heat of evaporation minus the sensible heat to cool down the

refrigerant from the condensation temperature to the evaporation

temperature:

Q

c

m

AC

Dx LT

ev

Z

Tcon

Tev

C

l

dT

6

where L(T

ev

) is the latent heat of ammonia at evaporation temper-

ature, and C

l

is the specic heat of liquid ammonia.

The model equations are solved by the implicit nite difference

scheme. A numerical program, written in FORTRAN, has been

developed to compute the performance coefcients (COPs) of the

machine. In our simulation, we have used the climatic data mea-

sured in Tetouan (3535

0

N, 523

0

W), Morocco, for a clear type

day of July. The other main parameters used in simulation are gi-

ven in the Appendix (Table 1).

We represent in Figs. 2 and 3, the effect of the aperture width of

collector (W) and external radius of reactor (R

2

) on the COPs of the

machine. The analysis of the results, shows that the COPs increases,

with increase in radius of reactor, and once the radius reaches a

critical value, the COPs decreases, because the increase in adsor-

bent mass (i.e. radius) of rector induces adsorption of high quantity

of ammonia at adsorption phase and hence, desorption of high

amount of ammonia at subsequent desorption phase. This pro-

duces more cooling and, consequently, we obtain high COPs. Nev-

ertheless, beyond this critical value, the bed is heated, but the heat

absorbed is not sufcient to desorb the required amount of

ammonia.

It is also observed that, for small values of reactor radius

(R

2

< 10 cm), there is no signicant inuence of W on the COPs, be-

cause the variation of the aperture width causes only heating (sen-

sible heat) of the adsorber. As result, the performance remains

unaffected. Unlike in the case of high radii of reactor

(R

2

> 10 cm), where more energy is needed to induce desorption

of ammonia, the inuence of W is apparently signicant. It is also

shown that, for each aperture width value, there exists an opti-

mum external radius of adsorbent bed.

Table 1

Main parameters used in simulation

Symbol Parameter Value Unit

PTC

C

ab

specic heat capacity of the absorber 0.49 kJ/

kg K

C

g

specic heat capacity of glass tube 0.75 kJ/

kg K

D

gi

inner diameter of the glass tube 0.11 m

D

go

outer diameter of the glass tube 0.115 m

D

o

outer diameter of the absorber 0.056 m

L

c

collector length 1.00 m

L

r

reactor length 0.70 m

a

ab

absorptivity of the absorber 0.92

a

g

absorptivity of the glass tube 0.05

b collector optical factor 0.90

ab

emissivity of the absorber 0.90

g

emissivity of the glass tube 0.85

q

ab

density of the absorber 7850 kg/m

3

q

g

density of the glass tube 2500 kg/m

3

c reectivity of the reecting surface 0.90

s transmitivity of the glass tube 0.90

HP

D

i

container inner diameter of HP 0.048 m

D

w

wick inner diameter of HP 0.044 m

w

porosity of wick 0.73

K

l

thermal conductivity of the liquid phase of the

working uid

0.63 W/

m K

K

w

thermal conductivity of wick material 46.00 W/

m K

AC/ammonia pair

C

s

specic heat of adsorbent 0.836 kJ/

kg C

H

i

heat transfer coefcient between the wall

(stainless steel) and the adsorbent bed

33.45

a

W/

m

2

K

D

Hads

latent heat of adsorption 1600 kJ/kg

L(Tev) latent heat of ammonia at evaporation

temperature (0 C)

1262.40 kJ/kg

R

1

internal radius of adsorbent bed (m) 0.028 m

porosity of adsorbent bed 0.71

K

e

equivalent Thermal conductivity of

adsorbent bed

0.431

a

W/

m K

Operating conditions

T

ads

adsorption temperature 297 K

T

con

condensation temperature 301 K

T

ev

evaporation temperature 273 K

a

These values are evaluated experimentally by A. Mimet [10].

Fig. 2. Effect of the aperture width of collector (W) on COPs.

0.05

0.1

0.15

0.2

0.25

0.2

0.4

0.6

0.8

1

0

0.05

0.1

0.15

0.2

E

x

te

rn

a

l ra

d

iu

s

o

f a

d

s

o

rb

e

n

t (m

)

A

p

e

rtu

re

w

id

th

(m

)

C

O

P

s

Fig. 3. COPs variation versus aperture width of collector and external radius of

adsorbent bed.

A. El Fadar et al. / Applied Thermal Engineering xxx (2008) xxxxxx 3

ARTICLE IN PRESS

Please cite this article in press as: A. El Fadar et al., Study of a new solar adsorption refrigerator powered by a parabolic trough collector,

Appl. Therm. Eng. (2008), doi:10.1016/j.applthermaleng.2008.06.012

5. Conclusions

The objective of this study is to show the feasibility of an

adsorption refrigerating system driven by PTC solar collector,

which is coupled with an annular heat pipe for transferring heat

towards the adsorbent bed.

A theoretical model and a numerical program have been

developed, in order to evaluate the performance of the adsorp-

tion-cooling machine. The numerical results show a great sensitiv-

ity of the performance coefcient of the machine to the radius of

the adsorber and the aperture width of collector. A number of

conclusions may be drawn:

1. For a given collector conguration, there exists an optimal

dimension of the reactor (optimal radius).

2. In the ranges investigated, the optimum performance of the

system is COPs = 0.18, when the external radius of the adsorber

and aperture width of the collector are 14.5 and 70 cm, respec-

tively. Therefore, the results obtained in this work, show a

promising performance in comparison with published data.

3. This work shows that the PTCis a useful component, for improve-

ment of the solar adsorptionrefrigerationsystems. This systemis

more efcient and lighter when coupled with heat pipe.

References

[1] E.E. Anyanwu, Environmental pollution: restructuring the refrigeration

industry as a way out, Int. J. Environ. Protect Eng. 26 (4) (2000) 1727.

[2] M.A. Alghoul, M.Y. Sulaiman, B.Z. Azmi, M.Abd. Wahab, Advances on multi-

purpose solar adsorption systems for domestic refrigeration and water

heating, Appl. Thermal Eng. 27 (2007) 813822.

[3] Hank Price and Vahab Hassani, Modular Trough Power Plant, Cycle and

Systems Analysis, January, 2002 NREL/TP-550-31240.

[4] S.P. Bird, M.K. Drost, Assessment of generic solar thermal concept for large

industrial process heat applications, in: Proceedings of the ASME Solar Energy

Division, Fourth Annual Conference, Albuquerque, NM, 1982.

[5] A. Abu-Zour, S. Riffat, M. Gillott, New design of solar collector integrated into

solar louvres for efcient heat transfer, Appl. Thermal Eng. 26 (16) (2006)

18761882.

[6] A. Bejan, Convection Heat Transfer, second ed., John Wiley & Sons, New York,

1995. pp. 323324.

[7] S. Nafey, H.S. Fath, S.O. El-Helaby, A.M. Soliman, Solar desalination using

humidication dehumidication processes. Part I. A numerical investigation,

Energy Convers. Manage. (45) (2004) 12431261.

[8] S.C. Mullick, S.K. Nanda, An improved technique computing the heat loss factor

of a tubular absorber, J. Solar Energy 42 (1989) 17.

[9] A. Faghri, Heat Pipe Science and Technology, Taylor & Francis, USA, 1995.

[10] A. Mimet, Ph.D. Thesis, Etude Thorique exprimentale dune machine

frigorique adsorption dammoniac sur charbon actif, FPMs, Mons,

Belgium, 1991.

4 A. El Fadar et al. / Applied Thermal Engineering xxx (2008) xxxxxx

ARTICLE IN PRESS

Please cite this article in press as: A. El Fadar et al., Study of a new solar adsorption refrigerator powered by a parabolic trough collector,

Appl. Therm. Eng. (2008), doi:10.1016/j.applthermaleng.2008.06.012

You might also like

- En Installation Manual Heater Type EJKDocument10 pagesEn Installation Manual Heater Type EJKخالد بنسالمNo ratings yet

- En ENSOL - Installation Instruction Tar PaperDocument21 pagesEn ENSOL - Installation Instruction Tar Paperخالد بنسالمNo ratings yet

- En Ensol - Installation Manual Water Heater With Solar Pump-GroupDocument16 pagesEn Ensol - Installation Manual Water Heater With Solar Pump-Groupخالد بنسالمNo ratings yet

- En ENSOL - Installation Instruction Flat RoofDocument24 pagesEn ENSOL - Installation Instruction Flat Roofخالد بنسالمNo ratings yet

- En ENSOL - Inroof Installation Instruction TileDocument20 pagesEn ENSOL - Inroof Installation Instruction Tileخالد بنسالمNo ratings yet

- 06 MultizoneBuilding PDFDocument213 pages06 MultizoneBuilding PDFmirofeloNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 4Document49 pagesChapter 4Jakir HossainNo ratings yet

- Math 112Document3 pagesMath 112janinasuzetteNo ratings yet

- Iso 8528-9Document24 pagesIso 8528-9raffacap50% (2)

- Midas Gen: RC Beam Serviceability Checking ResultDocument2 pagesMidas Gen: RC Beam Serviceability Checking ResultakankwasaNo ratings yet

- Algebra 2 Unit 3 StudentDocument68 pagesAlgebra 2 Unit 3 Studentapi-327127977No ratings yet

- Process Control Servo SystemDocument16 pagesProcess Control Servo SystemCarlos RamirezNo ratings yet

- Charlotte Perriand - From Photography To Design - de La Photographie Au DesignDocument3 pagesCharlotte Perriand - From Photography To Design - de La Photographie Au DesignCamille BinzNo ratings yet

- Thomson BSA Grease BrochureDocument1 pageThomson BSA Grease BrochureElectromateNo ratings yet

- Rose Diagrams Intro PDFDocument3 pagesRose Diagrams Intro PDFMahmood MuftiNo ratings yet

- Fundamentals of Thermodynamics (6th Edition) SONNTAG, BORGNAKKE VAN WYLENDocument814 pagesFundamentals of Thermodynamics (6th Edition) SONNTAG, BORGNAKKE VAN WYLENDarwinQuin63% (8)

- Oceanic Anoxic Events (O.a.e) Organic Rocks Deposition CretaceousDocument6 pagesOceanic Anoxic Events (O.a.e) Organic Rocks Deposition CretaceousJulian De Bedout OrdoñezNo ratings yet

- Thermal Physics Self-Made NotesDocument4 pagesThermal Physics Self-Made NotesYee Xien LimNo ratings yet

- Fatigue Failure Analysis of Fillet Welded Joints Used in Offshore StructuresDocument78 pagesFatigue Failure Analysis of Fillet Welded Joints Used in Offshore Structureschrism225836No ratings yet

- Analysis and Design of Suspension Cable BridgeDocument5 pagesAnalysis and Design of Suspension Cable BridgeNhel AlbrechtNo ratings yet

- An Elastic Second SkinDocument16 pagesAn Elastic Second SkinNop PiromNo ratings yet

- Advanced Math SyllabusDocument2 pagesAdvanced Math Syllabusapi-232573717No ratings yet

- Cable Element Analysis TechniquesDocument16 pagesCable Element Analysis TechniquesPankaj_Taneja_9684No ratings yet

- PhysicsDocument396 pagesPhysicsGreeny34No ratings yet

- Wall Integration Conventions S-CONCRETE R11 S-FRAMEDocument3 pagesWall Integration Conventions S-CONCRETE R11 S-FRAMESyed RaziuddinNo ratings yet

- Promaspray® F5 PDFDocument4 pagesPromaspray® F5 PDFhero6600No ratings yet

- Basic Theory Fluidization (Fluidized Bed) ExperimentDocument11 pagesBasic Theory Fluidization (Fluidized Bed) ExperimentMuhammad Reza100% (1)

- Static Analysis of A Go-Kart Chassis: March 2016Document7 pagesStatic Analysis of A Go-Kart Chassis: March 2016Najaf HussainNo ratings yet

- Electrical CircuitsDocument336 pagesElectrical CircuitspxppiezcNo ratings yet

- Science Matter Lesson PlanDocument2 pagesScience Matter Lesson Planapi-218287701100% (1)

- Lab 1Document25 pagesLab 1Self McNo ratings yet

- Equilibrium of Rigid BodiesDocument18 pagesEquilibrium of Rigid BodiesjahirNo ratings yet

- Ruling PlanetsDocument2 pagesRuling PlanetsshivaprasadamNo ratings yet

- EEG BCI For Dual Task Driving DetectionDocument9 pagesEEG BCI For Dual Task Driving DetectionBudi SetyawanNo ratings yet

- DIL 805 Quenching Dilatometer BrochureDocument14 pagesDIL 805 Quenching Dilatometer BrochureDeniz ShenNo ratings yet