Professional Documents

Culture Documents

Butterfly Valve

Uploaded by

SingSareblakKanaManahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butterfly Valve

Uploaded by

SingSareblakKanaManahCopyright:

Available Formats

BUTTERFLY

VALVES

HYFLO MKV CAST IRON 2.1

HYFLO MKV DUCTILE IRON 2.6

HYFLO MKV WATERMARK 2.8

(UCV) CAST IRON 2.11

STAINLESS STEEL HYGIENIC 2.13

June 2010

2.1

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

C

A

S

T

I

R

O

N

HYFLO MKV CAST IRON BUTTERFLY VALVE

SPECIFICATION

General purpose buttery valve.

Conforms to EN 593 standards.

ISO 9001 certied manufacturer.

Wafer or lugged cast iron body.

Stainless steel disc and stem.

EPDM or NBR seats.

AS2129 Table E ange connection as standard. ANSI-BS16.1/5

#125/150 connection available on request.

DESIGN FEATURES

1. AGA Approved for gas service. AGA certicate No. 4030 applies

to DN50-DN150 valves to a maximum pressure of 8 bar (800 kPa)

with an NBR seat. Available to suit Table E or ANSI 150 anges.

2. The Operating Lever is cast ductile iron for long life in all but the

most corrosive environments.

3. Lever handles have S/S 304 10 position notch plates and Memory

stop plates are also available. Gear operators have an innite

number of positions.

4. A raised key section on the liner ts into a matching keyway on

the inside of the valve body to provide greater exibility at the

disc seating area and prevent liner roll-out, a condition where

the seat can come away from the body when high velocities occur

or the valve is installed incorrectly.

5. The moulded seat design is easily replaced in the eld, provides

isolation of the body from the service uid and acts as a gasket

face for sealing.

6. The acetal bushing takes care of any operator induced side thrust

loads and when combined with chevron type secondary stem seal

ensures trouble free operation.

7. The webbed ange design of wafer body ensures correct and

positive alignment between anges - one of the criteria for good

buttery valve operation.

8. The valve has an extended neck for insulated pipe services.

9. Pinless disc design, eliminates one less leak path past the disc.

10. Valves can also be supplied with pneumatic, electric or hydraulic

actuators and with all accessories such as limit switches,

solenoid valves, manual override etc.

11. Valves can also be supplied with the disc diameter undercut to

ensure minimum torque and smallest possible actuator size for

throttling or low pressure shut-off actuated valve applications.

12. The Hyo MKV has a spherically machined disc to ensure

improved sealing from valve internals under higher operating

pressures. Stem and bushings etc never come into contact with

service uid.

Supplied as standard with either lever or gearbox.

An extra leaver, gearbox, spare seats and memory stop kits can also

be supplied separately.

NOTE: For matching bolt and nut sizes, lengths and qtys refer to

page 1.26 of Tradelink Industrial catalogue.

NOTE: for service other than HVAC water and AGA service please

consult for compatibility of seat elastomer and disc material with

service uid.

PRESSURE/TEMPERATURE RATING

For general uid service up to 1400 kPa (200PSI). Lugged valve

suitable for full rated pressure in downstream dismantled

condition, provided all installation requirements are met.

AGA approved to 800 kPa (116PSI) for sizes DN50-DN150 with NBR seat.

NBR Seat: -10C to +90C (0C to +80C continuous).

EPDM Seat: -15C to +120C (-5C to +100C continuous).

MATERIAL SPECIFICATION

Ref. Component Material

1 Body Cast Iron

2 Disc 304 Stainless Steel

3 Seat EPDM Or Nitrile (NBR)*

4 Upper Stem 304 Stainless Steel

5 Lower Stem 304 Stainless Steel

6 Packing EPDM Or Nitrile (NBR)*

7 Packing Gland Acetal

8 Snap Ring Carbon Steel

9 Top Retainer 304 Stainless Steel

10 Top Retainer Bolts 304 Stainless Steel

11 Bottom Plug Nickel Plated Mild SteeL

12 Operating Lever Cast Ductile Iron

13 Notch Plate 304 Stainless Steel

* EPDM as standard, NBR for AGA approved valves.

The information provided in this catalogue is based on original manufacturers designs and specications and subject to change without

notice. Crane Distribution accepts no liability for the accuracy of the information or the availability of products.

2.2

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

C

A

S

T

I

R

O

N

HYFLO MKV CAST IRON BUTTERFLY VALVE

Gearbox

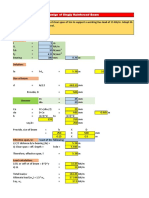

VALVE DIMENSIONS - mm

SIZE 50 65 80 100 125 150 200 250 300

d 51.5 63.5 78.0 101.5 125.0 148.0 198.0 248.0 298.0

g 90 107 125 146 179 206 257 312 362

H1 75 80 100 110 123 143 175 210 245

H2 130 137 157 171 184 203 238 270 310

H3 33 33 33 33 33 33 33 65 65

H4 238 250 290 314 340 379 446 545 620

L 43 46 46 52 56 56 60 68 78

T 12 12 12 12 12 12 12 16 16

W 32 47 66 89 113 139 191 242 291

A 9.5 9.5 11.8 11.8 14.5 14.5 14.5 * *

B 30 30 30 30 30 30 30 60 60

D 14 14 16 16 19 19 19 22 28

Kg waf 2.8 3.7 4.2 4.8 7.1 8.8 13 20 38

Kg lugg 3.9 5.0 6.6 8.2 10 12 19 30 47

* DN250-DN300 are keyway instead of double D, keyway width x depth 8 x 4, key 8 x 7. Weight in Kg is approximate only.

Lugged Style

GEARBOX DIMENSIONS - mm

TO FIT SIZE 50 65 80 100 125 150 200 250 300

E 45 45 45 45 45 45 45 63 63

H 74 74 74 74 74 74 74 85 85

L 165 165 165 165 165 165 185 250 250

W 150 150 150 150 180 180 220 260 260

Kg 5.5 5.5 5.5 5.5 5.5 5.5 6.5 9.5 9.5

FLANGE DRILLING DIMENSIONS AS2129 E - mm

SIZE 50 65 80 100 125 150 200 250 300

PCD 114 127 146 178 210 235 292 356 406

n 4 4 4 8 8 8 8 12 12

h waf 18 18 18 18 18 22 22 22 26

h lugg M16 M16 M16 M16 M16 M20 M20 M20 M24

For ANSI ange drilling dimensions see page 1.18.

Wafer Style

June 2010

2.3

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

C

A

S

T

I

R

O

N

HYFLO MKV CAST IRON BUTTERFLY VALVE

DN250 - DN300 DN50 - DN200

LEVER HANDLE DIMENSIONS - mm

SIZE 50 65 80 100 125 150 200 250 300

A 9.5 9.5 11.8 11.8 14.5 14.5 14.5 - -

B 23 23 23 23 23 23 23 62 62

L 285 285 285 285 285 285 385 485 485

Kg 0.88 0.88 0.88 0.88 0.88 0.88 1.03 2.7 2.7

VALVE FLOW COEFFICIENTS - Cv (USGPM)

SIZE 50 65 80 100 125 150 200 250 300

20 Open 10.8 18.3 27.8 42.3 68.3 97.6 173.5 271.0 390.3

30 Open 16.4 27.6 41.8 65.0 101.9 147.4 261.3 409.8 588.7

40 Open 25.5 43.0 65.4 101.9 159.4 229.8 408.7 637.5 918.2

50 Open 41.6 70.1 106.6 165.9 260.2 375.1 666.7 1040.7 1499.3

60 Open 67.3 114.0 171.9 269.9 419.6 607.1 1079.8 1686.9 2429.5

70 Open 108.4 184.1 278.5 435.8 680.8 979.0 1741.1 2720.0 3918.0

80 Open 167.3 282.2 428.0 667.8 1045.1 1504.7 2674.5 4179.3 5083.4

90 Fully Open 200.0 338.4 512.1 800.1 1250.0 1800.7 3201.4 5003.2 7203.9

Cv = 1.16 Kv

VALVE OPERATING TORQUE - Nm

SIZE 50 65 80 100 125 150 200 250 300

dP 6 Bar 18 23 30 38 57 85 158 250 347

dP 10 Bar 21 26 32 50 65 98 169 292 501

dP 16 Bar 23 27 35 51 79 112 239 356 525

Based on water as the uid with temperature range +1C to +80C. At least one operation cycle per month and a ow velocity in the pipe not more than 4m/s.

Top Flange Lever

TOP FLANGE MOUNTING DIMENSIONS TO ISO5211

SIZE 50 65 80 100 125 150 200 250 300

Type F07 F07 F07 F07 F07 F07 F07 F10 F10

N 90 90 90 90 90 90 90 125 125

M 70 70 70 70 70 70 70 102 102

M 4 4 4 4 4 4 4 4 4

Z 10 10 10 10 10 10 10 12 12

The information provided in this catalogue is based on original manufacturers designs and specications and subject to change without

notice. Crane Distribution accepts no liability for the accuracy of the information or the availability of products.

2.4

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

C

A

S

T

I

R

O

N

HYFLO MKV CAST IRON BUTTERFLY VALVE

BEFORE INSTALLATION CHECK

1. Pipe anges are free from weld spatter or swarf.

2. The anges are on the same centreline and their faces are

parallel.

3. The pipe internal does not contain objects that will obstruct the

disc from fully opening.

4. The pipe anges internal diameters are within the above minimum

and maximum dimensions. This is to make sure the disc does clear

the inside of the ange and the ange fully seals with the raised

gasket face of the seat.

5. Do not weld near the valve.

6. Do not use ange gaskets or sealing compounds.

INSTALLATION

1. Operate valve fully before and after installation.

2. Semi-open the valve so that the disc does not protrude outside of

body. This prevents damage to the disc and reduces initial torque.

3. Separate pipe anges enough to clear valve body and liner faces

to prevent damage to the seat during installation. Insert valve.

4. Manually loose t ange bolts and centre valve bore with pipe/

ange bore.

5. Open valve fully to ensure no contact between disc and pipe or

anges.

6. Progressively tighten bolts in diagonal sequence until metal to

metal contact is achieved between the valve body and anges.

7. Operate valve several times to ensure no obstruction to disc travel.

CORRECT INSTALLATION

PIPE FLANGE ID - mm

SIZE 50 65 80 100 125 150 200 250 300

Min ID 47 60 72 96 122 148 198 248 298

Max ID 60 76 90 114 140 168 219 275 323

June 2010

2.5

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

C

A

S

T

I

R

O

N

HYFLO MKV CAST IRON BUTTERFLY VALVE

HYFLO MKV CAST IRON BUTTERFLY VALVE CODES

COMPLETE EPDM T/E VALVES 50 65 80 100 125 150 200 250 300

Lugged w/-lever 076716 076717 076718 076719 076720 076721 076722 076723 076724

Wafer w/-lever 076728 076729 076730 076731 076732 076733 076734 076735 076736

Lugged w/-gearbox 076742 076743 076744 076745 076747 076748 076749 076750 076753

Wafer w/-gearbox 076660 076661 076662 076663 076664 076665 076666 076668 076669

AGA LUGGED NBR VALVES 50 65 80 100 125 150

Table E 076648 076649 076650 076651 076652 076653

ANSI 150 (IMP) 076871 076872 076874 076875 076876 076877

ANSI 150 (METRIC) 076849 076850 076852 076854 076856 076878

NBR T/E Lugged Lever 076659

SPARES 50 65 80 100 125 150 200 250 300

Gear Box 076686 076686 076687 076687 076688 076688 076689 076690 076691

Memory Stop Kit 075090 075090 075091 075091 075092 075092 075092

Lever Kit 076837 076837 076838 076838 076839 076839 076840 076841 076842

Spare seats for previous models

EPDM MKIV Seat 075341 075342 075343 075344 075345 075346 075347 075348 075349

NBR MKIV Seat 075516 075517 075518 075519 075520 075521 075522 075523 075524

MK3 EPDM 075000 075004 075006 075008 075009 075010 075012 075013 075014

MK3 NBR 075016 075017 075018 075019 075024 075040 075042 075047 075048

MK2 EPDM 076637 076639 076641 076643 076644 076645 076647 076657 076667

MK2 NBR 076676 076677 076678 076679 076680 076681 076682 076683 076684

MK1 NBR 076671 076675 076685 076696 076698

Standard valves - EPDM seat, AGA valves - NBR seat.

GEAR OPERATOR REDUCTION RATIOS

DN50 - DN200 24:1

DN250 - DN300 30:1

Memory Stop Kit

The information provided in this catalogue is based on original manufacturers designs and specications and subject to change without

notice. Crane Distribution accepts no liability for the accuracy of the information or the availability of products.

2.6

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

D

U

C

T

I

L

E

I

R

O

N

HYFLO MKV DUCTILE IRON BUTTERFLY VALVE

SPECIFICATION

General purpose buttery valve.

Conforms to EN 593 standards.

ISO 9001 certied manufacturer.

Wafer or lugged ductile iron body.

Stainless steel disc and stem.

EPDM seats.

AS2129 Table E Flange connection as standard.

ANSI-BS16.1/5 #125/150 connection available on request.

PRESSURE/TEMPURATURE RATING

For general uid service up to 1400 kPa (200psi).

Lugged valve suitable for 60% of full rated pressure, 800 kPa,

in downstream dismantled condition, provided all installation

requirements are met.

EPDM Seat: -15C to +120C (-5C to +100C continuous).

MATERIAL SPECIFICATION

Ref. Component Material

1 Body Ductile Iron

2 Disc 304 Stainless Steel

3 Seat EPDM

4 Upper Stem 304 Stainless Steel

5 Lower Stem 304 Stainless Steel

6 Packing EPDM

7 Packing Gland Brass

8 Snap Ring Carbon Steel

9 Top Retainer Nickel Plated or Epoxy Plated Steel

10 Top Retainer Bolts Nickel Plated Mild Steel

11 Bottom Cover Nickel Plated or Epoxy Plated Steel

12 Bottom Bolts Nickel Plated Mild Steel

Lugged Style

Wafer Style

VALVE DIMENSIONS - mm

SIZE 350 400 450 500 600

d 346.0 395.0 452.0 489.5 579.0

g 410 468 526 577 677

H1 280 315 335 385 450

H2 325 375 400 435 500

H3 65 75 75 100 100

H4 670 765 810 920 1050

L 78 102 114 127 154

T 17 20 20 23 23

W 343 386 438 476 562

B 60 70 70 90 90

D 28 38 38 45 55

Key 8x7 12x8 12x8 14x9 14x9

t1 4.0 5.0 5.0 5.5 5.5

t2 3.0 3.0 3.0 3.5 3.5

b 8.0 12.0 12.0 14.0 14.0

Kg waf 39 75 92 110 169

Kg lugg 59 82 110 162 264

Weight in Kg is approximate only.

For further details on installation of rubber lined buttery valves see

page 2.4.

NOTE: For matching bolt and nut sizes, lengths and qtys refer to

page 1.26 of Tradelink Industrial catalogue.

NOTE: for service other than HVAC water please consult for

compatibility of seat elastomer and disc material with service uid.

June 2010

2.7

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

D

U

C

T

I

L

E

I

R

O

N

HYFLO MKV DUCTILE IRON BUTTERFLY VALVE

VALVE FLOW COEFFICIENTS - Cv (USGPM)

SIZE 350 400 450 500 600

20 Open 532.3 694.9 878.1 1085.2 1562.2

30 Open 802.2 1047.3 1324.8 1635.9 2356.9

40 Open 1250.0 1632.7 2066.3 2550.9 3674.1

50 Open 2040.3 2665.8 3372.7 4164.1 5996.2

60 Open 3292.4 4318.0 5462.0 6746.4 9714.7

70 Open 5331.7 6964.3 8813.8 10882.3 15669.8

80 Open 8190.5 10698.0 13540.6 16715.9 24070.5

90 Fully Open 9804.7 12806.6 16208.6 20010.5 28814.6

Cv = 1.16 Kv

TOP FLANGE DIMENSIONS TO ISO5211

SIZE 350 400 450 500 600

Type F10 F14 F14 F16 F16

N 125 175 175 210 210

M 102 140 140 165 165

M 4 4 4 4 4

Z 12 18 18 22 22

VALVE OPERATING TORQUE - Nm

SIZE 350 400 450 500 600

dP 6 Bar 499 697 936 1208 2535

dP 10 Bar 619 802 1150 1485 2955

dP 16 Bar 1389 1851 2264 2791 5155

Based on water as the uid with temperature range +1C to +80C. At least

one operation cycle per month and a ow velocity in the pipe not more than

4m/s.

GEARBOX DIMENSIONS - mm

TO FIT SIZE 350 400 450 500 600

E 63 82 82 100 100

H 85 90 90 112 112

W 315 405 405 405 405

L 250 300 300 310 310

kg 10 19 19 32 32

TRADELINK INDUSTRIAL HYFLO MKV

DUCTILE IRON BUTTERFLY CODES

COMPLETE VALVE 350 400 450 500 600

Lugged w/-gearbox 076755 076761 076763 076765 076769

Wafer w/-gearbox 076670 076672 076673 076708 076714

Spares

Gearbox 076692 076694 076694 076704 076704

EPDM Seat 075350 075351 075352 075353 075356

NBR Seat 075525 075526 075527 075528 075530

Gearbox

GEAR OPERATOR REDUCTION RATIOS

DN350 30:1

DN400 - DN450 40:1

DN500 - DN600 50:1

PIPE FLANGE ID - mm

SIZE 350 400 450 500 600

Min ID 350 395 450 485 570

Max ID 361 412 463 510 585

FLANGE DRILLING DIMENSIONS AS2129 E - mm

SIZE 350 400 450 500 600

PCD 470 521 584 641 756

n 12 12 16 16 16

h waf 26 26 26 26 33

h lugg M24 M24 M24 M24 M30

For ANSI ange drilling dimensions see page 1.18.

Top Flange

The information provided in this catalogue is based on original manufacturers designs and specications and subject to change without

notice. Crane Distribution accepts no liability for the accuracy of the information or the availability of products.

2.8

HYFLO MKV WATERMARK BUTTERFLY VALVE

SPECIFICATION

Potable water service buttery valve.

WaterMark approval evaluated to ATS 5200.012 - 2005

Certicate No. WMKA20022.

Conforms to EN 593 standards.

ISO 9001 certied manufacturer.

Cast iron body with FBE coating to 350 microns.

Lugged valve body pattern stocked as standard.

Wafer valve body available on request.

EPDM grade seats in accordance with AS 4020.

AS2129 Table E ange connection as standard.

Valve Sizes stocked with Lever DN50 to DN150, with gear operator

DN100 to DN300.

Top ange mounting dimensions to ISO5211.

MATERIAL SPECIFICATION

Ref. Component Material

1 Body Cast Iron with FBE Coating 350 Microns

2 Disc CF8M Stainless Steel

3 Seat Peroxide Cured EPDM To As 4020

4 Upper Stem 316 Stainless Steel

5 Lower Stem 316 Stainless Steel

6 Packing EPDM

7 Packing Gland Acetal

8 Snap Ring Carbon Steel

9 Top Retainer 304 Stainless Steel

10 Top Retainer Bolts 304 Stainless Steel

11 Bottom Plug Nickel Plated Mild Steel

12 Operating Lever Cast Ductile Iron

13 NOtch Plate 304 Stainless Steel

DESIGN FEATURES

1. WaterMark Approval to ATS 5200.012 - 2005, Certicate No.

WMKA20022 for potable water service in valve sizes DN50 to

DN300.

2. Supplied as standard with either a lever (DN50-DN150) or

gearbox (DN100-DN300). Memory stop kits or actuators and

accessories are available.

3. Distinquishable from the standard Hyo MKV valve because of

the valve colour, the WaterMark valve is blue, the standard valve

is green with a yellow lever

4. Seat design to prevent 'roll out' when high velocities occur or

valve is installed incorrectly.

5. Seat design is easily replaced in the eld, isolates the uid from

the valve body and acts as a gasket face for seating.

6. The acetal bushing and chevron secondary stem seal ensures

trouble free operation.

7. The valve has an extended neck for insulated pipe services.

8. Pinless disc design eliminates one less leak path.

9. The Hyo MKV has a spherically machined disc to ensure

improved sealing from valve internals under higher operating

pressures. Stem and bushings etc never come into contact with

service uid.

PRESSURE/TEMPERATURE RATINGS

For potable water service up to 1400 kPa (200 PSI).

Lugged valve suitable for full rated pressure in downstream

dismantled condition, provided all installation requirements are met.

EPDM Seat: -15C to +120C (-5C to +100C continuous)

NOTE: For matching bolt and nut sizes. Lengths and qty's refer to

page 1.26. For installation instructions refer to page page 2.4. For top

ange mounting dimensions to ISO5211 refer to page 2.3.

NOTE: for service other than Potable water please consult with us for

compatibility of seat elastomer and disc materials with service uid.

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

W

A

T

E

R

M

A

R

K

Memory Stop Kit

June 2010

2.9

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

W

A

T

E

R

M

A

R

K

HYFLO MKV WATERMARK BUTTERFLY VALVE

VALVE DIMENSIONS - mm

SIZE 50 65 80 100 125 150 200 250 300

d 51.5 63.5 78.0 101.5 125.0 148.0 198.0 248.0 298.0

g 90 107 125 146 179 206 257 312 362

H1 75 80 100 110 123 143 175 210 245

H2 130 137 157 171 184 203 238 270 310

H3 33 33 33 33 33 33 33 65 65

H4 238 250 290 314 340 379 446 545 620

L 43 46 46 52 56 56 60 68 78

T 12 12 12 12 12 12 12 16 16

W 32 47 66 89 113 139 191 242 291

A 9.5 9.5 11.8 11.8 14.5 14.5 14.5 * *

B 30 30 30 30 30 30 30 60 60

D 14 14 16 16 19 19 19 22 28

Kg waf 2.8 3.7 4.2 4.8 7.1 8.8 13 20 38

Kg lugg 3.9 5.0 6.6 8.2 10 12 19 30 47

* DN250-DN300 are keyway instead of double D, keyway width x depth 8x4, key 8x7. Weight in Kg is approximate only.

GEARBOX DIMENSIONS - mm

TO FIT SIZE 50 65 80 100 125 150 200 250 300

E 45 45 45 45 45 45 45 63 63

H 74 74 74 74 74 74 74 85 85

L 165 165 165 165 165 165 185 250 250

W 150 150 150 150 180 180 220 260 260

Kg 5.5 5.5 5.5 5.5 5.5 5.5 6.5 9.5 9.5

Gearbox Lugged Style Wafer Style

FLANGE DRILLING DIMENSIONS AS2129 E - mm

SIZE 50 65 80 100 125 150 200 250 300

PCD 114 127 146 178 210 235 292 356 406

n 4 4 4 8 8 8 8 12 12

h waf 18 18 18 18 18 22 22 22 26

h lugg M16 M16 M16 M16 M16 M20 M20 M20 M24

For ANSI ange drilling dimensions see page 1.18.

The information provided in this catalogue is based on original manufacturers designs and specications and subject to change without

notice. Crane Distribution accepts no liability for the accuracy of the information or the availability of products.

2.10

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

H

Y

F

L

O

M

K

V

W

A

T

E

R

M

A

R

K

HYFLO MKV WATERMARK BUTTERFLY VALVE

VALVE FLOW COEFFICIENTS - Cv (USGPM)

SIZE 50 65 80 100 125 150 200 250 300

20 Open 10.8 18.3 27.8 42.3 68.3 97.6 173.5 271.0 390.3

30 Open 16.4 27.6 41.8 65.0 101.9 147.4 261.3 409.8 588.7

40 Open 25.5 43.0 65.4 101.9 159.4 229.8 408.7 637.5 918.2

50 Open 41.6 70.1 106.6 165.9 260.2 375.1 666.7 1040.7 1499.3

60 Open 67.3 114.0 171.9 269.9 419.6 607.1 1079.8 1686.9 2429.5

70 Open 108.4 184.1 278.5 435.8 680.8 979.0 1741.1 2720.0 3918.0

80 Open 167.3 282.2 428.0 667.8 1045.1 1504.7 2674.5 4179.3 5083.4

90 Fully Open 200.0 338.4 512.1 800.1 1250.0 1800.7 3201.4 5003.2 7203.9

Cv = 1.16 Kv

VALVE OPERATING TORQUE - Nm

SIZE 50 65 80 100 125 150 200 250 300

dP 6 Bar 18 23 30 38 57 85 158 250 347

dP 10 Bar 21 26 32 50 65 98 169 292 501

dP 16 Bar 23 27 35 51 79 112 239 356 525

Based on water as the uid with temperature range +1C to +80C. At least one operation cycle per month and a ow velocity in the pipe not more than 4m/s.

TRADELINK INDUSTRIAL HYFLO MKV WATERMARK BUTTERFLY VALVE CODES

SIZE 50 65 80 100 125 150 200 250 300

Lugged w/- lever 074604 074605 074606 074607 074608 074609

Lugged w/- gear op 074610 074611 074612 074613 074614 074615

DN250 - DN300 DN50 - DN200

Lever

LEVER HANDLE DIMENSIONS - mm

SIZE 50 65 80 100 125 150 200 250 300

A 9.5 9.5 11.8 11.8 14.5 14.5 14.5 - -

B 23 23 23 23 23 23 23 62 62

L 285 285 285 285 285 285 385 485 485

Kg 0.88 0.88 0.88 0.88 0.88 0.88 1.03 2.7 2.7

June 2010

2.11

(UCV) CAST IRON BUTTERFLY VALVE

SPECIFICATION

Throttling or low pressure applications for mechanical services or

general industry. Conforms to BS5155 specication, wafer, cast

iron body, stainless steel disc and stem, EPDM seat, AS2129 Table

E ange connection as standard. Operator mounting in accordance

with ISO 5211/1/2/3.

PRESSURE/TEMPERATURE RATING

For general uid service up to 300 kPa (43psi).

120C EPDM - food grade.

Valve Velocity Limits

Fluids 10 m/s

Gases 65 m/s

MATERIAL SPECIFICATION

Ref. Component Material

1 Bushing Acetal

2 Stem 316 Stainless Steel

3 Disc 316 Stainless Steel

4 Body Cast Iron

5 Seat EPDM

DESIGN FEATURES

1. The Disc diameter is undercut to ensure minimum torque and

smallest possible actuator size for throttling or low pressure shut-

off actuated valve applications.

2. Pinless Disc design eliminates possible leak path or risk of pin

failure.

3. Stem rention via circlip ensures stem cannot blow out if the valve

is over pressurised.

4. Primary and secondary sealing features, an interference t

between seat and disc, and seat and stem, do not rely on outside

anges.

5. Seat retention design minimises distortion/movement of the seat.

6. Moulded double o-rings on the seat between the seat and the

ange, and seat and stem surface maximise sealing.

7. Seat is not bonded to the body and is replaceable, enabling

extended service life.

8. Extended neck design for insulated pipe services.

9. Locating holes on the body wafer essential for alignment and

proper installation.

10. Disc is manufactured from 316 stainless steel for corrosion

protection.

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

(

U

C

V

)

C

A

S

T

I

R

O

N

The information provided in this catalogue is based on original manufacturers designs and specications and subject to change without

notice. Crane Distribution accepts no liability for the accuracy of the information or the availability of products.

2.12

(UCV) CAST IRON BUTTERFLY VALVE

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

(

U

C

V

)

C

A

S

T

I

R

O

N

TRADELINK INDUSTRIAL (UCV) CAST IRON BUTTERFLY CODES

SIZE 50 65 80 100 125 150 200 250 300

Wafer 075058 075059 075060 075061 075062 075063 075064

TOP FLANGE DIMENSIONS

NO. HOLES 4 4 4 4 4 4 4 4 4

DIA. HOLES 9 9 9 9 9 9 11 11 11

BOLT CIRCLE 70 70 70 70 70 70 102 102 102

Standard valves are bareshafted for actuation.

WEIGHT - kg

SIZE 50 65 80 100 125 150 200 250 300

kg 2.9 3.8 4.3 5.4 7.2 9 15.8 22.6 39.4

VALVE OPERATING TORQUE - Nm

SIZE 50 65 80 100 125 150 200 250 300

Wet 3 Bar 7.5 8.5 13 17 26 38 68 114 163

Dry 3 Bar 11 13 20 25 49 57 102 171 244

VALVE DIMENSIONS - mm

SIZE 50 65 80 100 125 150 200 250 300

A 90 90 90 90 90 90 127 127 127

B 32 32 32 32 32 32 32 50 50

C 140 152 159 178 191 203 241 273 311

D 42.9 46 46 52.3 55.6 55.6 60.5 68.3 77.7

E 94 112 128 158 190 210 266 330 375

F 53 68 82 103 129 152 202 252 302

G 55 65 75 94 105 123 149 198 225

H 30.6 50 69 89 115.6 141.5 192.3 242.6 292.5

Shaft Dia 14.0 14.0 14.0 19.1 19.1 22.0 22.0 30.0 30.0

Shaft Flat 9.5 9.5 9.5 12.7 12.7 15.9 15.9 24.0 24.0

VALVE FLOW COEFFICIENTS - USGPM

SIZE 50 65 80 100 125 150 200 250 300

20 7 10 15 26 43 59 108 178 256

30 16 23 36 61 98 138 247 396 587

40 28 42 65 108 177 247 437 705 995

50 49 68 109 178 278 398 687 1100 1697

60 77 108 167 275 447 637 1100 1795 2695

70 128 178 278 458 737 1097 1795 2995 4398

80 198 288 427 715 1095 1590 2790 4590 6790

90 Open 219 316 498 815 1290 1895 3290 5390 7990

June 2010

2.13

B

U

T

T

E

R

F

L

Y

V

A

L

V

E

S

S

T

A

I

N

L

E

S

S

S

T

E

E

L

H

Y

G

I

E

N

I

C

STAINLESS STEEL HYGIENIC BUTTERFLY VALVE

OPERATING TORQUE - Nm

SIZE 25 40 50 65 80 100

Torque 8 12 14 22 28 36

Also available with mounted actuator.

SPECIFICATION

Hygienic buttery valve.

Fully forged stainless steel.

Finish body 180 grit - disk 400 grit.

Spring loaded lever with four (4) locking positions.

Buttweld connection.

All parts are interchangeable within the respective size.

PRESSURE/TEMPERATURE RATING

Up to 1100 kPa (160psi) at 170C or down to minus 50C in closed

position.

MATERIAL SPECIFICATION

Ref. Component Material

1 Body 316 Stainless Steel

2 Disc 316 Stainless Steel

3 Stem 316 Stainless Steel

4 Liner Silicon as Standard

5 Handle 316 Stainless Steel

6 Handle Grip Plastic

Available with silicon or viton replaceable trim.

DIMENSIONS - mm

SIZE 25 40 50 65 80 100

A 121 121 121 121 162 162

B 24 24 26 27 32 40

TRADELINK INDUSTRIAL GENERIC HYGIENIC BUTTERFLY CODES

SIZE 25 32 40 50 65 80 100

304 SS 088101 088103 088105 088107 088109 088111

316L SS 088113 088115 088117 088119 088127 088121 088123

314 088125

Lever, 4 position 088129 088131

You might also like

- 2013-07-01 - SEQ WSS DC Code Design CriteriaDocument64 pages2013-07-01 - SEQ WSS DC Code Design CriteriaabhijithavalNo ratings yet

- ISO 10414 2 2002 EN FR PreviewDocument11 pagesISO 10414 2 2002 EN FR PreviewRosario PachecoNo ratings yet

- Butterfly Valves enDocument37 pagesButterfly Valves enMolitorisz AndorNo ratings yet

- 2009-272 Electricity Safety (Installations) RegulationsDocument91 pages2009-272 Electricity Safety (Installations) RegulationsKkswo KksNo ratings yet

- JW TICO Product Guide Issue 1-18Document48 pagesJW TICO Product Guide Issue 1-18Vin BdsNo ratings yet

- Chafe Chains & Floating Pick-Up and Messenger LinesDocument1 pageChafe Chains & Floating Pick-Up and Messenger LinestogentongNo ratings yet

- Power Cables: TM 5-683/NAVFAC MO-116/AFJMAN 32-1083Document9 pagesPower Cables: TM 5-683/NAVFAC MO-116/AFJMAN 32-1083dadyjoshNo ratings yet

- t166 PDFDocument3 pagest166 PDFRuben MamaniNo ratings yet

- General Specification: FGS 4L5Document21 pagesGeneral Specification: FGS 4L5Adeel Qaiser67% (3)

- Weholite: The Basics ofDocument24 pagesWeholite: The Basics ofbetopagoadaNo ratings yet

- HBM Measuring Torque Correctly COMPLETE EDITIONDocument261 pagesHBM Measuring Torque Correctly COMPLETE EDITIONElmirNo ratings yet

- FEMA 414 - Installing Seismic Restraints For Duct and PipeDocument91 pagesFEMA 414 - Installing Seismic Restraints For Duct and PipeDennis KrahnNo ratings yet

- IEC60947 3 Approved PDFDocument3 pagesIEC60947 3 Approved PDFosmpotNo ratings yet

- Gmsi10 Um013 - en PDocument216 pagesGmsi10 Um013 - en PAnonymous XM3KoTUTgNo ratings yet

- MSI Pipe and Valve InternationalDocument27 pagesMSI Pipe and Valve InternationalbawwsswwabNo ratings yet

- Hi Force CatalogDocument68 pagesHi Force CatalogmjscarNo ratings yet

- CVA Gate Globe Check Strainers CatalogDocument95 pagesCVA Gate Globe Check Strainers CatalogRiss0No ratings yet

- Airplaco Catalogue New - 2015 PDFDocument20 pagesAirplaco Catalogue New - 2015 PDFOnias GalvãoNo ratings yet

- Motor Circuit Analysis StandardsDocument4 pagesMotor Circuit Analysis StandardsThe Matrix100% (1)

- Higher Pressure and 3D CuttingDocument26 pagesHigher Pressure and 3D Cuttingdon_jopoNo ratings yet

- Inspection & Calibration of Torque WrenchesDocument7 pagesInspection & Calibration of Torque WrenchesJellyn Base100% (1)

- As IEC 61672.1-2004 Electroacoustics - Sound Level Meters SpecificationsDocument8 pagesAs IEC 61672.1-2004 Electroacoustics - Sound Level Meters SpecificationsSAI Global - APACNo ratings yet

- Iec 751Document2 pagesIec 751OwaisNo ratings yet

- Butt Fusion Jointing of PE Pipes and Fittings - Recommended ParametersDocument5 pagesButt Fusion Jointing of PE Pipes and Fittings - Recommended ParameterspametnjakovicmladjiNo ratings yet

- Durapac Gatos HidraulicosDocument108 pagesDurapac Gatos Hidraulicosgechaves1No ratings yet

- Overhead Crane Hoists eDocument20 pagesOverhead Crane Hoists eAltayeb YassinNo ratings yet

- Data Source Book P-7475HDocument51 pagesData Source Book P-7475HJoão13@No ratings yet

- Safety-Alert-Crown Saver Function Testing PDFDocument2 pagesSafety-Alert-Crown Saver Function Testing PDF孔超No ratings yet

- Spring Rail ClampsDocument10 pagesSpring Rail ClampsCarlos Catalán PinoNo ratings yet

- Runaway Speed of Hydraulic TurbinesDocument1 pageRunaway Speed of Hydraulic TurbinesSreelal Sree100% (2)

- DNV Rp-E101 - 2012-01Document18 pagesDNV Rp-E101 - 2012-01Stephen LewellenNo ratings yet

- G81 - 2 Housing Materials PDFDocument17 pagesG81 - 2 Housing Materials PDFHassan SaeedNo ratings yet

- What Is HDPE PIPEDocument7 pagesWhat Is HDPE PIPEKarthikeyan MoorthyNo ratings yet

- Planning Guidelines For Water and Sewerage - Network ModellingDocument23 pagesPlanning Guidelines For Water and Sewerage - Network ModellinghajihuzefaNo ratings yet

- Guidelines for securing loose studs in anchor chain by weldingDocument10 pagesGuidelines for securing loose studs in anchor chain by weldingchristianvanNo ratings yet

- 5.1 Power Systems Rev 01Document9 pages5.1 Power Systems Rev 01Yosep SibagariangNo ratings yet

- Biotemp: Biodegradable Dielectric Insulating FluidDocument4 pagesBiotemp: Biodegradable Dielectric Insulating FluidSamuel PakianathanNo ratings yet

- NZS 4541 2007 PDFDocument530 pagesNZS 4541 2007 PDFhonisme67% (3)

- Installation and Repair Strategy For Onshore Wind Turbines Using Specialized Materials Foundations and Towers Francis MongeonDocument19 pagesInstallation and Repair Strategy For Onshore Wind Turbines Using Specialized Materials Foundations and Towers Francis Mongeonjuli_radNo ratings yet

- ASME PTC8.2 - 1990 - Contrifugal PumpsDocument77 pagesASME PTC8.2 - 1990 - Contrifugal PumpsprakashsahooNo ratings yet

- HVIL FailureDocument13 pagesHVIL FailureankitNo ratings yet

- NABL Accredited Mechanical Testing Lab GuideDocument50 pagesNABL Accredited Mechanical Testing Lab GuideGautam GuptaNo ratings yet

- Routine & Acceptance Tests - InsulatorsDocument22 pagesRoutine & Acceptance Tests - InsulatorsavgNo ratings yet

- Ngc8206 AbbDocument316 pagesNgc8206 Abblafuria1234No ratings yet

- Butterfly Flu01 Omb 04 11Document16 pagesButterfly Flu01 Omb 04 11ila_368684492No ratings yet

- Modular I/O System Profibus Dpv1 750-333 / 750-833: Technical Description, Installation and ConfigurationDocument154 pagesModular I/O System Profibus Dpv1 750-333 / 750-833: Technical Description, Installation and Configurationtester11100% (1)

- FRP Cable Tray 1Document37 pagesFRP Cable Tray 1Vikas TanejaNo ratings yet

- Rubber SealsDocument15 pagesRubber Sealssanbarun100% (2)

- Specification For Butterfly ValvesDocument10 pagesSpecification For Butterfly Valvesdeepdaman18891No ratings yet

- NEMA VE 1 2017 Contents and ScopeDocument7 pagesNEMA VE 1 2017 Contents and ScopeShehiryar MuzamalNo ratings yet

- URLDocument21 pagesURLLyn Consing100% (3)

- BallValues PDFDocument12 pagesBallValues PDFDevdatt WaghuleNo ratings yet

- AAP S18 Butterfly Valves E2 SDocument9 pagesAAP S18 Butterfly Valves E2 SPete KardumNo ratings yet

- Aloyco Stainess Steel ValvesDocument26 pagesAloyco Stainess Steel Valvescristi_molins100% (1)

- Submittal73 74Document2 pagesSubmittal73 74Sushant GuptaNo ratings yet

- 3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsDocument4 pages3 Piece Tube Bore Ball Valves, / "-4": High Purity ApplicationsrodrurenNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- Ball-Type Kelly and Safety Valves GuideDocument3 pagesBall-Type Kelly and Safety Valves GuideAlfred Hernandez Mendoza50% (2)

- Mech Van Catalogue PDFDocument26 pagesMech Van Catalogue PDFVan Nguyen Huu VanNo ratings yet

- Parts Manual JLG 3507, 3508, 3509, 3512,3513, 4007,4008, 4009,4012, 4013Document496 pagesParts Manual JLG 3507, 3508, 3509, 3512,3513, 4007,4008, 4009,4012, 4013Андрей Яковлев100% (4)

- 01 Thermodynamic Process 2Document20 pages01 Thermodynamic Process 2Ashok PradhanNo ratings yet

- Astm A352-A352m-06-1Document5 pagesAstm A352-A352m-06-1Kishor JadhavNo ratings yet

- Howden Axial Fans HC Centrifugal Fans PDFDocument116 pagesHowden Axial Fans HC Centrifugal Fans PDFSurya Kiran KNo ratings yet

- Groz Rac DD 2-11-24!1!2 HP Direct Drive Air CompressorDocument6 pagesGroz Rac DD 2-11-24!1!2 HP Direct Drive Air CompressorMaroof AliNo ratings yet

- Singly Reinforced Beam ExcelDocument3 pagesSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Structural Cracks in BeamDocument2 pagesStructural Cracks in Beamswapnil gandhiNo ratings yet

- Ejercicios CORIOLIS PDFDocument2 pagesEjercicios CORIOLIS PDFAlejandro CGNo ratings yet

- Greenstar 25Si/30Si: User Instructions & Customer Care GuideDocument20 pagesGreenstar 25Si/30Si: User Instructions & Customer Care GuideJBNo ratings yet

- Mechanical Engineer Resume CAD Skills 12 Years ExperienceDocument3 pagesMechanical Engineer Resume CAD Skills 12 Years ExperienceNilay GandhiNo ratings yet

- Illustrative Worked Examples: Commentary of Irc: 6-2017Document4 pagesIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singla100% (1)

- DR650SEL2 Catalogo Partes PDFDocument75 pagesDR650SEL2 Catalogo Partes PDFEderNo ratings yet

- Shankar DurgamDocument9 pagesShankar DurgamasdfNo ratings yet

- TOX FinePress 45 201201 enDocument16 pagesTOX FinePress 45 201201 enSirbu SorinNo ratings yet

- Unitor Udf 2100 Ultrasonic Cleaner 230VDocument2 pagesUnitor Udf 2100 Ultrasonic Cleaner 230Vankarthik11No ratings yet

- Theory of Elasticity and Plasticity Lab Experiment No. 3 Study On AnisotropyDocument7 pagesTheory of Elasticity and Plasticity Lab Experiment No. 3 Study On AnisotropyVipul AgrawalNo ratings yet

- Kinematics of particlesDocument11 pagesKinematics of particlesmaitesecoNo ratings yet

- 4.2 Continuous Load Path: 4.3 Overall FormDocument10 pages4.2 Continuous Load Path: 4.3 Overall FormSirajMalikNo ratings yet

- Measuring Distance of Heavenly BodyDocument28 pagesMeasuring Distance of Heavenly BodykhanNo ratings yet

- "View" "Slide Show.": Resources Chapter MenuDocument62 pages"View" "Slide Show.": Resources Chapter Menuelty TanNo ratings yet

- EUROPART Inter Catalog Bus Spare Parts 2014-09 EN PDFDocument778 pagesEUROPART Inter Catalog Bus Spare Parts 2014-09 EN PDFludiloliku67% (3)

- Mathematical Analysis of The Structure and Performance of An Automated Bread Slicing Machine PDFDocument7 pagesMathematical Analysis of The Structure and Performance of An Automated Bread Slicing Machine PDFIonut DumistrascuNo ratings yet

- Lect3 - 2020 SEM2 1920Document25 pagesLect3 - 2020 SEM2 1920Praven KumarNo ratings yet

- MCL 703 Assignment - Heat Transfer AnalysisDocument4 pagesMCL 703 Assignment - Heat Transfer AnalysisabhijeetNo ratings yet

- CHP 4 - 4.3 Determinate Structural AnalysisDocument57 pagesCHP 4 - 4.3 Determinate Structural Analysismhazarath murariNo ratings yet

- Weld Defect Code Acceptance CriteriaDocument17 pagesWeld Defect Code Acceptance CriteriaNavanitheeshwaran Sivasubramaniyam100% (3)

- Harley-Davidson P&a 2020 en WebOptimisedDocument103 pagesHarley-Davidson P&a 2020 en WebOptimisedAmanNo ratings yet

- CE 213 (Sec A)Document4 pagesCE 213 (Sec A)সানিNo ratings yet

- Strength & failure modes of concreteDocument12 pagesStrength & failure modes of concretemaneeshaNo ratings yet

- B21et Pea BOMDocument9 pagesB21et Pea BOMvanapeerNo ratings yet