Professional Documents

Culture Documents

PD12C Free Fall

Uploaded by

Ed CalheOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PD12C Free Fall

Uploaded by

Ed CalheCopyright:

Available Formats

SERIES

PD12C

PD15B

HYDRAULIC HOIST

WITH FREE FALL

Information in this publication is specific to those hoists with

Free Fall. For additional information, refer to the PD12C,

PD15B and PD17A Installation, Maintenance and Service

Manual, publication LIT-2103

PACR

WINCH DIVISION

P.O. BOX 547 BROKEN ARROW, OK U.S.A. 74013

PHONE (918) 251-8511 FAX (918) 259-1575

www.paccarwinch.com

PB-226

6/2003

PRINTED IN U.S.A.

PD12C & PD15B

FULL RELEASE & CONTROLLED FREE FALL

GENERAL SAFETY RECOMMENDATIONS

Personnel must not be allowed to

pass or stand under a suspended

load. Accidentally activating the hoist

free fall mechanism could result in the

load free-falling to the ground which

could result in property damage, per-

sonal injury or death.

When operating the full release free fall, no attempt

may be made to retard or stop the descending load

using the hoist controls. Since the full release mech-

anism is not designed to stop a descending load, any

attempt to do so could result in damage to the hoist

and/or the machine it is mounted on, which could

result in property damage, personal injury or death.

Equipment operators must receive sufficient training and practice to be able to antici-

pate the response of the hoist to control handle movement. Failure to properly train

operators may result in sudden loss of load control, which could result in property dam-

age, personal injury or death.

IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCT AND/OR SYSTEMS

DESCRIBED HEREIN OR OF RELATED ITEMS CAN CAUSE PROPERTY DAMAGE PERSON-

AL INJURY OR DEATH.

This document and other information from PACCAR Winch Division provides product and/or sys-

tem options for further investigation by users having technical expertise. It is important that you

analyze all aspects of your applicaiton and review the information concerning the products or sys-

tems in this manual. Due to the variety of operating conditions and applicaitons for these products

or systems, the user of the entire system, through his own analysis and testing, is solely respon-

sible for making the final selection of the products and systems and assuring that all performance,

safety and warning requirements are met.

Free fall hoists are designed to operate properly with the motor and brake valve originally installed

at the factory. If, for any reason, a different motor and/or brake valve is to be installed, written

approval must be obtained from the PACCAR Winch Division Engineering Department. Improper

hydraulic hook-up or failure to use an approved motor and/or brake valve may result in sudden loss

of load control, which could result in property damage, personal injury or death.

FOLLOW THE WARM-UP PROCEDURE STATED IN

LIT-2103 R1.

FULL RELEASE FREE FALL TESTING AND OPERA-

TION

A light test load (1000 lbs (454 kg) approximately) should

be lifted a few feet from the ground. The free fall control

valve handle should be moved into the full release posi-

tion. The handle should then be detented in that position.

If the ambient temperature is very low, the load may fall

at a fairly low velocity, but once the brake housing has

warmed up the load should fall freely. Once the operator

has gained a feel for the controls, the load and drop dis-

tance may be increased. NO ATTEMPT SHOULD BE

MADE TO RETARD THE SPEED OF THE DESCEND-

ING LOAD, OR TO STOP THE DESCENDING LOAD.

Any attempt to do this may result in a wire rope failure,

severe damage to the hoist, or destabilizing the crane or

structure on which the hoist is mounted.

CONTROLLED FREE FALL TESTING AND OPERATOR

TRAINING

A light load (1000 lbs (454 kg) approximately) should be

lifted a few feet from the ground. The operator should

move the controlled free fall valve handle smoothly and

slowly towards the release position. As soon as the load

starts to move, the operator should stop moving the han-

dle. This test is to determine that the controlled free fall is

working and to give the operator a feel for the handle

movement required to initially release the load. Over short

lowering distances it will be difficult to bring the load to a

smooth stop before it reaches the ground. Very smooth

movements of the control handle are required in order to

modulate the speed of the descending load.

Once the operator has obtained the feel for the control

handle release point, the load may be raised higher, this

will give the operator a better opportunity to modulate the

speed of the descending load, both to speed up and slow

down to a stop.

When the operator has become confident using the 1000

lb (454 kg) load, then the load may be increased incre-

mentally to the maximum free fall design load for the crane

or other support structure, or 4600 lbs (2090 kg) bare drum

line pull, whichever is the least.

The operator should never operate the valve abruptly, as

this will cause the load to accelerate at a high rate, and to

reach a high velocity. The metering pump (see Controlled

Free Fall Circuit on following pages) will then over com-

pensate, and slow the load down even to a stop. If this

should happen, the control valve should be closed

smoothly, but not abruptly, and the lowering cycle restart-

ed. If the valve is not closed while the metering pump is

bringing the load to a near or actual stop, pressure will rise

very quickly in the release circuit, and the cycle will begin

again resulting in a rapid surging while lowering this load.

Under no circumstances should the opera-

tor let go of the handle, or return the han-

dle to neutral abruptly, as this will cause the

free fall brake to apply instantaneously

leading to a severe shock load throughout

the hoisting system. Attempting to stop a

descending load with a full release mecha-

nism could result in damage to the hoist

and/or the machine it is mounted on, which

could result in property damage, personal

injury or death.

Personnel must not be allowed to pass or

stand under a suspended load. Accidentally

activating the hoist free fall mechanism could

result in the load free-falling to the ground

which could result in property damage, per-

sonal injury or death.

The drum assembly consists of three basic assemblies:

a) Drum with integral ring gear. The drum is not inter-

changeable with the drum used on the standard hoist.

b) Output planetary gear set

c) Primary planetary gear set

The full & controlled release free fall group consists of

a large diameter multi-plate wet disc brake, which is

clamped between the rear face of the brake housing and

a spring applied piston. A brake shaft is splined to the

brake plates. The brake shaft passes through the base

side plate and into the drum, where it is splined into the

outer planet carrier. Thus, when in normal hoisting and

lowering mode the brake plates are clamped by the

spring applied piston, preventing the brake shaft and out-

put planet carrier from rotating.

When the free fall is activated, hydraulic pressure is

applied to the piston, which is then moved back com-

pressing the brake springs, and releasing the multi-disc

brake. This allows the brake shaft and output planet car-

rier to rotate, and in turn allows the cable drum to freely

rotate. The output sun gear and input planet carrier

assembly also rotate, but the input sun gear and motor

shaft remain stationary.

Control Group (controlled free fall only) The control

group consists of three elements:

a) A metered oil supply to the controlled free fall brake

release piston. This oil supply is set between 1.6 gpm

(6.1 lpm) and 1.8 gpm (6.8 lpm). The lower setting is

used if it is desired to restrict the lowering velocity to a

fairly low value, and the higher setting is used if lower-

ing speeds of approximately 1500 fpm (457 mpm) are

required. The actual lowering speed of the load will

vary depending on the working layer at the time and

the drum barrel diameter.

b) The metered oil supply passes through the control

valve. The valve has been selected with a particular

metering spool to provide good control over the wide

range of loads which will be handled.

c) Between the control valve and the brake release port,

the hydraulic line is divided, one side going to the

brake release port and the other side going to the

metering pump.

The metering pump is attached externally to the end of

the free fall brake housing and is keyed to the brake shaft,

so that when the brake is released and the brake shaft

rotates, it drives the pump.

When the pressure increases in the brake release line,

the drum is allowed to rotate and the load begins to accel-

erate downwards. The brake shaft rotates at approxi-

mately the same speed as the drum and drives the meter-

ing pump. As the speed increases, the metering pump

begins to draw oil away from the brake release line, and

thus decreases the brake release pressure. This stabi-

lizes the velocity for a given handle movement on the

control valve and also limits the maximum velocity should

the control valve be fully open, however, as mentioned

above, if the control valve is fully opened abruptly, it will

cause the metering pump to overcompensate, causing

the load to descend in a rapid surging motion.

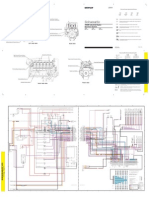

FREE FALL OPERATION

To

Drain

1.8 gpm (6.8 lpm)

to

2.2 gpm (8.3 lpm)

Cooling Oil In

Free Fall

Brake

Release Port

1.6 gpm (6.1 lpm) to

1.8 gpm (6.8 lpm)

800 psi

(5500 kPa)

Port 1

Port 2

P

T

PD12C Controlled Free Fall Circuit

Valve Supplied by Customer

Valvoil SV10S02G106C103A

Optional 06 Detent. See Text

Free Fall

Brake

Release Port

Normal Location of Vent Plug

for Hoists Mounted Upright

1.5 gpm

(5.7 lpm)

MINIMUM

1500 psi

(10300 kPa)

Oil Level

Plug

Alternate Location

of Vent Plug for

Hoists Mounted

Inverted

PD12C Full Release Free Fall Circuit

Metering

Pump

F

U

L

L

R

E

L

E

A

S

E

F

R

E

E

F

A

L

L

C

O

N

T

R

O

L

L

E

D

F

R

E

E

F

A

L

L

Controlled Free Fall Parts

Full Release Free Fall Parts

Apply Loctite #242 to

threads and torque to

75 lb-ft (103 N-m)

Apply Loctite #242 to

threads and torque to

9 lb-ft (12 N-m)

Apply Loctite #242 to

threads and torque to

75 lb-ft (103 N-m)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalheNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Whitepaper Fuel SystemsDocument8 pagesWhitepaper Fuel SystemsQaiser Iqbal100% (4)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 3500B Industrial Engine Electrical System: Left Side View Rear ViewDocument2 pages3500B Industrial Engine Electrical System: Left Side View Rear ViewEd Calhe0% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- WOMA Technical Data All Pumps en MedidasDocument11 pagesWOMA Technical Data All Pumps en MedidasEd CalheNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Volvo Prosis 2013 VMDocument2 pagesVolvo Prosis 2013 VMEd CalheNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- WarrenCATDynoReport2 3508Document11 pagesWarrenCATDynoReport2 3508Ed CalheNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Calibrating Pressure GaugesDocument4 pagesCalibrating Pressure GaugesRonny AndalasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- !rex Roller To Part Book TableDocument1 page!rex Roller To Part Book TableEd Calhe0% (1)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- BJ Pacemaker Spare Parts RQDocument1 pageBJ Pacemaker Spare Parts RQEd Calhe100% (1)

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 3406Document2 pages3406Ed CalheNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Datasheet 2494Document1 pageDatasheet 2494Ed CalheNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Hammer Master JCBDocument1 pageHammer Master JCBEd CalheNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Iadc Bit GradingDocument1 pageIadc Bit GradinganarkasisNo ratings yet

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- System Operation Mechanical Cat 3306 SN EpsDocument37 pagesSystem Operation Mechanical Cat 3306 SN EpsEd Calhe94% (18)

- 3 Way Direct Acting Solenoid Valve SV83Document4 pages3 Way Direct Acting Solenoid Valve SV83Ed CalheNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 261 267Document7 pages261 267Ed CalheNo ratings yet

- Top Driven Bowen BarcoDocument65 pagesTop Driven Bowen BarcoingcalderonNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Grooy D9Awiñg'S: Cam LineDocument1 pageGrooy D9Awiñg'S: Cam LineEd CalheNo ratings yet

- Power Swivel Torque ReactionDocument6 pagesPower Swivel Torque ReactionEd CalheNo ratings yet

- Injector Cut-Out Test ProcedureDocument9 pagesInjector Cut-Out Test ProcedureEd CalheNo ratings yet

- Strippers JU y JU HDocument5 pagesStrippers JU y JU HEd CalheNo ratings yet

- Melco Type F and FC Manual Valve PartsDocument4 pagesMelco Type F and FC Manual Valve PartsEd CalheNo ratings yet

- Oteco Shear Pin ChartDocument1 pageOteco Shear Pin ChartEd Calhe100% (1)

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalheNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- KG Act 3121269Document24 pagesKG Act 3121269Gustavo KemeñyNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- Cat314 MCVDocument11 pagesCat314 MCVAimHigh100% (1)

- Introduction To Machinery Principles: Mochammad Ariyanto, ST, MTDocument31 pagesIntroduction To Machinery Principles: Mochammad Ariyanto, ST, MTutsmanheruNo ratings yet

- 2001 Hermetic Check Operating InstructionsDocument6 pages2001 Hermetic Check Operating InstructionsAndres CarmonaNo ratings yet

- Ceiling DiffuserDocument2 pagesCeiling Diffuserabidch143No ratings yet

- Batidora HL600Document20 pagesBatidora HL600Dinosaurio1990No ratings yet

- Catalogue PROAUDIO With Pricelist 13-07-2015Document104 pagesCatalogue PROAUDIO With Pricelist 13-07-2015AntonioPalloneNo ratings yet

- Samsung Plasma TV TipsDocument75 pagesSamsung Plasma TV TipsErick Rodriguez100% (3)

- 2N7002K Small Signal MOSFET: 60 V, 380 Ma, Single, N Channel, SOT 23Document6 pages2N7002K Small Signal MOSFET: 60 V, 380 Ma, Single, N Channel, SOT 23Marcus SaxNo ratings yet

- WeBuyCars Sell Cars For Cash Free Online Vehicle ValuationsDocument1 pageWeBuyCars Sell Cars For Cash Free Online Vehicle ValuationsTimidha GovenderNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- "2005" Seminar Information: Jeep With 2.5 or 4.0 Liter Engines & Aw4 TransmissionDocument2 pages"2005" Seminar Information: Jeep With 2.5 or 4.0 Liter Engines & Aw4 TransmissionRoman NavaNo ratings yet

- CHK001 - Individual Apartment Checklist - Sign-OffDocument1 pageCHK001 - Individual Apartment Checklist - Sign-OffsummerNo ratings yet

- Daily Monitoring Defect SheetDocument15 pagesDaily Monitoring Defect Sheetmanju nathNo ratings yet

- Exhaust Header Length Calculation - OcmsDocument4 pagesExhaust Header Length Calculation - Ocmssayantan ghoshNo ratings yet

- HSN CodeDocument13 pagesHSN CodeDeepak GuptaNo ratings yet

- Mouse PDFDocument5 pagesMouse PDFjadhavbhavesh1131No ratings yet

- Desmontaje Mando Final D155AX-6Document3 pagesDesmontaje Mando Final D155AX-6claudioNo ratings yet

- DataSheet IGPMC-111GPDocument5 pagesDataSheet IGPMC-111GPMaaeglobal ResourcesNo ratings yet

- User Manual Toyota Supra MK4Document192 pagesUser Manual Toyota Supra MK4Wisnel Lara0% (1)

- Somfy GlydeaDocument14 pagesSomfy GlydeaKarth CenaNo ratings yet

- Manual JukeDocument345 pagesManual JukeMosta GartusNo ratings yet

- Embedded System Materials From A To ZDocument2 pagesEmbedded System Materials From A To ZAhmedYasserNo ratings yet

- 60x60 Led PanelDocument3 pages60x60 Led PanelKarthikeyan .NNo ratings yet

- GX1000 B Quick Reference ManualDocument26 pagesGX1000 B Quick Reference ManualRafał KwaśnyNo ratings yet

- Mosfet As AC SwitchDocument1 pageMosfet As AC Switchduppal35No ratings yet

- Diamec U6: Service Kits ForDocument47 pagesDiamec U6: Service Kits Forpeter_157608700No ratings yet

- 240, 260 Brakes Repair and MaintenanceDocument35 pages240, 260 Brakes Repair and Maintenancevanapeer100% (5)

- IRS2304 and IR2304 ComparisonDocument7 pagesIRS2304 and IR2304 ComparisonGiraldoCarpioRamosNo ratings yet

- CHS Module 4 - Install Computer Systems and NetworksDocument72 pagesCHS Module 4 - Install Computer Systems and NetworksLawrence Cada Nofies96% (55)

- Volkswagen MKVI Jetta W/keyless Start Traction Control Button Retrofit Kit Installation InstructionsDocument28 pagesVolkswagen MKVI Jetta W/keyless Start Traction Control Button Retrofit Kit Installation InstructionstomoNo ratings yet