Professional Documents

Culture Documents

DVM PLUS3 1 Outdoor Units

Uploaded by

Sattar Al-JabairCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DVM PLUS3 1 Outdoor Units

Uploaded by

Sattar Al-JabairCopyright:

Available Formats

Outdoor Units

Outdoor Units

Outdoor Units

Outdoor Units

SAMSUNG DVM Air Conditioner

DVM PLUS III

2010

High Ambient

DVM PLUS3__01_Outdoor units.indd 63 2010-03-08 5:19:40

Outdoor Units

DVM PLUS3__01_Outdoor units.indd 2 2010-03-08 5:18:34

Outdoor Units

DVM PLUS3__01_Outdoor units.indd 3 2010-03-08 5:18:34

2

1

2

3

Outdoor units

Indoor units

Accessories

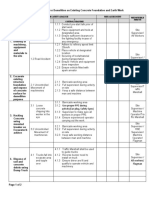

I. Products

6

9

11

1

2

3

4

5

6

7

8

Specifications

Dimensional drawing

PCB connector layout

Electrical wiring diagram

Sound pressure level

Operation limit

Cycle operation mode

Cycle function parts

II. Outdoor units

14

21

22

24

25

26

27

34

DVM PLUS3__01_Outdoor units.indd 2 2010-03-08 5:18:35

3

O

u

t

d

o

o

r

u

n

i

t

s

P

r

o

d

u

c

t

s

I

n

s

t

a

l

l

a

t

i

o

n

III. Installation

38

39

43

44

46

48

54

56

1

2

3

4

5

6

7

8

Outdoor unit combinations

Space requirements

Placing the outdoor units

Electric specifications

Wiring works

Refrigerant piping works

Option switches & function keys

Error codes

DVM PLUS3__01_Outdoor units.indd 3 2010-03-08 5:18:35

4

DVM PLUS III

DVM PLUS3__01_Outdoor units.indd 4 2010-03-08 5:18:35

5

P

r

o

d

u

c

t

s

I. Products

1 Outdoor units .............................................6

2 Indoor units ................................................9

3 Accessories .............................................11

DVM PLUS3__01_Outdoor units.indd 5 2010-03-08 5:18:35

6

1

Outdoor units

1-1. Nomenclature

' Classification

Outdoor unit R

D DVM

J FJM

D CAC

^ Capacity*

1/10 HP(3 digits)

Airflow direction

TROPICAL H/P Q

TROPICAL C/O T

H/P H

C/O C

H/R R

Type

General V

Unitary (RoofTop) R

DVM SLIM S

DVM MINI M

GHP G

Water DVM D

Model name

RVX

RD

' ^

H

V

T T

Q X

100

100

F

G

E

A

I

I I

I Rating voltage

220V, 60Hz B

220~240V, 50Hz E

380~415V, 50Hz, 3 phase G

380V, 60Hz, 3 phase H

460V, 60Hz, 3 phase J

I Version

Export A~Z

I Refrigerant

R410A X

DVM PLUS3__01_Outdoor units.indd 6 2010-03-08 5:18:35

7

P

r

o

d

u

c

t

s

TON 20.8 22.4 24.0 25.5 27.0 28.5

HP 26 28 30 32 34 36

Model Name RD260/280/300/320/340/360VQXGA

1-2. Line-up

TON 6.4 8.0 9.5

HP 8 10 12

Model Name RD080/100/120VQXGA

TON 12.8 14.4 16.0 17.5 19.0

HP 16 18 20 22 24

Model Name RD160/180/200/220/240VQXGA

DVM PLUS3__01_Outdoor units.indd 7 2010-03-08 5:18:35

8

1

Outdoor units

1-3. Outdoor unit combinations

1) Basic models

2) Combinations

Classification Capacity (Ton) Capacity (HP) Model

Single unit

6.4 8 RD080VQXGA

8.0 10 RD100VQXGA

9.5 12 RD120VQXGA

Classification Capacity (Ton) Capacity (HP)

Basic model

RD080VQXGA RD100VQXGA RD120VQXGA

Module unit

12.8 16 2

14.4 18 1 1

16.0 20 2

17.5 22 1 1

19.0 24 2

20.8 26 2 1

22.4 28 1 2

24.0 30 3

25.5 32 2 1

27.0 34 1 2

28.5 36 3

DVM PLUS3__01_Outdoor units.indd 8 2010-03-08 5:18:35

9

P

r

o

d

u

c

t

s

Indoor units

Model name

' Classification

Indoor unit (R410A) AVX

^ Classification by product group

Cassette type C

Duct type D

Wall mounted type W

Convertible type T

Mode

Heat Pump/Heat Recovery H

Product notation

Cassette type

Slim 1way S

2way 2

Mini 4way M

4way 4

Duct type

Slim S

Middle Static Pressure U

Wall mounted type

MB B

Neo Forte N

I Capacity*

1/10 kW (3 digits)

I Rating voltage

1, 220V, 60Hz B

1, 208V~230V, 60Hz C

1, 220V~240V, 50Hz E

I Version

Export A~Z

* Index

Notation Cooling Heating

022 2.2 2.5

028 2.8 3.2

036 3.6 4.0

045 4.5 5.0

056 5.6 6.3

060 6.0 6.8

071 7.1 8.0

090 9.0 10.0

112 11.2 12.5

128 12.8 13.8

140 14.0 16.0

RVX

AVX

'

V

C

^

H

S

T

H

100

022

F

E

E

E

I I I

2-1. Nomenclature

2

DVM PLUS3__01_Outdoor units.indd 9 2010-03-08 5:18:35

10

2

Indoor units

2-2. Line-up

2.2kW 2.8kW 3.6kW 4.5kW 5.6kW 6.0kW 7.1kW 9.0kW 11.2kW 12.8kW 14.0kW

Slim

1 way

cassette

Mini

4 way

cassette

4 way

cassette

Slim

duct

MSP

duct

Neo-

Forte

Capacity

Type

DVM PLUS3__01_Outdoor units.indd 10 2010-03-08 5:18:36

11

P

r

o

d

u

c

t

s

Accessories

3

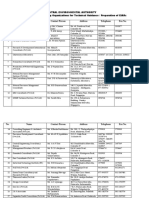

Classification Product Model Image Application model

Integrated

management

system

Controller

DMS MIM-D00A DVM Series, FJM, CAC

S-NET 3 MST-P3P DVM Series, FJM, CAC

S-NET mini MST-S3W DVM Series, FJM, CAC

Interface

module

SiM MIM-B12 DVM Series, FJM

Centralized

control system

Controller

Centralized

controller

MCM-A202B DVM Series, FJM, CAC

Function controller MCM-A100 DVM Series, FJM, CAC

Operation mode

selection switch

MCM-C200 DVM Series

Interface

module

Centralized

controller interface

module

MIM-B13B Mini DVM(R410A), DVM PLUS III, FJM

Individual control

system Controller

Controller

Wireless remote

controller

MR-CH01 Cassette, Duct(Receiver needed)

Wired remote

controller(Premium)

MWR-WS0 Cassette, Wall-mounted, Duct, Console

Wired remote

controller

(Multi function)

MWR-WE00 Cassette, Wall-mounted, Duct, Console

Wired remote

controller

MWR-WH00 Cassette, Wall-mounted, Duct, Console

Simplified wired

remote controller

MWR-SH00 Cassette, Wall-mounted, Duct, Console

Wireless

signal

receiver kit

Wireless

signal

receiver

MRK-A00 Duct (For wireless remote controller)

Receiver

wire

MRW-10A Duct (For wireless remote controller)

7-day scheduler MWR-BS00 Cassette, Wall-mounted, Duct

Building management

system

Lonworks

interface module

MIM-B07 DVM Series, FJM

Guest room management

system

Key-tag interface

module

MIM-B02 DVM Series, FJM

External contact

interface module

MIM-B14

Mini DVM(R410A), DVM PLUS III,

FJM(Non MHFKEA)

+ DVM Series : Mini DVM, DVM PLUS III

DVM PLUS3__01_Outdoor units.indd 11 2010-03-08 5:18:36

12

Accessories

3

Classification Feature Model Description Relevant unit Remark

Y-joint

MXJ-YA1509K 15.0 kW and below

DVM PLUS III Requisite

MXJ-YA2512K Over 15.0 ~ 40.6 kW and below

MXJ-YA2812K Over 40.6 ~ 46.4 kW and below

MXJ-YA2815K Over 46.4 ~ 69.6 kW and below

MXJ-YA3119K Over 69.6 ~ 98.6 kW and below

MXJ-YA3819K Over 98.6 ~ 100.5 kW and below

Outdoor joint

(Outdoor

Connection)

MXJ-T3819K Below 36 HP DVM PLUS III Requisite

Header joint

MXJ-HA2512K Below 46.4 kW

DVM PLUS III Requisite

MXJ-HA3115K Below 69.6 kW

MXJ-HA3819K Over 69.7 kW

EEV kits

MXD-A13K116A

Below 3.6 kW (1 Room) +

5.6 kW ~9.0 kW (1Room)

Wall-mounted

(For 2 indoor

units)

Option

MXD-A13K200A Below 3.6 kW (2 Rooms)

MXD-A16K200A 5.6 kW~9.0 kW (2Rooms)

MXD-A22K200A Over 9.0 kW (2Rooms)

MXD-A13K216A

Below 3.6 kW (2 Rooms) +

5.6 kW ~ 9.0 kW (1Room)

Wall-mounted

(For 3 indoor

units)

MXD-A13K300A Below 3.6 kW (3 Rooms)

MXD-A16K213A

Below 3.6 kW (1 Room) +

5.6 kW ~ 9.0 kW (2Rooms)

MXD-A16K300A 5.6 kW ~ 9.0 kW (3Rooms)

MEV-A13SA Below 3.6 kW (1 Room)

Wall-mounted

(For single unit)

MEV-A16SA 5.6 kW ~ 9.0 kW (1Room)

Drain pump

MDP-E075SEE Slim Duct (2.2 ~ 7.1) kW

- Option

MDP-E075SEE1 Slim Duct (9.0 ~ 14.0) kW

MDP-M075SGU1 MSP Duct (9.0/11.2) kW

MDP-M075SGU2 MSP Duct (12.8/14.0) kW

MDP-M075SGU3 MSP Duct (5.6/7.1) kW

Front panel

PSSMA Slim 1 way cassette

- Requisite

PMSMA Mini 4 way cassette

P4SMA 4 way cassette

DVM PLUS3__01_Outdoor units.indd 12 2010-03-08 5:18:36

13

O

u

t

d

o

o

r

u

n

i

t

s

II. Outdoor units

1 Specifications ......................................... 14

2 Dimensional drawing ...............................21

3 PCB connector layout ..............................22

4 Electrical wiring diagram .........................24

5 Sound pressure level ...............................25

6 Operation limit ..........................................26

7 Cycle operation mode .............................27

8 Cycle function parts .................................34

DVM PLUS3__01_Outdoor units.indd 13 2010-03-08 5:18:36

14

1

Specifications

Type

Model Name Basic RD080VQXGA RD010VQXGA RD120VQXGA

Power Supply / V/ Hz 3/ 380~415/ 50 3/ 380~415/ 50 3/ 380~415/ 50

Mode

*1)

- Heat Pump Heat Pump Heat Pump

Performance

Horse Power HP 8 10 12

Capacity

Cooling

*2)

kW 22.4 28.0 33.5

Btu/h 76,400 95,500 114,300

TR 6.4 8.0 9.5

Cooling

*3)

kW 22.4 25.0 28.5

Btu/h 76,400 85,300 97,200

TR 6.4 7.1 8.1

Heating

*4)

kW 25.0 31.5 37.5

Btu/h 85,300 107,500 128,000

TR 7.1 9.0 10.7

Power

Nominal Input

Cooling

*2)

kW

5.09 7.36 10.00

Cooling

*3)

8.09 8.93 11.02

Heating 5.74 7.18 9.06

Nominal Running

Current

Cooling

*2)

A

8.5 13.1 19.1

Cooling

*3)

14.3 15.7 20.5

Heating 10.9 12.7 17.9

Circuit Breaker (MCCB/ELB/ELCB) A 25 30 40

COP

Cooling

*2)

- 4.40 3.40 2.85

Cooling

*3)

- 2.77 2.80 2.59

Heating - 4.36 4.39 4.14

Compressor

Model -

ZPD72KCE-

TFD

ZP72KCE-TFD ZPD72KCE-

TFD

ZP72KCE-TFD ZPD83KCE-

TFD

ZP83KCE-TFD

Type - Digital Scroll Fixed Scroll Digital Scroll Fixed Scroll Digital Scroll Fixed Scroll

Number EA 1 1 1 1 1 1

Piston Displacement cc/Rev 67.1 67.1 67.1 67.1 77.2 77.2

Output kW 5.75 5.65 5.75 5.65 6.65 6.4

Lubricant

Type - 3MAF POE 3MAF POE 3MAF POE

Charging cc 1,981 1,981 1,981 1,981 1,981 1,981

Fan

Type / Control - Propeller/BLDC Propeller/BLDC Propeller/BLDC

Motor Output W 630 630 630

Airflow Rate m

3

/min 170 170 200

External Static

Pressure

Max.

mmAq 8 8 8

Pa 78.5 78.5 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch High Pressure Switch High Pressure Switch

- Crank Case Heater Crank Case Heater Crank Case Heater

- Fuse for PCB Fuse for PCB Fuse for PCB

Electronic Type

- Over Voltage Protection Over Voltage Protection Over Voltage Protection

- Current Transformer Current Transformer Current Transformer

-

Fan Motor Overheat/Current

protector

Fan Motor Overheat/Current

protector

Fan Motor Overheat/Current

protector

Piping

Connections

Liquid , mm 9.52 9.52 12.70

Gas , mm 19.05 22.23 28.58

Oil (Flare) , mm 6.35 6.35 6.35

Installation

Limitation

Max. Length m 200 200 200

Max. Height m 50 (40) 50 (40) 50 (40)

Refrigerant

Type - R410A R410A R410A

Factory Charging kg 8.5 8.5 8.5

Sound

4)

Sound Pressure dB(A) 57 58 60

Set Size

Net Weight kg 280 280 280

Shipping Weight kg 297 297 297

Net Dimensions (WxHxD) mm 1200 x 1668 x 765 1200 x 1668 x 765 1200 x 1668 x 765

Shipping Dimensions (WxHxD) mm 1268 x 1868 x 832 1268 x 1868 x 832 1268 x 1868 x 832

Cable

Main Power (Below 50m) mm

2

CV 2.5 CV 2.5 CV 4

Communication mm

2

0.75~1.5 0.75~1.5 0.75~1.5

Operating

Temp. Range

Cooling C -5~50 -5~50 -5~50

Heating C -20~24 -20~24 -20~24

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 14 2010-03-08 5:18:37

15

O

u

t

d

o

o

r

u

n

i

t

s

Type

Model Name

Basic RD160VQXGA RD180VQXGA

Basic

RD080VQXGA 2 1

RD100VQXGA 1

RD120VQXGA

Power Supply / V/ Hz 3/ 380~415/ 50 3/ 380~415/ 50

Mode

*1)

- Heat Pump Heat Pump

Performance

Horse Power HP 16 18

Capacity

Cooling

*2)

kW 44.8 50.4

Btu/h 152,800 171,900

TR 12.7 14.3

Cooling

*3)

kW 44.8 47.4

Btu/h 152,800 161,700

TR 12.7 13.5

Heating

*4)

kW 50.0 56.5

Btu/h 170,600 192,800

TR 14.2 16.1

Power

Nominal Input

Cooling

*2)

kW

10.18 12.45

Cooling

*3)

16.18 17.02

Heating 11.48 12.92

Nominal Running

Current

Cooling

*2)

A

17.0 21.6

Cooling

*3)

28.6 30.0

Heating 21.8 23.6

Circuit Breaker (MCCB/ELB/ELCB) A 50 60

COP

Cooling

*2)

- 4.40 4.05

Cooling

*3)

- 2.77 2.78

Heating - 4.36 4.37

Compressor

Model - ZPD72 ZPD83 ZP72 ZP83 ZPD72 ZPJ83 ZP72 ZPI83

Type - Digital Scroll Fixed Scroll Digital Scroll Fixed Scroll

Number EA 2 2 2 2

Piston Displacement cc/Rev 67.1 67.1 67.1 67.1

Output kW 5.75 5.65 5.75 5.65

Lubricant

Type - 3MAF POE 3MAF POE

Charging cc 1,981 1,981 1,981 1,981

Fan

Type / Control - Propeller/BLDC Propeller/BLDC

Motor Output W 630 x 2 630 x 2

Airflow Rate m

3

/min 170 x 2 170 x 2

External Static

Pressure

Max.

mmAq 8 8

Pa 78.5 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch High Pressure Switch

- Crank Case Heater Crank Case Heater

- Fuse for PCB Fuse for PCB

Electronic Type

- Over-voltage Protection Over-voltage Protection

- Current Transformer Current Transformer

- Fan Motor Overheat/Current Protector Fan Motor Overheat/Current Protector

Piping

Connections

Liquid , mm 15.88 15.88

Gas , mm 28.58 28.58

Discharge Gas , mm - -

Oil (Flare) , mm 6.35 6.35

Installation

Limitation

Max. Length

m 200 200

ft 656 656

Max. Height

m 50 (40) 50 (40)

ft 164 (131) 164 (131)

Refrigerant

Type - R410A R410A

Factory Charging kg 8.5 x 2 8.5 x 2

Sound

4)

Sound Pressure dB(A)

Set Size

Net Weight kg 280 x 2 280 x 2

Shipping Weight kg 297 x 2 297 x 2

Net Dimensions (WxHxD) mm (1200 x 1668 x 765) x 2 (1200 x 1668 x 765) x 2

Shipping Dimensions (WxHxD) mm (1268 x 1888 x 832) x 2 (1268 x 1888 x 832) x 2

Cable

Main Power (Below 50m) mm

2

CV 6 CV 10

Communication mm

2

0.75~1.5 0.75~1.5

Operating

Temp. Range

Cooling C -5~50 -5~50

Heating C -20~24 -20~24

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 15 2010-03-08 5:18:37

16

1

Type

Model Name

Basic RD200VQXGA RD220VQXGA

Basic

RD080VQXGA

RD100VQXGA 2 1

RD120VQXGA 1

Power Supply / V/ Hz 3/ 380~415/ 50 3/ 380~415/ 50

Mode

*1)

- Heat Pump Heat Pump

Performance

Horse Power HP 20 22

Capacity

Cooling

*2)

kW 56.0 61.6

Btu/h 191,000 210,100

TR 15.9 17.5

Cooling

*3)

kW 50.0 53.5

Btu/h 170,600 182,500

TR 14.2 15.2

Heating

*4)

kW 63.0 69.0

Btu/h 215,000 235,500

TR 17.9 19.6

Power

Nominal Input

Cooling

*2)

kW

14.72 17.36

Cooling

*3)

17.86 19.95

Heating 14.36 16.24

Nominal Running

Current

Cooling

*2)

A

26.2 32.2

Cooling

*3)

31.4 36.2

Heating 25.4 30.6

Circuit Breaker (MCCB/ELB/ELCB) A 60 60

COP

Cooling

*2)

- 3.80 3.55

Cooling

*3)

- 2.80 2.68

Heating - 4.39 4.25

Compressor

Model - ZPD72 ZPJ83 ZP72 ZPI83 ZPD72 ZPD83 ZP72 ZP83

Type - Digital Scroll Fixed Scroll Digital Scroll

Number EA 2 2 1 1 1 1

Piston Displacement cc/Rev 67.1 67.1 67.1 77.2 67.1 77.2

Output kW 5.75 5.65 5.75 6.65 5.65 6.4

Lubricant

Type - 3MAF POE 3MAF POE

Charging cc 1,981 1,981 1,981 1,981 1,981 1,981

Fan

Type / Control - Propeller/BLDC Propeller/BLDC

Motor Output W 630 x 2 630 x 2

Airflow Rate m

3

/min 170 x 2 170 x 1 + 200 x 1

External Static

Pressure

Max.

mmAq 8 8

Pa 78.5 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch High Pressure Switch

- Crank Case Heater Crank Case Heater

- Fuse for PCB Fuse for PCB

Electronic Type

- Over-voltage Protection Over-voltage Protection

- Current Transformer Current Transformer

- Fan Motor Overheat/Current Protector Fan Motor Overheat/Current Protector

Piping

Connections

Liquid , mm 15.88 15.88

Gas , mm 28.58 28.58

Discharge Gas , mm - -

Oil (Flare) , mm 6.35 6.35

Installation

Limitation

Max. Length

m 200 200

ft 656 656

Max. Height

m 50 (40) 50 (40)

ft 164 (131) 164 (131)

Refrigerant

Type - R410A R410A

Factory Charging kg 8.5 x 2 8.5 x 2

Sound

4)

Sound Pressure dB(A)

Set Size

Net Weight kg 280 x 2 280 x 2

Shipping Weight kg 297 x 2 297 x 2

Net Dimensions (WxHxD) mm (1200 x 1668 x 765) x 2 (1200 x 1668 x 765) x 2

Shipping Dimensions (WxHxD) mm (1268 x 1888 x 832) x 2 (1268 x 1888 x 832) x 2

Cable

Main Power (Below 50m) mm

2

CV 10 CV 10

Communication mm

2

0.75~1.5 0.75~1.5

Operating

Temp. Range

Cooling C -5~50 -5~50

Heating C -20~24 -20~24

Specifications

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 16 2010-03-08 5:18:37

17

O

u

t

d

o

o

r

u

n

i

t

s

Type

Model Name

Basic RD240VQXGA RD260VQXGA

Basic

RD080VQXGA 2

RD100VQXGA 1

RD120VQXGA 2

Power Supply / V/ Hz 3/ 380~415/ 50 3/ 380~415/ 50

Mode

*1)

- Heat Pump Heat Pump

Performance

Horse Power HP 24 26

Capacity

Cooling

*2)

kW 67.2 72.8

Btu/h 229,200 248,300

TR 19.1 20.7

Cooling

*3)

kW 57.0 69.8

Btu/h 194,400 238,100

TR 16.2 19.8

Heating

*4)

kW 75.0 81.5

Btu/h 256,000 278,100

TR 21.3 23.2

Power

Nominal Input

Cooling

*2)

kW

20.00 17.54

Cooling

*3)

22.04 25.11

Heating 18.12 18.66

Nominal Running

Current

Cooling

*2)

A

38.2 30.1

Cooling

*3)

41.0 44.3

Heating 35.8 34.5

Circuit Breaker (MCCB/ELB/ELCB) A 75 75

COP

Cooling

*2)

- 3.36 4.15

Cooling

*3)

- 2.59 2.78

Heating - 4.14 4.37

Compressor

Model - ZPD72 ZPD83 ZP72 ZP83 ZPD72 ZPD83 ZP72 ZP83

Type - Digital Scroll Fixed Scroll Digital Scroll Fixed Scroll

Number EA 2 2 3 3

Piston Displacement cc/Rev 77.2 77.2 67.1 67.1

Output kW 6.65 6.4 5.75 5.65

Lubricant

Type - 3MAF POE 3MAF POE

Charging cc 1,981 1,981 1,981 1,981

Fan

Type / Control - Propeller/BLDC Propeller/BLDC

Motor Output W 630 x 2 630 x 3

Airflow Rate m

3

/min 200 x 2 170 x 3

External Static

Pressure

Max.

mmAq 8 8

Pa 78.5 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch High Pressure Switch

- Crank Case Heater Crank Case Heater

- Fuse for PCB Fuse for PCB

Electronic Type

- Over-voltage Protection Over-voltage Protection

- Current Transformer Current Transformer

- Fan Motor Overheat/Current Protector Fan Motor Overheat/Current Protector

Piping

Connections

Liquid , mm 19.05 19.05

Gas , mm 31.75 31.75

Discharge Gas , mm - -

Oil (Flare) , mm 6.35 6.35

Installation

Limitation

Max. Length

m 200 200

ft 656 656

Max. Height

m 50 (40) 50 (40)

ft 164 (131) 164 (131)

Refrigerant

Type - R410A R410A

Factory Charging kg 8.5 x 2 8.5 x 3

Sound

4)

Sound Pressure dB(A)

Set Size

Net Weight kg 280 x 2 280 x 3

Shipping Weight kg 297 x 2 297 x 3

Net Dimensions (WxHxD) mm (1200 x 1668 x 765) x 2 (1200 x 1668 x 765) x 3

Shipping Dimensions (WxHxD) mm (1268 x 1888 x 832) x 2 (1268 x 1888 x 832) x 3

Cable

Main Power (Below 50m) mm

2

CV 10 CV 16

Communication mm

2

0.75~1.5 0.75~1.5

Operating

Temp. Range

Cooling C -5~50 -5~50

Heating C -20~24 -20~24

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 17 2010-03-08 5:18:37

18

1

Specifications

Type

Model Name

Basic RD280VQXGA RD300VQXGA

Basic

RD080VQXGA 1

RD100VQXGA 2 3

RD120VQXGA

Power Supply / V/ Hz 3/ 380~415/ 50 3/ 380~415/ 50

Mode

*1)

- Heat Pump Heat Pump

Performance

Horse Power HP 28 30

Capacity

Cooling

*2)

kW 78.4 84.0

Btu/h 267,400 286,500

TR 22.3 23.9

Cooling

*3)

kW 72.4 75.0

Btu/h 247,000 255,900

TR 20.6 21.3

Heating

*4)

kW 88.0 94.5

Btu/h 300,300 322,500

TR 25.0 26.9

Power

Nominal Input

Cooling

*2)

kW

19.81 22.08

Cooling

*3)

25.95 26.79

Heating 20.10 21.54

Nominal Running

Current

Cooling

*2)

A

34.7 39.3

Cooling

*3)

45.7 47.1

Heating 36.3 38.1

Circuit Breaker (MCCB/ELB/ELCB) A 75 100

COP

Cooling

*2)

- 3.96 3.80

Cooling

*3)

- 2.79 2.80

Heating - 4.38 4.39

Compressor

Model - ZPD72 ZPD83 ZP72 ZP83 ZPD72 ZPD83 ZP72 ZP83

Type - Digital Scroll Fixed Scroll Digital Scroll Fixed Scroll

Number EA 3 3 3 3

Piston Displacement cc/Rev 67.1 67.1 67.1 67.1

Output kW 5.75 5.65 5.75 5.65

Lubricant

Type - 3MAF POE 3MAF POE

Charging cc 1,981 1,981 1,981 1,981

Fan

Type / Control - Propeller/BLDC Propeller/BLDC

Motor Output W 630 x 3 630 x 3

Airflow Rate m

3

/min 170 x 3 170 x 3

External Static

Pressure

Max.

mmAq 8 8

Pa 78.5 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch High Pressure Switch

- Crank Case Heater Crank Case Heater

- Fuse for PCB Fuse for PCB

Electronic Type

- Over-voltage Protection Over-voltage Protection

- Current Transformer Current Transformer

- Fan Motor Overheat/Current Protector Fan Motor Overheat/Current Protector

Piping

Connections

Liquid , mm 19.05 19.05

Gas , mm 31.75 31.75

Discharge Gas , mm - -

Oil (Flare) , mm 6.35 6.35

Installation

Limitation

Max. Length

m 200 200

ft 656 656

Max. Height

m 50 (40) 50 (40)

ft 164 (131) 164 (131)

Refrigerant

Type - R410A R410A

Factory Charging kg 8.5 x 3 8.5 x 3

Sound

4)

Sound Pressure dB(A)

Set Size

Net Weight kg 280 x 3 280 x 3

Shipping Weight kg 297 x 3 297 x 3

Net Dimensions (WxHxD) mm (1200 x 1668 x 765) x 3 (1200 x 1668 x 765) x 3

Shipping Dimensions (WxHxD) mm (1268 x 1888 x 832) x 3 (1268 x 1888 x 832) x 3

Cable

Main Power (Below 50m) mm

2

CV 16 CV 16

Communication mm

2

0.75~1.5 0.75~1.5

Operating

Temp. Range

Cooling C -5~50 -5~50

Heating C -20~24 -20~24

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 18 2010-03-08 5:18:38

19

O

u

t

d

o

o

r

u

n

i

t

s

Type

Model Name

Basic RD320VQXGA RD340VQXGA

Basic

RD080VQXGA

RD100VQXGA 2 1

RD120VQXGA 1 2

Power Supply / V/ Hz 3/ 380~415/ 50 3/ 380~415/ 50

Mode

*1)

- Heat Pump Heat Pump

Performance

Horse Power HP 32 34

Capacity

Cooling

*2)

kW 89.6 95.2

Btu/h 305,600 324,700

TR 25.5 27.1

Cooling

*3)

kW 78.5 82.0

Btu/h 267,800 279,700

TR 22.3 23.3

Heating

*4)

kW 100.5 106.5

Btu/h 343,000 363,500

TR 28.6 30.3

Power

Nominal Input

Cooling

*2)

kW

24.72 27.36

Cooling

*3)

28.88 30.97

Heating 23.42 25.30

Nominal Running

Current

Cooling

*2)

A

45.3 51.3

Cooling

*3)

51.9 56.7

Heating 43.3 48.5

Circuit Breaker (MCCB/ELB/ELCB) A 100 100

COP

Cooling

*2)

- 3.62 3.48

Cooling

*3)

- 2.72 2.65

Heating - 4.29 4.21

Compressor

Model - ZPD72 ZPD83 ZP72 ZP83 ZPD72 ZPD83 ZP72 ZP83

Type - Digital Scroll Fixed Scroll Digital Scroll Fixed Scroll

Number EA 2 1 2 1 1 2 1 2

Piston Displacement cc/Rev 67.1 77.2 67.1 77.2 67.1 77.2 67.1 77.2

Output kW 5.75 6.65 5.65 6.4 5.75 6.65 5.65 6.4

Lubricant

Type - 3MAF POE 3MAF POE

Charging cc 1,981 1,981 1,981 1,981 1,981 1,981 1,981 1,981

Fan

Type / Control - Propeller/BLDC Propeller/BLDC

Motor Output W 630 x 3 630 x 3

Airflow Rate m

3

/min 170 x 2 + 200 x 1 170 x 1 + 200 x 2

External Static

Pressure

Max.

mmAq 8 8

Pa 78.5 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch High Pressure Switch

- Crank Case Heater Crank Case Heater

- Fuse for PCB Fuse for PCB

Electronic Type

- Over-voltage Protection Over-voltage Protection

- Current Transformer Current Transformer

- Fan Motor Overheat/Current Protector Fan Motor Overheat/Current Protector

Piping

Connections

Liquid , mm 19.05 19.05

Gas , mm 31.75 31.75

Discharge Gas , mm - -

Oil (Flare) , mm 6.35 6.35

Installation

Limitation

Max. Length

m 200 200

ft 656 656

Max. Height

m 50 (40) 50 (40)

ft 164 (131) 164 (131)

Refrigerant

Type - R410A R410A

Factory Charging kg 8.5 x 3 8.5 x 3

Sound

4)

Sound Pressure dB(A)

Set Size

Net Weight kg 280 x 3 280 x 3

Shipping Weight kg 297 x 3 297 x 3

Net Dimensions (WxHxD) mm (1200 x 1668 x 765) x 3 (1200 x 1668 x 765) x 3

Shipping Dimensions (WxHxD) mm (1268 x 1888 x 832) x 3 (1268 x 1888 x 832) x 3

Cable

Main Power (Below 50m) mm

2

CV 16 CV 16

Communication mm

2

0.75~1.5 0.75~1.5

Operating

Temp. Range

Cooling C -5~50 -5~50

Heating C -20~24 -20~24

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 19 2010-03-08 5:18:38

20

Specifications

1

Type

Model Name

Basic RD360VQXGA

Basic

RD080VQXGA

RD100VQXGA

RD120VQXGA 3

Power Supply / V/ Hz 3/ 380~415/ 50

Mode

*1)

- Heat Pump

Performance

Horse Power HP 36

Capacity

Cooling

*2)

kW 100.8

Btu/h 343,800

TR 28.7

Cooling

*3)

kW 85.5

Btu/h 291,600

TR 24.3

Heating

*4)

kW 112.5

Btu/h 384,000

TR 32.0

Power

Nominal Input

Cooling

*2)

kW

30.00

Cooling

*3)

33.06

Heating 27.18

Nominal Running

Current

Cooling

*2)

A

57.3

Cooling

*3)

61.5

Heating 53.7

Circuit Breaker (MCCB/ELB/ELCB) A 100

COP

Cooling

*2)

- 3.36

Cooling

*3)

- 2.59

Heating - 4.14

Compressor

Model - ZPD72 ZPD83 ZP72 ZP83

Type - Digital Scroll Fixed Scroll

Number EA 3 3

Piston Displacement cc/Rev 77.2 77.2

Output kW 6.65 6.4

Lubricant

Type - 3MAF POE

Charging cc 1,981 1,981

Fan

Type / Control - Propeller/BLDC

Motor Output W 630 x 3

Airflow Rate m

3

/min 200 x 3

External Static

Pressure

Max.

mmAq 8

Pa 78.5

Safety

Devices

Mechanical Type

- High Pressure Switch

- Crank Case Heater

- Fuse for PCB

Electronic Type

- Over-voltage Protection

- Current Transformer

- Fan Motor Overheat/Current Protector

Piping

Connections

Liquid , mm 19.05

Gas , mm 38.10

Discharge Gas , mm -

Oil (Flare) , mm 6.35

Installation

Limitation

Max. Length

m 200

ft 656

Max. Height

m 50 (40)

ft 164 (131)

Refrigerant

Type - R410A

Factory Charging kg 8.5 x 3

Sound

4)

Sound Pressure dB(A)

Set Size

Net Weight kg 280 x 3

Shipping Weight kg 297 x 3

Net Dimensions (WxHxD) mm (1200 x 1668 x 765) x 3

Shipping Dimensions (WxHxD) mm (1268 x 1888 x 832) x 3

Cable

Main Power (Below 50m) mm

2

CV 25

Communication mm

2

0.75~1.5

Operating

Temp. Range

Cooling C -5~50

Heating C -20~24

*1) Mode = HP : Heat Pump, HR : Heat Recovery

*2) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 35C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*3) Nominal cooling capacities are based on;

Indoor temperature : 27C DB, 19C WB / Outdoor temperature : 46C DB, Equivalent refrigerant piping : 7.5m , Level differences : 0m

*4) Nominal heating capacities are based on;

Indoor temperature : 20C DB, 15C WB / Outdoor temperature : 7C DB, 6C WB, Equivalent refrigerant piping : 7.5m, Level differences : 0m

*5) Sound level was acquired in a dead room. Thus actual noise level may be different depending on the installation conditions.

*6) Specifications are subject to change without prior notice for product improvement.

DVM PLUS3__01_Outdoor units.indd 20 2010-03-08 5:18:38

21

O

u

t

d

o

o

r

u

n

i

t

s

2-1. RD080/100/120VQXGA

No. Name Description No. Name Description

1 Gas pipe connection 57.10, knock-out hole 10 Power & communication wiring conduit 34.50, knock-out hole hole-side

2 High pressure gas pipe connection 57.10, knock-out hole 11 Power & communication wiring conduit 34.50, knock-out hole hole-side

3 Liquid pipe connection 37.10, knock-out hole 12 Power & communication wiring conduit 34.50, knock-out hole hole-side

4 Oil balance pipe connection between units 32.10, knock-out hole 13 Power & communication wiring conduit 34.50, knock-out hole hole-side

5 Power & communication wiring conduit 34.50, knock-out hole hole-front 14 Power & communication wiring conduit 27.80, knock-out hole hole-side

6 Power & communication wiring conduit 34.50, knock-out hole hole-front 15 Power & communication wiring conduit 34.50, knock-out hole hole-side

7 Power & communication wiring conduit 43.70, knock-out hole hole-front 16 Pipe connection through base Pipes connection opening with cover

8 Power & communication wiring conduit 43.70, knock-out hole hole-front 17 Condensate drain holes 20mm-2 holes

9 Power & communication wiring conduit 43.70, knock-out hole hole-front 18 Foundation bolts positions 4-12 x 20 slit-hole

Unit : mm

Dimensional drawing

2

DVM PLUS3__01_Outdoor units.indd 21 2010-03-08 5:18:39

22

PCB connector layout

3

3-1. Main PCB

1 6 7 8 9 2

3

4

5

10

11

12

13 23 24 25 26 27 28 29 32

31 35

16 20 21 22 17 18 19 14 15

33

30

34

36

37

No. CN # COLOR FUNCTION

1 CN901 Red Power Trans Out (AC 17V)

2 CN13 Black 5V for Interface Module

3 CN31 Red CommunicationwithIndoorUnits(COM1)

4 CN32 Yellow Communication with Outdoor units

5 CN12 Blue 12V for Interface Module

6 CN92 Black Sub MICOM Download

7 CN91 Black Main MICOM Download

8 CN10 White Main MICOM Download (N/A)

9 CN100 White Main MICOM Download (N/A)

10 CN83 Yellow 3 Phase Detection

11 OPT1 White Mode Selector (Cooling/Heating)

12 CN51 Red CT Sensor

13 CN70 Black AC 230V Input

14 CN76 Yellow Comp.1 CCH, Comp.2 CCH

15 CN15 White Comp.3 CCH, Accum. CCH

16 CN81 Black Oil Valve 1

17 CN82 Yellow Oil Valve 2

18 CN80 Red Oil Valve 3

19 CN72 Blue Compressor Control

No. CN # COLOR FUNCTION

20 CN74 Red Hot gas Bypass Valve

21 CN71 White PWM Valve

22 CN73 Yellow 4 Way Valve

23 CN84 Blue Main Cooling Valve (HR Only)

24 CN85 Yellow Outdoor Unit EEV Valve

25 CN75 White EVI Bypass Valve

26 CN86 Blue Liquid Bypass Valve

27 CN41 Blue Low Pressure Sensor

28 CN42 Red High Pressure Sensor

29 CN49 White Sump Sensor, Ambient Sensor

30 CN48 Red EVI-In Sensor, EVI-Out Sensor

31 CN47 White

Oil Balance Sensor, Cond. Out

Sensor, Liquid Tube Sensor

32 CN44 White

Comp. Discharge 1,2,3 Sensor,

Suction Sensor

33 CN64 Blue EVI EEV

34 CN63 Yellow Main EEV2

35 CN65 Black HR EEV (HR Only)

36 CN62 Blue Main EEV1

37 CN99 White Main-BLDC Driver PCB Connector

DVM PLUS3__01_Outdoor units.indd 22 2010-03-08 5:18:39

23

O

u

t

d

o

o

r

u

n

i

t

s

3-2. BLDC Driver PCB

3-3. Noise filter PCB

3-4. CT PCB

43

38

34

35

37

36

39

41

40

42

No. CN # COLOR FUNCTION

34 CN701 Blue AC 230V Input

35 GT2 White Power Trans In (AC 230V)

36 CN703 Black AC 230V Output

37 CN501 White

Main-BLDC Driver

PCB Connector

38 CN101 White Motor Signal

39 CN301 White Motor Power

No. CN # COLOR FUNCTION

40 L/N Silver AC 230V Input

41 CN702 White Earth

42 CN701 Blue AC 230V Output

No. CN # COLOR FUNCTION

43 CN61 Red Comp. 1,2 CT Output

DVM PLUS3__01_Outdoor units.indd 23 2010-03-08 5:18:40

24

4

Electrical wiring diagram

K13 K14 Unit option

On On MAIN unit

On Off SUB 1 unit

Off On SUB 2 unit

Off Off SUB 3 unit

DVM PLUS3__01_Outdoor units.indd 24 2010-03-08 5:18:41

25

O

u

t

d

o

o

r

u

n

i

t

s

Sound pressure level

5

5-1. Operation sound level

1m

Microphone

Front

+ These operation values were obtained in a dead room. Sound pressure level will vary depending on a range of

factors such as the construction of the particular room where the equipment is installed.

+ Operation sound level may differ depending on operation and ambient conditions.

E

Note

Model High

RD080VQXGA 57

RD100VQXGA 58

RD120VQXGA 60

Unit: dB(A)

5-2. NC curves (Heat Pump)

1) RD080VQXGA

3) RD120VQXGA

2) RD100VQXGA

S

o

u

n

d

p

r

e

s

s

u

r

e

l

e

v

e

l

(

d

B

)

Octave band center frequency(Hz)

70

NC 65

65

60

55

50

45

40

35

30

25

63 125 250 500 1000 2000 4000 8000

NC 60

NC 55

NC 50

NC 45

NC 40

NC 35

NC 30

S

o

u

n

d

p

r

e

s

s

u

r

e

l

e

v

e

l

(

d

B

)

Octave band center frequency(Hz)

70

NC 65

65

60

55

50

45

40

35

30

25

63 125 250 500 1000 2000 4000 8000

NC 60

NC 55

NC 50

NC 45

NC 40

NC 35

NC 30

S

o

u

n

d

p

r

e

s

s

u

r

e

l

e

v

e

l

(

d

B

)

Octave band center frequency(Hz)

70

NC 65

65

60

55

50

45

40

35

30

25

63 125 250 500 1000 2000 4000 8000

NC 60

NC 55

NC 50

NC 45

NC 40

NC 35

NC 30

DVM PLUS3__01_Outdoor units.indd 25 2010-03-08 5:18:41

26

6

Operation limit

6-1. Cooling 6-2. Heating

50

10 15 20 25 30

45

40

35

30

25

20

15

10

5

0

-5

O

u

t

d

o

o

r

t

e

m

p

e

r

a

t

u

r

e

(

F

D

B

)

R

a

n

g

e

f

o

r

o

p

e

r

a

t

i

o

n

R

a

n

g

e

f

o

r

p

u

l

l

d

o

w

n

o

p

e

r

a

t

i

o

n

Indoor temperature(F WB)

10 15 20 25 30

25

20

15

10

5

0

-5

-10

-15

-20

O

u

t

d

o

o

r

t

e

m

p

e

r

a

t

u

r

e

(

F

D

B

)

R

a

n

g

e

f

o

r

w

a

r

m

i

n

g

u

p

o

p

e

r

a

t

i

o

n

Indoor temperature(F WB)

Range for

continuous

operation

DVM PLUS3__01_Outdoor units.indd 26 2010-03-08 5:18:41

27

O

u

t

d

o

o

r

u

n

i

t

s

Cycle operation mode

7

7-1. Description of cycle function parts

No Classification Description

1 A DVI (Digital Vapor Injection) compressor

2 B FVI (Fixed Vapor Injection) compressor 1

3 C FVI (Fixed Vapor Injection) compressor 2

4 D PWM solenoid valve

5 E Discharge temperature sensor of DVI compressor

6 F Discharge temperature sensor of FVI compressor 1

7 G Discharge temperature sensor of FVI compressor 2

8 H Oil separator

9 I Capillary tube from oil separator

10 J High pressure switch

11 K Hot gas bypass solenoid valve

12 L Check valve

13 M High pressure sensor

14 N Reversing solenoid valve (4way valve)

15 O Heat exchanger of outdoor unit (Condensing unit)

16 P Ambient air temperature sensor

17 Q Cond_out temperature sensor

18 R Main EEV 1 ( For heating operation)

19 S Main EEV 2 ( For heating operation)

20 T Check valve

21 U Liquid bypass solenoid valve

22 V EVI EEV

23 W Turbo Intercooler

24 X EVI_in temperature sensor

25 Y EVI_out temperature sensor

26 Z Liquid tube temperature sensor

27 a EVI bypass pilot solenoid valve

28 b Suction temperature sensor

29 c Accumulator

30 d Accumulator CCH (Crank Case Heater)

31 e Oil solenoid valve 1

32 f Oil solenoid valve 2

33 g Oil solenoid valve 3

34 h Oil balancing service valve between units

35 i Low pressure sensor

36 j Check valve

37 k Crank case heater of DVI compressor

38 m Crank case heater of FVI compressor 1

DVM PLUS3__01_Outdoor units.indd 27 2010-03-08 5:18:41

28

7

Cycle operation mode

No Classification Description

39 n Crank case heater of FVI compressor 2

40 o Sump(Base) temperature sensor

41 p Oil temperature sensor

42 q Capillary tube from hot gas bypass valve

43 r Capillary tube from liquid bypass valve

44 s High pressure liquid service valve

45 t Low pressure gas service valve only for HR/MCU unit

46 u EEV of indoor unit

47 v Eva_in temperature sensor

48 w Heat exchanger of indoor unit (Evaporating unit)

49 x Eva_out temperature sensor

50 y HR check valve

51 z Main cooling check valve

52 a Main cooling pilot solenoid valve

53 b Outdoor pilot solenoid valve

54 c HR EEV

55 d HR EEV check valve

56 e

High pressure gas service valve in HR/MCU unit

Low pressure gas service valve in HP unit (Heat Pump)

57 f Heating solenoid valve

58 g Cooling solenoid valve

59 h MCU liquid bypass solenoid valve

60 i MCU main heating pilot solenoid valve

61 j MCU EEV

62 k Sub cooler_in temperature sensor

63 m Sub cooler

64 n Sub cooler_out temperature sensor

65 o Sub cooler EEV

66 p

Liquid service valve between MCU &

Indoor unit

67 q

Gas service valve between MCU &

Indoor unit

68 r EEV bypass service valve

69 s EEVs for wall mount & ceiling unit in MCU

7-1. Description of cycle function parts

DVM PLUS3__01_Outdoor units.indd 28 2010-03-08 5:18:41

29

O

u

t

d

o

o

r

u

n

i

t

s

Category Description

1 Sensor

Temperature Temperature sensor

Pressure High / Low Pressure sensor

2 Valve

Solenoid

ss

Solenoid valve

Pilot Solenoid

sss

Pilot solenoid valve

Expansion

EE

Electronic Expansion Valve (EEV)

Reversing Reversing valve

Check Check valve

Service Service valve (Angle & ball type)

3 Switch & Heater

Pressure Switch High pressure switch (Mechanical type)

Heater HH Electric heater

4 Others

Compressor

DVI (Digital Vapor Injection) Compressor

FVI (Fixed Vapor Injection) Compressor

Accumulator Accumulator

Heat Exchanger Condensing or Evaporating unit

Sub cooler Turbo Intercooler or Sub cooler

Capillary Capillary tube

DVM PLUS3__01_Outdoor units.indd 29 2010-03-08 5:18:41

30

Cycle operation mode

7

7-2. Cycle diagrams

1) RD080/100/120/VQXG(DVM PLUS III - 8/10/12HP )

g

B

H

H

A

k

H

s

s

D

E F

H

I

T

W

Y

Z

b

f

h

j

o

d

p

K

C

U

r

q

O

P

Q

G

U

V

S

e

t

E

R

N

M

L

J

s

s

s

a

c

i

m

s

s

E

V

X

s

DVM PLUS3__01_Outdoor units.indd 30 2010-03-08 5:18:42

31

O

u

t

d

o

o

r

u

n

i

t

s

2) EEV kits & Indoor units

(1) MXD series

(3) Indoor units

(2) MEV series

s

E

E

e

q

p

u

E

v w x

q

p

v w x

q

p

s

E

p

s

E

E

E

e

q

p

2 rooms

Indoor units with built-in EEV Indoor units without EEV (Wall mounted)

3 rooms Single room

DVM PLUS3__01_Outdoor units.indd 31 2010-03-08 5:18:42

32

7

Cycle operation mode

7-2. Cycle diagrams

3) Cooling operation

Unit Outdoor unit Indoor unit Outdoor unit

Cooling operation C C C C C C

Heating operation

E E E E EE

C

o

o

l

i

n

g

C

o

o

l

i

n

g

C

o

o

l

i

n

g

C

o

o

l

i

n

g

C

o

o

l

i

n

g

C

o

o

l

i

n

g

H

H

H

s

s

H

E

s

s

s

ss

E

L

o

w

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

l

i

q

u

i

d

H

i

g

h

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

g

a

s

H

i

g

h

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

l

i

q

u

i

d

L

o

w

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

g

a

s

DVM PLUS3__01_Outdoor units.indd 32 2010-03-08 5:18:42

33

O

u

t

d

o

o

r

u

n

i

t

s

4) Heating operation

Unit Outdoor unit Indoor unit Outdoor unit

Cooling operation

Heating operation C C C C C C

E E E E EE

H

e

a

t

i

n

g

H

e

a

t

i

n

g

H

e

a

t

i

n

g

H

e

a

t

i

n

g

H

e

a

t

i

n

g

H

e

a

t

i

n

g

H

H

H

s

s

H

E

s

s

s

ss

E

L

o

w

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

l

i

q

u

i

d

H

i

g

h

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

g

a

s

H

i

g

h

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

l

i

q

u

i

d

L

o

w

t

e

m

p

e

r

a

t

u

r

e

&

p

r

e

s

s

u

r

e

g

a

s

DVM PLUS3__01_Outdoor units.indd 33 2010-03-08 5:18:42

34

8

Cycle function parts

8-1. RD080/100/120VQXG

DVI compressor

Oil separator

High pressure sensor

Low pressure sensor

Accumlator

PWM valve

Ambient air temp. sensor

Liquid service valve

Low pressure gas service valve

Cond_out temp. sensor

EVI EEV

Liquid

bypass valve

Turbo

intercooler

FVI compressor

Hot gas bypass valve

High pressure switch

Discharge temp. sensor

Oil valve

Sump temp. sensor

Oil service valve

DVM PLUS3__01_Outdoor units.indd 34 2010-03-08 5:18:46

35

O

u

t

d

o

o

r

u

n

i

t

s

8-2. A description of cycle function parts

No Cycle parts Functions

1

DVI compressor

Digital Vapor Injection)

DVI compressor coupled with vapor injection controls the capacity 10 to 100% of its ca-

pacity.

It enhances cooling and heating performance and COP with using vapor injection.

2

FVI compressor

(Fixed Vapor Injection)

FVI compressor coupled with vapor injection is fixed compressor. It enhances cooling,

heating performance and COP with using vapor injection.

3 PWM valve

|t is used for variation of digital compressors capacity. When the valve is open, the DVI

compressor keeps the unloading state, otherwise loading state.

4 Discharge temp. sensor

It measures the temperature of compressor outlet. The main function of it is to protect

compressor from overheating.

5 Oil separator

It separates oil and refrigerant discharged from the compressor and returns the oil into

compressor again.

6 High pressure switch It protects the system from abnormal high pressure. (Open : 4.1Mpa, Close : 3.5 Mpa)

7 Hot gas bypass valve

When the suction pressure becomes abnormal low pressure, it opens.

During the oil balance operation, it makes high pressure for the shell of compressor

8 High pressure sensor

The main function of it controls the capacity of compressor in pursuit of target of high

pressure in heating operation by measuring the value of the system.

9 4way valve It enables to change operating mode into cooling and heating mode.

10 Ambient air temp. sensor It measures the temperature of ambient.

11 Cond_out temp. sensor It has application to know subcooling and the complete point of defrost.

12 Main EEV 1, 2

It controls the amount of refrigerant entering outdoors heat exchanger in heating

operation.

13 Liquid bypass valve When the compressor is overheating, it opens to make discharge temperature low.

14 EVI EEV

It enables to secure sufficient subcooling and control the amount of vapor entering into

vapor port of compressor.

15 Turbo intercooler

Through turbo intercooler, heat is exchanged each other between saturated liquid

refrigerant and a little expanded refrigerant.

16 EVI_in temp. sensor

These temperature sensors enable to control EVI EEVs step to secure superheat.

17 EVI_out temp. sensor

18 Liquid tube temp. sensor

It is used to know subcooling.

(Subcooling = The saturated temp. of high pressure - Liquid tube temp.)

19 EVI bypass valve This valve closes during application of vapor injection.

20 Suction temp. sensor This is applied to know superheat in heating mode with the low pressure sensor.

21 Accumulator Ambient air temperature sensor (Tair)

22 Oil valve When oil balance operation happens, this valve opens.

23 Low pressure sensor

The main function of it is to control the capacity of compressor in pursuit of target of low

pressure in cooling operation by measuring the low pressure.

24 Sump(Base) temp. sensor

With checking sump temperature of compressor, it prevents the compressor from liquid

back and overheating.

25 Oil temp. sensor While the oil balance is operating, it make a self-diagnosis of the oil valve.

26 Main cooling valve

Through this valve, the high pressure gas of refrigerant is discharged into indoor unit which

needs heating operation in main cooling operation.

27 Outdoor EEV valve

In order to prevent outdoor heat exchanger from refrigerant accumulation in main cooling

operation,

this valve closes, otherwise Main EEV controls the amount of refrigerant.

28 HR EEV

It controls the amount of liquid refrigerant between outdoor unit and indoor unit in main

heating operation.

DVM PLUS3__01_Outdoor units.indd 35 2010-03-08 5:18:47

DVM PLUS III

DVM PLUS3__01_Outdoor units.indd 36 2010-03-08 5:18:47

37

I

n

s

t

a

l

l

a

t

i

o

n

III. Installation

1 Outdoor unit combinations ......................38

2 Space requirements ................................39

3 Placing the outdoor units .........................43

4 Electric specifications ..............................44

5 Wiring works.............................................46

6 Refrigerant piping works ..........................48

7 Option switches & function keys .............54

8 Error codes ..............................................56

DVM PLUS3__01_Outdoor units.indd 37 2010-03-08 5:18:47

38

1

Outdoor unit combinations

1-1. Basic model

1-2. Compact combinations

Classification Capacity (Ton) Capacity (HP) Model

Total capacities of the connectable

indoor units (kW)

Maximum number of

connectable indoor

units

Single unit

6.4 8 RD080VQXGA 11.2 ~ 29.1 10

8.0 10 RD100VQXGA 14.0 ~ 36.4 10

9.5 12 RD120VQXGA 16.8 ~ 43.6 14

Classification

Capacity

(Ton)

Capacity

(HP)

RD080VQXGA RD100VQXGA RD120VQXGA

Total capacities of the

connectable Indoor

units(kW)

Maximum number of

connectable Indoor units

Compact

combinations

12.8 16 2 22.4 ~ 58.2 16

14.4 18 1 1 25.2 ~ 65.5 18

16.0 20 2 28.0 ~ 72.8 20

17.5 22 1 1 30.8 ~ 80.0 24

19.0 24 2 33.5 ~ 87.1 28

20.8 26 2 1 36.4 ~ 94.6 30

22.4 28 1 2 39.2 ~ 101.9 32

24.0 30 3 42.0 ~ 109.2 34

25.5 32 2 1 44.8 ~ 116.4 36

27.0 34 1 2 47.5 ~ 123.5 40

28.5 36 3 50.3 ~ 130.7 43

DVM PLUS3__01_Outdoor units.indd 38 2010-03-08 5:18:48

39

I

n

s

t

a

l

l

a

t

i

o

n

2

Space requirements

2-1. Single installation

2-2. Group installation

300 or

more(S2)

300 or more

200 or more

500 or

more(S1)

10 or more

10 or

more

Front

300 or

more (S2)

500 or

more (S1)

10 or

more

10 or

more

10 or

more

10 or

more

20 or more 20 or more

20 or more 20 or more

20 or

more

600 or more

10 or

more

300 or

more

300 or

more

300 or

more

500

or

more

500 or more

10 or

more

20 or more

300 or more

200 or more

400 or

more

Front

Front

Front

Front Front

Front

Wall height unrestricted

Wall height unrestricted

Front wall height 1500 mm and less

Rear wall height 500 mm and less

Side wall height Height unrestricted

Front : S1 + h1/2, Rear : S2 + h2/2

+ The suggested installation above has concerned minimum installation space.

+ To secure enough service space and performance of system, take account of more sufficient space.

+ The required minimum space between outdoor units for service and performance of system is 100 mm at least.

E

Note

(Unit: mm)

(Unit: mm)

If the height of the wall exceeds the above

value, more space should be added to the

front and rear space individually.

DVM PLUS3__01_Outdoor units.indd 39 2010-03-08 5:18:48

40

2

Space requirements

2-3. Installing duct for horizontal exhaust discharge

It is necessary to install an air-discharge duct (field supply) to direct exhaust from the fan horizontally if it is difficult

to provide a minimum space of 2m between the air-discharge duct outlet and a nearby obstacle.

DVM PLUS3__01_Outdoor units.indd 40 2010-03-08 5:18:48

41

I

n

s

t

a

l

l

a

t

i

o

n

2-4. Installing the outdoor unit in harsh environments

In abnormally harsh environments such as cold and/or windy areas, sufficient countermeasures to guard against

excessive wind and snow should be taken to ensure the unit's correct operation. Snow-proof duct (field supply)

should be fitted to the unit and direct exposure to the wind should be avoided as much as possible. When the unit

is expected to operate in cooling mode in condition under 10C, in snowy areas, in environments subject to strong

winds or rain, install air inlet and outlet ducting as shown in the below example

+ The frame/foundation should be higher than expected snowfall.

+ The foundation must be solid and the unit must be secured with anchor bolts.

+ Be sure to install unit in a place strong enough to withstand its weight.

+ When installing on a roof subject to strong wind, countermeasures must be taken to prevent the unit form being

overturned.

+ Any lack of strength may cause unit to fall down, resulting in a personal injury.

+ For more detail information about installation, refer to installation manual.

Caution

DVM PLUS3__01_Outdoor units.indd 41 2010-03-08 5:18:49

42

2

Space requirements

2-5. Dimensional drawing of snow-proof duct

1) RD080/100/120VQXGA

(Unit: mm)

DVM PLUS3__01_Outdoor units.indd 42 2010-03-08 5:18:49

43

I

n

s

t

a

l

l

a

t

i

o

n

3

Placing the outdoor units

3-1. Anchor bolts position

3-2. Removing fasteners of compressors leg

A

(Unit: mm)

B

Anchor bolt(4-15)

6

7

7

4

5

6

7

(1) Open the front cabinet near the bottom.

The compressors are fastened with nuts at 6 places.

(2) Remove nut washer, washer and stopper nut from compressors

with a tool.

(3) Refasten them with the nut washer only.

Stopper Nut Washer Nut Washer

Remove

+ Pay your attention not to touch the copper pipes as detaching the fasteners.

+ The stopper nut and washer should be removed. If this work is not conducted correctly, it can cause outdoor unit

to vibrate and make much noise.

Caution

Model A B

RD080/100/120VQXGA 1200 1058

DVM PLUS3__01_Outdoor units.indd 43 2010-03-08 5:18:49

44

Electric specifications

4

4-1. Basic models

Classification Capacity (Ton) Capacity (HP) Model MCCB(A) ELB

Single unit

6.4 8 RD080VQXGA 25 25A, 30mA 0.1 Second or less

8.0 10 RD100VQXGA 30 30A, 30mA 0.1 Second or less

9.5 12 RD120VQXGA 40 40A, 30mA 0.1 Second or less

Model

Units Power supply Comp. OFM

Hz Volts Min. Max. MCA MFA RLA kW FLA

RD080VQXGA 50 380~415 380 415 25 1.1 4.9

RD100VQXGA 50 380~415 380 415 30 1.1 4.9

RD120VQXGA 50 380~415 380 415 40 1.1 4.9

+ All wiring, components and materials to be procured on the site must comply with the applicable local and national codes.

DVM PLUS3__01_Outdoor units.indd 44 2010-03-08 5:18:49

45

I

n

s

t

a

l

l

a

t

i

o

n

4-2. Combinations

Model

Units Power supply Comp. OFM

Hz Volts Min. Max. MCA MFA RLA kW FLA

RD160VQXGA 50 380~415 380 415 50 2.2 9.8

RD180VQXGA 50 380~415 380 415 55 2.2 9.8

RD200VQXGA 50 380~415 380 415 60 2.2 9.8

RD220VQXGA 50 380~415 380 415 70 2.2 9.8

RD240VQXGA 50 380~415 380 415 80 2.2 9.8

RD260VQXGA 50 380~415 380 415 80 3.3 14.7

RD280VQXGA 50 380~415 380 415 85 3.3 14.7

RD300VQXGA 50 380~415 380 415 90 3.3 14.7

RD320VQXGA 50 380~415 380 415 100 3.3 14.7

RD340VQXGA 50 380~415 380 415 110 3.3 14.7

RD360VQXGA 50 380~415 380 415 120 3.3 14.7

+ The relationship between the starting time and the starting current (Digital Scroll Comp. + Fixed Scroll Comp)

+ RLA is based on the following conditions.

- Indoor temp. : 27C DB/ 19C WB

- Outdoor temp. : 35C DB

+ Voltage range

Units are suitable for use on electrical systems where voltage

supplied to unit terminal is not below or above listed range limits.

+ Maximum allowable voltage variation between phases is 2%.

+ Select wire size based on the larger value of MCA.

+ MFA is used to select the circuit breaker and the ground fault circuit interrupter (earth leakage circuit breaker).

N Abbreviations

- MCA: Min. Circuit Amps. (A)

MCA = 1.25 X LOAD1 + LOAD2

(LOAD1: RLA of Digital Comp. / LOAD2: RLA of Fixed Comp. + FLA of Fan Motor)

- MFA: Max. Fuse Amps. (A)

- RLA: Rated Load Amps. (A)

- OFM: Outdoor Fan Motor

- FLA: Full Load Amps. (A)

- kW : Rated Motor Output (kW)

S

t

a

r

t

i

n

g

c

u

r

r

e

n

t

Starting time

RLA

Classification Capacity(Ton) Capacity(HP)

Basic model

MCCB(A) ELB

RVXVHT075FE RVXVHT100FE RVXVHT125FE

Module unit

12.8 16 2 25+25

14.4 18 1 1 25+30

16.0 20 2 30+30

17.5 22 1 1 30+40

19.0 24 2 40+40

20.8 26 1 2 25+25+30

22.4 28 3 25+30+30

24.0 30 2 1 30+30+30

25.5 32 1 2 30+30+40

27.0 34 3 30+40+40

28.5 36 40+40+40

DVM PLUS3__01_Outdoor units.indd 45 2010-03-08 5:18:49

46

5

Wiring works

5-1. External connection diagram of DVM PLUS III

1) 3 phase 4 wires

R S T N R S T N OF1 OF2 OF1 OF2

3 phase 4 wires

(380~415V)

3 phase 4 wires

(380~415V)

Communication

cable among

outdoor units

220~230V 220~230V

Indoor Outdoor Outdoor

Communication

cable between

indoor and

outdoor units

Earth

Earth

Earth

Earth

Main unit Sub unit

Indoor

MCCB

+ELB

or

ELCB

MCCB

+ELB

or

ELCB

Connect the power cable of the outdoor unit after checking that R-S-T-N(3 phase 4 wires) is properly connected.

The communication cable between indoor and outdoor units has no polarity.

Arrange the cables using cable ties.

DVM PLUS3__01_Outdoor units.indd 46 2010-03-08 5:18:49

47

I

n

s

t

a

l

l

a

t

i

o

n

5-2. Caution of wiring work

3 phase 4 wires,

380~415V

MCCB

ELB

To sub unit

communication cable

Outdoor Unit

1. Be sure to connect the suitable length of power wiring to the power wiring terminal block using ring terminal

above the figures.

2. Make sure to fix wiring using cable tie like above the figures.

3. After wiring, reinstall the housing cover which has an isolator into the middle frame.

Connecting the ring terminal of 3 phase cable (CV) Connecting the ring terminal of 3 phase cable (FCV)

A

B

C

A B C

A

B

2

5

0

m

m

C

A B C

+ Make sure that all wiring should not contact with piping line during the field wiring work. If not, the vibration of

compressor can make a damage to wiring and piping. It may result in fire.

+ Make sure to pass electrical wiring of the power cable (3 phase 4 wires) through a conduit hole of the front side.

CAUTION

Base line Base line

Middle frame

Housing cover

A B C

30mm 60mm 90mm

A B C

30mm 60mm 90mm

DVM PLUS3__01_Outdoor units.indd 47 2010-03-08 5:18:50

48

6

Refrigerant piping works

6-1. Notice & Cautions

Cautions Correct piping work Wrong piping work

The refrigerant piping should be the

same level or lower than connecting

position of piping to outdoor units.

Piping work should be run with side

direction for better uniform distribution

of refrigerant and oil like next diagram.

Outdoor joint kits should be installed in

a horizontal direction, even it is a low

pressure pipe.

When the piping length between

outdoor and branch joints is 2m or

more, a vertical trap has to be installed

like right diagram.

Less than 1m

2m or more

2m or more

200~300mm

Horizontal length = over 100mm

Minimum

100mm

DVM PLUS3__01_Outdoor units.indd 48 2010-03-08 5:18:50

49

I

n

s

t

a

l

l

a

t

i

o

n

Example of piping layouts for DVM PLUS III

6-2. Example of piping layouts

Using

Y-joint

Using

Header

joint

DVM PLUS3__01_Outdoor units.indd 49 2010-03-08 5:18:51

50

6

Refrigerant piping works

6-3. Piping examples

*2) As an outdoor unit is located in a lower position than indoor unit, level difference is 40m.

1 The refrigerant amount of the system must be less than 100kg. For more detail, refer to the page 760.

Classification Branch with Y-joint Branch with Y and Header joint Branch with Header joint

One outdoor unit

installed

Multiple outdoor

units installed

Items Examples Remarks

Max.

piping

length

Outdoor

~

Indoor unit

Piping

(Equivalent

piping)

200m below

(220m below)

Branch with Y-joint a+b+c+d+e+f+g+p 200m (220m)

Equivalent pipe length

Y-joint:0.5m, Header:1m

Branch with Y-joint

and Header joint

a+i+k 200m (220m)

a+b+h 200m (220m)

Branch with

header joint

a+i 200m (220m)

Total

piping

1000m below

Branch with Y-joint

a+b+c+d+e+f+g+p+h+i+j+k+l+m+n

1000

Branch with Y-joint

and Header joint

a+b+c+d+e+f+g+p+h+i+j+k

1000m

Branch with

Header joint

a+b+c+d+e+f+g+p+h+i 1000m

Outdoor

~

Outdoor unit

Piping 10m below r 10, s 10, t 10m

Equivalent

piping

13m below r 13, s 13, t 13m

Level

difference

Outdoor ~

Indoor unit

Piping 50m / 40m

*2)

H1 50m / 40m

Indoor ~

Indoor unit

Piping 15m below H2 15m

Outdoor ~

Outdoor unit

Piping 5m below H3 5m

Allowable

length

after

branch

The first

branch

~

the farthest

indoor unit

Piping 45m below b+c+d+e+f+g+p 45 m, i 45m

Piping 90m below

*1)

It needs to satisfy required conditions

Only apply

DVM PLUS III

Distribution kit Model Remarks

Allowable

From distribution kit to

indoor unit

3m MEV-A13SA / MEV-A16SA (For 1 indoor unit)

For wall-mounted

indoor unit From distribution kit to

indoor unit

20m

MXD-A13K116A / MXD-A13K200A / MXD-A16K200A /

MXD-A22K200A (For 2 indoor units)

MXD-A13K216A / MXD-A13K300A / MXD-A16K213A /

MXD-A16K300A (For 3 indoor units)

Required condition Example

The first branch

joint ~

the farthest

indoor unit

If the sum of pipe length (b+c+d+e+f+g+p) is over 45m, (but not

exceed : 90m) increase pipe size of b,c,d,e,f,g (b,c,d,e,f,g : pipe 1 size

up)

Total pipe length

If main pipe size is not increased,

a+bx2+cx2+dx2+ex2+fx2+gx2+h+i+j+k+l+m+n+p1000m

If main pipe size is not increased,

ax2+bx2+cx2+dx2+ex2+fx2+gx2+h+i+j+k+l+m+n+p1000m

Each Y-joint ~

each indoor

h,I,j,..p45m

Between

indoor units

The difference between the distance of the outdoor unit to the farthest

indoor unit and the distance of the outdoor unit to the farthest indoor

unit 45m (a+b+c+d+e+f+g+p)-(a+h) 45m

G F

h i j k l m n

b

a

c d e f g p

b

a

c d e f g h

i

k

j

b

a

c d e f g h

i

G F

h i j k l m n

b

a

c d e f g p

b

a

c d e f g h

i

k

j

b

a

c d e f g h

i

G F

h i j k l m n

b

a

c d e f g p

*1) Required condition

DVM PLUS3__01_Outdoor units.indd 50 2010-03-08 5:18:51

51

I

n

s

t

a

l

l

a

t

i

o

n

Outdoor unit connection pipe size : (A1), (A2), (A3) Branch joint : (D), (E), (F)

Indoor units capacity

Pipe size (O.D. mm)

Liquid pipe Gas pipe

2.2~5.6 kW 6.35 12.70

7.1~14.0 kW 9.52 15.88

Model Capacity of outdoor

MXJ-T3819K Below 36 HP

A1 : Select the pipes according to the outdoor unit

capacity with following table.

A2 : Select the pipes according to sum of outdoor

unit capacities behind the outdoor joint with

following table.

A3 : Select the main pipe of outdoor units with the

following table.

Pipe size between branch joints : (B)

Pipe size between branch joints and indoor unit (C)

Outdoor multi

connection

branch joint (D)

Select the pipe size according to the indoor's capacity.

B Branch joint of outdoor units multi connection (D)

Model Total indoor unit capacity

MXJ-YA1509K 15.0 kW and below

MXJ-YA2512K Over 15.0~40.6 kW and below

MXJ-YA2812K Over 40.6~46.4 kW and below

MXJ-YA2815K Over 46.4~69.6 kW and below

MXJ-YA3119K Over 69.6~98.6 kW and below

MXJ-YA3819K Over 98.6~100.5 kW and below

Y-joint

(F)

B First branch joint (E)

Select branch joint according to the outdoor unit's

capacity

B Branch joint (F)

Select the pipe size according to the capacity sum of

indoor units which are connected below this pipe.

1) Y-joint

Select the pipe size according to the capacity sum

of indoor units which are connected below this pipe.

6-4. Pipe selection

*A1 : Pipes to the outdoor unit (Liquid, Gas)

*A2 : Pipes between outdoor joint kits (Liquid, Gas)

*A3 : Main pipes (Liquid, Gas)