Professional Documents

Culture Documents

1.6 MVA Oil Type Transformer GTP - Mar22-2011

Uploaded by

Ramesh Cuppu0%(1)0% found this document useful (1 vote)

661 views15 pagesoil transformer

Original Title

1.6 MVA Oil Type Transformer GTP_Mar22-2011

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentoil transformer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0%(1)0% found this document useful (1 vote)

661 views15 pages1.6 MVA Oil Type Transformer GTP - Mar22-2011

Uploaded by

Ramesh Cuppuoil transformer

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 15

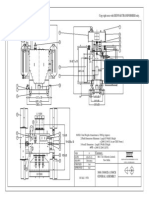

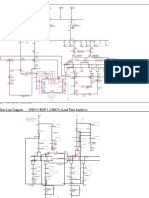

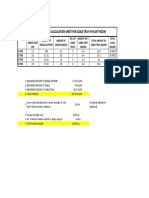

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

1 of 15

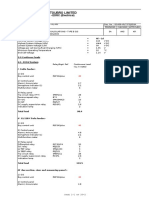

Schedule K

TECHNICAL PARTICULARS FOR OIL FILLED AUXILIARY TRANSFORMERS

A.

OIL FILLED AUXILIARY TRANSFORMERS

1.0 General :

1.1 Make : Voltamp Transformers

Ltd.

1.2 Type : Oil filled

1.3 Number of Windings per

phase

: Two

1.4 Number of Phases : Three

1.5 Service Outdoor

1.6 Reference Standard : IS 2026 & CBIP

Publications.

2.0 Rating :

2.1 Type of Cooling : ONAN

2.2 Rated Output

I. With ONAN Cooling

MVA

1.6

2.3 Rated Voltage (No-Load) kV

H.V. : 6.6

L.V. : 0.433

System Voltage Variation : 10%

2.4 Rated Current A

H.V. : 139.96

L.V. : 2133.39

2.5 Rated Frequency Hz : 50 5%

2.6 Connection

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

2 of 15

H.V. : Delta

L.V. : Star

2.7 Vector Group Reference : Dyn11

2.8 Voltage withstand Time

s

a. 110% of rated voltage : Continuous

b. 125% of rated voltage : 60 sec

c. 140% of rated voltage : 5sec

d. 150% of rated voltage : 1 sec

2.9 Overfluxing Capability

a. For Overfluxing Factor 1.1 : Continuous

b. 1.25 : 60 sec

c. 1.4 : 5 sec

3.0 Temperature

3.1 Reference ambient

temperature

C 50

3.2 Temperature rise over

reference ambient Deg. C :

a. Of Top oil by thermometer

C : 50

b. Of winding by resistance C : 55

3.3 Maximum continuous over

loading capacity of the

transformer without

exceeding the specified

winding temperature

At ambient

of 40C

&

80% OF

Initial

loading

: % Overload Time

At 110%

At 130%

At 150%

At 200%

4 hrs.

1.5hrs

1 hrs

N.A.

3.4 Thermal time constant h Approx. 2.5 Hrs

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

3 of 15

4.0 Tappings

4.1 Type : Off Circuit

4.2 Capacity : 11 KV, 150 Amp

4.3 Range - Steps x % variation : +/-5%in steps of 2.5%

4.4 Taps provided on HV/LV

Winding.

: HV side

5.0 Insulation Level

5.1 Separate source power

frequency voltage

withstand.

kV rms

Winding Bushing

H.V : 20 28

L.V. : 3 3

L.V. Neutral (for bushing) : 3 3

5.2 Induced overvoltage

withstand.

kV rms

Winding Bushing

H.V : }Twice the rated }

voltage and

} double

} frequency

}

}

L.V. :

L.V. Neutral ( for bushing) :

5.3 Full wave lightning impulse

withstand voltage

kV peak

Winding Bushing

H.V : 60 75

L.V. : NA NA

6.0 Impedance at Principal

Tap at Rated Frequency

and 75 C winding

temperature with 100%

rating

:

6.1 Impedance at principal tap % : 6.25% (without

negative tolerance

with +10% tol.)

6.2 Impedance at maximum

voltage tap

% : 5.9375

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

4 of 15

6.3 Impedance at minimum

voltage tap

% 6.5625

6.4 Reactance at rated current

for principal tap

% : 6.148%

6.5 Resistance at 75C. % 1.125%

6.6 Zero Sequence Impedance

at 75C at principal tap.

% : 5.94% (Approx.)

6.7 Capacitance of Windings F / phase :

a. H.V. - Earth

b. L.V. - Earth

c. H.V - L.V

: 491 pf

487 pf

600 pf

7.0 Guaranteed Losses at

Principal Tap, Full Load

and 75C.

7.1 No load losses at rated

voltage and at rated

frequency and without any

+ve tolerances

kW : 1.6 KW (max.)

7.2 Load Losses at rated current

without any +ve tolerances

kW : 18.0 kw (max.)

7.3 Total losses kW : 19.6 KW (max.)

8.0 Efficiency at 75C and 0.8

Power Factor Lag and at

unity power factor

:

0.8 p.f. unity p.f.

8.1 At full load % : 98.49 98.79

8.2 At 3/4 full load % : 98.79 99.03

8.3 At 1/2 full load % : 99.24 99.06

8.4 Maximum efficiency % : 99.334

8.4.1 Load and Power Factor at

which it occures

: 29.814 Load @ unity

P.F.

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

5 of 15

9.0 Regulation at Full Load

at 75C

:

9.1 At unity power factor % : 1.314

9.2 At 0.8 power factor lagging % : 4.679

10.0 No Load Current referred to

HV at rated frequency

10.1 At 90% rated voltage A : Approx. 1% of FLRC

10.2 At 100% rated voltage A : Approx.2% of FLRC

10.3 At 110% rated voltage A : Approx.3% of FLRC

11.0 Approximate Maximum

Flux Density

11.1 At 90% rated voltage Wb / m

2

: 1.53

11.2 At 100% rated voltage Wb / m

2

: 1.7

11.3 At 110% rated voltage Wb / m

2

: 1.87

12.0 Maximum Current Density :

12.1 H.V. Winding A / cm

2

: 300

12.2 L.V. Winding A / cm

2

: 300

12.3 Maximum Current Density

under short circuit

:

12.3.1 H.V. Winding A / cm

2

: 4800

12.3.2 L.V. Winding A /

cm

2

: 4800

13.0 Withstand Time without

injury for

13.1 Three phase dead short

circuit at terminal with rated

voltage maintained on the

other side

s : 2

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

6 of 15

13.2 Single phase short-circuit at

terminal with rated voltage

maintained on other side

s : 2

14.0 Cooling System

14.1 a. Radiators on the main

tank

Number of radiators

: Yes

4

15.0 Details of Tank

15.1 Material : Low Carbon Steel

15.2 Thickness of sides mm : 5

15.3 Thickness of bottom mm : 6

15.4 Thickness of cover mm : 10

15.5 Tank Designed for :

15.5.1 Vacuum withstand capability

or main tank and accesories

mm of Hg

: 250

15.5.2 Vacuum leak rate of

transformer

N.A.

15.5.3 Pressure kN / m

2

: 34.7

16.0 Core

16.1 Type - Core or shell : Core

16.2 Core material : CRGO silicon steel

laminations

16.3 Thickness of lamination mm : 0.27 to 0.3 mm

16.4 Insulation of lamination : Carlite

16.5 Equivalent cross-sectional

area

cm : 350

16.6 Type of joint between core

and yoke

Mitred interleaved

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

7 of 15

16.7 Percentage silicon content Approx.4%

17.0 Coils

17.1 Type of Coil :

a. H.V : Continuous disc

b. L.V. : Spiral

17.2 Conductor Material : Electrolytic copper

17.3 Insulating Material : CLASS - A

a. H.V - Turn : Oil impregnated paper

b. L.V - Turn Oil impregnated paper

c. L.V. - Earth : Press board

d. H.V. - L.V. : Press board

17.4 Magnetising inrush current A Approx. 5to 6 times of

FLRC

17.5 Magnetising current at rated

frequency and at rated

voltage

A Approx.2%of FLRC at

rated voltage

17.6 Conductor area approx

HV

LV

In sq. mm (approx.)

26.94

711.13

18.0 Off-circuit tap changer

details

18.1 Make : Voltamp / Paragon

18.2 Type : Off Circuit

18.3 Rated Voltage class of tap

changer

kV : 11 KV

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

8 of 15

18.4 Rated Current A : 150A

18.5 Auxiliary Power kW : NA

18.6 Step voltage V 165 volts

18.7 Number of steps 4

18.8 Control Manual

18.9 Maximum Short Circuit

Current withstand capability :

a. Current A/mm2 : 1.29

b. Time s : 2

18.10 Local indicator furnished for :

a. Tap position : NA

18.11 Number of revolutions to

complete one step

: NA

18.12 Time to complete one step on

Manual operation

s : NA

18.13 Approximate overall weight kg Included in total

weight

18.14 Approximate overall

dimensions(With 5% Tol.)

mm Included in total

weight

18.15 Approximate overall quantity

of oil

L Included in total

weight

18.16 Whether the following

provisions are provided?

a) Padlocking

b) Auxiliary switch for

interlocking

c) Safety limit switch

Yes

NA

NA

19.0 Insulating Oil

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

9 of 15

19.1 Approximate volume equired

for first filling?

Main tank

Conservator and radiators

L :

580

305

19.2 10% excess oil furnished ? : Yes

19.3 Oil conforms to : : IS-335

19.3.1 Details of oil furnished

I) Moisture content

ii) Gas content

iii) Max tan value at 90C

iv) Resistivity

v) Interfacial tension at 27C

vi) Breakdown strength

ppm

-cm

N / m

kV

:

Before first filling

As per IS: 335

20.0 Bushings : HV / LV / LVN

20.1 Make : HV-AP/JP/CJI

LV&LVN Porcelain

20.2 Type : HV- Porcelain

LV&LVN-Porcelain

20.3 Reference Standard : IS-2099

20.4 Voltage Class kV : HV/LV/LVN-17.5

/1.1/1.1

20.5 Type of atmosphere : Highly Polluted

20.6 Creepage Distanc mm

: 25mm /KV

20.7 Free space required for

bushing removal

mm : 1000

20.8 One minute power frequency

withstand voltage.

kV rms : HV/LV/LVN-28/3/3

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

10 of 15

20.9 Impulse withstand voltage

kV peak

: HV/LV/LVN-75/NA/NA

20.10 Rated current A HV/LV/LVN-

630/3150/3150

20.11 Rated short circuit current

and duration

kA/

s

HV 40 KA for 3 Sec

LV 50 KA for 2 Sec

20.12 Cantilever strength of the

bushing

kg As per IS-2099

20.13 Weight of the assembled

bushings

kg As per IS-3347

20.14 Mounting arrangement of the

bushing

HV- Cable box

LV-Bus duct flange

21.0 Minimum Clearance

21.1 Between Phases :

a. In air

I. H.V.

ii. L.V.

mm

mm

:

:

90

25

b. In oil

I. H.V.

ii. L.V.

mm

mm

:

:

10

10

21.2 Between Phase & Earth :

a. In air

I. H.V.

ii. L.V.

mm

mm

:

:

70

20

b. In oil

I. H.V.

ii. L.V.

mm

mm

:

:

10

10

21.3 Clearance between core and

coil

mm 10

21.4 Clearance between coils mm 10

10

21.5 Clearance between neutral to

ground in air

mm

22.0 Terminal Connections

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

11 of 15

22.1 H.V. : Cable box

22.2 L.V. : Bus duct flange

22.3 L.V. Neutral : Inside Bus duct

23.0 Marshalling Box

23.1 Weatherproof, suitable for

outdoor duty

: Yes

23.2 Degree of protection : IP-55

23.3 Painting shade Siemens Grey RAL-

7032

24.0 Terminal Blocks :

24.1 Make : Elmex / Connect well

24.2 Type : Clip on type

24.3 20% spare terminals

furnished?

: Yes

25.0 Wiring

25.1 Cable type : FRLS XLPE insulated

25.2 Voltage grade V : 1.1 KV

25.3 Conductor Size

Material

Stranded

mm

2

Yes/No.

:

:

:

2.5 sq. mm

Stranded Cu

Yes

26.0 Trip and Alarm Contacts

Ratings (OTI and WTI)

26.1 Voltage V : 220 V DC

26.2 Rated :

Making current A : 0.25/0.5 A

Breaking Current A : 0.25/0.5 A

27.0 Accessories

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

12 of 15

Each transformer furnished

with fittings and accessories

as per specification ?

Yes / No : Yes.

28.0 Detail of Conservator

28.1 Volume of Conservator L : 90 Ltr. (Approx.)

28.2 Volume of oil between the

highest and lowest levels

L : 45 ltrs. (approx.)

29.0 Pressure Release devices /

Explosion vent

a. Minimum pressure the

device is set to operate /

rupture

kg / cm

2

0.56

b. Alarm and trip contacts

provided

Yes trip contract

only

30.0 Spare Parts

Each transformer furnished

with spare parts as per

specification

: Yes

31.0 Approximate Overall

Dimension

(With 5% Tol.)

31.1 Length mm : 3750

31.2 Breadth mm : 3110

31.3 Height mm : 2635

31.4 Crane lift (a) for untanking

core and coil assembly

(including sling)

mm 3250

32.0 Approximate Weights

32.1 Core with clamps

Windings with insulation

kg.

kg

: }

} -- Core &

} winding - 2090

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

13 of 15

32.2 Tanks, fittings and

accessories

kg. : 1850

32.3 Oil kg. : 790

32.4 Total Weight kg. : 4730

33.0 Shipping Data

33.1 Weight of the heaviest

package

Core / coil

Tank

kg. :

} Total wt. to be

} lifted 4180 kg

} (Approx.)

33.2 Dimension of the largest

package (LxBxH)

mm : 3750 x 3110 x 2635

33.3 Height for untanking the tank mm 3250

33.4 List the parts detached for the

transport

Radiators,

Conservator and

rollers

34 Proposed method of

transportation for the

transformer

Filled with oil

35.0 Tests to be conducted on

each Transformer

35.1 Routine tests as per

specification / relevant

standards will be provided?

: Yes as per IS-2026

35.2 Tank pressure test on each

transformer :

a. Test Pressure kN / m

2

: As per CBIP

b. Duration h : As per CBIP

c. Permanent deflection mm : As per CBIP

35.3 Tank vacuum test on each

transformer :

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

14 of 15

a. Vacuum kN / m

2

: As per CBIP

b. Duration h : As per CBIP

c. Permanent deflection mm : As per CBIP

35.4 Oil leakage test on each

transformer

:

a. Test pressure kN / m

2

: As per CBIP

b. Duration h ; As per CBIP

35.5 Core bolt withstand voltage

for 1 minute on each

transformer

kV : 2 KV rms

36 GENERAL

Minimum draw bar pull

required to move the

transformer on level track?

--

37 ACCESSORIES

A. NEUTRAL CURRENT

TRANSFORMER

37.1 General

37.1.1 Make :

PRAGATI/KAPPA/AE

37.1.2 Type : Resin cast

37.1.3 Reference Standard : IS:2705

37.1.4 Use : Back up earth fault

37.2 Rating

37.2.1 C.T.Ratio A : 2500/1

37.2.2 Class :

5P20

37.2.3 Insulation level kV rms /

kV peak

: N.A.

Project : 2X135 MW Meenakhi

Energy Pvt. Lmt.

Package:

LV Oil filled transformer

Bidders Name:

M/S.Voltamp Transformers Ltd.

E-50994

Rev. : 00

15 of 15

37.2.4 Burden VA : 15

37.3 Insulation Class : A

37.3.1 Temperature rise at rated

burden over top oil

temperature

C : As per IS : 2705

37.4 Characteristics

37.4.1 Secondary resistance R

CT

at

75C

:

N.A.

37.4.2 Knee point voltage V

k

V :

37.4.3 Excitation current at V

k/2

A . :

37.5.0 Dimension and Weights

37.5.1 Dimension(LxBxH) (With 5%

Tol.)

mm : Included in overall

dimensions

37.5.2 Weight kg : Included in overall

dimensions

37.6 Tests : As per standard

B TEMPERATURE

INDICATORS

(OTI / WTI )

37.7.1 Manufacturer Prefect Control /

Precimeasures

37.7.2 Range 0-150 C

37.7.3 Accuracy % 1.5% of FSD

You might also like

- Electrical Boq for Sulphuric Handling at EnclosureDocument2 pagesElectrical Boq for Sulphuric Handling at EnclosureKrishNo ratings yet

- 33kV-11.5kV transformer drawingDocument7 pages33kV-11.5kV transformer drawingIrshad Khan100% (1)

- O20361-E-STN-04-DC-9059 Earth Mat & Earth Strip Sizing CalculationDocument21 pagesO20361-E-STN-04-DC-9059 Earth Mat & Earth Strip Sizing CalculationrkinspiresNo ratings yet

- One-Line Diagram - SFNY (Load Flow Analysis) : CB15-4 CB20-2 CB18-2Document19 pagesOne-Line Diagram - SFNY (Load Flow Analysis) : CB15-4 CB20-2 CB18-2Geetha BirudalaNo ratings yet

- RFC-HSM-LTG - Notes & Details - Ra-20120816Document25 pagesRFC-HSM-LTG - Notes & Details - Ra-20120816raj sekharNo ratings yet

- Earthing Conductor SizingDocument3 pagesEarthing Conductor SizingVelavan AnnamalaiNo ratings yet

- SC Calculations - EditDocument118 pagesSC Calculations - Editeps.hvdc.ocNo ratings yet

- Tesla Model 3 - Emergency First Responders Guide.Document31 pagesTesla Model 3 - Emergency First Responders Guide.Iqtidar ANo ratings yet

- SLD Aux PDFDocument6 pagesSLD Aux PDFaviral mishraNo ratings yet

- KK Spun India Limited: Municipal Corporation Katni EgisDocument2 pagesKK Spun India Limited: Municipal Corporation Katni EgisPankaj KumarNo ratings yet

- 180 VOLVO Codigos de Erros L60F L70F PDFDocument180 pages180 VOLVO Codigos de Erros L60F L70F PDFManuel casanova86% (7)

- JD-132-QH-E41-03 - Strand Conductor SizingDocument15 pagesJD-132-QH-E41-03 - Strand Conductor SizingRami The OneNo ratings yet

- 51 Sdms 01rev022 For Distribution TransformerDocument20 pages51 Sdms 01rev022 For Distribution Transformernadeem UddinNo ratings yet

- General notes and details for substation constructionDocument1 pageGeneral notes and details for substation constructionA.K.M Shafiq MondolNo ratings yet

- LV Relay SettingDocument12 pagesLV Relay SettingRatheesh KumarNo ratings yet

- 10KVA Online UPS SpecificationDocument1 page10KVA Online UPS Specificationashif28No ratings yet

- ISO27k GDPR Mapping Release 1Document19 pagesISO27k GDPR Mapping Release 1Tannyk PonceNo ratings yet

- 752-65L-0005 Cable Interconnection Schedule (Sg-75a-101&102)Document21 pages752-65L-0005 Cable Interconnection Schedule (Sg-75a-101&102)Aravind DasanNo ratings yet

- Protection Coordination Report: Camerich Paper Private LTDDocument42 pagesProtection Coordination Report: Camerich Paper Private LTDramesh cuppuNo ratings yet

- Moe-13-Rusa-689 - Iom For 420KV GisDocument234 pagesMoe-13-Rusa-689 - Iom For 420KV Gisموسي النحلهNo ratings yet

- 400KV GT Tech DataDocument21 pages400KV GT Tech Datasrigirisetty208No ratings yet

- Acdb MCCB Setting Calculation - DH BSP - DH BSP - 30.05.17Document6 pagesAcdb MCCB Setting Calculation - DH BSP - DH BSP - 30.05.17Sathiya SeelanNo ratings yet

- SS P1 - Busduct 20 7 15 R0 PDFDocument18 pagesSS P1 - Busduct 20 7 15 R0 PDFSureshbabuNo ratings yet

- Earthing Cal - Rev-01 - As Per Mecon Comnt.Document9 pagesEarthing Cal - Rev-01 - As Per Mecon Comnt.Prateek SinghNo ratings yet

- Design Guide FOR Distribution System PlanningDocument19 pagesDesign Guide FOR Distribution System Planningdhairyashil_dspNo ratings yet

- 210014-P7003-E01-0038 - 00 CCPP 150kV Substation - Datasheet For Battery & Charger (Asbuilt)Document26 pages210014-P7003-E01-0038 - 00 CCPP 150kV Substation - Datasheet For Battery & Charger (Asbuilt)rizkyNo ratings yet

- Item200 500kVA 6xDocument55 pagesItem200 500kVA 6xscribd_raja100% (1)

- 1.list of Drawings For Cable Sealing System KHONSA SubstationDocument5 pages1.list of Drawings For Cable Sealing System KHONSA SubstationmanishNo ratings yet

- VR La Batterie Edited 15Document8 pagesVR La Batterie Edited 15SOMU_61No ratings yet

- Chimney - Electrical Works SpecDocument54 pagesChimney - Electrical Works Specmyselfashinthedark100% (1)

- Battery Sizing 3 Trafo (Latest)Document20 pagesBattery Sizing 3 Trafo (Latest)jm.mankavil6230No ratings yet

- 12493-500kva CRT With Oltc-R2Document8 pages12493-500kva CRT With Oltc-R2Hari HaranNo ratings yet

- Rev. Status: Customer Drawing ListDocument12 pagesRev. Status: Customer Drawing ListAbdus SalamNo ratings yet

- 1.6 Mva Dry Type TransformerDocument10 pages1.6 Mva Dry Type TransformerRamesh CuppuNo ratings yet

- 1.6 Mva Dry Type TransformerDocument10 pages1.6 Mva Dry Type TransformerRamesh CuppuNo ratings yet

- 765kV Greater Noida-Mainpuri Line - Rev 0Document24 pages765kV Greater Noida-Mainpuri Line - Rev 0Abhisek SurNo ratings yet

- Single Line Diagram r6Document1 pageSingle Line Diagram r6Quảng Thành NamNo ratings yet

- Approved - 216 KV LA - GTP & DrgsDocument22 pagesApproved - 216 KV LA - GTP & DrgsGuru MishraNo ratings yet

- (English) The World in 2050 (The Real Future of Earth) - BBC & Nat Geo DocumentariesDocument30 pages(English) The World in 2050 (The Real Future of Earth) - BBC & Nat Geo Documentariesnagendrasteer100% (2)

- Material EquivalentsDocument25 pagesMaterial EquivalentsAditya B. Ryanto100% (6)

- Earthing Diagram NFL CWDocument1 pageEarthing Diagram NFL CWSoumitra GuptaNo ratings yet

- Emergency oil drain pit plan and sectionDocument1 pageEmergency oil drain pit plan and sectionAbhay ThakurNo ratings yet

- Gurranted Technical PartDocument9 pagesGurranted Technical PartTarun GodiyalNo ratings yet

- FS4005 Cable TraysDocument8 pagesFS4005 Cable Traysm_925No ratings yet

- Upgrade Electrical Systems at Abqaiq Plants: Plan Elevation and General Arrangement Drawing For 111-091-MCC-002Document6 pagesUpgrade Electrical Systems at Abqaiq Plants: Plan Elevation and General Arrangement Drawing For 111-091-MCC-002Asad MaherNo ratings yet

- Transformers Losses Nov 2013Document4 pagesTransformers Losses Nov 2013saji kumarNo ratings yet

- Design and verification of busway and cable for SMDB to LP loadDocument10 pagesDesign and verification of busway and cable for SMDB to LP loadAhmed MagdyNo ratings yet

- NMML1-PST-8-C-2112-08 - SH 2 of 4Document1 pageNMML1-PST-8-C-2112-08 - SH 2 of 4lalitendu jenaNo ratings yet

- Common Oil Soak Pit - As Per BOTDocument93 pagesCommon Oil Soak Pit - As Per BOTzumanNo ratings yet

- Earthing Case StudiesDocument10 pagesEarthing Case StudiesVIKRAM DESAINo ratings yet

- JD-132-QA-E41-01 - TUBE SIZING 50 DGRDocument14 pagesJD-132-QA-E41-01 - TUBE SIZING 50 DGRRami The OneNo ratings yet

- 33kv SLDDocument1 page33kv SLDKhajaBurhan100% (1)

- Technical Data 33kV AIS VH3Document5 pagesTechnical Data 33kV AIS VH3mahi229No ratings yet

- Ts of 33 KV in Door Switch Board-IDocument29 pagesTs of 33 KV in Door Switch Board-ISunil SinghNo ratings yet

- GTP DrakeDocument2 pagesGTP DrakeBalasubramanya BarkurNo ratings yet

- Power Transformer - 1M - CDocument3 pagesPower Transformer - 1M - CahmedelgharibNo ratings yet

- Booster Pump Motor Technical Data Sheet ReviewedDocument7 pagesBooster Pump Motor Technical Data Sheet ReviewedSantoshkumar GuptaNo ratings yet

- GA Sample Full ICOG PDFDocument17 pagesGA Sample Full ICOG PDFAnagha DebNo ratings yet

- M6 EL 6107 R0 - Cable Carrier SystemDocument13 pagesM6 EL 6107 R0 - Cable Carrier SystemyuvrajNo ratings yet

- GTP BatteryDocument17 pagesGTP Batteryraj_stuff006No ratings yet

- Bial 3 MLD STP Load Calculation Sheet For Cable Tray in Plant RoomDocument4 pagesBial 3 MLD STP Load Calculation Sheet For Cable Tray in Plant RoomRUPESH KUMARNo ratings yet

- CIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byDocument6 pagesCIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byUmamaheshwarrao VarmaNo ratings yet

- Transformer DSDocument4 pagesTransformer DSjuliyet vNo ratings yet

- DC Load Calc PDFDocument8 pagesDC Load Calc PDFArunava BasakNo ratings yet

- SLD of 6.6kV Unit Board 7UADocument10 pagesSLD of 6.6kV Unit Board 7UAVenkatesh RaoNo ratings yet

- Lanco 8.5 Mva GTP Rv.01Document14 pagesLanco 8.5 Mva GTP Rv.01Pankaj TiwariNo ratings yet

- 630kva Transformer Oil TypeDocument28 pages630kva Transformer Oil TypeRamesh CuppuNo ratings yet

- 1.6 MVA Rating and Diagram Plate - Mar22-2011Document1 page1.6 MVA Rating and Diagram Plate - Mar22-2011Ramesh CuppuNo ratings yet

- Data Sheet For Lighting TransformerDocument2 pagesData Sheet For Lighting TransformerRamesh CuppuNo ratings yet

- 2.5 MVA Dry Type Trans. Rating PlateDocument1 page2.5 MVA Dry Type Trans. Rating PlateRamesh CuppuNo ratings yet

- 1.6 MVA Oil Type Transformer GTP - Mar22-2011Document15 pages1.6 MVA Oil Type Transformer GTP - Mar22-2011Ramesh Cuppu0% (1)

- Approval of 355kW 6.6kV Comp. MotorDocument16 pagesApproval of 355kW 6.6kV Comp. MotorRamesh CuppuNo ratings yet

- HT Motors For CHP 550kW 6600V - R3Document18 pagesHT Motors For CHP 550kW 6600V - R3Ramesh CuppuNo ratings yet

- 6.6KV 2000A 40KA/3S Station Apparatus Allocation ChartDocument267 pages6.6KV 2000A 40KA/3S Station Apparatus Allocation ChartRamesh CuppuNo ratings yet

- HT Motors For CHP 550kW 6600V - R3Document18 pagesHT Motors For CHP 550kW 6600V - R3Ramesh CuppuNo ratings yet

- Data Sheet For Cep MotorDocument9 pagesData Sheet For Cep MotorRamesh CuppuNo ratings yet

- Setting Data Sheet For 0.415 kV-Unit Switchgear #1: Outgoing Feeder - 1 For Boiler MCC #1Document59 pagesSetting Data Sheet For 0.415 kV-Unit Switchgear #1: Outgoing Feeder - 1 For Boiler MCC #1Ramesh CuppuNo ratings yet

- Data Sheet 1500kw 6.6kv Pa Fan MotorDocument4 pagesData Sheet 1500kw 6.6kv Pa Fan MotorRamesh CuppuNo ratings yet

- Data Sheet For Cep MotorDocument9 pagesData Sheet For Cep MotorRamesh CuppuNo ratings yet

- 1 VS: 33000 V Ik": 20016.23A: Electrical One-Line DiagramDocument1 page1 VS: 33000 V Ik": 20016.23A: Electrical One-Line DiagramRamesh CuppuNo ratings yet

- Repf 1 PRINTDocument18 pagesRepf 1 PRINTRamesh CuppuNo ratings yet

- 1 VS: 33000 V Ik": 20016.23A: Electrical One-Line DiagramDocument1 page1 VS: 33000 V Ik": 20016.23A: Electrical One-Line DiagramRamesh CuppuNo ratings yet

- Report Revised 080114Document49 pagesReport Revised 080114Ramesh CuppuNo ratings yet

- Report 180414Document39 pagesReport 180414Ramesh CuppuNo ratings yet

- Report Revised 080114Document49 pagesReport Revised 080114Ramesh CuppuNo ratings yet

- Unifi Business Form 100mbps 47sites - (AG.K.2023.063) SignedDocument2 pagesUnifi Business Form 100mbps 47sites - (AG.K.2023.063) Signedvanesa lawNo ratings yet

- BUILDING TECH 1 Lect 3 MASONRYDocument42 pagesBUILDING TECH 1 Lect 3 MASONRYElyzaGutierrezCabacesNo ratings yet

- Manual ACU802Document100 pagesManual ACU802raal0No ratings yet

- Game LogDocument38 pagesGame LogВлад ТреничNo ratings yet

- Text Rewriter and SpinnerDocument1 pageText Rewriter and SpinnerHARAM MANDNo ratings yet

- EUROCONTROL Guidelines On Conformity Assessment Ed 2.0Document72 pagesEUROCONTROL Guidelines On Conformity Assessment Ed 2.0mdmanninoNo ratings yet

- Virgin TV V6 Quickstart Guide For Existing CustomersDocument28 pagesVirgin TV V6 Quickstart Guide For Existing CustomersAnonymous yA5TGHNo ratings yet

- Multimedia ComputingDocument29 pagesMultimedia ComputingVikky GourNo ratings yet

- The Microprocessor and Its Architecture ExerciseDocument38 pagesThe Microprocessor and Its Architecture ExerciseAsteriPurnomoNo ratings yet

- General and Particular Differential Equations Solutions - Videos, Examples PDFDocument1 pageGeneral and Particular Differential Equations Solutions - Videos, Examples PDFTakudzwa ZengeraniNo ratings yet

- GE461 Intro to Data Science (40chDocument39 pagesGE461 Intro to Data Science (40chMuhammed NaciNo ratings yet

- 49 Printable Bingo Card Templates - Tip JunkieDocument1 page49 Printable Bingo Card Templates - Tip JunkiebobNo ratings yet

- Markel 5100 Catalog PDFDocument4 pagesMarkel 5100 Catalog PDFlenin olazabalNo ratings yet

- Sony TV LCD AZ1-L CHASSISDocument5 pagesSony TV LCD AZ1-L CHASSISmontezumaNo ratings yet

- Computer Graphics - Ugc Net Solved Paper PDFDocument119 pagesComputer Graphics - Ugc Net Solved Paper PDFChandana Swathi100% (1)

- Android Smart City Travelling ProjectDocument11 pagesAndroid Smart City Travelling ProjectpatoNo ratings yet

- XpathDocument3 pagesXpathLena Dutf0% (1)

- Design and Analysis of Leaf Spring Using Composite Materials IJERTV7IS050254Document8 pagesDesign and Analysis of Leaf Spring Using Composite Materials IJERTV7IS050254k VENKATESHWARANNo ratings yet

- Magnomatics BrochureDocument4 pagesMagnomatics BrochureVijay17101972No ratings yet

- Pet Blowing MachineDocument5 pagesPet Blowing Machinedinesh patilNo ratings yet

- Daniefer M - Best BuyDocument6 pagesDaniefer M - Best BuyArchana mittalNo ratings yet

- Module 2 - Series DC MotorDocument8 pagesModule 2 - Series DC MotorMARY JOY MAGAWAYNo ratings yet

- Ec2034 TV PDFDocument171 pagesEc2034 TV PDFHrishikesh Deshpande100% (3)

- OSPF Flashcards by Frederick Karban - BrainscapeDocument51 pagesOSPF Flashcards by Frederick Karban - BrainscapeLIBERTY GAMIRANo ratings yet

- Rec. ITU-R BT.601-5Document31 pagesRec. ITU-R BT.601-5michele.casartelli4607No ratings yet