Professional Documents

Culture Documents

Guidelines For Preservation of Stores

Uploaded by

Anonymous rYZyQQot55Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guidelines For Preservation of Stores

Uploaded by

Anonymous rYZyQQot55Copyright:

Available Formats

COAST GUARD LOGISTICS

PRESERVATION OF STORES

GUIDELINES FOR PRESERVATION

OF STORES

GUIDELINES FOR PRESERVATION

OF STORES

GUIDELINES FOR PRESERVATION OF STORES

0101. The main objective of store depots is to provide the stores to the demanding units at

the earliest and to maintain a healthy inventory at all times to meet the requirements of the

demanding units. The machinery stores form an important part in the inventory of store

depots and it is imperative that the same are stowed in such a way at the store depots that

their properties and shape remains intact without any variations. In order to safeguard

against deterioration, the attention needs to be paid for proper practices of preservation of

stores items.

0102. The damage caused in storage, transshipment or because of environmental action on

the material and its properties, leading to material change and making it less capable of

performing designed functions is called deterioration.

0103. Different environmental conditions may produce stress which could cause

deterioration in the designed functions. The factors could be physical, chemical and

biological or conditions governing interplay of these leading to variation in properties of the

stores/materials. These can be the divided into following two groups.

(a) Natural environment such as gravity, climatic conditions, dust, moisture,

biological attack etc.

(b) Environment generated by acceleration, shock, compression, vibration, chemical

and industrial pollution, electromagnetic interference, static electricity, acoustics

etc.

Tropical Climate

0104. It is a combination of fairly high relative humidity with prolonged and sustained high

temperature and high saline content of the atmosphere, which provides conditions conducive

for corrosion. Prevailing temperature and humidity are also conducive for the growth of

micro-organisms and insects.

Factors Responsible for Deterioration

0105. The factors which are responsible for the deterioration of stores are classified as

physical, chemical and biological.

(a) Physical factors. Sunlight, heat, dust, grime and similar agents responsible

for deterioration are grouped under the term Physical factors.

(b) Chemical factors. Moisture and water, salts, acids, alkaloid vapors and gases

and such other substances are categorized as Chemical factors.

1

(c) Biological factors. The Biological factors include rodents, insects, microbes

and other living forms.

0106. The independent agents may not act simultaneously or all the agents may also affect

the stored items at the same time. The sequence of action from the agents responsible for

deterioration may have a very important effect on the material and stores.

Preventive Measures & Ideal Storage Conditions

0107. Protection of stores and equipment from deterioration is mandatory to provide

reliability of the stores for the end user. This can be achieved by preventive and prophylactic

measures. The former is achieved by modifying storage to avoid conditions conducive to

deterioration due to inherent characteristics of stores as well as different agencies. The latter

are preventive treatments to avoid or deter the deteriorating agencies or modify

characteristics of stores. These preventive treatments may be in built i.e. provided during

manufacture by way of design and construction materials or treatment given after

manufacture.

Items Needing Preservation

0108. Items requiring deliberate preservation should be identified in each store depot and

the record of same along with their location is also required to be maintained.

0109. Preservation can be broadly classified into two parts:-

(a) External Preservation.

(b) Internal Preservation.

(a) External Preservation. The external preservation is required to protect stores

against environmental condition such as heat, moisture and dust. The following

guidelines are to be followed for external preservation:

(i) Items should be kept in its original packing, except where the original

packing is poor or deteriorated. In the latter case the packing must be

completely replaced with new packing.

(ii) Items should not be stored in the open as far as possible. Where it is

unavoidable, dunnage and waterproof covering must be used, where

necessary.

(iii) Items requiring AC or dehumidified storage should be identified and kept

in such spaces.

(iv) Store depots must be kept absolutely dust free.

2

(v) For protection of stores against moisture, silica gel should be used,

where necessary.

(vi) Metal items should be painted or greased in order to prevent corrosion

and stowed in a location to avoid moisture.

(vii) Chalk powder should be applied to rubber items in order to prevent them

from cracking and to keeping them soft.

0110. In the case of items such as untreated steel plates, propellers and propeller shafts,

external preservation work may be contracted out till the in-house expertise is achieved.

0111. Preservation through hermetic sealing may be contracted out to local trade if

required or achieved as in-house capability.

0112. Internal Preservation. Internal Preservation is applicable to various types of

engines, prime mover, motors, generators, dynamos and such equipment which are required

to be operated periodically. The boxes in which such items are stored should give a

preservation schedule and record must be affixed to them. Details and location of items

requiring internal preservation should remain available with the staff of Store depot.

Responsibility of Store Depots

0113. The Officer-in- charge store depot is responsible for preservation of stores under his

charge. The Oi/Cs of the store depots are responsible for the preparation of a comprehensive

annual preservation plan and ensure that it is carried out regularly and effectively.

0114. A store depot must provide a very clean and healthy environment which is essential

for both preservation of stock as well as for achieving conducive working conditions for the

staff. In order to achieve the required level of cleanliness, the following are required:-

There should be a clearly designated work area where all work such as

un-packing and preservation can be done.

The floor should be in a good physical condition and washed periodically.

The vacuum cleaners must be used to keep the racks and the floor free of dust.

Opening of storehouses must be controlled to minimize the ingress of dust into

the store houses.

0115. Vacuum cleaning of racks and floors has to be done regularly in order to remove the

accumulated dust. The dust control may also require doors and windows to be kept closed

with air conditioning system to bring in filtered air.

3

0116. Tidy working environment in storehouses has a direct bearing on productivity. It can

be encouraged by keeping the work area clearly demarcated from the storage area. Proper

arrangement of racks and sufficient illumination also play important role in the tidiness.

Ventilation and Dust Control

0117. In general the items/stores available at the Coast Guard Store Depots are susceptible

to dust and proper care is required to be undertaken against accumulation of dust. Through

cleaning of the stores and surrounding areas with vacuum cleaner is required on regular

basis. The items such as signaling projectors, starters, Distribution boards, routine

maintenance kits sea water pumps, radar wave guides, communication and navigation

equipment and their spares, seals etc are very sensitive to the dust particles and the area

where these items are stored must be cleaned thoroughly.

0118. Ventilation through doors and windows also brings with it dust into the storehouse. It is

therefore advisable for storehouses to be provided with dust free ventilation through intake

and exhaust fans. Intake fans should be fitted with filters to remove dust.

General Principles of storage

0119. The general principles of storage are as follows:-

Dunnage. Dunnage prevents moisture from the ground or floor reaching the

stores and allows proper ventilation beneath a stack. It also facilitates ventilation

within the stack, apart from enabling cleaning beneath the stack. It also provides

firm and stable base for the stores and in specific cases prevents termites from

attacking stores.

Store Hygiene. In order to maintain the store hygiene the following must be

observed:-

- Cleanliness.

- Proper ventilation to keep the stores and store rooms dry and prevention of

heat accumulation.

- Segregation of infested stores and disinfestations of store houses.

Prophylactic Measures. These consist of regular spraying and fumigation of store

houses with insecticides and fumigants in case the store is susceptible to

infestation.

Sequence of issue. The stores received first must be issued first in order to avoid

accumulation of old stores.

4

Periodical Inspection. In order to detect deterioration, stores should be

periodically examined and immediate action must be initiated to treat the stores

if ant deterioration is detected.

Fire Fighting Systems. It is very important for the safety of the stores at the

store depots that a fire fighting system automatic or manual must be available

with adequate fire points at key locations. The places where use of water may

cause corrosion of stores and equipment, suitable fire extinguishing system

should be installed.

Specialized Storage

0120. The following are the different types of specialized storage:-

Air conditioned storage.

Dehumidified storage.

Long item storage.

Cable drum storage.

Extra heavy item/outdoor storage.

Flammable storage.

Hazardous storage.

Air Conditioned Storage

0121. The requirements of low temperature vary from item to item. However, taking into

account the range of items requiring air conditioned storage and the costs involved, the

following minimum conditions may be achieved for air conditioned storage:-

Temperature not to exceed 22

0

C.

Relative humidity not to exceed 50%.

0122. The air conditioned storage is very expensive and results in 200% to 400% extra

storage costs. It is therefore vital that both horizontal and vertical dimensions in AC storage

are exploited to the maximum and items should be stored right up to the ceiling.

0123. Insulation is extremely important in AC storage. The windows should also be

appropriately insulated.

0124. The heat emissions inside AC store rooms are primarily from light and people.

Low heat emitting and covered lamps should be fitted and lights should be switched on

only in the required areas and the personnel without specific work should not be allowed

inside the AC store. The maintenance contracts may also be executed to maintain the

air conditioners in operational conditions and to ensure minimum down time.

5

Dehumidified Storage

0125. Dunnage prevents moisture from ground or floor reaching to the stores and allows

proper ventilation beneath the stack. It not only facilitates ventilation within the stack, but also

enables proper cleaning underneath the stack and in specific cases prevents termites from

attacking the stores. Humidity in most of the coastal states ranges from 80% to 90%

throughout the year. The specific items viz. PCB, gaskets, rubber products and other special

items are required to be stored at places with which are less humid.

0126. Dehumidification in storage is achieved by:-

Airtight packing.

Vacuum sealing of packing.

Dehumidified storage space.

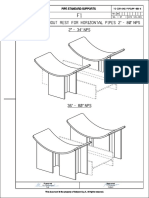

Long Items

0127. Long items cannot be placed on the racks and are invariably left on the floor in

outdoors and in open spaces. To store these items efficiently, cantilever supports are

required. Cantilever racks can be fixed on to the walls. The cantilever supports will save the

long items for directly coming in contact with water.

Cable Storage

0128. Cables are required to be stored after winding over the drums and issue should be

made after un-reeling the cable and cutting off the required length.

Flammable Stores

0129. Flammable stores are those stores that are highly combustible. Flammable stores

include oils, greases and paints. These stores should be stored in a separate store where the

following is provided:-

Automatic fire warning system.

Additional firefighting equipment in the vicinity.

Automatic fire fighting system if possible.

Extra Heavy Item /Outdoor Storage

0130. The items that cannot be stored indoors for reasons of weight or bulk may be

stored outdoors. The only stores that can be stored outdoors are the exceptionally

heavy items viz. anchors, chain cables, shafts and propellers.

6

0131. The items stored outdoor must be stored on specially made hard stands which

should meet the following standards:-

It must be at least 50 cm clear above the surrounding land and should not

get flooded during rains.

The hard stand must have an even surface with adequate slope so that

the rain water falling on it should not stagnate and must run off quickly.

The hard stand must be large enough for items to be stored in a manner

so as they can be inspected at regular intervals.

It should be possible for a mobile crane to get on the hard stand to place

or remove items.

Greasing/ Oiling and Preservative Coating

0132. There are a large number of metal items which require greasing and oiling to

preserve them form corrosion. After the greasing or oiling, the item should be put into

the preservation packing. Items such as chain cables require preservation coatings to

be applied periodically.

Use of Chalk

0133. The rubberized items such as the Gemini boats, rain coats are required to be

stored in the Air conditioned storage. Such material are generally kept in soft condition

and prevented from cracking by application of the chalk powder.

0134. The items requiring special preservation care normally arrive in a preserved

condition and in appropriate packing. While taking such items on charge, special care is

to be taken and it is important that:-

The sealed packages are not opened without the approval of the Officer in

Charge of the store depot.

On occasions where the package is opened, it is again packed back

carefully so that its original preserved state is restored.

Special Stowage and Preservation of Stores

0135. Special care is to be taken for certain items and stores. The method for

preservation and storage of certain important items/store which require special stowage

arrangements and preservation is enumerated in the succeeding Articles.

Acid

0136. Acids are dangerous and should not be kept near any stores of an inflammable

nature, nor where they, or the fumes from them, may cause damage to other stores.

7

Violent reaction may occur if acids come into contact with metals or water. The

containers should be clearly marked with the full description of the contents. Acids are

highly corrosive when concentrated and needs to be handled with care to prevent harm

or injury. Specific safety precautions need to be taken when handling, transporting and

storing acids and medical help should be immediately made available if accidental

contact occurs.

Handling. It is advisable that chemical-resistant apron, chemical-

resistant gloves and chemical splash goggles should be worn at all times

when handling acid to protect eyes and skin. Concentrated acid is toxic if

inhaled, so avoid breathing it in and always handle it while under a fume

hood.

Transportation. Unbreakable bottle carriers or PVC-coated bottles

while transporting acid should be used. It is advisable to check for cracks

on the acid bottle before picking it up or touching it. Look for spilled acid

on the handle before touching the bottle. Small amounts of acid can be

flushed down with large quantities of water.

Storage. Acids should be stored in a dedicated wooden cabinet.

Wooden cabinets are better than metal cabinets for storing acids because

metal corrodes easily from acid fumes. Always keep a color-coded acid

bottle cap on bottles so that it is easy to identify the acids stowed in

different bottles. Acids should be kept away from inflammable material. In

no case, acids to be stowed in the Naval Store-rooms of ships except

where a special acid store is provided for storage.

Emergency. If exposed to a harmful acid such as HCL, medical

attention should be sough immediately. If acid splashes on skin, water

may be used to rinse it for 15 to 20 minutes. If acid gets into eyes, eyes

should be immediately flushed with water for a minimum of 15 to 20

minutes. If acid soaks your clothing, immediately remove the clothing

before it gets onto the skin.

Ball Bearing

0137. It is important that ball-bearings in stores are kept in the packing in which they

are originally received from the manufacturer. It is also desirable that such packing

should not be opened at any time before the bearings are required for installation. They

should be stored in a position which will not involve the risk of dust or moisture entering

the boxes, or melting of the preservative grease. If for any specific reason, a ball-

bearing has been unwrapped from its original packing, and is again placed in store, it

must be ensured that the bearing and its packing are in the same condition in which it

would be received from the manufacturer. The bearings are coated in a protective layer

8

of grease, wax or other rust prevention compound and if opened to the air, the same is

liable to contaminate. In order to maintain the bearings in serviceable condition, the

following are to be ensured:-

The bearings, filled with grease should be monitored periodically for their

lubricating properties.

Bearings should be stored away from dusty environment which can cause

problems if the dusts sits on bearing surfaces or enters bearing races.

Bearings must be laid down flat on the storage shelves. The loads acting

on the rolling elements are now evenly distributed whereas, with on edge

or standing storage, much of the load would act on just one or two of the

bearings rolling elements. Moreover, the weight of the rings and rolling

elements in the standing position might cause permanent deformation as

the rings are relatively thin walled.

Ensure that the area is dry and has a cool steady temperature without any

drafts to avoid condensation. The temperature should be stable within

reasonable limits and not allowing the temperatures to fluctuate more than

10

0

C per hour.

Setting up a first in first out stock rotation policy, to ensure bearings arent

stored for long periods of time.

Regular maintenance and inspections of the store where the bearing is

stored should be performed at regular intervals.

Barometer

0138. Mercurial Barometers. Mercurial Barometers are delicate instruments and need

careful handling and packing. During storage or transit they shall be kept in the boxes

in which they are supplied. When returning defective instruments a short statement of

the defects shall be furnished and included in the box. Repairable mercurial barometers

with unbroken tubes, returned for repairs shall be carefully packed, and stored with

cisterns upwards. Barometers must be inverted very slowly, otherwise the top of the

tube may broke by the impact of mercury. When the tubes are broken, the loose

mercury shall be poured into a bottle and well corked. Gold slides and counter weights

shall be detached and returned separately.

Method of transportation. While transporting the mercury barometer, fill

the vacuum part with mercury and turn the barometer upside down to

prevent any air from entering. This also applies to indoor transport,

9

regardless of distance. For long distance transport, carry it in a leather

carrying case keeping the barometer in the upside down position.

Storing the mercury barometer in a leather carrying case. Check the

leather carrying case so the barometer will not come off, inspect that the

shoulder belt is not worn-out, and the cap can be tightened securely. When

everything is checked out, put the barometer, which has been turned

upside down, in the leather carrying case slowly. When the mercury cistern

is about to enter the leather carrying case, grab the adjusting screw

securely with one hand and lift up the leather carrying case with the other

hand so that the top of the mercury barometer bottom sits on the leather

carrying case. After putting the barometer into the leather case, fill

cushioning material around the mercury cistern for support.

0139. Aneroid Barometers. Great care should be exercised in handling these

instruments in order to prevent the glass being broken and the needle becoming

detached from its piddle. The N.P.L. certificates issued with Aneroid Barometers,

should always accompany the instruments on return. The hole for adjusting pointer

should be covered with a screw cap (if any) or with thin paper to keep out dust and

insects. Do not transport these barometers by air, as barometer capsules may break

from exceeding its measuring range.

Cameras

0140. Normally cameras supplied for usage are of robust external construction, but

they are essentially delicate stores because:-

Shutters are timed with precision to a small fraction of a second.

Lenses are adjusted to focus within extremely fine limits.

Lenses are constructed, in part, of optical glass that are soft in the sense

that the highly polished surfaces are easily damaged.

Dry and dust-free stowage is essential and so far as practicable the normal

store temperature should not be lower than 10 Deg Cel, or higher than

19 Deg Cel. temperature fluctuations should not be greater than

2 Deg Cel. on either way.

Lenses and shutters, if attached to cameras when received, should in no

circumstances be removed for separate stowage. Lenses should never

be rubbed with materials such as linen or chamois leather; they should be

suitably protected from dust when received, but not otherwise touched

except by technical staff.

10

0141. In order to have the cameras stored in proper place, the following are to be

ensured:-

Avoid Electronic Equipment. Avoid placing the camera near an electronic

device which generates a magnetic field. Long-term exposure to a strong

magnetic field could damage the camera's LCD screen and other electronic

components.

Avoid Extreme Temperatures. Camera is required to be stored in an

area where it won't be subjected to extreme temperature fluctuations.

Extreme heat can damage the camera case, while extreme cold could

damage the camera's LCD screen.

Avoid High Humidity. Storing the camera in extremely damp location could

damage the camera's components over a period of time and end up with

humidity inside the lens, which could lead to condensation inside the camera,

and the same may ruin the photos and damage the internal electronics of the

camera. Camera is required to be placed in a sealed plastic bag with a

moisture-absorbing desiccant, just to provide additional protection against

humidity.

Remove Component. It is recommended to remove the battery and memory

card from camera when not use in for longer duration. If it is a DSLR camera,

the interchangeable lens should also be removed and the camera's lens caps

and guards should also be used for protection.

Check for Mold and Mildew. It is recommended to take the camera out of

storage every 4-6 weeks in order to prevent mold and mildew.

Cells, Accumulators and Batteries

0142. Special care shall be taken that all cells and batteries are stored in a dry and

well-ventilated store, and if possible, protected from extreme cold/ hot conditions. In

storing dry cells, care shall be taken that their terminals do not touch each other and

that no articles are placed on them which are likely to cause a short circuit. Spare

secondary cells for radio purposes shall be kept dry when stowed in the Store, and

positive and negative groups shall be stowed separately in a manner which will prevent

access of moisture. The following care is to be ensured:-

Keep Batteries in the Original Packaging if Possible. Storing batteries

sealed in their original packaging ensures that they remain protected from

humidity.

11

Store Rechargeable Batteries at a 40 percent Charge. Rechargeable

batteries with lithium or nickel chemistry should be stored at around a 40

percent charge. This minimizes the degradation due to age, and still allowing

the battery to slowly discharge itself, which is crucial for its operational health.

Always Store Batteries with the Positive and Negative Terminal away

from each other. If batteries are stored with positive and negative terminals

touching they may begin conducting electricity idly, which will discharge them.

Storing batteries in their original package will help in preventing the same.

Leave Plastic Caps on Batteries Terminal when Applicable. Some of the

batteries, including many 9 Volt batteries, come with a plastic cap fitted over

the terminals. Leave these caps on during storage to prevent the batteries

from conducting electricity and losing their charges.

Dry and Well-Ventilated Store. Special care shall be taken that all cells

are stores in a dry and well-ventilated store, and, if possible, protected from

extreme cold and heat with ideal temperature around 17 Deg Cel.

Torch batteries. Torch batteries deteriorate by being allowed to remain in

torches when not in use. All batteries are to be stowed so as to allow a free

current of air to circulate between the tiers, and both ends shall be easily

opened for inspection.

0143. Cells for transit shall be packed so as to prevent the breakage of insulation or

damage to the connections or containing vessels. The following method of packing for

the large type of secondary cells has been standardized:-

A piece of spun yarn is passed under the bottom of each cell and through

the holes in the terminals.

Light crates of in. batteries are constructed of sizes, just sufficient to

take one cell each with its band of spun yarn.

Cells are placed in the crates and light battens screwed on top to prevent

any vertical movement of the cell within the crate. The battens are placed

so as not to hide the spun yard referred to in serials mentioned above.

The crates are packed in cases-two, three or four to a case, according to

the size of the cells-with two inches of straw or wood wool all round.

On unpacking, the crates are lifted out of the cases by the spun yarn

band. The cells are taken out of the crates by this means also after

removal of top battens.

12

0144. All persons likely to handle the larger type of cells are to be made aware of the

fact that the internal part of the cells is loose, and easily displaced. Most of the damage

which has occurred in the past may be attributed to careless handling in the process of

unpacking and especially to attempts to lift the cells by the terminals.

0145. Saw dust shall never be used for packing batteries as it is hygroscopic. They

are always to be wrapped individually in waxed paper, and shavings used for packing.

Torch batteries deteriorate by being allowed to remain in torches when not in use. All

batteries are to be stowed so as to allow a free current of air to circulate between the

tiers; and both ends shall be easily open to inspection.

0146. Nickel Iron Batteries. The following instructions shall be compiled with in

regard to the care and maintenance of batteries, nickel iron:-

Storage conditions shall be as clean, dry and cool, as possible, but low

temperatures shall be avoided.

The cells shall be examined every six months, any corrosion product removed

and the exposed parts greased with petroleum jelly as necessary. In tropical

climates, examination for corrosion shall take place every three months.

Care to be taken that the charging instructions affixed to the cardboard

containers are not obliterated in any way during storage.

No naked flame shall be brought near the cells during charging and the space

in which the cells are charged shall be well ventilated.

As a considerable amount of gas is evolved while being charged, frequent

topping up of the cells is necessary to keep the caustic potash at the correct

level. Distilled water shall be used for this purpose. It is also necessary that

the level of the caustic potash be maintained above the top of the plates.

0147. Batteries for Aldis Signaling Lanterns. The lead terminals of batteries

are easily damaged. When returning or drawing these batteries they shall be

transported in battery boxes.

Contacts, Contact Screws

0148. Contacts, contact screws, etc., should be stores in the boxes and paper wrapping

in which they are received. Electric contactors and their components are moisture-

sensitive components or assemblies which need to be packed in vacuum-sealed dry

bags together with a drying agent and humidity indicator. Dry bags should not have

holes, dents, or cracks of any kind which may influence the packaged materials or the

moisture protection characteristics of the packaging material.

13

Cotton Waste

0149. Cotton waste shall be stowed in a cool dry place and contamination by oil or fat

shall be avoided. Where such contamination is suspected the temperature of the

doubtful bale shall be taken and if it is found to be in excess of the surrounding

atmosphere, investigation as to the cause shall be carried out immediately. Such

investigation might result in the prevention of spontaneously combustion occurring in a

few days or even weeks. Cotton waste which is found to be contaminated with oil,

grease or moisture should not retain on board unless it can be issued within a very short

time.

Cordage

0150. Cordage shall be stowed according to description and size and where practicable

in a dry, cool, well ventilated storeroom. It shall not be exposed to damp, draught or

direct sunlight nor allowed to come into contact with metals or water. Air space shall be

arranged between the cordage and the deck of the store room. On supply, cordage will

be tallied showing the date of the last test and services for which the rope shall not be

used. To this end, it is important that the tallies are safeguarded against loss or damage

causing obliteration of the last date of test, etc. In order to avoid deterioration in store

rooms, the most aged cordage shall be used first.

Curtains

0151. Curtains and over cases in ships and establishments can be rendered

unserviceable, after a very short life (due to excessive shrinkage of the material when

unsuitable chemical agents are used in laundering processes. As an endeavor to

prolong the life of such articles a dry cleaning process only should be used, the work

being carried out by a reputable firm.

0152. In the case of ships and establishments where dry cleaning facilities cannot be

arranged locally, over cases and curtains should be washed with care, using ordinary

yellow hard soap and tepid water.

Deoxidine

0153. There is the possibility that the acid content of Deoxidine may attack the metal of

the container, with the consequent generation of hydrogen gas, which could in time

possibly cause the drum to burst. Care should, therefore, be taken when handling

drums. Drums should invariably be pierced before opening. The quantity of hydrogen

evolved is small and should not constitute a danger in itself.

14

Diving Apparatus

0154. Breast-ropes, etc., for divers, contain rubber and shall be stowed in a cool, dry

place. They should, on supply from yards and store depots, have metal tabs attached

showing length of the rope and the date of test. Care must be taken to ensure long life

of the items:-

Wetsuit care is essential for prolong life. A well cared wetsuit will last for many

seasons. The most important factors are rinsing the suit after every dive and

storage. Both these factors will increase the life of wetsuit.

After each and every dive, it is important to rinse wetsuit in freshwater. Place

the wetsuit in a bath and also add an antiseptic liquid to remove any salt and

other organic residue. Using a wetsuit shampoo should also help.

After rinsing, turn the suit inside out to dry. It is best to avoid drying out

wetsuit under direct sunlight. Exposing the suit for long periods under the heat

of the sun, may deteriorate the neoprene.

When storing wetsuit, it is best to place it on a wide hangar. Try to store in a

cool, dry environment, for preventing exposure to direct sunlight. Avoid folding

the wetsuit tightly or leaving it folded for extensive periods. Doing so will

permanently damage the suit.

For additional wetsuit care, once wetsuit has dried out, lubricate the fasteners

and zippers with a silicone spray or some other non petroleum lubricant. This

will reduce the likelihood of zipper getting jammed due to a build up of salt

crystals and salt deposition.

Electric Cables

0155. All cables shall be stowed in a dry, well-ventilated store, on reels where

practicable or coiled and wrapped properly. Heavy electric cable, however, including

lead-cased of half inch or more in diameter should not be placed on fitted reels but kept

on board in the form in which received, i.e., on a contractors drum or done up in a large

coil. All cables should be supplied with sealed ends, and the Logistics Officer is to

ensure that after cutting a length of cable for issue, the cut end is resealed by the

application of Chatterton Compound and adhesive tape.

All cables shall be stowed in a dry, well ventilated store, away from any oil

and chemicals preferably on cable drums/reels and wrapped as supplied

from the Depot/firm. All cables on receipt are to be clearly marked with the

pattern number and date of receipt.

15

Keep cable drum upright. The drum is designed to be handled in upright

position. It may not sustain if lifted lying flat.

When the drum must be rolled for some reason, always roll the drum in the

direction of arrow. This way, the cable will not unwind or loosen on the

drum. Limit rolling up to the distance of five meters.

Lift the drum without causing any damage to the cable, a shaft through the

centre of the drum may be used for lifting.

When handling with fork lift, the forks must be longer than the width of the

drum being lifted. Preferably, different widths of drums should be marked on

the forks enabling the operator to select the correct position for the given

drum size. Leave sufficient room between drums so that the fork doesnt

damage the drum.

Avoid punching nails into cable drums. If nailing is utmost necessary, make

sure that they don't touch the cable.

Make sure that each drum is provided with stoppers to prevent from rolling

during storage.

Stacking of cable drums should be avoided.

During transportation, the cable drum shall be fastened to the base through

the centre hole or across the flanges with wires or ropes. To prevent

movement of drums, a combination of wedges and transportation support

should be used and tied down front and rear.

Cable drums must not be dropped from the vehicle. The drum is to be lifted

either by winch or fork-lift.

The site chosen for storage of cable drums must be level and dry. It should

have a firm, preferably concreted surface. This will avoid sinking of the

drums and difficulty in subsequent shifting.

All cable drums should be stored in such a manner as to leave sufficient

space between them for air circulation.

During storage, the drum should be rolled to an angle of 90 degree once

every three months. Also, tie bolts shall be checked and tightened at regular

intervals.

16

Always turn a cable drum using turn table. Never use crow bar if turn table

is not available. Two well greased plates can be used instead.

0156. The Logistics Officer is to ensure that all cables on receipt are clearly marked

with the pattern number and date of receipt. A cable held in the store shall be similarly

identified, to ensure that issues of cable are in accordance with the dates of receipt. In

this respect, reels shall be empties first before winding on a cable received at a later

date.

0157. The Electrical Officer is to inspect the cables and stowage annually. Signs of

deterioration or defective storage shall be dealt with in conjunction with the Logistics

Officer. The Establishment List of Cables held on Board is to be reviewed annually by

the Electrical Officer and any changes considered necessary forwarded to the relevant

authority.

0158. Supply personnel should understand that heat and moisture are injurious to all

cables and also that oil will cause rapid deterioration of rubber insulation. If deterioration

is apparent, due to either of the above circumstances during the period between annual

inspections, the fact shall be reported, to the Electrical Officer and the Logistics Officer.

All cables held on board for a period of five years shall be returned for survey, suitably

labeled.

Electric Welding

0159. It is important that welding electrodes are kept dry since the castings readily

absorb moisture and the efficiency of welds is liable to be seriously affected thereby.

The electrodes which may have soaked with water are unfit for use. The following points

must be adhered to for better stowage of the welding electrodes:-

Welding electrodes must be properly stored in order to deposit quality

welds. When electrodes absorb moisture from the atmosphere, they must

be dried in order to restore the ability to deposit quality welds. Electrodes

with too much moisture may lead to cracking or porosity.

Store electrodes in hermetically sealed containers, which provide excellent

protection against moisture pickup. Do not open the hermetically sealed

containers until the electrode is needed for use.

When the electrodes have been exposed to the atmosphere for period of a

few days, the electrode can be re-dried for usage.

Any electrode should be discarded if excessive re-drying causes the coating

to become fragile and flake or break off while welding.

17

Fire Extinguishers

0160. All extinguishers should be stored in their separate cartons as originally

supplied, or, if these are not available, in brown paper or cardboard cartons improvised

for the purpose, so as to protect them from dampness and the collection of dust etc. As

a precaution against corrosion, with resultant loss of contents by leakage or

evaporation, refills should when necessary be given two coats of black paint. Care

should however, be taken to ensure that no part of the instructions of the tin is

obliterated by paint.

0161. Charged extinguishers in store should always be stowed horizontally and tested.

Foam type extinguishers, in cold weather should be stowed in a position where the

temperature is not likely to fall below 8 Deg Cel. The effectiveness of the extinguishers

is improved if the temperature is not allowed to fall below about 16 Deg Cel.

0162. A thin brass sheet shall be made to fit on the extinguisher and the following

information shall be stamped on it:-

Date when last filled.

Date when solutions were last tested.

Date when last pressure-tested.

0163. Any extinguishers not fitted with brass sheet shall be proved with a label, wired

to the extinguisher, with the above information stamped on it.

0164. Before Foam Type Extinguishers are returned to the Logistics Officer when

ships pay off, or for other reasons, they shall be discharged, and the liquid containers

rinsed with fresh water and thoroughly dried. To avoid unnecessary waste of the

chemical charges, this operation should be arranged to coincide, as far as practicable,

with the periodical discharge trials. New extinguishers, when received, shall be

examined internally, to ensure that they are free from moisture.

Flags, Bunting and Woolen Goods

0165. Flags, except those in use, bunting and woolen goods (e.g., drawers, stockings,

etc.) shall be kept neatly folded in suitable cupboards, with naphthalene on the articles

and between the folds for their preservation from the ravages of moth. Naphthalene, or

such other preparation as may be authorized, shall be applied from time to time; but the

18

strictest precautions against fire shall be observed in the use of any inflammable oil or

spirit. The foreign ensigns and other flags likely to be remain in store for some time

shall be tied up in bags or paper parcels, with each flag containing naphthalene.

0166. Salt, even in small amounts, has a pronounced tendering effect upon silk, and if

salt water is allowed to dry on a silk flag, the salt tends to be absorbed by the flag and

becomes increasingly difficult to remove completely. Silk flags which have been in

contact with salt water are to be washed in fresh water before storing. They should be

rinsed three or four times in fresh water (as soft as possible) the water being changed

on each occasion, and then thoroughly air dried. The operation should consist of simply

rinsing, and the flags should then be hung out to drain, without wringing or subjecting to

any harsh treatment which would be liable to damage the fibers of the silk. It is very

important to ensure that the flags are thoroughly dried before being put away, as

storage of silk in a damp condition would, in itself, be sufficient to cause deterioration.

There is no objection to drying in an artificially warmed atmosphere if necessary, but

exposure to high temperature should be avoided.

0167. The woolen goods must be stored in a manner as mentioned below:-

All woolen goods must be protected from moisture, since wool is strongly

hygroscopic and readily absorbs moisture.

Storing wool and other clothing like flags, bunting etc. in plastic doesnt

allow insects to breathe properly. Storing clothing in breathable cotton or

paper will allow air to circulate.

Storing foreign ensigns, other flags and wool items in pillow cases or paper

bags with naphthalene will also create a barrier that bugs and insects will

not penetrate.

Place mothballs or moth crystals inside the storage containers. Scatter

mothballs in layers throughout the clothing.

Keep wool clothing cool. Temperatures below 40 degrees Fahrenheit.

Check on stored clothing periodically every four to eight weeks for signs of

insect damage. Replace the mothballs or moth crystals periodically into

storage.

19

Flat storage is the best option for flags. Enameled metal shelves, drawers or

acid-free boxes may be used for storing flags. The flags may be placed in

the boxes or drawers flat, if possible. If folding becomes necessary, acid-

free tissue paper should be used to form soft rolls around which the folds

can be shaped, to prevent creases from forming. Even so, folded flags

should be removed and refolded differently every few months.

Gas Cylinders

0168. Gas cylinders whether charged or empty are not to be stowed adjacent to

inflammable materials.

0169. Hydrogen cylinders are charged to the pressure of 1,800 lbs, per sq. in. Special

care should, therefore, be taken that fully charged cylinders are not exposed to the

direct rays of the sun in tropical climates. The cylinders should be stored as per the

following points:-

Suitable labels with appropriate colors must be placed on the cylinders. The

label and cylinder color are means of identification of the gas contents and

the nature of the hazard associated with the gas contained in the cylinder.

Full or empty compressed gas cylinders should be stored in a well ventilated

area, preferably in the open, with some weather protection. The area on

which cylinders are stored must be well-drained to prevent corrosion of

cylinder bases. The location must be free from the risk of fire and well away

from sources of heat or ignition.

It is recommended to store cylinders vertically. Vertically stored cylinders

must always be secured. When standing or rotating and walking cylinders

about their vertical axis, be aware of the hazards of uneven sloping, slippery

and unstable surfaces as well as loose surfaces. Whenever possible use a

cylinder trolley for transporting cylinders higher than ones waist height.

Do not store any other products in a cylinder store, particularly oil, paint or

corrosive liquids.

Full cylinders must be stored separately from the empty cylinders, and

cylinders of different gases whether full or empty must be segregated from

each other.

It is essential that while handling or storing cylinders containing toxic gases

that the cylinder valve outlet threaded plug or cap is always replaced in the

valve outlet when the cylinder is not in use or connected to a manifold or

20

regulator. The cylinder valve outlet threaded plug or cap acts as a

secondary valve to the valve itself and provides increased safety against

leakage.

All cylinders should be considered and treated as full, regardless of their

content. This means, keep cylinders away from artificial heat sources (e.g.

flames or heaters). Avoid under-ground storage where possible.

Use mechanical aids (ramps, trolleys, forklifts, scissor lifts) in preference to

direct manual handling of cylinders.

Ensure cylinders are positively secured to mechanical lifting/ handling

devices prior to movement.

Gyro Compass Stores

0170. Gyro compass spares should be kept free from dust in a dry store maintained at

a constant temperature as far as practicable. All parts should be retained in their boxes

and protective wrappings until required for use, and similar precautions to those

adopted for the handling and storage of electrical and delicate store, should be taken as

regards these stores generally.

0171. Bearings for gyro-compasses are specially selected, cleaned and oiled and

enclosed in sealed cartons. They should never be unwrapped until actually required to

be placed on a compass. If, on opening, they are found to be discolored, or in any way

defective, they should be returned with a report of the circumstances.

0172. Special care must be taken at all times in handling and packing gyro-compass

instruments (whether serviceable or unserviceable) for transit, reference being made

when necessary to the relevant packaging specification sheets. Special transport boxes

are provided for the casings and rotors, vertical rings, compensator weights, mercury

boxes, lower half-phantoms, spiders complete, suspensions, magnetic contractors,

magnet holders, trolleys, azimuth motors and azimuth motor relays of the Admiralty gyro

compass.

0173. It is essential that no seals are broken and that all components remain in their

boxes until required for fitting, the defective part being returned in the box in which the

replacement was supplied. The following points are to be adhered while storing the gyro

spares:-

Gyro compass are to be stored in flat and upright position.

21

A gyro is a very delicate high precision instrument and should be handled

delicately. The heart of the system is the sensitive element, which is fixed in

a gimbaled system with vibration damping springs. As the element is quite

heavy it is always packed separately. The sensitive element is never to be

mounted in the gyro housing when transported.

If gyro will be stored for an extended period of time, it should be powered up

every six months and allowed to spin for 10-15 minute. This redistributes the

oil or grease throughout the bearings. If left to sit, the oil and grease will

pool at the bottom of the unit and cause friction damage of the upper

bearing upon the next start-up.

Inflammable Stores

0174. All stores having a flash point of 65 Deg Cel or under are classified as

inflammable and require special precautions as regards handling, transport and

stowage. Inflammable stores shall be stowed in the inflammable store or, where no

such store is provided, in the spirit room and no deviation shall be allowed except for

the following:-

Inflammable liquids for which specific approval has been given for bulk

stowage.

Petrol and paraffin when supplied in cans or 5 gallon drums are to be stowed

in open racks, with tray bottoms, on the weather or upper deck, in a position

from which they can readily be thrown overboard in an emergency. They are to

be clear of the smoking places selected for officers and ships company.

Emergency access to the containers should also be provided.

0175. The instructions issued from time to time in respect of stowage of inflammable

stores shall be strictly complied with. All tanks containing inflammables, when kept in

the spirit room of ships should be stowed in a special locker to ensure necessary

precautions being taken against fire. Highly inflammable liquids, i.e., those having a

flash point below 23 Deg Cel should be drawn off, on the upper or main deck only. The

operation should be carried out in the day time when this is possible. If, however, a light

is necessary, a gas-tight safety lamp should always be used.

0176. Care shall be taken when hoisting or lowering the drums in inflammable store, to

avoid sparks due to contact between metals. Every precaution shall be taken to guard

against creating sparks when unpacking cases which are liable to have an inflammable

vapors content.

22

0177. Liquid metal polish shall also be stowed in the inflammable store and in ship

where this is not provided shall be stowed in a small tank (locked) in a store approved

by the Commanding Officer, or in a tank on the weather deck. Phosphorous must never

be stowed between decks.

0178. At establishments where inflammable stores have to be stowed in the open, the

following precautions are to be taken:-

At the approaches, a warning notice is to be prominently displayed, as:-

DANGER inflammable (or Explosive Risk) NO SMOKING OR NAKED LIGHTS.

Where practicable sufficient First aid fire fighting appliances appropriate to

the risk are to be sited at a convenient point in the vicinity.

Special precautions are to be taken with damaged containers and Leakers

until they can decanted. Highly inflammable liquids (i.e., those having a flash

point of less than 23 Deg Cel.) in drums, are not to be stowed in stacks which

are too high.

Insulating Material

0179. Coils and articles in which rubber-covered cable is used should be stowed away

from oil and grease.

Magnetic Compasses and Gear

0180. Magnetic compasses are particularly delicate instruments which require care in

handling and stowage. They shall be stowed away from ferrous metal items. Many

common electrical devices exert a magnetic pull therefore the compass must be stored

away from computers, speakers and radios.

Mahogany Furniture

0181. Mahogany furniture and fittings in ships and establishments should not, in any

circumstances, be pained or enameled.

Meteorological Instruments

0182. Care shall be taken in the handling and stowage of pen arms and pen for open

scale barographs and distant reading thermographs, as they are delicate and easily

damaged. These articles should, therefore, be retained in their packing until required for

use.

23

Optical Instruments

0183. Optical instruments must be carefully cleaned and dried before being put away

and shall not be stowed in damp compartments or in compartments where excessive

temperatures are, likely to be experienced. It is essential that optical instruments shall

be sent in for repair before defects become too acute, otherwise no repair will make

them serviceable again. Commanding Officers should ensure that all optical

instruments are inspected frequently by a responsible officer and defective instruments

are exchanged at the first opportunity. The following points must be taken care of:-

Cleaning is one of the procedures used to keep an optical instrument at its

peak performance. Dust, finger prints, and stains can degrade even the best

optical system, resulting in poor performance. Failing to remove certain types

of contamination in a timely manner can damage the optics or optical

coatings. Cleaning consists of a series of simple, easy steps. To master these

steps, all that is required is frequent practice. The optical instrument must be

carefully cleaned and dried before being put away and shall not be stowed in

damp compartments or in compartments where excessive temperatures are

likely to be experienced. The protection caps must be placed on the sensor

and the cable connectors wherever not in use.

Few optical instruments are completely watertight and periodical overhaul by

staff is generally necessary in order to maintain their performance at high

standard.

Organic Fibrous Material

0184. Organic fibrous material such as used cotton waste, old bunting, cordage

shakings, strands from cordage, collision mats, coir, fenders and canvas, steel wire

wool, when stored in a wet or damp state, is liable to generate heat, and care shall be

taken to avoid danger from this cause. Every opportunity should be taken to return

such materials to the depot. Risk of an outbreak of fire becomes serious when a small

percentage (about 5 percent) of oil or fat is present, or when such fibrous material, in a

thoroughly dry condition, is subjected to moderate warmth, e.g., from a radiator, from a

warm roof, or from heating of the deck above, during building operations. Care must be

taken for following:-

Oil and solvent-soaked rags must be stored and disposed of properly to

prevent combustion fires. It is important to maintain proper fire extinguishing

equipment and smoke detectors in all areas where flammable and

combustible materials are being used and stored.

24

Oil-soaked rags are a spontaneous combustion hazard because as the oil

oxidizes, heat is released. If the heat is not dissipated, it can build up and

ignite the rags. Special oily-waste cans should be used to store oil-soaked

rags. These containers allow air to flow around the rags, thus dissipating the

heat. The waste cans should not have plastic liners and they should be

emptied daily.

Paint Removers

0185. Paint removers are generally highly inflammable and should be handled

carefully. When the vapors of the paint remover come into contact with naked flames or

drawn through the hot ash zone of cigarettes or pipes, toxic gases, e.g., phosphate, are

produced. It shall not be used in confined spaces and no smoking or naked lights shall

be allowed when it is being used. Care must be taken for following:-

Storing and handling paints, varnishes, or thinners require special attention

to flammability characteristics.

Store paint remover in sealed containers under shed in a cool area, away

from direct sunlight and extreme temperatures.

Do not stock paint material near to any ignition sources.

Do not put back half or unused material back in original container,

containing the supplied material, to avoid contamination.

Handle with care. Do not stir the material. Before application soft mixing is

recommended.

Always keep in recommended plastic cans.

Avoid skin and eye contact by wearing overalls, gloves, goggles, and air

mask etc.

Spillage on skin should immediately be removed by thorough washing with

water and soap or suitable cleaner. Eye should be flushed with fresh water.

Avoid inhalation of vapors and paint mist by wearing suitable air mask. In

the event of ingestion and eye contact, seek medical attention immediately.

Painting must be carried out in well ventilated area. This as industrial

product contains corrosive materials and is hazardous. It should be used

with adequate precautions. Smoking in the area should not be permitted.

25

Rubber Goods

0186. The rubber and gutta-percha goods, including steam packing where rubber forms

a part of the packing, shall be stowed in a cool, dark place so far as practicable

complying with the following conditions:-

Temperature 10 Deg Cel - 16 Deg Cel.

Atmosphere fairly humid.

0187. The rubber sheet shall be laid flat where practicable and tubing carefully coiled,

care being taken to avoid kinks. It is important that stocks are issued according to age

and that surpluses are not allowed to accumulate. Tallies shall be attached to rubber

sheet and tubing showing the date of receipt. Inspections shall be made periodically to

ascertain the conditions of stocks.

0188. The rubber washes, small tubing, etc., shall be kept in a dry, cool place, freely

covered with Scottish, talc. Rubber shall be stowed under pressure, and so far as

instruments, witches and other small fittings, having rubber washers, etc., are

concerned, it is important that pressure on the washers should be obviated by

slackening nuts and bearing parts. The surfaces of the rubber parts which have to be

separated while fitting are to liberally coated with Scottish talk or a thin, paste of

graphite and water.

0189. The I.R. eyepieces for gun-sighting telescopes deteriorate if kept in the boxes

with the telescopes. They shall be stowed separately under the general storage

conditions for rubber-articles. Wrist rings shall be kept on cylinders of suitable size

made of card board or stiff paper.

0190. For stowage of rubber items special care is to be taken. If not stowed properly

Rubbers goods change their physical properties during storage and ultimately become

unserviceable, due excessive hardening, softening, cracking, crazing, or other surface

degradation. These changes may come as a result of one particular factor or a

combination of factors, such as the action of oxygen, ozone, light, heat, humidity or oils

and solvents. The deleterious effects of these factors may, however, be minimized by

careful choice of storage conditions. Liberal dusting with French chalk should be carried

out. The following points must be considered while storing the rubber items:-

Temperature. The storage temperature should preferably be maintained

below 25C because at higher temperatures deterioration occurs more

rapidly. Sources of heat in storage rooms should be so arranged that the

temperature of stored articles never exceeds 25C.

26

Storerooms to be kept dark by keeping the doors and windows of the

storehouse closed as much as possible and by painting the glass panes

with some dark colored paint. Dark colored curtains may be hung over

rack/bins and wherever feasible.

Heat insulated buildings are preferable. Storehouse flooring may be

sprinkled with water during summer months to keep the temperature down

to optimum level.

Humidity. The relative humidity in the store room should be maintained

below 75%. Very moist or very dry conditions should be avoided. Where

ventilation is necessary it should be kept to a minimum. Condensation

should never be allowed to take place.

Light. Rubbers should be protected from light, in particular rather strong

sunlight and strong artificial light with a high ultra-violet content. Unless the

articles are packed in opaque containers, it is advisable to cover any

windows of storage rooms with a red or orange coating or screen.

Ventilation. Where possible, rubber should be protected from circulating

air by wrapping, storage in airtight containers or by other suitable means.

Deformation. Rubbers should, wherever possible, be stored in a relaxed

condition free from tension, compression or other deformation. Rubber

sheets shall be laid flat not more than 50 to a stack where practicable and

tubing carefully coiled, care being taken to avoid kinks. Large O-rings and

seals must be suspended on pegs otherwise it will lead to severe

deterioration. If it is impossible to avoid deformation, it should be kept to a

minimum since deformation can lead to cracking and permanent change of

shape. Where articles are packed in a strain-free condition they should be

stored in their original packaging. It is important that stocks are issued

according to age and that surplus stocks are not allowed to accumulate.

Tallies shall be attached to rubber sheet and tubing showing the date of

receipt. Where racking or piling is adopted, the height of the stack should

not exceed 5 feet in respect of mounted tyres and 6 feet in respect of un-

mounted tyres.

Contact with Liquid & Semi-Solid Materials. Rubbers should not be

allowed to come into contact with solvents, oil, greases or any other

semi-solid materials at any time during storage, unless so packed by the

manufacturer. In certain cases rubber components may require to be stored

coated with the fluid in which they are to be used.

27

Contact with Metal. Direct contact with certain metals, for example

manganese, iron and particularly copper and its alloys, for example brass

and compounds of these materials are known to have deleterious effects on

some rubbers. Rubber should not be stored in contact with such metals, or

materials impregnated with their compounds, but should be protected by

wrapping or separation with a layer of suitable material, for example paper,

polythene.

Contact with Non-Metals. Due to possible transfer of plasticizers or other

ingredients, rubbers must not be stored in contact with PVC. Different

rubbers should preferably be separated from each other.

Cleaning. Where necessary, cleaning should be carried out with the aid of

soap and water. Disinfectants or other organic solvents must not be used.

After cleaning, the article should be dried at room temperature and not

placed near a source of heat.

Lip Seals. Lip type seals should always be stored in such a way as to

prevent the sealing edges being damaged.

Methods of Inspection & Test. The rubber and unassembled rubber

details should be given a careful periodical examination for: Permanent

distortion, mechanical damage, flats or other defects, tackiness or

noticeable surface softening or hardening and cracks

0191. Gasket is another item that is used between two surfaces and is used to join the

surfaces together. The gasket fills the gap between the two joining surfaces and is used

to prevent the leakage of fluid out of the machinery and knocking noise from the

equipment. The gasket are made from material such as rubber, cardboard, asbestos,

paper etc and therefore are very delicate and requires proper care in storage. It must be

stored in the store away from humidity, high temperatures and water. The gaskets

should be stored in its original packing inside boxes to prevent them from damages.

Stop Watches

0192. The mechanism of service stop watches is of a delicate nature and proper care

should be exercised in the use of these watches. They shall not be altered for use as

wrist watches. It is sometimes necessary for various fire control purposes; to mark the

dials of stop watches with different colored inks but particular care should be exercised

in making these temporary markings to avoid damage to the hands or mechanism.

Watches issued on permanent loan to Departmental Officers shall be kept, when not in

use, in the locked metal and baize lined drawers provided for this purpose.

28

Straight Edges

0193. Straight edges should not be strained or thrown out by careless handling or

stowage and should be protected by wooden covers or strips secured by wire. The

protective covers of surface plates should be similarly secured.

Synthetic Paints

0194. Synthetic paints have a limited shelf life, therefore extreme care is to be

exercised while preparing the replenishment demands for these paints. It is also

important that the old stock should not be allowed to accumulate. As a safeguard

against possible deterioration, the drums of synthetic paints in stores are to be stored in

inverted position once in three months in order to minimize the risk of hard settlement of

pigment. In addition the following is recommended:-

Do not use gasoline or similar volatile liquids as thinners.

Paint drums should be stored in a building/boatswain store with a fire

protection system, such as a sprinkler, water spray or carbon dioxide

system. Materials that react with water to create a fire hazard cannot be

stored in the same room with paint.

All storage rooms should have adequate ventilation system that can provide

a complete change of air. The controls for the ventilation system must be

located outside of the room.

Regardless of the size of the paint storage room, there should be a clear

aisle through the room at least three feet wide.

Printed Circuit Boards(PCB)

0195. The PCBs are the heart of any electrical/ electronic system and even a single

scratch on them may render them un-serviceable. It is therefore very important that the

same must be handled carefully. The PCBs are required to be stowed in a controlled

temperature where the heat/ humidity is not very high and the same must be stored in

the original packing away. Some of the components mounted on the PCB are also very

sensitive and the exposure to sun light may damage them therefore the same are

delivered in the dark packing. Care is to taken to maintain the pickings intact.

0196. PCB`s are hygroscopic i.e. they are extremely sensitive towards moisture. The

microscopic structure of the multilayer material develops a strong capillary power that

soaks up the humidity of the surrounding air. Even under very dry conditions, it is a

question of time before water accumulates in the stored PCB`s. For example: At storage

29

conditions of 20 C and 35 % of humidity the weight of the epoxy raisin of the Multilayer

PCB`s rises 0.12 % due to the accumulation of moisture. If the capillary effect leads to

an increase of more than 0.17 %, a gas pressure of 8-10 bar can be reached, causing

de-lamination of the board. The danger of de-lamination can rise again due to unsafe

transportation and long storage times. The components in the PCBs are also very

sensitive to temperature, moisture and dust particles and may cause

damage/malfunctioning of PCBs. Following are recommended to avoid the described

problems:-

PCBs should be stored in temperature controlled room (20-25

0

C). A rapid

fall in temperature of more than 7

0

C, causes condensation on the stored

PCBs. Constant low humidity is necessary. Humidity should never exceed

65%. The airtight sealed package with silica gel packets must be kept intact

although the polyethylene packages capability of keeping humidity away is

not really reliable. Do not expose to direct sunlight, corrosive gas or liquid

environment.

The storage time of PCBs should be as short as possible. PCBs should be

taken out as per the first-in, first out rule. The polyethylene packages

should be taken away just before the use. Remaining PCBs should be

repacked again. To avoid exposure to draught, the packages should be

stored in boxes.

Wear gloves while handling to avoid defect due to static electricity.

Valves

0197. The valves are used in the control systems and they are very sensitive to the dust

particles. It is recommended that the valves must be stored in a completely dust free

environment with proper (preferably original) covering.

Compressor and Pumps

0198. The representatives of manufacturers (OEM) should visit store depot to inspect

the compressors and pumps (which are of critical nature and are required to be stored

for longer period) at regular interval within the warrantee/guarantee period. The same

has to be incorporated in the terms and conditions of supply order/contract.

Preservatives required may be applied under supervision of reps of PAC/OEM. The

pumps are susceptible to dust and care must be taken to ensure that the area where

the pumps are stored are free from dust and regular maintenance and cleaning of that

area is being undertaken.

30

Electric Motors

0199. Electric motors with greased bearing need not be lubricated. If received with

grease fitting, it should be removed and plugged or capped.

Hoses

0200. For stowage of hoses, the following steps are recommended:-

Rubber hose products in storage can be affected adversely by temperature,

humidity, ozone, sunlight, oils, solvents, corrosive liquids and fumes,

insects, rodents and radioactive materials and therefore the same must be

stored in an air conditioned space with controlled temperature and humidity.

The appropriate method for storing hose depends to a great extent on its

size (diameter and length), the quantity to be stored, and the way in which it

is packaged. Hose should not be piled or stacked to such an extent that the

weight of the stack creates distortions on the lengths stored at the bottom.

Since hose products vary considerably in size, weight, and length, it is not

practical to establish definite recommendations on this point. Hose having a

very light material of wall will not support as much load as could a hose

having a heavier material of wall or hose having a wire reinforcement. Hose

which is shipped in coils or bales should be stored so that the coils are in a

horizontal plane.

Whenever feasible, rubber hose products should be stored in their original

shipping containers, especially when such containers are wooden crates or

cardboard cartons which provide some protection against the deteriorating

effects of oils, solvents, and corrosive liquids; shipping containers also

afford some protection against ozone and sunlight.

Certain rodents and insects will damage rubber hose products, and

adequate protection from them should be provided.

Cotton jacketed hose should be protected against fungal growths if the hose

is to be stored for prolonged periods in humidity conditions.

The ideal temperature for the storage of rubber products ranges from 50 to

70 F (10C to 21C) with a maximum limit of 100F (38C). As far as

possible, provisions to be made to store such hoses in controlled

temperature.

Exposure to direct or reflected sunlight, even through windows, should be

avoided. Uncovered hose should not be stored under fluorescent or mercury

lamps which generate light waves harmful to rubber.

31

Items should be stored on a first-in, first-out basis, since even under the

best of conditions, an unusually long shelf life could deteriorate certain

hoses.

Storing Materials in Open Yard

0201. Storing materials in open area requires attention to combustible materials,

access, power lines and fire protection.

Combustible Materials. Stack combustible materials securely. Stacks or

piles must be no more than 12 feet high. Store combustible material at least

10 feet away from a building or structure.

Access. Driveways between and around combustible storage piles must be

at least 15 feet wide. Keep them free from accumulations of material or

rubbish. Use a map grid system of 50 by 150 feet when planning driveways

in open-yard combustible material storage areas (subject to availability of

sufficient space)

Power lines. Do not store materials under power lines or where materials

may block entrance or emergency equipment/ electrical fittings such as

switch boards, sockets, junction boxes and MSBs.

Fire Protection. Provide portable fire extinguishing equipment at accessible

marked locations in the Depots so that the nearest extinguisher is no more

than 50 feet.

Preservation in Store Depots

0202. The basic methods of preservation in store depots are as follows:-

Temperature Control. Certain items viz. rubberized items require

controlled temperature and thus air conditioned space for storage.

Humidity Control. Silica gel or dehumidifiers are required to be used for

protection of items from moisture and humidity.

Dust Control. The items should be stored in a dust free environment

Greasing and Oiling. There is a large number of metallic items which

requires greasing or oiling to prevent them. After greasing/oiling, these

items should be put into preservation packing.

Preservation Coating. Items like steel plates, chain cables, propellers,

anchors and propeller shafts requires preservation coatings to be applied

periodically.

32

Use of Chalk. Items made of rubber which do not require to be stored in air

conditioned spaces are generally kept soft and prevented from cracking by

application of chalk.

Running the Equipment. Various types of engines, prime movers, motors

and generators require periodic running to prevent seizure. The technical

assistance in accordance with preservation schedules of such equipment

may be sought from the CSO(Tech) of concerned Regional Headquarters.

Preservation Management

0203. In order to carry out effective preservation management, the following are

necessary:-

Information about every item in the store house that needs special

preservation.

Preservation routine in respect of each such item.

The information regarding such preservation routines should be held readily

available in the offices of CGSDs.

The Officer-in-Charge of Store Depot is responsible for preparation of

comprehensive annual preservation plan and to ensure that the same is

carried out as per the schedule program. The record of such maintenance is

also required to be stored at the Store Depots.

Steps for preserving each and every type of item must be compiled and

promulgated by the Officer-in-Charge of Store Depots. Such instructions

should be direct and clear so that no ambiguity exists about the action and

scheduling.

The Oi/C store Depots should also make available the wherewithal required

to execute preservation and also ensure that the Planned Preservation

Program (PPP) is carried out on schedule.

On the basis of PPP, a plan must be prepared in each store house to cover

all the items that requires preservation. The annual plan, monthly schedules