Professional Documents

Culture Documents

Sds (Special Direct System) Drills: V. Ryan © 2006

Uploaded by

Nguyễn Hồng DươngOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sds (Special Direct System) Drills: V. Ryan © 2006

Uploaded by

Nguyễn Hồng DươngCopyright:

Available Formats

SDS (SPECIAL DIRECT SYSTEM) DRILLS

V. Ryan 2006

SDS (Special Direct System) Drills are extremely powerful and used when extra power is

required, for heavy duty jobs. They have three basic functions that allow normal drilling,

hammer action and chiselling. Furthermore, SDS Drills can hold large diameter drill bits well

passed the 13mm diameter limit of normal drills. Professionals tend to select this type of drill

for major projects.

However, SDS Drills tend to by heavy compared to ordinary drills which means they are

unsuitable when working up a ladder or for small jobs such as light drilling - when a small

power drill would be suffice.

1. The cord is carefully laid out so that it cannot trip the person using the drill.

2. It is good practice to use a circuit breaker. This will cut power if any electrical fault in the

drill is detected.

3. Always wear safety goggles to protect the eyes. Never operate equipment like this without

eye protection.

4. When using an SDS Drill hold both the normal handle and front handle securely. This will

help steady the drill as it vibrates during use. It also allows the user to put pressure against

the drill as it is used to drill holes in difficult materials.

5. The person using the drill should space their feet apart. This helps the person balance and

lean into the drill, applying his/her weight safely.

6. Always check that electrical wires or water pipes are not in the area of intended drilling.

Drilling through an electrical wire can be extremely dangerous.

7. Always seek instruction / training from an appropriately qualified instructor before using

any tools, especially power tools.

A basic SDS Drill is shown below. Even basic drills are provided with necessary fitments

such as a front handle. It is strongly recommended that the front handle is always fitted

before use . SDS Drills should not be used in one hand, it should be firmly supported by both

hands in order to take the weight. Adjustments to speed can be made by the speed control

dial whilst hammer, normal or chisel action can be selected by altering the position of

the lever at the top of the drill.

TYPICAL SDS DRILL CHISEL

A range of chisels are supplied for SDS Drills. A typical chisel is shown opposite. The shaft

is the part that locks into the chuck of the drill. The chisel point is ground to a suitable

angle (normally 60 degrees). This type of chisel could be used to chip away concrete or

stone.

You might also like

- Power ToolsDocument9 pagesPower ToolsNatalia Lopez RobredoNo ratings yet

- Corded Hammer Drills: V. Ryan © 2006Document4 pagesCorded Hammer Drills: V. Ryan © 2006Nguyễn Hồng DươngNo ratings yet

- Sample LASDocument14 pagesSample LASJoseph Joram SabrosoNo ratings yet

- Skil Table Saw Owners ManualDocument104 pagesSkil Table Saw Owners ManualPamela CloudNo ratings yet

- makita4200NH Saw PDFDocument20 pagesmakita4200NH Saw PDFtkmrmrNo ratings yet

- dw384 Manual PDFDocument7 pagesdw384 Manual PDFEfrain KaracNo ratings yet

- Circular Saw: 185 MM (7-1/4") MODEL 5007NLDocument16 pagesCircular Saw: 185 MM (7-1/4") MODEL 5007NLdan-gabiNo ratings yet

- Sears Belt Sander L0711118Document24 pagesSears Belt Sander L0711118WildratNo ratings yet

- Dremel 16" Scroll SawDocument21 pagesDremel 16" Scroll SawTink EretteNo ratings yet

- Mts 01 ADocument45 pagesMts 01 ApaquitatorresNo ratings yet

- Manual 5007NDocument32 pagesManual 5007NKevin WalshNo ratings yet

- FORCE INTERNATIONAL BAND SAW 3460015 - ManualDocument40 pagesFORCE INTERNATIONAL BAND SAW 3460015 - ManualAl CrosbyNo ratings yet

- S/Crrft3M: ScrollDocument22 pagesS/Crrft3M: ScrollJL AlexanderNo ratings yet

- Safe Working With Powered Hand DrillsDocument26 pagesSafe Working With Powered Hand Drillsmwesigye brianNo ratings yet

- WARNING! Read and Understand All Instructions. Failure To Follow All InstrucDocument5 pagesWARNING! Read and Understand All Instructions. Failure To Follow All InstruciconoclasticjarheadNo ratings yet

- Mastercraft JigSaw 54-8219 E 4.7Document9 pagesMastercraft JigSaw 54-8219 E 4.7shadowrider83No ratings yet

- Makita 2708Document29 pagesMakita 2708Reuel JacintoNo ratings yet

- Craftsman°: Random Orbit SanderDocument12 pagesCraftsman°: Random Orbit SanderJuan PillajoNo ratings yet

- KS7802T - GATOR WEB - Manual-MinDocument13 pagesKS7802T - GATOR WEB - Manual-Mintyler CLausNo ratings yet

- Electronic Reciprocating Saw Variable Speed 1 Inch Stroke: Owner'S ManualDocument12 pagesElectronic Reciprocating Saw Variable Speed 1 Inch Stroke: Owner'S Manualctrpoint2004No ratings yet

- 2022 Power Tools (BSME)Document26 pages2022 Power Tools (BSME)kkiyo2113No ratings yet

- Drill PressDocument12 pagesDrill PressRPShepherdNo ratings yet

- Circular Saw Scie Circulaire Sierra Circular: Instruction Manual Manuel D'Instruction Manual de InstruccionesDocument32 pagesCircular Saw Scie Circulaire Sierra Circular: Instruction Manual Manuel D'Instruction Manual de InstruccionesmarioNo ratings yet

- ManualDocument27 pagesManualJos TorNo ratings yet

- Manual Policorte CompletoDocument36 pagesManual Policorte CompletoDivino CésarNo ratings yet

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDocument29 pagesOperator'S Manual Manuel de L'Utilisateur Manual Del Operadoranilr008No ratings yet

- Makita 2705 TableSaw ManualDocument60 pagesMakita 2705 TableSaw ManualwdowiuueNo ratings yet

- 12" Radial Arm Saw: (Model 33-890) (Model 33-891) (Model 33-892)Document28 pages12" Radial Arm Saw: (Model 33-890) (Model 33-891) (Model 33-892)Marinoiu MarianNo ratings yet

- Sander Spindle OSS450 OmDocument14 pagesSander Spindle OSS450 OmDoug HigelNo ratings yet

- 15-Amp Magnesium Circular Saw: ITEM #0325953Document16 pages15-Amp Magnesium Circular Saw: ITEM #0325953DONALDO CONTRERASNo ratings yet

- N096694, D28710Document40 pagesN096694, D28710Jose ZuletaNo ratings yet

- Serra Circular Makita 5007 ManualDocument32 pagesSerra Circular Makita 5007 ManualEduardo PennaNo ratings yet

- AIRS / R.RRFT$ M RN - : Owners ManualDocument24 pagesAIRS / R.RRFT$ M RN - : Owners ManualLesley RuseNo ratings yet

- Black and Decker Instruction ManualDocument5 pagesBlack and Decker Instruction Manualava_lanaNo ratings yet

- Craftsman Jointer ManualDocument32 pagesCraftsman Jointer ManualcaddlemanNo ratings yet

- 6013BR TaladroDocument20 pages6013BR TaladroAlexis Neira ToledoNo ratings yet

- Craftsman 12-Inch Bandsaw ManualDocument32 pagesCraftsman 12-Inch Bandsaw Manualottuser100% (1)

- dw159 QuDocument23 pagesdw159 QuSilverio JaimeNo ratings yet

- Bandsaw ManualDocument24 pagesBandsaw ManualTanto TenNo ratings yet

- Esmeril Makita PDFDocument16 pagesEsmeril Makita PDFwjzabalaNo ratings yet

- Pole Saw InstructionsDocument1 pagePole Saw InstructionsmaineknitterNo ratings yet

- Mek TopicDocument5 pagesMek TopicdevmarineacademyNo ratings yet

- Craftsman Plate Joiner 900.277300Document31 pagesCraftsman Plate Joiner 900.277300Dan CarsonNo ratings yet

- XtremePower 61108Document10 pagesXtremePower 61108Roberto PolancoNo ratings yet

- Cut-Off Saw 355Mm, Abrasive Disc: 1. Safety InstructionsDocument4 pagesCut-Off Saw 355Mm, Abrasive Disc: 1. Safety InstructionsJerick HernandezNo ratings yet

- Makita Drywall Screwdriver Model: 6821Document12 pagesMakita Drywall Screwdriver Model: 6821wdowiuueNo ratings yet

- Circular Saw ManualDocument156 pagesCircular Saw Manualcci100% (1)

- Craftsman Miter Saw ManualDocument44 pagesCraftsman Miter Saw ManualJuan0% (1)

- 00, D28110Document52 pages00, D28110drimitrixNo ratings yet

- Axminster AWSS-18 Flex - Manual PDFDocument26 pagesAxminster AWSS-18 Flex - Manual PDFOlesea LebedevNo ratings yet

- 6 Machines and Machine Processs 1aDocument28 pages6 Machines and Machine Processs 1aAlfred KuwodzaNo ratings yet

- Black&Decker 3" X 21" Dragster Belt SanderDocument6 pagesBlack&Decker 3" X 21" Dragster Belt SanderwdowiuueNo ratings yet

- 2012NB Manual PDFDocument20 pages2012NB Manual PDFMoises TinteNo ratings yet

- Manual 000004336Document19 pagesManual 000004336ridho_kresnaNo ratings yet

- Craftsman Oscillating Sander 351.215000Document20 pagesCraftsman Oscillating Sander 351.215000Dan CarsonNo ratings yet

- ' - : - Airs/ CRRFT$ Ivlrn: Owner'SDocument33 pages' - : - Airs/ CRRFT$ Ivlrn: Owner'SsNo ratings yet

- Safety With Hand and Portable Power Tools: Training Programme OnDocument38 pagesSafety With Hand and Portable Power Tools: Training Programme OnVishwash GoyalNo ratings yet

- Cấu Trúc Nguồn Tổng ĐàiDocument23 pagesCấu Trúc Nguồn Tổng ĐàiNguyễn Hồng DươngNo ratings yet

- Induction Cooker TeardownDocument14 pagesInduction Cooker TeardownNguyễn Hồng DươngNo ratings yet

- Co Channel Interference Cancellation by The Use of Iterative Digital Beam Forming Method M. Emadi and K. H. SadeghiDocument16 pagesCo Channel Interference Cancellation by The Use of Iterative Digital Beam Forming Method M. Emadi and K. H. SadeghiNguyễn Hồng DươngNo ratings yet

- Iterative MIMO Signal Detection With Inter-Cell Interference Cancellation For Downlink Transmission in Coded OFDM Cellular SystemsDocument5 pagesIterative MIMO Signal Detection With Inter-Cell Interference Cancellation For Downlink Transmission in Coded OFDM Cellular SystemsNguyễn Hồng DươngNo ratings yet

- 3AP1 DTC en - V9 - Epost PDFDocument8 pages3AP1 DTC en - V9 - Epost PDFjoan75No ratings yet

- OVR T2 3N 80-440s P QS Surge Protective DeviceDocument3 pagesOVR T2 3N 80-440s P QS Surge Protective DeviceErik Marcelo BarrenecheaNo ratings yet

- A-Manual, CNG Sensor EngDocument14 pagesA-Manual, CNG Sensor EngerwinNo ratings yet

- Ata 56 - Windows CorDocument15 pagesAta 56 - Windows CorIdrisNo ratings yet

- Motorized Mechanical Can CrusherDocument4 pagesMotorized Mechanical Can CrusherANAND KRISHNANNo ratings yet

- Investigatory Project On Moving Coil GalvanometerDocument16 pagesInvestigatory Project On Moving Coil GalvanometerDuo Genius- Physics Wallah InspiredNo ratings yet

- 5 Pen PC TechnologyDocument15 pages5 Pen PC TechnologyManasa Gowda100% (1)

- Service Manual: DEH-1400RDocument59 pagesService Manual: DEH-1400Rkarol1301No ratings yet

- List of Vessel Equipment To Be Handed OverDocument9 pagesList of Vessel Equipment To Be Handed OverOMS BROMONo ratings yet

- Piping Training Course - Part - 1Document162 pagesPiping Training Course - Part - 1Ibrahim Braneci100% (1)

- Sulky Linear Actuators (Six Versions)Document1 pageSulky Linear Actuators (Six Versions)Petro ServisasNo ratings yet

- Optical Fiber CableDocument7 pagesOptical Fiber CablePankaj Kumar KushwahaNo ratings yet

- Manual Utilizare Aer Conditionat DaewooDocument72 pagesManual Utilizare Aer Conditionat DaewooAndra-Bertha SanduleasaNo ratings yet

- Single Family DwellingDocument27 pagesSingle Family Dwellingjayson platinoNo ratings yet

- JST eSM PDFDocument5 pagesJST eSM PDFMichael SokoliukNo ratings yet

- D25 & D245S Electric SchematicDocument2 pagesD25 & D245S Electric Schematicfaris amsyalNo ratings yet

- 21 Safety Rules For Working With Electrical EquipmentDocument6 pages21 Safety Rules For Working With Electrical EquipmentVasudev AgrawalNo ratings yet

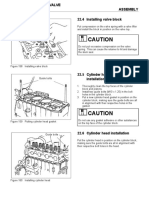

- Manual Moteur S3L2 Mitsubishi (100-195)Document96 pagesManual Moteur S3L2 Mitsubishi (100-195)Ludwig Levallet100% (1)

- Belt Conveyors For Bulk Materials Conveyor: Traducir Esta PáginaDocument4 pagesBelt Conveyors For Bulk Materials Conveyor: Traducir Esta PáginaDIEGO FERNANDO CADENA ARANGONo ratings yet

- Fakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaDocument8 pagesFakulti Teknologi Kejuruteraan Mekanikal Dan Pembuatan Universiti Teknikal Malaysia MelakaThaneswaran BaluNo ratings yet

- Harga Jayamas Medica IndustriDocument6 pagesHarga Jayamas Medica IndustriYuli astutiNo ratings yet

- Camera Comparrison ChartDocument1 pageCamera Comparrison ChartAbdulRedha AhmedNo ratings yet

- Operating, Service Maintenance Manual: Vehicle Identification NoDocument901 pagesOperating, Service Maintenance Manual: Vehicle Identification NoArkadiusz SmagowskiNo ratings yet

- Cs 3Document2 pagesCs 3Mario PitaNo ratings yet

- KPM Round Series Miniature Gas Pumps: DC Power, Pressure To 300 MMHG (5.8 Psi)Document1 pageKPM Round Series Miniature Gas Pumps: DC Power, Pressure To 300 MMHG (5.8 Psi)Louis ChenNo ratings yet

- Spare Parts List: (Replaces 104 21 35-96)Document8 pagesSpare Parts List: (Replaces 104 21 35-96)danNo ratings yet

- Control PidDocument77 pagesControl PidWillard MusengeyiNo ratings yet

- Takamaz XC XLseriesDocument24 pagesTakamaz XC XLseriesPham LongNo ratings yet

- BOSCH SERVOCOM 8098. D PDFDocument2 pagesBOSCH SERVOCOM 8098. D PDFeduardo carcelenNo ratings yet

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosDocument10 pagesManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranNo ratings yet