Professional Documents

Culture Documents

Epoxy Adhesives in Civil Engineering Projects

Uploaded by

smartman350 ratings0% found this document useful (0 votes)

156 views2 pagesEpoxy Adhesives in Civil Engineering

Original Title

Epoxy Adhesives in Civil Engineering

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEpoxy Adhesives in Civil Engineering

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

156 views2 pagesEpoxy Adhesives in Civil Engineering Projects

Uploaded by

smartman35Epoxy Adhesives in Civil Engineering

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Epoxy Adhesives in Civil Engineering

SpecialChem | Edward M Petrie - Jun 18, 2008

There are many applications for epoxy adhesives in civil engineering applications. This week's

editorial takes a broad look at the reasons why epoxies are highly valued in these projects and

where the development of these materials may take us.

Epoxy adhesives have been used considerably in the last several decades for the construction,

repair, and rehabilitation of our transportation infrastructures. Epoxy systems are highly valued

in these projects because they can be formulated to set outdoors in a relatively short period of

time, they have good adhesion to a number of materials of construction, and they provide

relatively good weathering properties and durability.

Table 1 lists several applications for epoxy adhesives in civil engineering projects. Epoxy

adhesives are generally considered to be the "workhorse" of the industry. In the construction or

repair of roads and bridges, epoxy adhesives have primarily been used for bonding concrete

and for bonding stiffening members or repair structures to degrading concrete facilities.

Airfield runways and aprons

Highway and bridge joints

Bridge abutments

Concrete lined canals,

traverse and longitudinal

joints

Multilevel parking lot joints

Underground tunnel construction

joints and sections

Attaching metal studs in concrete

Bonding pancake lighting systems on

airport runways, parking lots, etc.

Bonding traffic markers on roadways

and road dividers

Table 1 : Common Applications and Polymeric Resins Used in the Construction and Repair of

the Transportation Infrastructure

Epoxies are high priced, but they have better chemical resistance and durability than other

adhesives, and they have dominated the market in outdoor applications. Significant advantages

of the epoxy based adhesives are that they have no solvents and, therefore, exhibit little

shrinkage. They cure relatively fast and are not as exposed to inclement weather as are slower

curing systems. Their physical properties do not change significantly on aging in the field.

One problem with early epoxy formulations is that they cured to a relatively brittle material. By

using reactive flexibilizers, such as polysulfides, epoxy adhesive formulators have obtained the

flexibility required for many applications in this industry. Polyamides and even coal tars have

also been used to provide flexibility to epoxy base resins.

Another problem is that many two-component, room temperature curing epoxies cure with a

high exotherm. This can cause the mixed uncured epoxy to get very hot. Excessive heat of

exotherm provides a safety hazard and significantly shortens the working life of the mixed

adhesive. This problem is generally solved by mixing small batches or using continuous mixing

equipment.

Cured concrete may be bonded to cured concrete, as in the installation of precast buttons to a

highway surface. Steel bridge railings may be bonded to the concrete surface of a bridge

sidewalk. In the case of deteriorated concrete, the adhesive can be used to rebuild the structure

to its former line and grade. Epoxy adhesives are also commonly used on other roadway

materials, such as asphalt and brick; however, the predominant application is concrete

substrates. The most frequent combinations of substrates that are bonded with adhesives in this

market segment are:

Cured concrete to cured concrete

Cured concrete to other materials

New concrete to cured concrete, and

New concrete to other materials.

In the bonding of cured concrete to cured concrete, the adhesive is applied directly to the

substrates. In the case of new concrete, a bonding agent may be incorporated into the concrete

formulation or the adhesive may be applied to the non-concrete surface.

There are many applications for bonding cured concrete to another material. These include

bonding of plastic reflectors to road surfaces or dividers, attachment of railings or metal

structures, and bonding of floor covering materials.

For applying new concrete over old concrete, such as in the case of a patch, epoxy is often the

best solution as a replacement for the new concrete. In these formulations an epoxy mortar is

made using aggregate similar to the aggregate used in concrete mixtures. Adhesion is excellent

and the epoxy mortar has generally better properties than the concrete; however, it is a

relatively high cost solution. The old concrete surface should be cleaned and sandblasted down

to sound concrete.

n the future, the use of adhesives in this market is expected to grow significantly due to the

aging infrastructures. An interesting application that has received much attention because of the

aging road infrastructure in many regions is the repair and strengthening of existing concrete

structures. Concrete beams can be strengthened by attaching steel plates and composites.

The use of epoxy adhesive systems with fiber reinforcement is expected to increase

significantly. Such adhesives will be applied to bridge piers, beams, and other elements

requiring repair. These adhesives can be used to not only repair deteriorating structures but

they will also provide added strength to new structures.

1,2

References

1. Meier, U., "Composite Material in Bridge Repair", Applied Composite Materials, vol. 7,

2000, pp. 75-94.

2. Field Test Increases Viability of Composites in Bridge Repair", Engineering News

Record, vol. 237, no. 12, September 16, 1996, p. 22.

You might also like

- Civil Engineering Project TitlesDocument3 pagesCivil Engineering Project TitlesShamsUlislamNo ratings yet

- Civil EngineeringDocument16 pagesCivil EngineeringAgus Sholehudin AnzieNo ratings yet

- How 3D Printing Revolutionized Civil Engineering Models and Construction(38 charactersDocument7 pagesHow 3D Printing Revolutionized Civil Engineering Models and Construction(38 charactersChong Ting ShengNo ratings yet

- Name: Syahril Afiefi Bin Sabli MATRIX NO: 2014401504 Group: P36Document3 pagesName: Syahril Afiefi Bin Sabli MATRIX NO: 2014401504 Group: P36Amirul AizadNo ratings yet

- Calculus AssignmentDocument51 pagesCalculus AssignmentPranshuBhatnagarNo ratings yet

- What Do We Teach When We Teach Tech Ethics? A Syllabi AnalysisDocument7 pagesWhat Do We Teach When We Teach Tech Ethics? A Syllabi AnalysisVictor Villacorta ElliottNo ratings yet

- Hydrology For Civil EngineeringDocument9 pagesHydrology For Civil EngineeringLeo SerasingheNo ratings yet

- ChE 401 CRD Assignment-4Document3 pagesChE 401 CRD Assignment-4Husnain GujjarNo ratings yet

- Engineering Society AssignmentDocument12 pagesEngineering Society AssignmentAghilan AlanzNo ratings yet

- Importance of Civil Engineering in Public LifeDocument5 pagesImportance of Civil Engineering in Public LifeAmit Singh100% (1)

- FOR USE Areas: Industry OnDocument5 pagesFOR USE Areas: Industry OnMichael UrbanoNo ratings yet

- Civil Engineering and Its SpecializationsDocument4 pagesCivil Engineering and Its SpecializationsAngelica Lirio GoromNo ratings yet

- APEGA Code of EthicsDocument1 pageAPEGA Code of EthicsfdgfdgfdgfNo ratings yet

- Public Speaking Course SyllabusDocument3 pagesPublic Speaking Course SyllabusslatorNo ratings yet

- Lecture 1 Energy EngineeringDocument7 pagesLecture 1 Energy EngineeringCricket loversNo ratings yet

- Polymer ScienceDocument101 pagesPolymer SciencereddyNo ratings yet

- Problem of RehologyDocument4 pagesProblem of RehologyShagufta AfaqueNo ratings yet

- Code of Conduct and Ethics For Engineers in UgandaDocument13 pagesCode of Conduct and Ethics For Engineers in UgandaWanambwa Silagi100% (1)

- A Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Document20 pagesA Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Ankur SemleNo ratings yet

- Civil Engineering Material AssignmentDocument1 pageCivil Engineering Material Assignmentjason_wong_125No ratings yet

- Study On Utilization of Fly Ash As A Replacement of Cement ProfessorDocument57 pagesStudy On Utilization of Fly Ash As A Replacement of Cement ProfessorSHANKAR PRINTINGNo ratings yet

- Polychloroprene ProductionDocument1 pagePolychloroprene ProductionBramJanssen76No ratings yet

- Selection of Materials For Chemical Engineering EquipmentDocument4 pagesSelection of Materials For Chemical Engineering EquipmentVuong BuiNo ratings yet

- AECT210-Lecture 41 PDFDocument14 pagesAECT210-Lecture 41 PDFM Pradeep KumarNo ratings yet

- School of Technology Diploma in Buidling Year 1 Atgb 1363 Building Science & Services ReportDocument12 pagesSchool of Technology Diploma in Buidling Year 1 Atgb 1363 Building Science & Services ReportTan Zhen HuiNo ratings yet

- Engineering Ethics in 40 CharactersDocument6 pagesEngineering Ethics in 40 CharactersNurul MukminahNo ratings yet

- PEB Singapore guidelines registration professional engineerDocument12 pagesPEB Singapore guidelines registration professional engineerAndyNo ratings yet

- Chapter 9Document17 pagesChapter 9JajejijojuNo ratings yet

- Importance of CEP in Civil EngineeringDocument4 pagesImportance of CEP in Civil EngineeringSalman ShujaNo ratings yet

- EG2401 T308 Project7 Final ReportDocument17 pagesEG2401 T308 Project7 Final ReportRuben SukumarNo ratings yet

- AIR POLLUTANT CONCENTRATION MODELS-libre PDFDocument23 pagesAIR POLLUTANT CONCENTRATION MODELS-libre PDFRebenciucNarcis-CristianNo ratings yet

- Materials Science and Engineering Notes 091110Document12 pagesMaterials Science and Engineering Notes 091110Mete MetelanNo ratings yet

- Optimal and adaptive control systemsDocument7 pagesOptimal and adaptive control systemsSeungnam Kim100% (1)

- Ethics of Corporate Virtues ExploredDocument26 pagesEthics of Corporate Virtues ExploredVamsiKrishnaKondapuramNo ratings yet

- Autocad Lab ReportDocument9 pagesAutocad Lab ReportArsl RanaNo ratings yet

- Probability and Statistics: Inferences Concerning ProportionsDocument31 pagesProbability and Statistics: Inferences Concerning ProportionsPriya PooriNo ratings yet

- Course Syllabus 1. Course Title Integral Calculus 2. Course DescriptionDocument7 pagesCourse Syllabus 1. Course Title Integral Calculus 2. Course DescriptionLanzSudioNo ratings yet

- The Civil Engineering LawDocument7 pagesThe Civil Engineering LawJohn Carlo de LeonNo ratings yet

- Enzyme KineticsDocument35 pagesEnzyme KineticsFaye Y. Santiago100% (3)

- Ies Civil Engineering Reference Books.Document1 pageIes Civil Engineering Reference Books.wondertree100% (1)

- Civil Engineering Reference BooksDocument2 pagesCivil Engineering Reference Booksdevbrat boseNo ratings yet

- CHE181 - Code of Ethics For Chemical Engineers PDFDocument27 pagesCHE181 - Code of Ethics For Chemical Engineers PDFEden Espanol OrginNo ratings yet

- Seminar 8th SemDocument31 pagesSeminar 8th Sempratik peguNo ratings yet

- CE312 Construction Materials PresentationDocument4 pagesCE312 Construction Materials PresentationKyle SarmientoNo ratings yet

- Thermoplastic&ThermosetDocument7 pagesThermoplastic&Thermosetrex tanongNo ratings yet

- Legal Ethics Cases IIDocument72 pagesLegal Ethics Cases IIMavz PelonesNo ratings yet

- Syllabus For CHE 543 F2018Document6 pagesSyllabus For CHE 543 F2018Sena ErarslankılıçNo ratings yet

- Chemical Engineering SyllabusDocument49 pagesChemical Engineering Syllabusyugal sharmaNo ratings yet

- Civil EngineeringDocument22 pagesCivil EngineeringSudeepSMenasinakaiNo ratings yet

- STRUCTURAL STEEL DESIGN HOMEWORKDocument15 pagesSTRUCTURAL STEEL DESIGN HOMEWORKJoshua CalaNo ratings yet

- Lecture 4 - Flexure Basics and Stress AnalysisDocument48 pagesLecture 4 - Flexure Basics and Stress AnalysisKetanNo ratings yet

- Civil Engineering Standards DocumentsDocument3 pagesCivil Engineering Standards DocumentsKesavanNo ratings yet

- Combustion in Premixed & Diffusion FlamesDocument16 pagesCombustion in Premixed & Diffusion FlamesRahul Singh TomarNo ratings yet

- Plagiarism Report PDFDocument75 pagesPlagiarism Report PDFVikrant SrivastavaNo ratings yet

- NOTES SOCIETY CEM585 3aDocument4 pagesNOTES SOCIETY CEM585 3aNadhirah LnfNo ratings yet

- Review checklist for chemical engineering principlesDocument1 pageReview checklist for chemical engineering principlesJaven MagadiaNo ratings yet

- Che520 Tutorial Questions Covenant UniversityDocument3 pagesChe520 Tutorial Questions Covenant UniversityifiokNo ratings yet

- CalculusDocument42 pagesCalculusRaisulNo ratings yet

- Ce511 Tabinas HW02 PDFDocument17 pagesCe511 Tabinas HW02 PDFKathlyn Kit TabinasNo ratings yet

- Bridge DesignDocument33 pagesBridge DesignMaiwand KhanNo ratings yet

- 1 Conversion FactorsDocument2 pages1 Conversion Factorssmartman35No ratings yet

- Gantt & Critical Path DiagramDocument3 pagesGantt & Critical Path Diagramsmartman35No ratings yet

- Vibration StandardsDocument32 pagesVibration Standardssmartman35No ratings yet

- Piles DesignDocument15 pagesPiles Designvenkatesh19701No ratings yet

- SP43Document352 pagesSP43Umar MohammadNo ratings yet

- Seismic Rehabilitation of BuildingsDocument18 pagesSeismic Rehabilitation of Buildingssmartman35No ratings yet

- Pile DesignDocument5 pagesPile DesignpeyostailNo ratings yet

- Manhole Benching Installation & RepairDocument2 pagesManhole Benching Installation & Repairsmartman35No ratings yet

- Vehicle Loads To BS5400Document3 pagesVehicle Loads To BS5400smartman35No ratings yet

- SP43Document352 pagesSP43Umar MohammadNo ratings yet

- Seismic Rehabilitation of BuildingsDocument18 pagesSeismic Rehabilitation of Buildingssmartman35No ratings yet

- Load Bearing WallsDocument1 pageLoad Bearing Wallssmartman35No ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Outline 03Document14 pagesOutline 03Carlos Rene Mamani TrujilloNo ratings yet

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionssgopalkn7559No ratings yet

- Aashto-H20, Hs20 & Hl93 LoadingDocument5 pagesAashto-H20, Hs20 & Hl93 Loadingsmartman35100% (3)

- Field Tests of Building MaterialsDocument4 pagesField Tests of Building Materialssmartman3550% (2)

- Outline 03Document14 pagesOutline 03Carlos Rene Mamani TrujilloNo ratings yet

- Fire-Specifications For Fire Free Coatings-Manu Spec FF88Document6 pagesFire-Specifications For Fire Free Coatings-Manu Spec FF88smartman35No ratings yet

- Gunite or Shotcrete ProcessDocument1 pageGunite or Shotcrete Processsmartman35No ratings yet

- AASHTO-load Rating & Legal Design Truck (References)Document1 pageAASHTO-load Rating & Legal Design Truck (References)smartman35No ratings yet

- AASHTO Load Ratings-3 & Looking To LRFRDocument19 pagesAASHTO Load Ratings-3 & Looking To LRFRsmartman35No ratings yet

- Field Tests of Building MaterialsDocument4 pagesField Tests of Building Materialssmartman3550% (2)

- Bolted Beam Column ConnectionsDocument16 pagesBolted Beam Column Connectionssgopalkn7559No ratings yet

- AASHTO-load Rating & Legal Design Truck (References)Document1 pageAASHTO-load Rating & Legal Design Truck (References)smartman35No ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- BridBridge Spange SpanDocument3 pagesBridBridge Spange Spansmartman35No ratings yet

- Outline 03Document14 pagesOutline 03Carlos Rene Mamani TrujilloNo ratings yet

- AASHTO Load Ratings-1Document1 pageAASHTO Load Ratings-1smartman35No ratings yet

- Software Test ReportDocument4 pagesSoftware Test ReportSabahat HussainNo ratings yet

- SYNOPSIS For Job PortalDocument6 pagesSYNOPSIS For Job PortalAkanksha Verma90% (10)

- Vienna ModernDocument85 pagesVienna ModernZain ZulfiqarNo ratings yet

- Data Collector 2.03.00Document20 pagesData Collector 2.03.00vyaskingNo ratings yet

- KALEKİMDocument18 pagesKALEKİMqaisalkurdyNo ratings yet

- Ahmed Mohammed EL Desouky 2007Document8 pagesAhmed Mohammed EL Desouky 2007Hazem MohamedNo ratings yet

- Mock Test Jee MainDocument142 pagesMock Test Jee MainAkash Ghosh0% (1)

- 3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureDocument4 pages3M Cold Shrink Cable Joints MV HV 11kV 33kV 66kV BrochureMohammed MustafaNo ratings yet

- Reliance Jio Industry AnalysisDocument45 pagesReliance Jio Industry AnalysisBhavya BhartiNo ratings yet

- HCIE-R&S Huawei Certified Internetwork Expert-Routing and Switching Training Lab Guide PDFDocument228 pagesHCIE-R&S Huawei Certified Internetwork Expert-Routing and Switching Training Lab Guide PDFliviuemanuelNo ratings yet

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsDocument6 pagesStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009No ratings yet

- Petri Net Modeling and ApplicationsDocument13 pagesPetri Net Modeling and ApplicationsRishiraj SenguptaNo ratings yet

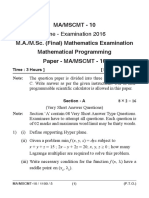

- Ma-Mscmt-10 J16Document5 pagesMa-Mscmt-10 J16Dilip BhatiNo ratings yet

- Engineering QuotesDocument10 pagesEngineering QuotesGendakenNo ratings yet

- GameBoy Programming ManualDocument298 pagesGameBoy Programming Manualdiceman2037100% (4)

- R5310105-Structural Analysis - IIDocument4 pagesR5310105-Structural Analysis - IIsivabharathamurthyNo ratings yet

- Maximum Power Tracking System for Solar Panels Using Automatic ControlDocument79 pagesMaximum Power Tracking System for Solar Panels Using Automatic ControlHarish VarmaNo ratings yet

- A380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaDocument66 pagesA380-LEVEL III - ATA 42 Integrated Modular Avionics - Avionics DaAbolfazl Mazloomi100% (11)

- PalindromeDocument7 pagesPalindromeZy AdrianneNo ratings yet

- OSHA Standard For Fixed Ladders SummaryDocument12 pagesOSHA Standard For Fixed Ladders SummarysesabcdNo ratings yet

- GRAS 46BE 1/4Document9 pagesGRAS 46BE 1/4nino16041973No ratings yet

- AGA-3 Comparison Normal BetaDocument12 pagesAGA-3 Comparison Normal BetahailriqNo ratings yet

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 pageChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimNo ratings yet

- Signals and Systems - MjrobertsDocument3 pagesSignals and Systems - Mjrobertspriyakanthr5883100% (1)

- Fall Protection Marking GuidelinesDocument2 pagesFall Protection Marking GuidelinescuervohijoguachoNo ratings yet

- Scallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesDocument3 pagesScallops Are Cut Outs in Weld Corners Which Are Used in Many Structures As in BridgesJanuel BorelaNo ratings yet

- Tli R3.0 PDFDocument6,465 pagesTli R3.0 PDFz_sadiq25% (4)

- PartesDocument136 pagesPartesFernando Erazo NavarreteNo ratings yet

- IPE 401-Drive SystemDocument16 pagesIPE 401-Drive SystemElmerNo ratings yet

- HW03 5ad S19 PDFDocument2 pagesHW03 5ad S19 PDFbobNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionFrom EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Perfume Engineering: Design, Performance and ClassificationFrom EverandPerfume Engineering: Design, Performance and ClassificationRating: 4 out of 5 stars4/5 (5)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for Siting and Layout of FacilitiesFrom EverandGuidelines for Siting and Layout of FacilitiesNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisFrom EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNo ratings yet