Professional Documents

Culture Documents

GEN-046 MOS-DR-01 - Sewer Water Pipe (Clay Pipe) Belowground Installation

Uploaded by

Francisco M. RamosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GEN-046 MOS-DR-01 - Sewer Water Pipe (Clay Pipe) Belowground Installation

Uploaded by

Francisco M. RamosCopyright:

Available Formats

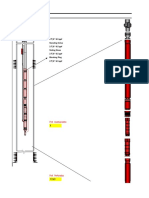

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 1 of 15

SEWER WATER PIPE (CLAY PIPE) BELOWGROUND

INSTALLATION

00 23.08.2012

Rev Date Status Developed By Reviewed By Approved By

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 2 of 15

TABLE OF CONTENTS

Section No

Description Page No.

1.0 Introduction Page 3

2.0 References Page 3

3.0 Planning Stage Page 4

4.0 Construction Stage Page 4-13

5.0 Completion Stage Page 13-14

6.0 Responsibility Page 15

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 3 of 15

1.0 Introduction

This Method Statement defines the method of installing the Sewer Water Pipe,

Fittings and accessories.

This method statement covers the works associated with the installation of

Sewer Water Pipe for the Internal Sewer Network and to connect to Future

External Ashghal Trunk Sewer Network, between Manholes to Manholes,

House Connection Pipe from Ground Discharge of various Building.

2.0 Reference

Reference is made to the Design and Detail Drawings, Mechanical

Specifications, and the Employers Requirements.

Reference is made to the design and constructs contract, Mechanical

Specifications, and the Employers Requirements. The standards indicated

therein will be followed (where applicable) for the execution of the works.

2.1 Relevant documentation

A. Latest Mechanical Specifications, Drainage Installation Section

20.1.06 Drainage System.

B. Latest Edition and Publication of QCS, Sewerage Division and

Ministry of Public Works, State of Qatar

C. Code for Saudi Arabian Standard Organization,

SASO/GSO/EN295/2008 which is fully complying with EN295 &

ASTM C700.

.

D. Latest Approved Infrastructure & Coordinated Shop Drawings.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 4 of 15

3.0 Planning Stage

3.1 Preparation of Drawings

3.1.1 Check construction drawings and inform the scope of works at

areas concerned.

3.1.2 Prepare shop drawings at areas concerned and followed by others

progressively.

3.1.3 Submission of Schedule of Manufacturers List on type, brand and

Model of materials / equipment to be used for approval from

Consultant and Employer.

3.2 Preparation of Materials

3.2.1 Check for any damages and replace any defective materials before

delivery to site.

3.2.2 Upon delivery to site, check serial no., model no., damage during

transportation, to make sure same as shipping list / delivery order.

Check catalogues for specification compliance.

3.3 Tools and Equipments

3.3.1 All tools for use on the site are to be in an operable condition.

Defective extension wire & plugs are not allowed.

3.3.2 Ensure equipment / machinery used is in proper conditions and

securely supported before delivered to site.

a. Pipe shavers

b. Band Clamps

c. Air Blower

d. Grinders & Drill machines

e. Various Hand Tools

f. Mobile Crane

g. Excavator & Loaders

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 5 of 15

h. Dump Trucks, Trailers and Water Trucks

i. Compactors

j. Drainage Pipe Water Gravity Testing Plug

k. Other necessary tools and instruments.

4.0 Construction Stage

4.1 Unloading & Storage at Site

4.1.1 Pipes are to be checked on unloading.

a) With Crane or Excavator

Use lifting belts; chain or ropes may not be used.

The lifting belts must be placed outside around the pallets

and outside the base timber.

Steer the pallets manually to prevent them colliding with

anything.

Do not move the pallets on the truck with the aid of levers

or crowbars.

Do not allow the pipes to be impacted by any hard object

(e.g. crane hook, chain etc.).

b) With Forklift Truck

When placing the pallets transversely on the forks, make

sure the forks are positioned sufficiently widely apart

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 6 of 15

When placing the pallets longitudinally on the forks, place

protective timber between the parcel and the forks base.

Better is to transport the parcel in transversal direction on

the fork teeth.

When transporting individual pipes by sliding a tooth into

a pipe, always have protective material between the forks

and the pipe.

4.1.2 Storage at Site

4.1.2.1 Do not put the pallets down on to hard ground with a bang.

4.1.2.2 Put the pallets down only on ground that is sufficiently hard to

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 7 of 15

prevent the base timber sinking into it

4.1.2.3 Leave sufficient space between individual pallets.

4.1.2.4 To avoid damage to the sealing elements, store individual

pipes only on a wooden base.

4.1.2.5 Store fittings standing upright on their sockets.

4.2 Pipe Laying & Installation

4.2.1 Before the pipes are laid, check both ends of each pipe, optically in

order to find any cracks that might have occurred in the course of

transport.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 8 of 15

4.2.2 The paint mark must always point upwards. This ensure: * The pipe

inverts will be level (any steps that might arise between two pipes

will be within the permissible tolerance)

4.2.3 Install pipe according to required gradient and shall be executed as

the following steps:

Step 1: Keep the trench width narrow, especially at the top of the

pipe. A wide trench means more load on the pipeline.

Step 2: Spread bedding material in front of last pipe laid. Smooth it out.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 9 of 15

Step 3: Imported bedding should be at least 4 inches thick thicker for larger pipe. Make

sure the bedding is packed down.

Step 4: Use grade rod, laser or grade machine to check grade of bedding. This means

less pipe handling when the pipe is laid.

Step 5: Dig bell or coupling holes before pipe is laid. Just scoop out bedding with a

shovel.

Step 6: Keep water out of the trench so bedding can be placed and graded accurately.

Pipe joints can be made easier too.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 10 of 15

Step 7: Pump out the water or use well points sunk below the depth of the trench

bottom.

Step 8: Follow manufacturers instructions for installation of flexible compression joints.

Make sure joints are clean before installing them.

Step 9: If a bar is used to shove the pipe home use a block of wood to cushion the bell.

Make sure the pipe is laid straight and to grade.

Step 10: Tamp a layer of bedding material under the pipe haunches, not under the bell.

This gives the pipe added support and keeps it in line.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 11 of 15

Step 11: If too much bedding is thrown on top of the pipe, it wont get under the pipe

even with tamping. Dont let this happen!

Step 12: Make sure fittings, stubs and risers are well supported. Tamp soil around and

under haunches of the pipe and fittings.

Step 13: Use short stubs with flexible compression joints at manhole walls. They will

take care of manhole settlement.

Step 14: Hand cover the pipe with about 12 inches of backfill over the top of the pipe.

This protects the pipe during final backfilling.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 12 of 15

Step 15: Do not let rocks or lumps get into the trench. They can damage the pipe and

ruin the alignment.

Step 16: Place final backfill into the trench at an angle. This keeps impact on the

installed pipe to a minimum.

Step 17: Heavy compaction equipment should be used with caution. Pipe can be

damaged if impact is not carefully controlled.

4.3 Gravity Test

4.3.1 Gravity sanitary sewer and Industrial drainage system shall be tested

with potable water, well water or sea water.

4.3.2 Gravity test shall be done from manhole to manhole or a column of

water equivalent to the rim elevation of the upstream manhole if pipe

is to be tested separately.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 13 of 15

4.3.3 Gravity test shall be maintained for a period of 4 hours for lines

whose joints have not been backfilled or are above ground piping

while 24 hours shall be maintained for lines whose joints have been

backfilled.

4.3.4 If manholes are not part of the test or a section of pipe is to be

tested, the pipe ends shall be covered with plumbers test plugs.

4.3.5 An extension pipe is provided on the test plugs at selected location

for water filling and drain points and at least one pipe riser for the

water head required that shall be accessible for visual inspection.

4.3.6 Plumbers test plugs that are not used for other purposes shall be

kept open while filling of water to release air inside the system and

shall be closed when the system has been properly vented.

4.3.7 Water filling into the pipe being tested shall be from a water truck or a

ground level water tank with electric or engine-driven pump. A water

hose shall be placed direct to the manhole, to the pipe being tested

or to a pipe connection provided at the plumbers test plug.

4.3.8 All joints shall be exposed and cleaned for visual inspection.

4.3.9 Partial sand covering and backfilling on the body of the pipe being

tested shall be done to prevent floatation during test.

4.3.10 Drain valve shall be provided at the lowest portion of the pipe being

tested for safe draining after inspection.

4.3.11 Water used for testing can be re-used for another gravity test, for

water flooding of pipe sand covering, for water spray of trenches or

discharge to a designated area.

4.3.12 Repair methods for leaking pipes, joints and fittings shall be in

accordance with the requirement and project specification.

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 14 of 15

5 Completion Stage

5.1 The site inspection is carried out to ensure conformance of the installation

work.

5.2 A Request for Inspection form is forwarded to the Employers

representative as above said.

6 Responsibility

c) Project Manager

The Project Manager will have the overall responsibility for the execution

and management of the project. The Project Manager will provide the

direction to achieve the completion of the project in accordance with the

contract terms and conditions.

d) Senior Mechanical Engineer

The Senior Mechanical Engineer is the overall responsibility for the

execution of the site work.

e) Project Coordinator

The Project Coordinator is the overall responsible person for process

implementation.

f) Site Engineer

The Site Engineer is responsible for all installation activities at job sites.

g) Site Supervisor

The Site Supervisor is responsible to monitor, supervise and coordinate all

the site activities.

h) QA/QC Engineer

SIDRA VILLAGE STAFF HOUSING FOR SIDRA MEDICAL AND RESEARCH CENTER

Document No.

MOS-DR-01

Revision 00 Page: 15 of 15

The QA/QC Engineer is responsible to responsible for all materials/

installation/ test inspection on site.

i) Safety Officer

The Safety Officer is responsible for implementing the safety programmers,

including running weekly toolbox meetings and monthly safety meetings.

You might also like

- Civil and Structures Deliverables: Document Control Register (Doc. No# 111-503-PM-DCR-001)Document25 pagesCivil and Structures Deliverables: Document Control Register (Doc. No# 111-503-PM-DCR-001)smazNo ratings yet

- TR2222 - Pipeline Flooding, Cleaning, Gauging and Pressure TestingDocument20 pagesTR2222 - Pipeline Flooding, Cleaning, Gauging and Pressure Testingmaximusala83No ratings yet

- Final - Commercial & SOR-Vol IDocument86 pagesFinal - Commercial & SOR-Vol IengharshNo ratings yet

- Company Profile PT - Tri Daya MaximaDocument8 pagesCompany Profile PT - Tri Daya Maximabenno adi sulistyonoNo ratings yet

- KR Parco Ps6 Ms 0001 M.S For ConcreteDocument11 pagesKR Parco Ps6 Ms 0001 M.S For ConcretebulzaeNo ratings yet

- P4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCDocument19 pagesP4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCLahiru IndrajithNo ratings yet

- Standard Details - 2019 PDFDocument101 pagesStandard Details - 2019 PDFngronau124545No ratings yet

- HSE-OCP-013. Cold CuttingDocument4 pagesHSE-OCP-013. Cold Cuttingibrahim0% (1)

- FuelStations PDFDocument163 pagesFuelStations PDFhasan syukurNo ratings yet

- Manpower ListDocument4 pagesManpower ListgkNo ratings yet

- MBR Villa Programme UpdateDocument7 pagesMBR Villa Programme UpdateAnish ChandranNo ratings yet

- 3-OPER-030 Blind Installation and Removal PDFDocument28 pages3-OPER-030 Blind Installation and Removal PDFSameer KulkarniNo ratings yet

- Asmuss Pipes and FittingsDocument106 pagesAsmuss Pipes and FittingsJohn HarkenNo ratings yet

- Installation Method StatementDocument6 pagesInstallation Method StatementgururajNo ratings yet

- Installation Armstrong Ceiling SystemsDocument24 pagesInstallation Armstrong Ceiling Systemsmelgarcia829No ratings yet

- Con DuctbankDocument25 pagesCon DuctbankLimuel EspirituNo ratings yet

- Ssec Profile 2010Document47 pagesSsec Profile 2010Syaiful AzliNo ratings yet

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -No ratings yet

- Booster Pump Foundation Excavation ProcedureDocument9 pagesBooster Pump Foundation Excavation ProcedurekbldamNo ratings yet

- Ep 08 030 37Document18 pagesEp 08 030 37Muhammad AwaluddinNo ratings yet

- QS Letters GuideDocument4 pagesQS Letters GuideZahoor Ahmed MohsanNo ratings yet

- NS1 Work Plan Procedure For CW Piping Installation Rev.4Document47 pagesNS1 Work Plan Procedure For CW Piping Installation Rev.4namdq-1No ratings yet

- DRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Document37 pagesDRP001-OUF-SPE-W-000-008-B4 (Painting of New Equipment & Piping)Kannan MurugesanNo ratings yet

- 02 - 2012 - PTPAPE - Pipeline EngineerDocument2 pages02 - 2012 - PTPAPE - Pipeline EngineerCandra Setya NugrohoNo ratings yet

- Continental Engineering Corporation: Methodology For Production of Granular Sub BaseDocument8 pagesContinental Engineering Corporation: Methodology For Production of Granular Sub BasenaseebNo ratings yet

- Method Statement For Vertical StructureDocument7 pagesMethod Statement For Vertical StructureAdel SaqqaNo ratings yet

- SAES-L-470 PDF Download - Trenchless Pipelines Construction - PDFYARDocument7 pagesSAES-L-470 PDF Download - Trenchless Pipelines Construction - PDFYARZahidRafiqueNo ratings yet

- Method Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFDocument8 pagesMethod Statement For CW INTAKE SCREEN WASH WATER SYSTEM FLUSHING BL.1 5 PDFFredie UnabiaNo ratings yet

- Schedule NarrativeDocument298 pagesSchedule NarrativetabtawanNo ratings yet

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Document10 pagesQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNo ratings yet

- Local Employment Policy Handbook PDFDocument135 pagesLocal Employment Policy Handbook PDFrodi_dumitru5709No ratings yet

- Bedding & Back Filling SpecificationDocument3 pagesBedding & Back Filling SpecificationMohammed Asimuddin Farooqui100% (1)

- TEC-321000 - MET-DoR-001 (Method Statement For Road and Paving Works) (K)Document7 pagesTEC-321000 - MET-DoR-001 (Method Statement For Road and Paving Works) (K)kyle vincentNo ratings yet

- General Works To Support Pipeline-Non Pipeline Activities-Tmg OkDocument5 pagesGeneral Works To Support Pipeline-Non Pipeline Activities-Tmg Okarif rhNo ratings yet

- Installation of Pipeline by HDD For NGN Pipeline ProjectDocument48 pagesInstallation of Pipeline by HDD For NGN Pipeline ProjectDie HArd100% (1)

- T-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623Document77 pagesT-14.427.475 Work Method Statement For Construction of Abutment and Slope Protection Works - 210623JosiahNo ratings yet

- Work Method Statement For Structure ErectionDocument12 pagesWork Method Statement For Structure ErectionMuhammad TeguhNo ratings yet

- 2016-06-20 ACX-APL5 Installation Time Schedule Rev06Document17 pages2016-06-20 ACX-APL5 Installation Time Schedule Rev06julio arroyoNo ratings yet

- Microsoft Word - F12254-CDB-W03-QUA-ITP-60053 - 06-001 PDFDocument7 pagesMicrosoft Word - F12254-CDB-W03-QUA-ITP-60053 - 06-001 PDFmuahdib100% (1)

- 250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchDocument22 pages250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchAbdullah AbdullahNo ratings yet

- VD V013 ZPM Pro 1507Document105 pagesVD V013 ZPM Pro 1507abdulNo ratings yet

- Saudi KAD Contracting Company Contract No. 6600034300 SK-POC-01 Rev 4 - Project Organization Chart Dated: February 13, 2017Document1 pageSaudi KAD Contracting Company Contract No. 6600034300 SK-POC-01 Rev 4 - Project Organization Chart Dated: February 13, 2017Saudi KadNo ratings yet

- Rev-2 Method Statement For Building Construction Works Puma Energy Daulatpur ProjectDocument12 pagesRev-2 Method Statement For Building Construction Works Puma Energy Daulatpur ProjectM Waqas HabibNo ratings yet

- Basics of Pressure Piping For Junior EngineersDocument36 pagesBasics of Pressure Piping For Junior Engineersتدریس زبان ESLNo ratings yet

- Example Safe Work Method StatementDocument2 pagesExample Safe Work Method StatementHamza NoumanNo ratings yet

- Khadimally RT011215Document33 pagesKhadimally RT011215jkj_13874No ratings yet

- Check List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelDocument6 pagesCheck List For: Screed Works: Subcontractor Contractor Section of Work: Civil LOCATION: Parcel 18, Plot 405 LevelAminovic PlusNo ratings yet

- Design Firefighting System For Oil Installation of PSODocument14 pagesDesign Firefighting System For Oil Installation of PSOSyed Zainul IslamNo ratings yet

- E&I Tool Box ContentsDocument1 pageE&I Tool Box ContentsChandan RayNo ratings yet

- Sapura 2000: Derrick Pipelay BargeDocument4 pagesSapura 2000: Derrick Pipelay BargeKarun DasNo ratings yet

- Lowering of PipelineDocument5 pagesLowering of PipelineLarry Ubu100% (1)

- J213-AHC-EMD-MS-C-04-R0 MS For Substructure Waterprooing Bitumen CoatDocument7 pagesJ213-AHC-EMD-MS-C-04-R0 MS For Substructure Waterprooing Bitumen CoatKafeel AbbasNo ratings yet

- METHOD STATEMENT FOR Piping & Erection PipeDocument14 pagesMETHOD STATEMENT FOR Piping & Erection PipeAbdullah AbdullahNo ratings yet

- Hyundai Electric ESS Project List-1Document2 pagesHyundai Electric ESS Project List-1Rachmat HermawanNo ratings yet

- Cause and Effect AnalysisDocument13 pagesCause and Effect AnalysisAadi KhanNo ratings yet

- Installation Guide For PVC Sewer Pipe: (ASTM D3034 & F679)Document26 pagesInstallation Guide For PVC Sewer Pipe: (ASTM D3034 & F679)dep_vinNo ratings yet

- Mos - Relocating of Fire Fighting - KAYANDocument19 pagesMos - Relocating of Fire Fighting - KAYANjagp_24No ratings yet

- Method Statement Pipe Handling and AssemblyDocument6 pagesMethod Statement Pipe Handling and AssemblyDanny NguNo ratings yet

- Work Method Statement of PipingDocument13 pagesWork Method Statement of PipingBinod DavisNo ratings yet

- 21 14Document6 pages21 14Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument9 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument4 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 21 12Document7 pages21 12Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument9 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 21 8Document7 pages21 8Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument7 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument7 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument6 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument9 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 21 6Document19 pages21 6Francisco M. RamosNo ratings yet

- 21 7Document10 pages21 7Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument30 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 21 3Document16 pages21 3Francisco M. RamosNo ratings yet

- 22 6Document13 pages22 6Francisco M. RamosNo ratings yet

- 22 7Document10 pages22 7Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument13 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument17 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument18 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument17 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument18 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- Green Line UndergroundDocument7 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 22 9Document13 pages22 9Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument22 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 16 4Document5 pages16 4Francisco M. RamosNo ratings yet

- Green Line UndergroundDocument6 pagesGreen Line UndergroundFrancisco M. RamosNo ratings yet

- 16 5Document13 pages16 5Francisco M. RamosNo ratings yet

- 16 6Document4 pages16 6Francisco M. RamosNo ratings yet

- 16 3Document5 pages16 3Francisco M. RamosNo ratings yet

- 16 2Document6 pages16 2Francisco M. RamosNo ratings yet

- Using Different Perforated Lids On The MAS-100 Family Air SamplersDocument6 pagesUsing Different Perforated Lids On The MAS-100 Family Air SamplersJuan Salvador MaestreNo ratings yet

- Datasheet Dc-m9204 & Di-M9204 Manual Call PointDocument4 pagesDatasheet Dc-m9204 & Di-M9204 Manual Call PointHajji MehdiNo ratings yet

- Et200sp Ai 4xrtd TC 2 3 4 Wire HF Manual en-US en-US PDFDocument80 pagesEt200sp Ai 4xrtd TC 2 3 4 Wire HF Manual en-US en-US PDFSrikar TanukulaNo ratings yet

- Truebluepower: Advanced Lithium-Ion Battery TB17Document2 pagesTruebluepower: Advanced Lithium-Ion Battery TB17Milad YadollahiNo ratings yet

- PPC Porcelain Solid Core Post Insulators and Operating RodsDocument23 pagesPPC Porcelain Solid Core Post Insulators and Operating RodsCHRISTIANNo ratings yet

- Ascorbic Acid Iodometric TitrationDocument2 pagesAscorbic Acid Iodometric TitrationÂngelo Jesus100% (8)

- Team 6 - Crystal MazeDocument56 pagesTeam 6 - Crystal MazeLohith YadavNo ratings yet

- East West Pipe Rack For Piping Project J-80: Sendan International Company LTDDocument25 pagesEast West Pipe Rack For Piping Project J-80: Sendan International Company LTDFarrukh Javed100% (1)

- C1107Document4 pagesC1107Pankaj PaulNo ratings yet

- Phy 109 PDFDocument1 pagePhy 109 PDFsohamNo ratings yet

- VMware Site Recovery Manager (SRM) 5.0 Step by Step Setup GuideDocument110 pagesVMware Site Recovery Manager (SRM) 5.0 Step by Step Setup Guidehj192837No ratings yet

- Result For: Trucks & CV / 4 Wheeler - LCV / Asia Motor Works / AMW 2518 HLDocument3 pagesResult For: Trucks & CV / 4 Wheeler - LCV / Asia Motor Works / AMW 2518 HLmanoj_doshi_1No ratings yet

- Line Protection: Return To Main IndexDocument44 pagesLine Protection: Return To Main IndexAli RazaNo ratings yet

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDocument7 pagesDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9No ratings yet

- Report Torsion TestDocument27 pagesReport Torsion TestCherif ChokeirNo ratings yet

- Pal LeDocument10 pagesPal LemoebiuszeroNo ratings yet

- LIDO Introduction PDFDocument127 pagesLIDO Introduction PDFStiliyana Bakalova100% (2)

- Unit 5: Extra Practice: KeyDocument1 pageUnit 5: Extra Practice: KeyMuniz BarbosaNo ratings yet

- CS412, Fall 2010, Assignment 1: SolutionDocument8 pagesCS412, Fall 2010, Assignment 1: SolutionpeacekentNo ratings yet

- HK102H To-92Document3 pagesHK102H To-92The FatherNo ratings yet

- A-Dec 571 and 6300 Dental Light PDFDocument24 pagesA-Dec 571 and 6300 Dental Light PDFSergio RodriguezNo ratings yet

- FonaDocument36 pagesFonaiyadNo ratings yet

- MCQs On Queue With AnswersDocument7 pagesMCQs On Queue With AnswersBabuLalSainiNo ratings yet

- Mini Project 1Document16 pagesMini Project 1SadikAhmedNo ratings yet

- DefluoridationDocument13 pagesDefluoridationSuha Yechwad100% (1)

- IMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicDocument10 pagesIMAC XXVII Conf s22p008 Automated Estimation Aircrafts Center Gravity Using Static DynamicatommotaNo ratings yet

- SANS Institute: Unix Security ChecklistDocument9 pagesSANS Institute: Unix Security ChecklistRufino UribeNo ratings yet

- Design of Ms Pipe:: - (40 MM NB, Class'b'Document4 pagesDesign of Ms Pipe:: - (40 MM NB, Class'b'Kancharla Naga Ratna KumarNo ratings yet

- INFA3227 Esquema 01-MAR-2021Document9 pagesINFA3227 Esquema 01-MAR-2021sasgarisNo ratings yet