Professional Documents

Culture Documents

325D - Technical NPI

Uploaded by

Victor Acuña100%(8)100% found this document useful (8 votes)

677 views48 pagesThis presentation provides new and different New Product Introduction (NPI) information on the 325D Hydraulic Excavator. This first printing contains information on the EAME Market Gosselies produced 325D only. The 325d will be available in the NACD and APD markets early in 2006.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis presentation provides new and different New Product Introduction (NPI) information on the 325D Hydraulic Excavator. This first printing contains information on the EAME Market Gosselies produced 325D only. The 325d will be available in the NACD and APD markets early in 2006.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(8)100% found this document useful (8 votes)

677 views48 pages325D - Technical NPI

Uploaded by

Victor AcuñaThis presentation provides new and different New Product Introduction (NPI) information on the 325D Hydraulic Excavator. This first printing contains information on the EAME Market Gosselies produced 325D only. The 325d will be available in the NACD and APD markets early in 2006.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 48

SERV7105-12

Vol. 12, No. 1

December 2005

TECHNICAL PRESENTATION

325D HYDRAULIC EXCAVATOR

INTRODUCTION

New Product Introduction

(NPI)

GLOBAL SERVICE LEARNING

325D HYDRAULIC EXCAVATOR

INTRODUCTION

AUDIENCE

Service personnel who understand the principles of machine systems operation, diagnostic

equipment, and testing and adjusting procedures.

CONTENT

This presentation provides new and different New Product Introduction (NPI) information on

the 325D Hydraulic Excavator. This presentation may be used for self-paced and self-directed

training. This first printing contains information on the EAME Market Gosselies produced

325D only. The 325D will be available in the NACD and APD markets early in 2006.

OBJECTIVES

After learning the information in this presentation, the technician will be able to:

1. locate and identify the new major components on the 325D Hydraulic Excavator, and

2. explain the operation of the new components in the system.

REFERENCES

NOTE: The references listed below are only for the EAME Market Gosselies produced 325D.

Reference materials for Aurora and Akashi produced 325D machines will be released at a later

date.

325D Hydraulic Excavator Specalog HEHH3290

325D Hydraulic Excavator Specifications Manual RENR7233

325D Hydraulic Excavator Systems Operations Manual RENR7234

325D Hydraulic Excavator Test and Adjust Manual RENR7235

325D Hydraulic Excavator Parts Book SEBP4442

325D Hydraulic Excavator Tool Control Systems Operation RENR7389

Estimated Time: 1 Hour

Visuals: 37

Handouts: 4

Form: SERV7105-12

Date: Vol. 12, No. 1, 2005

2005 Caterpillar Inc.

TABLE OF CONTENTS

INTRODUCTION..................................................................................................................5

Similarities and Differences .............................................................................................6

MACHINE WALK-AROUND...............................................................................................7

OPERATOR'S STATION......................................................................................................13

ENGINE................................................................................................................................24

HYDRAULIC SYSTEM......................................................................................................26

MAINTENANCE ITEMS....................................................................................................40

TOOL CONTROL SYSTEM...............................................................................................41

CONCLUSION.....................................................................................................................43

HYDRAULIC SCHEMATIC COLOR CODE.....................................................................44

HANDOUTS.........................................................................................................................45

POSTTEST...........................................................................................................................46

POSTTEST ANSWER KEY................................................................................................48

SERV7105-12 - 3 - NPI

Vol. 12, No. 1, 2005

NOTES

SERV7105-12 - 4 - NPI

Vol. 12, No. 1, 2005

INTRODUCTION

The 325D is a new model from Caterpillar and is a direct replacement for the 325C Hydraulic

Excavator. The 325D was first introduced in December 2005 to the EAME market. The 325D

operating weight is approximately 29,240 Kg (64,500 lbs) for a long undercarriage machine.

The 325D fits in the 25 metric ton class of excavators. The 325D is a versatile machine

capable of performing a wide range of tasks by using various work tools available.

The presentation discusses the component locations and systems operation of the Gosselies

produced 325D Hydraulic Excavator. Basic engine and machine component locations will be

discussed. The travel system and implement hydraulics will also be covered.

There will be different machine arrangements available in the EAME market, including:

- 325D L (325D excavator with a long, fixed standard width undercarriage)

- 325D LN (325D excavator with a long, fixed narrow width undercarriage)

1

SERV7105-12 - 5 - NPI

Vol. 12, No. 1, 2005

325D HYDRAULIC EXCAVATORS

INTRODUCTION

2005 Caterpillar Inc.

2

Similarities and Differences

The above chart displays the similarities and differences between the 325D and the 325C.

This illustration compares the basic features of the 325D to the previous 325C. The chart

illustrates if the features are different, similar, or the same.

New and improved features include:

- Tier III ACERT engine

- Cab and styling

- Monitoring system

SERV7105-12 - 6 - NPI

Vol. 12, No. 1, 2005

SIMILARITIES AND DIFFERENCES

FEATURES DIFFERENT SIMILAR SAME

X

X

X

X

X

X

X

X

X

X

Machine Appearance

Monitoring System

Maintenance Items

Tool Control Systems

Machine ECM

Travel System

Engine

Operators Station

Implement Hydraulic System

Undercarriage

MACHINE WALKAROUND

- Stick (1)

- Boom (2)

- Operator station (3)

- Access door behind cab (4)

- Engine access cover (5)

- Access door to radiator compartment (6)

- Counterweight (7)

3

SERV7105-12 - 7 - NPI

Vol. 12, No. 1, 2005

1 2

4

6 7 5

3

The compartment behind the operator station includes the following components:

- Machine and Tool Control ECM (1)

- Air conditioning condenser and receiver (2)

- Window washer reservoir (3)

- Master disconnect switch and circuit breakers (4)

- Dual element, radial seal air filter (5)

- Batteries (6)

4

SERV7105-12 - 8 - NPI

Vol. 12, No. 1, 2005

1

2

3

4

6

5

The radiator access compartment is located in front of the counter weight. The door is hinged

on the right and has a locking latch on the left side to keep it closed. This door provides access

to assist in cleaning some of the cooling system components.

- Air to Air After Cooler (ATAAC) (1)

- Fuel pressure sensors (2)

- Hydraulic oil cooler (3)

- Fuel priming pump (4) (will be changed to electric)

- Fuel filter (5)

- Ether start aid solenoid (6)

- Engine coolant overflow bottle (7)

- Fuel water separator (8)

- Radiator (located behind the water separator and coolant overflow bottle) (9)

- Pattern change valve (not shown) located on compartment floor.

5

SERV7105-12 - 9 - NPI

Vol. 12, No. 1, 2005

1

2

4

3

5

6

7

8

9

This illustration shows access to the top of the machine from the right side.

The engine access cover (1) allows access to the engine from the top of the machine.

The machine hydraulic oil reservoir (2) is located between the pump compartment and the

diesel fuel tank on the right side of the machine and is accessed from the top of the machine.

The diesel fuel filler cap (3) is accessed from the top of the machine.

The storage compartment (4) is located in the front of the machine.

The step and hand rail (5) at the right front of the machine can be used for access to the top of

the machine.

6

SERV7105-12 - 10 - NPI

Vol. 12, No. 1, 2005

1

3

5

2

4

The illustration shows the pump compartment on the right side of the machine. The

compartment is accessed from the right side of the machine when the rear access door is open.

Some of the visible components are:

- Quick coupler solenoid valve (1)

- Engine oil SOS port (2)

- Engine oil filter (3)

- Pilot pump (4)

- Medium pressure solenoids (5)

- Medium pressure circuit pump (6)

- Pressure taps for auxiliary tool solenoids (7)

- Pilot filter (8)

- Pilot system SOS port (9)

- Pilot system pressure port (10)

- Pilot system relief valve (11)

7

SERV7105-12 - 11 - NPI

Vol. 12, No. 1, 2005

9

10

11

8

4

6

7

1

2

3

5

Additional visible components are:

- Power shift solenoid and proportional reducing valve (PSPRV) (12)

- Right pump horsepower adjustment (13)

- Right pump swashplate maximum angle adjustment (14)

- Right pump (15)

- Left pump (16)

- Left pump horsepower adjustment (17)

- Left pump swashplate maximum angle adjustment (18)

- Hydraulic system return oil filter (19)

- Case drain filter (20)

8

SERV7105-12 - 12 - NPI

Vol. 12, No. 1, 2005

13

12

14

15

16

20

19

18

17

OPERATOR'S STATION

The 325D contains a newly designed cab and introduces a new operator's station with improved

visibility and operator comfort. For operator comfort the new cab offers a fully adjustable air

suspended seat with side-to-side shock absorption, which provides maximum operator comfort.

The new "D" series monitor provides increased functionality for the operator. Conveniently

placed switches, gauges, information display, and controls improve operator comfort,

awareness, and efficiency. The fuse panel is relocated to the left side of the lunch box compart-

ment behind the operators seat. A 24 volt AM FM radio is standard in the right console.

9

SERV7105-12 - 13 - NPI

Vol. 12, No. 1, 2005

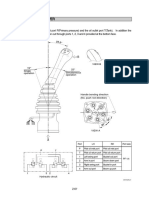

The hydraulic activation lever (1) has been redesigned for the 325D, however, its purpose is

still the same. With the lever in the DOWN position (shown), the hydraulic activation solenoid

is in the de-activated position.

The ground level emergency engine shutoff switch (2) is located on the bottom of the seat

mount. The shutoff switch will shut off the engine without having to climb into the cab. Once

the shutoff switch is turned ON and then OFF, the key start switch must be cycled for the

machine to operate again.

10

SERV7105-12 - 14 - NPI

Vol. 12, No. 1, 2005

1

2

All of the operator functions are incorporated into the right side of the operator's station. They

are:

- Engine speed dial switch (1)

- Key start switch (2)

- Cigar lighter (3)

- Soft switch panel (4)

- Rocker switches (5)

- HVAC controls (6)

- Radio (7)

11

SERV7105-12 - 15 - NPI

Vol. 12, No. 1, 2005

1

2

3

4

5 6

7

The soft switch panel includes switches that either turn a function on/off or allow the operator

to toggle through different modes of the selected function. The soft switches provide the

operator with the following functions:

Two-speed travel (1)

When the button is pushed the travel speed is toggled between low and auto.

- The rabbit indicator indicates auto speed.

- The tortoise indicator indicates low speed.

Automatic Engine Speed Control (AESC) Switch (2)

The AESC function automatically reduces engine speed while there is no hydraulic demand,

which reduces noise and fuel consumption.

- The AESC switch disables and enables the AESC function.

- The first stage AESC reduces the engine speed by 100 rpm after there has been no

hydraulic demand for approximately three seconds.

- The second stage AESC reduces the engine rpm to approximately 1300 rpm after there

has been no hydraulic demand for an additional three seconds.

- The second stage AESC delay times and rpm can be changed using the monitor or

Caterpillar Electronic Technician (Cat ET).

12

SERV7105-12 - 16 - NPI

Vol. 12, No. 1, 2005

1 2 3 4

8 7 6 5

SERV7105-12 - 17 - NPI

Vol. 12, No. 1, 2005

Travel alarm cancel (3)

The travel alarm cancel switch is a momentary two-position switch.

- The travel alarm sounds when travel is detected.

- The travel alarm stops immediately if the travel alarm cancel switch is depressed.

- The travel alarm switch is reset every time the travel pressure switch opens.

Work tool switch (4)

The work tool switch will display the selected work tool on the monitor display. Press the

switch repeatedly to change the selected work tool. When the desired work tool is highlighted

in the monitor display press the "OK" button on the monitor to select the work tool shown.

Work lights (5)

The work lights switch toggles between the different work light combinations.

- Pattern 1 - Chassis work lights and cab work lights.

- Pattern 2 - Chassis work lights, cab work lights, and boom work lights.

Upper window wipers (6)

The wiper switch toggles between the different modes of the wipers.

- Six second delay.

- Three second delay.

- Continuous operation.

- Off.

Upper window washer (7)

The windshield washer fluid switch is an ON/OFF switch.

Heavy lift (8)

The heavy lift mode can be selected to boost lifting capability and provide improved

controlability of heavy loads.

- When heavy lift is turned on, the main relief valve maximum pressure increases from

35,000 MPa (5080 psi) to 36,000 MPa (5225 psi), making it possible to operate at the

high pressure.

- In heavy lift mode, the maximum engine speed is limited to engine speed dial 6

(1510 90 rpm).

- Hydraulic horsepower maximum output is reduced to 60%.

The toggle and rocker switch panel contains switches that control additional functions:

Quick coupler lock control (1)

The quick coupler lock control switch is a spring centered toggle switch.

- The top position locks the quick coupler.

- The bottom position unlocks the quick coupler.

Fine swing control (2)

The fine swing control switch is a two-position rocker switch.

- The top position activates fine swing control. Fine swing control improves the swing

control during swing deceleration.

- The bottom position deactivates fine swing control.

Rear window washer (3)

The rear window washer fluid switch is a two-position rocker switch.

- The top position activates the windshield washer fluid.

- The bottom position deactivates the windshield washer fluid.

13

SERV7105-12 - 18 - NPI

Vol. 12, No. 1, 2005

1 2 3 4

SERV7105-12 - 19 - NPI

Vol. 12, No. 1, 2005

Rear window wiper (4)

The rear window wiper switch is a two-position rocker switch.

- The top position activates the wiper.

- The bottom position deactivates the wiper.

The back-up switches are located behind the right armrest. The right switch (1) controls the

engine rpm. The left switch (2) toggles between back-up and auto.

The left switch activates/deactivates the Back-up Mode. When Back-up Mode is active, a fixed

power shift pressure is provided to the pumps. The fixed power shift pressure limits maximum

pump output and allows the machine to continue operating in a Derate Mode. Machine

productivity will be limited while the machine is in Back-up Mode.

The right switch is used to control the engine speed while Back-up Mode is active. Holding the

right switch in the DOWN position decreases the engine rpm. Holding the right switch in the

UP position increases the engine rpm.

The diagnostic connector (3) is located inside of the operator's station behind the right armrest,

beside the back-up switches.

The HVAC control ECM (4) is also located below the right console.

14

SERV7105-12 - 20 - NPI

Vol. 12, No. 1, 2005

1

2

3

4

The 325D monitor has been updated. The 325D shares this new monitor with the 320D, 323D,

324D, 330D, 345C, 365C, and the 385C machines.

The monitor is a full color Liquid Crystal Display (LCD) that displays the various parameters

of the machine.

- Alert Indicator (1)

- Clock (2)

- Fuel Gauge (3)

- Hydraulic Oil Temperature Gauge (4)

- Engine Speed Dial Indicator (5)

- Engine Coolant Temperature Gauge (6)

- Operating Hours (7)

- Work Tool Indicator (8)

15

SERV7105-12 - 21 - NPI

Vol. 12, No. 1, 2005

1

2

3

4

5

6

7

8

The monitor contains eight buttons that control navigation on the monitor screen. The four

directional button are left (1), up (2), down (3), and right (4). The directional buttons navigate

the cursor through the various screens.

The four navigational buttons are home (5), menu (6), back (7), and OK (8).

16

SERV7105-12 - 22 - NPI

Vol. 12, No. 1, 2005

1

2

3

4

5 6

7 8

The fuse panel for the 325D has been relocated to the left side of the lunch box panel behind

the operator's seat.

17

SERV7105-12 - 23 - NPI

Vol. 12, No. 1, 2005

ENGINE

The 325D is equipped with a C7 ACERT Engine (1). It is rated at 140 kW(188 hp) at

1800 rpm.

Also visible is the engine crankcase breather (2), engine oil dipstick (3), SOS coolant

sampling valve (4), engine oil fill (5), and the inlet air heater (6).

18

SERV7105-12 - 24 - NPI

Vol. 12, No. 1, 2005

1

4

3

6

2

5

The engine cooling fan on the 325D is now mechanically driven off the front of the engine.

19

SERV7105-12 - 25 - NPI

Vol. 12, No. 1, 2005

20

HYDRAULIC SYSTEM

The 325D uses a negative flow type hydraulic system. The main control valve and pumps are

similar to the 325C. The engine cooling fan is now driven off of the engine. The 325D

continues using many of the C excavator features, such as automatic priorities and tool con-

trol systems.

SERV7105-12 - 26 - NPI

Vol. 12, No. 1, 2005

Stick Cylinder

Bucket Cylinder Boom Cylinders

Swing Motor Travel Motors

Pilot

Control

Valves

Priority

Valves

Main

Hydraulic

Pumps

M

Pilot

Pump

Tank

Pilot Manifold

Main Control Valve Group

MAIN HYDRAULIC SYSTEM

The pilot pump (1) is driven off the right hydraulic pump. The pilot pump draws oil from the

main pump suction line. The oil is sent to the pilot filter and then to the pilot system.

The medium pressure pump (2), when installed, is driven off the left hydraulic pump. The

medium pressure pump also draws oil from the main pump suction line.

21

SERV7105-12 - 27 - NPI

Vol. 12, No. 1, 2005

1

2

The 325D pilot manifold is the same as the "C" pilot manifold. The pilot manifold is accessible

by removing the cover plate under the machine, behind the swing bearing. The manifold is

located directly below the main control valve. Pilot manifold components visible are:

- Two-speed travel solenoid (1)

- Swing brake solenoid (2)

- Hydraulic activation valve (3)

- Hydraulic activation solenoid (4)

22

SERV7105-12 - 28 - NPI

Vol. 12, No. 1, 2005

1

2

3

4

23

The main hydraulic system is a negative flow controlled system. The main hydraulic system

supplies hydraulic power at high pressures and high flow rates to perform work. Two main

hydraulic pumps supply oil to the main control valve group. The individual hydraulic circuits

are controlled by valves in the the main control valve group.

The main hydraulic system supplies the following circuits:

- Swing

- Stick

- Travel

- Boom

- Bucket

- Tool control

SERV7105-12 - 29 - NPI

Vol. 12, No. 1, 2005

BL2 AL2

M

Swing Motor

Travel Left Travel Right

Bucket

Cylinder

Boom

Cylinder

Boom

Cylinder

Stick

Cylinder

AR3 BR3 AR4 BR4

AL3 BL3

Stick Swing Boom Bucket

OUT IN RIGHT LEFT OPEN CLOSE DOWN UP

No.1

Travel

No.2

Swing

No.3

Lock

Out In

Stick 2

OUT

Boom 1

UP

Bucket

OPEN

Atch Travel R

FWD

Trv L

FWD

Swing R

Stick 1

OUT Boom 2

BL1 AR1 BR1

Travel Motor Right Travel Motor Left High Pressure Line

Single Single

Double Double

325D HYDRAULIC SCHEMATIC

NEUTRAL

AL1

P

aL1 bR1 aR1 bL1

PU2 aR1 aR2 PL2

P

P

PU2

PL2 bL4 bL3 bL2 bL1

BL3 AL3

aL1

BL1 BL1

AL1

AL1

aL2

BR4 AR4 aR4 BR3

AR1

aR3 aR2 aR1

BR1

AR3

bR1 bR2 bR3 bR4

bL3 bL2 bL4 aL2 aR3 aR4 bR3 bR4

The 325D uses a Caterpillar designed main hydraulic pump group (1) rated at 2 x 235 L/Min

(2 x 65 gpm). The pump group is similar to the pump group used on the 325C.

The right pump (6) is driven by the engine via a flexible coupling. The left pump (9) is driven

directly off the right pump. Each pump rotating group has its own regulator. The regulators are

used to adjust the output flow of the pumps. Each pump rotating group also has its own

pressure tap and pressure sensor.

A power shift PRV (2) is mounted on the top, rear of the right regulator case. The power shift

PRV uses pilot system oil and sends it to the main hydraulic pumps as a control signal pressure.

The power shift pressure is measured at pressure tap (3).

Additional pump and components shown in this photo are:

- Right pump regulator horsepower adjustment (4)

- Right pump regulator swashplate maximum angle adjustment (5)

- Left pump regulator horsepower adjustment (7)

- Left pump regulator swashplate maximum angle adjustment (8)

24

SERV7105-12 - 30 - NPI

Vol. 12, No. 1, 2005

7

9

8

5

4

6

1

2

3

The 325D contains one case drain filter (1) for the pump case drain and the swing and travel

system case drains. The case drain filter is located in the main pump compartment.

The pilot oil filter (4) is also located in the main pump compartment. The pilot oil filter base

contains the pilot system relief valve (2), the hydraulic system SOS test port (3), and the pilot

oil pressure test port (5).

The hydraulic oil level sight gauge (6) is located on the rear of the hydraulic tank and is visible

in the pump compartment. The return hydraulic system oil filter (7) is also located in the pump

compartment.

25

SERV7105-12 - 31 - NPI

Vol. 12, No. 1, 2005

1

5

6

7

4

3

2

The engine oil filter (1) is remotely mounted in the pump compartment for easy serviceability.

The engine oil filter base contains the engine oil SOS port (2).

26

SERV7105-12 - 32 - NPI

Vol. 12, No. 1, 2005

1

2

The main control valve group is located in the center of the upper structure of the machine.

The main control valve group receives pilot oil signals from the operator controls in the cab.

Each pilot signal then causes the appropriate control valve to shift in the correct direction.

When a control valve shifts, oil flows from the main hydraulic pumps to the appropriate

hydraulic cylinder or hydraulic motor to perform work. The 325D main control valve is similar

to the 325C valve. The valves are:

- Stick 2 (1)

- Boom Rod End Relief Valve (2)

- Boom 1 (3)

- Bucket (4)

- Attachment (5)

- Right Travel (6)

- Straight Travel Valve (7)

- Main Relief Valve (8)

- Right Side NFC Relief Valve (9)

27

SERV7105-12 - 33 - NPI

Vol. 12, No. 1, 2005

1 3 5 8

9

7 2

4 6

Additional valves in the main control valve are:

- Left Travel (10)

- Swing (11)

- Stick 1 (12)

- Boom 2 (13)

- Auxiliary Valve for Tool Control (14)

- Left Side NFC Signal Line (15)

28

SERV7105-12 - 34 - NPI

Vol. 12, No. 1, 2005

13 14

15

11 12

10

Two travel pressure switches (not shown) and the swing/implement pressure switch (1), are

located under the cab. The pressure switches are activated by pilot oil. The switches close at

490 49 kPa (71 7 psi) and open at 290 0 kPa (42 0 psi).

The pressure switches are inputs to the Machine and Tool Control ECM. The Machine and

Tool Control ECM uses these inputs to tell when a hydraulic function has been activated and

will turn the Automatic Engine Speed Control (AESC)/one touch low idle back to the current

speed dial setting. When only the swing/implement pressure switch is activated, the Machine

and Tool Control ECM will release the swing brake. When all three pressure switches are

activated, the Machine and Tool Control ECM will energize the straight travel solenoid.

29

SERV7105-12 - 35 - NPI

Vol. 12, No. 1, 2005

1

The 325D has a pilot operated, two stage main relief valve. The relief valve settings are

35000 490 kPa (5080 71 psi) for implement/travel and 36000 490 kPa (5225 71 psi) for

heavy lift mode. The high pressure setting for heavy lift must be correctly adjusted before

adjustments can be made for implement/travel settings. Refer to the Testing and Adjusting

manual RENR7235 for the proper procedure on setting the main relief valve.

30

SERV7105-12 - 36 - NPI

Vol. 12, No. 1, 2005

31

The 325D is available with the heavy lift option. Heavy lift provides a means to have increased

hydraulic pressure available to help complete the task.

Heavy lift is activated by pressing the heavy lift switch (1) on the soft switch panel in the

operators station. The heavy lift switch is an input to the Machine and Tool Control ECM. The

Machine and Tool Control ECM limits engine speed to speed dial 6 and activates the heavy lift

solenoid (2), which directs pilot oil to the main relief valve (3). At the same time the Machine

and Tool Control ECM increases the power shift pressure to decrease the pump output flow.

Decreasing the pump output flow provides increased controlability and hydraulic smoothness

during a heavy lift operation. Heavy lift mode limits the pumps to a maximum of

approximately 60% of the normal hydraulic horsepower.

Heavy Lift Specs:

- Engine rpm for Heavy Lift is the engine speed dial 6 setting.

- Hydraulic horse power is limited to 60% of full power during Heavy Lift.

- Main relief maximum pressure during Heavy Lift is 36000 kPa 490 kPa

(5225 71 psi).

SERV7104-04 - 37 - NPI

03/05

3

2

1

The 325D uses automatic priorities for certain functions based on the position of the joysticks.

The boom priority (1) and the swing priority (2) pressure reducing valves are located behind the

swing bearing on the left side of the machine.

The boom priority PRV provides boom up priority over the stick in function. The swing-

priority PRV provides swing priority over the stick in or stick out function.

32

SERV7105-12 - 38 - NPI

Vol. 12, No. 1, 2005

1 2

The 325D has one swing motor (1) that receives oil from the swing control valve. The swing

control valve receives pump oil from the left pump. The swing drive oil level can be checked

with dipstick (2).

33

SERV7105-12 - 39 - NPI

Vol. 12, No. 1, 2005

1

2

MAINTENANCE ITEMS

Caterpillar Electronic Technician (Cat ET) or the monitoring system can be used for testing and

calibrating the machine.

Extended fluid change intervals are available with the proper SOS procedures.

34

SERV7105-12 - 40 - NPI

Vol. 12, No. 1, 2005

TOOL CONTROL SYSTEM

The tool control system for the 325D is similar in function to the tool control systems for the

320C - 330C medium excavators, although the medium pressure circuit is now a stand-alone

function.

The optional tool control system maximizes work tool productivity by configuring hydraulic

flow, pressure, and operator controls to match a specific work tool. System versatility enables a

wide range of tools to be used.

The 325D is available in the EAME market with the following factory installed Tool Control

systems:

- System 16 - provides two pump flow in a single direction, has a direct return system to

the hydraulic tank, and includes a mechanical line relief valve (LRV) for lower psi tools

(single action).

- System 17 (Multifunction) - provides one or two pump flow in one or two directions

(single action or double action) and has a direct return system to the hydraulic tank.

System 17 has full electronic controls and features an independent medium pressure

circuit used for such applications as a rotating shear or ditch cleaning bucket.

35

SERV7105-12 - 41 - NPI

Vol. 12, No. 1, 2005

SERV7105-12 - 42 - NPI

Vol. 12, No. 1, 2005

The 325D will be available in the NACD and APD markets early in 2006. The 325D's pro-

duced in Akashi and Aurora can be equipped with the following factory installed Tool Control

systems:

- System 3 (Hammer) - provides two pump flow in a single direction only. This system

also includes a mechanical LRV for lower psi tools (single action).

- System 5/15 (Thumb) - provides one pump flow in both directions (extend/retract double

action) and can be controlled with a foot pedal (system 5) or with joystick buttons (sys-

tem 15).

- System 14 (Multifunction) - provides one or two pump flow in one or two directions

(single action or double action). System 14 has full electronic controls and features an

independent medium pressure circuit used for such applications as a rotating shear or

ditch cleaning bucket.

CONCLUSION

This presentation has provided New Product Introduction (NPI) information for the Caterpillar

325D Hydraulic Excavator. The new components and their locations were identified and

discussed. The information in this NPI document pertains to the 325D Hydraulic Excavators

that will first be produced in Gosselies for the EAME market. This document will be updated

as the Akashi and Aurora produced machines near their first ship dates.

Refer to the latest service literature for more information and specifications.

36

SERV7105-12 - 43 - NPI

Vol. 12, No. 1, 2005

37

HYDRAULIC SCHEMATIC COLOR CODES

The colors on the hydraulic schematics and cross-sectional views shown throughout this

presentation denote specific meanings. This illustration identifies the meaning of each color.

SERV7105-12 - 44 - NPI

Vol. 12, No. 1, 2005

Red - High Pressure Oil

Red / White Stripes - 1st Pressure Reduction

Pink - 3rd Reduction in Pressure

Red / Pink Stripes - Secondary Source Oil Pressure

Orange - Pilot, Charge or Torque Converter Oil

Blue - Trapped Oil

Brown - Lubricating Oil

Cat Yellow - (Restricted Usage)

Green / White Stripes -

Scavenge / Suction Oil or Hydraulic Void

Identification of Components

within a Moving Group

Black - Mechanical Connection. Seal

Dark Gray - Cutaway Section

Light Gray - Surface Color

White - Atmosphere or Air (No Pressure)

Purple - Pneumatic Pressure

Yellow - Moving or Activated Components

Orange / Crosshatch - 2nd Reduction in Pilot,

Charge, or TC Oil Pressure

Orange / White Stripes - Reduced Pilot, Charge, or

TC Oil Pressure

Red Crosshatch - 2nd Reduction in Pressure

Green - Tank, Sump, or Return Oil

HYDRAULIC SCHEMATIC COLOR CODE

SERV7105-12 - 45 - NPI

Vol. 12, No. 1, 2005 Handout No. 1

R

e

d

-

H

i

g

h

P

r

e

s

s

u

r

e

O

i

l

R

e

d

/

W

h

i

t

e

S

t

r

i

p

e

s

-

1

s

t

P

r

e

s

s

u

r

e

R

e

d

u

c

t

i

o

n

P

i

n

k

-

3

r

d

R

e

d

u

c

t

i

o

n

i

n

P

r

e

s

s

u

r

e

R

e

d

/

P

i

n

k

S

t

r

i

p

e

s

-

S

e

c

o

n

d

a

r

y

S

o

u

r

c

e

O

i

l

P

r

e

s

s

u

r

e

O

r

a

n

g

e

-

P

i

l

o

t

,

C

h

a

r

g

e

o

r

T

o

r

q

u

e

C

o

n

v

e

r

t

e

r

O

i

l

B

l

u

e

-

T

r

a

p

p

e

d

O

i

l

B

r

o

w

n

-

L

u

b

r

i

c

a

t

i

n

g

O

i

l

C

a

t

Y

e

l

l

o

w

-

(

R

e

s

t

r

i

c

t

e

d

U

s

a

g

e

)

G

r

e

e

n

/

W

h

i

t

e

S

t

r

i

p

e

s

-

S

c

a

v

e

n

g

e

/

S

u

c

t

i

o

n

O

i

l

o

r

H

y

d

r

a

u

l

i

c

V

o

i

d

I

d

e

n

t

i

f

i

c

a

t

i

o

n

o

f

C

o

m

p

o

n

e

n

t

s

w

i

t

h

i

n

a

M

o

v

i

n

g

G

r

o

u

p

B

l

a

c

k

-

M

e

c

h

a

n

i

c

a

l

C

o

n

n

e

c

t

i

o

n

.

S

e

a

l

D

a

r

k

G

r

a

y

-

C

u

t

a

w

a

y

S

e

c

t

i

o

n

L

i

g

h

t

G

r

a

y

-

S

u

r

f

a

c

e

C

o

l

o

r

W

h

i

t

e

-

A

t

m

o

s

p

h

e

r

e

o

r

A

i

r

(

N

o

P

r

e

s

s

u

r

e

)

P

u

r

p

l

e

-

P

n

e

u

m

a

t

i

c

P

r

e

s

s

u

r

e

Y

e

l

l

o

w

-

M

o

v

i

n

g

o

r

A

c

t

i

v

a

t

e

d

C

o

m

p

o

n

e

n

t

s

O

r

a

n

g

e

/

C

r

o

s

s

h

a

t

c

h

-

2

n

d

R

e

d

u

c

t

i

o

n

i

n

P

i

l

o

t

,

C

h

a

r

g

e

,

o

r

T

C

O

i

l

P

r

e

s

s

u

r

e

O

r

a

n

g

e

/

W

h

i

t

e

S

t

r

i

p

e

s

-

R

e

d

u

c

e

d

P

i

l

o

t

,

C

h

a

r

g

e

,

o

r

T

C

O

i

l

P

r

e

s

s

u

r

e

R

e

d

C

r

o

s

s

h

a

t

c

h

-

2

n

d

R

e

d

u

c

t

i

o

n

i

n

P

r

e

s

s

u

r

e

G

r

e

e

n

-

T

a

n

k

,

S

u

m

p

,

o

r

R

e

t

u

r

n

O

i

l

H

Y

D

R

A

U

L

I

C

S

C

H

E

M

A

T

I

C

C

O

L

O

R

C

O

D

E

SERV7105-12 - 46 - NPI

Vol. 12, No. 1, 2005 Handout No. 2

Posttest

Directions: Circle the correct letter indicating the best answer for each question.

1. Which of the following features on the 325D is the same as it was on the 325C?

A. Engine

B. Operator's station

C. Undercarriage

D. Monitoring system

2. What will cause the monitoring system master condition lamp to blink ON and OFF?

A. High hydraulic oil temperature

B. Low engine oil pressure

C. High coolant temperature

D. Low hydraulic system oil level

3. Which Tool Control system is not available on the Gosselies produced 325D?

A. Medium pressure circuit

B. System 15

C. System 16

D. System 17

4. The service tool diagnostic connector is relocated on the 325D to the:

A. radiator compartment

B. air cleaner/battery compartment

C. in the cab behind the operator's seat

D. in the cab in the right console

5. What information is shown in the lower display window on the monitor?

A. Tool control currently selected

B. Engine rpm

C. Service meter hours

D. Hydraulic oil pressure

6. Which component is no longer located in the radiator compartment?

A. Hydraulic oil cooler

B. Machine and Tool Control ECM

C. Fuel filter

D. Fuel pressure sensors

SERV7105-12 - 47 - NPI

Vol. 12, No. 1, 2005 Handout No. 3

Posttest (continued)

7. Which function is not prioritized by the priority pressure reducing valves?

A. Boom up

B. Stick in

C. Boom down

D. Stick out

8. The boom and swing priority pressure reducing valves are located:

A. Beneath the operator platform below the seat

B. Behind the swing bearing on the right side

C. Behind the swing bearing on the left side

D. Beneath the operator platform below the foot pedals

9. The Auxiliary valve for the Tool Control is located on the left end of the main control

valve.

A. True

B. False

10. The main implement pumps on the 325D are rated at:

A. 2 X 230 L/min

B. 2 X 235 L/min

C. 2 X 240 L/min

D. 2 X 245 L/min

SERV7105-12 - 48 - NPI

Vol. 12, No. 1, 2005 Handout No. 4

Posttest Answer Key

1. C

2. D

3. B

4. D

5. A

6. B

7. C

8. C

9. A

10. B

You might also like

- Serv1852 02 TXT8Document52 pagesServ1852 02 TXT8ابو احمد100% (8)

- Tractor D7R Schematic Sstem HydraulicDocument11 pagesTractor D7R Schematic Sstem HydraulicGerald Gutierrez100% (1)

- ServDocument74 pagesServDANIEL VARGAS RODRIGUEZ100% (6)

- System OperationDocument82 pagesSystem OperationAntonio MejicanosNo ratings yet

- Serv 1813Document198 pagesServ 1813DANIEL VARGAS RODRIGUEZ83% (6)

- 770 & 772 PDFDocument235 pages770 & 772 PDFMárioJácome100% (3)

- Sistema de Traslado - TextoDocument32 pagesSistema de Traslado - Textolalo11715100% (2)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- Load SensingDocument27 pagesLoad SensingRobert Gordon100% (6)

- 330C Hyd Sys-OpDocument164 pages330C Hyd Sys-OpTaz Juan G96% (28)

- Global Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesDocument23 pagesGlobal Service Learning: 300D Series Hydraulic Excavators - Tier Iii Enginesazry_alqadry100% (3)

- DiavelDocument831 pagesDiavelManuel Martinez CarranzaNo ratings yet

- CAT 345 B AGS 01 Up Hydraulic SchematicDocument7 pagesCAT 345 B AGS 01 Up Hydraulic SchematicGanapati Hegde100% (6)

- Main Pump (Flow) - Test - Constant Horsepower Flow Control: Cerrar SIS Pantalla AnteriorDocument38 pagesMain Pump (Flow) - Test - Constant Horsepower Flow Control: Cerrar SIS Pantalla AnteriorClemente Flores100% (1)

- 327437028 จูน 320b 330b PDFDocument10 pages327437028 จูน 320b 330b PDFhamda100% (2)

- Load Sensing/Pressure Compensated Hydraulics (LS/PC)Document15 pagesLoad Sensing/Pressure Compensated Hydraulics (LS/PC)Victor AcuñaNo ratings yet

- Load Sensing/Pressure Compensated Hydraulics (LS/PC)Document15 pagesLoad Sensing/Pressure Compensated Hydraulics (LS/PC)Victor AcuñaNo ratings yet

- Load Sensing/Pressure Compensated Hydraulics (LS/PC)Document15 pagesLoad Sensing/Pressure Compensated Hydraulics (LS/PC)Victor AcuñaNo ratings yet

- Load Sensing/Pressure Compensated Hydraulics (LS/PC)Document15 pagesLoad Sensing/Pressure Compensated Hydraulics (LS/PC)Victor AcuñaNo ratings yet

- Plumbing Pipe and Fitting SymbolsDocument8 pagesPlumbing Pipe and Fitting Symbolsburhansucipto0% (1)

- Pump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDocument2 pagesPump GP - Main Hydraulic: 325D and 329D Excavator Hydraulic System - AttachmentDennis OlayaNo ratings yet

- Global Service LearningDocument63 pagesGlobal Service LearningEslamAldenAbdo100% (4)

- Curso Cat 966h-972h STMGDocument63 pagesCurso Cat 966h-972h STMGSilas F Pimenta92% (12)

- Global Service Learning: 950H Wheel Loader, 962H Wheel Loader, and It62H Integrated ToolcarrierDocument63 pagesGlobal Service Learning: 950H Wheel Loader, 962H Wheel Loader, and It62H Integrated Toolcarriergildercarrascal100% (2)

- Braden WinchesDocument32 pagesBraden Winchescacalot93No ratings yet

- Static and Dynamic Balancing of Rigid RotorsDocument20 pagesStatic and Dynamic Balancing of Rigid RotorsTeng Soon Chye100% (1)

- 345 Calibracion PRVDocument5 pages345 Calibracion PRVJordan Ravelo100% (1)

- 9com No PDFDocument2 pages9com No PDFbalajiNo ratings yet

- SERV1852 - TXT1.Introducción 330DDocument47 pagesSERV1852 - TXT1.Introducción 330DDiego Alonso Huaraca BalerianoNo ratings yet

- 924f Wheel Loader 5nn00001-Up (Machine) Powered by 3114 Engine (Sebp2341 - 49) - DocumentationDocument49 pages924f Wheel Loader 5nn00001-Up (Machine) Powered by 3114 Engine (Sebp2341 - 49) - Documentationjulio cesar100% (2)

- Brake System - D8R/TDocument10 pagesBrake System - D8R/Tardan fadilahNo ratings yet

- Uenr3219uenr3219 SisDocument2 pagesUenr3219uenr3219 Sisابو احمد100% (5)

- Serv1852 02 TXT2 PDFDocument24 pagesServ1852 02 TXT2 PDFابو احمد100% (13)

- 330D System Operation Hydraulic RENR9584Document263 pages330D System Operation Hydraulic RENR9584Jorge Zamora91% (11)

- 966g - II Renr4398-02 Hyd SchemDocument2 pages966g - II Renr4398-02 Hyd SchemEnergy Sun Biocar100% (4)

- Serv7107 V05N01 TXT7Document32 pagesServ7107 V05N01 TXT7azry_alqadry100% (6)

- 777F - Serv1828 - TXTDocument272 pages777F - Serv1828 - TXTalexander_198575% (4)

- Uenr3241uenr3241-00 SisDocument4 pagesUenr3241uenr3241-00 SisYvan Vidal Calapuja Machaca100% (2)

- D6NDocument47 pagesD6NRodrigo Ricardo Véliz Meza100% (3)

- Plano Hidraulico 980HDocument20 pagesPlano Hidraulico 980HEver Luis Toledo Chanca100% (1)

- Transmission Hydraulic SystemDocument3 pagesTransmission Hydraulic Systemcristian chuquicondor torres100% (1)

- Cargador Cat 950 PDFDocument35 pagesCargador Cat 950 PDFjorge soto a.100% (1)

- 980F Wheel Loader 8CJ00001-UP (MACHINE) POWERED by 3406 Engine1212 - 57) - Systems & ComponentsDocument38 pages980F Wheel Loader 8CJ00001-UP (MACHINE) POWERED by 3406 Engine1212 - 57) - Systems & ComponentsTransportation MaintananceNo ratings yet

- 330D Hyd Schematic RENR9980Document2 pages330D Hyd Schematic RENR9980Energy Sun Biocar100% (5)

- Excavadora CatDocument8 pagesExcavadora CatDammiam Gatica100% (2)

- CrossoverDocument6 pagesCrossoverRendy Pratama100% (3)

- Service Training Malaga 320D/325D Hydraulic Excavators: Pump & Pump ControlsDocument13 pagesService Training Malaga 320D/325D Hydraulic Excavators: Pump & Pump Controlsمحمد يونس100% (1)

- Diagrama Hidraulico m315d Renr9476renr9476-04 SisDocument2 pagesDiagrama Hidraulico m315d Renr9476renr9476-04 SisServimaquinaria Millan S.A.C100% (1)

- VMS 1Document121 pagesVMS 1Subash ChandraboseNo ratings yet

- Global Service Learning: M325D MH / M325D L MH Material HandlersDocument52 pagesGlobal Service Learning: M325D MH / M325D L MH Material Handlersanon_828943220100% (2)

- D PWT D6riii PDFDocument2 pagesD PWT D6riii PDFDennis Olaya100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document24 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Eckard GuendelNo ratings yet

- III-2 Rolls-Royce Boegschroef Timca Manual + Scedules T9255-56 Rev A PDFDocument117 pagesIII-2 Rolls-Royce Boegschroef Timca Manual + Scedules T9255-56 Rev A PDFMischa CHO100% (1)

- maquinariaV9N1 TXT PDFDocument85 pagesmaquinariaV9N1 TXT PDFcematp0% (1)

- 966h Systems OperationDocument8 pages966h Systems OperationSele CasMa ヅ100% (4)

- d10 T InglesDocument106 pagesd10 T InglesDiego PizarroNo ratings yet

- 3TNV88 NHBDocument29 pages3TNV88 NHBPablo Burgos100% (1)

- Electrical Component LocationDocument5 pagesElectrical Component LocationNova kurniawan 34No ratings yet

- Load Sensing2Document6 pagesLoad Sensing2Victor Acuña0% (1)

- Load Sensing2Document6 pagesLoad Sensing2Victor Acuña0% (1)

- Load Sensing2Document6 pagesLoad Sensing2Victor Acuña0% (1)

- Load Sensing2Document6 pagesLoad Sensing2Victor Acuña0% (1)

- LSPC 3PCDocument16 pagesLSPC 3PCVictor Acuña100% (3)

- LSPC 3PCDocument16 pagesLSPC 3PCVictor Acuña100% (3)

- LSPC 3PCDocument16 pagesLSPC 3PCVictor Acuña100% (3)

- LSPC 3PCDocument16 pagesLSPC 3PCVictor Acuña100% (3)

- 01 IntroducDocument7 pages01 IntroducKevine KhaledNo ratings yet

- PPPC Hyd Sys SLDDocument68 pagesPPPC Hyd Sys SLDKarim Abouhiga100% (2)

- PPPC Hyd Sys SLDDocument68 pagesPPPC Hyd Sys SLDKarim Abouhiga100% (2)

- Meeting Guide d10tDocument106 pagesMeeting Guide d10tAlcanfred Cte Bto100% (5)

- Piping Legend Valve Legend Abbreviations General General NotesDocument50 pagesPiping Legend Valve Legend Abbreviations General General NotesnitinNo ratings yet

- 330D - Technical NPIDocument51 pages330D - Technical NPIVictor Acuña100% (7)

- 49 Apu PDFDocument68 pages49 Apu PDFAaron Harvey50% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document9 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Elie AbisaadNo ratings yet

- 374F Excavator Hydraulic System, 349-1966-07Document2 pages374F Excavator Hydraulic System, 349-1966-07Mayumi Lizarme Buezo100% (1)

- En - 1676 - Hydraulic Systems For Truck TractorsDocument4 pagesEn - 1676 - Hydraulic Systems For Truck TractorsAli ShdiefatNo ratings yet

- 785d HydraulicDocument2 pages785d HydraulicSainbayr SainaaNo ratings yet

- Testing and Adjusting Hydraulic PressureDocument6 pagesTesting and Adjusting Hydraulic Pressuremink4u100% (2)

- 320D Forest Machine Hydraulic System - AttachmentDocument2 pages320D Forest Machine Hydraulic System - AttachmentdkjiofcdcdkxxkzlxzxzNo ratings yet

- 320B 322B and 325B Excavators Maintenance Intervals PDFDocument79 pages320B 322B and 325B Excavators Maintenance Intervals PDFAnonymous L0MgezUGBK100% (2)

- Https Sisred - Venequip.com Sisweb Sisweb Techdoc Techdoc Print - PDF 2Document25 pagesHttps Sisred - Venequip.com Sisweb Sisweb Techdoc Techdoc Print - PDF 2Jose Corcega britoNo ratings yet

- HyperMotard - 1100 1100S 2008-09 OptDocument741 pagesHyperMotard - 1100 1100S 2008-09 OptManuel Octavio Sanchez GalindoNo ratings yet

- Hydraulic Fan SystemDocument4 pagesHydraulic Fan SystemEVER DAVID SAAVEDRA HUAYHUA100% (1)

- 966H Fan SystemDocument3 pages966H Fan SystemSaidou COULIBALYNo ratings yet

- 08 User Manual Eng - Com PDFDocument36 pages08 User Manual Eng - Com PDFVictor AcuñaNo ratings yet

- Piston Pump: Systems Operation - FundamentalsDocument6 pagesPiston Pump: Systems Operation - FundamentalsVictor AcuñaNo ratings yet

- Vane Pump: Systems Operation - FundamentalsDocument7 pagesVane Pump: Systems Operation - FundamentalsVictor AcuñaNo ratings yet

- Vane Pump: Systems Operation - FundamentalsDocument7 pagesVane Pump: Systems Operation - FundamentalsVictor AcuñaNo ratings yet

- Piston Pump: Systems Operation - FundamentalsDocument6 pagesPiston Pump: Systems Operation - FundamentalsVictor AcuñaNo ratings yet

- RT-258 - A1 - Inspection and Overhaul in - CleanedDocument13 pagesRT-258 - A1 - Inspection and Overhaul in - CleanedFaye BachtisNo ratings yet

- Acessórios Cloro Gás - VaccupermDocument28 pagesAcessórios Cloro Gás - Vaccupermbalzac1910% (1)

- Safety Valves For Industrial ApplicationDocument164 pagesSafety Valves For Industrial ApplicationJOHNNo ratings yet

- rp6378 MTDocument14 pagesrp6378 MTMessi EmetievNo ratings yet

- PH 1600 Series Data Sheet en 126926Document4 pagesPH 1600 Series Data Sheet en 126926detroja tusharNo ratings yet

- Ac20 135 PDFDocument18 pagesAc20 135 PDFJawariNo ratings yet

- Akshay Pawar CV2Document3 pagesAkshay Pawar CV2Akshay pawarNo ratings yet

- Datos Bomba Jockey - AccesoriosDocument12 pagesDatos Bomba Jockey - AccesoriosCarol ParedesNo ratings yet

- LS V05s Datasheet Rev20140131 1Document2 pagesLS V05s Datasheet Rev20140131 1Pieter BartlemaNo ratings yet

- DrillingDocument50 pagesDrillingMM pHiveNo ratings yet

- Wall Hung and Floor Standing Condensing Boilers Up To 280 KWDocument12 pagesWall Hung and Floor Standing Condensing Boilers Up To 280 KWJosé MacedoNo ratings yet

- Group 5 RCV Lever: 1. StructureDocument7 pagesGroup 5 RCV Lever: 1. StructureSergey MovchanNo ratings yet

- OWDDocument48 pagesOWDMạnh Ngô ĐứcNo ratings yet

- RLS 70-100-130 - eDocument28 pagesRLS 70-100-130 - eJosep Alexander Gutierrez ReyesNo ratings yet

- Manual Ingles Secadores Hhe HHL Hhs SeriesDocument68 pagesManual Ingles Secadores Hhe HHL Hhs SeriesHoney18180% (1)

- Belize E180Document15 pagesBelize E180FloraliaNo ratings yet

- Algas SDI ZIMMER Brochure InternationalDocument4 pagesAlgas SDI ZIMMER Brochure InternationalTECKNIPETROL 001No ratings yet

- He Thong Chua Chay FoamDocument27 pagesHe Thong Chua Chay FoamVũ Hằng PhươngNo ratings yet

- Compabloc 207-235Document248 pagesCompabloc 207-235Anie EkpenyongNo ratings yet

- 14-ApGreid - Line Sizing Rev.2Document18 pages14-ApGreid - Line Sizing Rev.2Dhanny MiharjaNo ratings yet

- CCPPDocument173 pagesCCPPscribdhas2006No ratings yet