Professional Documents

Culture Documents

API 610 11ed.

Uploaded by

Roberto Galicia FrancoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 610 11ed.

Uploaded by

Roberto Galicia FrancoCopyright:

Available Formats

Goulds 3700

API 610 11th Edition / ISO 13709 2nd Edition

API OH2 Overhung, Single Stage, Radially Split

2 Goulds 3700

Proven API Leadership

ITT Goulds Pumps is a proven leader in API Pumps

More than 20,000 units installed

- More than 17,000 OH2/OH3s

- More than 3,000 BB1/BB2/BB3 pumps

40+ years of API expertise

Participating member on API 610 and

API 682 committees

Goulds 3700

A Leader in API-Engineered Pump Package Solutions

Family of API Pumps

ITT Goulds Pumps has a family of proven API pumps:

Overhung pumps

Single- and two-stage between-bearing pumps

Multistage between-bearing pumps axially split

Barrel multistage - radially split

Vertical, double-casing pumps

Specialty pumps

8000 HP/6000 kW Testing Capability

Our expanded test facility can test your pump in

the most demanding conditions.

Testing at rated speeds is critical to assess the

impact of dynamic conditions including vibration.

API Engineering Expertise

We are experts in packaging engineered pumps that

meet your demanding applications with true

conformance to the latest API specifications.

We have extensive experience in nearly every type of

driver, bearing, seal, piping configuration, nozzle

configuration, flange and baseplate design to meet

your application needs.

ITT is a world leader in technology and engineering

including hydraulics, materials science, mechanical

design and fluid dynamics.

Broad Applications

Petroleum refining, production and distribution

Petrochemical and demanding chemical processing

High-temperature applications including

boiler circulation

General industrial applications requiring high

temperatures or high pressures

Industry-Leading Hydraulic Coverage

We offer extensive coverage to meet your

process needs.

Better hydraulic fits can mean improved efficiency

and long-term reliability and parts life.

Goulds 3700 3

Goulds 3700

High-Temperature and Pressure Process

Pumps That Meet or Exceed ISO 13709 and

API 610 11th Edition

Safety, reliability and versatility are the key words for our

end-suction, centerline-mounted, overhung (OH-2) API

610 process pump.

Safety and Reliability

We provide engineered solutions with true conformance to

the latest API specifications including the stringent

emissions containment per API 682. The result is a safe

and rugged overhung API process pump designed for a

20-year life.

Services

Column reflux, hot oil, stabilizer overhead, column

bottoms, reboiler, stripper overhead, column charge,

reactor feed, heat transfer, injection, tower bottoms,

slop gas oil, fuel blending, heavy gas oil, scrubber

circulation, offsite hydrocarbon transfer

End Suction API 610/ISO 13709 Process Pump

Designed for optimum reliability

State-of-the-art mechanical design features

54 casing sizes and choice of impellers with most

casings

Serviceability

Capacity to 8,500 GPM (1930 m3/h)

Total dynamic head to 1,200 feet (360 m)

Temperature to 800 F (425 C)

Pressure to 870 PSIG (60 bar)

Materials: Available in a wide range of materials

including all API 610 constructions and custom application

needs.

Engineered Hydraulics: An industry-leading 135

hydraulic combinations to better match your process for

efficiency and reliability. Custom hydraulics are available.

Engineered Packaging with a wide range of drivers,

seals, piping, nozzle configurations, flanges, baseplates

and QC testing.

Model 3700

Model 3700 on high-temperature service at a U.S. Gulf Coast refinery.

Gold Tailings Pumps in Australia - 3700 4x6-19

Improved Bearing Environment

Bearing frame fins provide optimum heat dissipation.

Condition-monitoring sites allow easy and consistent

monitoring of temperature and vibration. Provision

for instrumentation mounting per API 670 available.

Large oil sight glass allows viewing of the condition

and level of oil, critical for bearing life.

Extra-large oil sump means cooler-running bearings.

Proven channeled oil lubrication system ensures

flow-through of cooled oil to thrust and radial bearings.

Standard dual oil rings, positively located, provide oil

flow to channeled oil lubrication system and prevent

oil foaming.

Not All Pumps are Designed for Low Flows

Many users throttle pumps to attain low flow rates, which

creates bearing and seal issues. The traditional enclosed

impeller passageways would be too small to properly

manufacture at these low flow rates.

3700LF Low-Flow Solution - Fully API compliant

The 3700 LF semi-open radial vane Barske type impeller

eliminates these enclosed impeller limitations. The unique

circular volute casing eliminates diffusers, thus reducing

the pump size, footprint and lifetime costs.

Goulds 3700

Standard Features for Optimum Reliability

Proven API 610 Nozzle-Load Design

Rugged casing and baseplate/pedestal support

system provides flange-loading capability exceeding

API 610 / ISO 13709 requirements without the use of

a bearing frame support.

Full Flange Rating Pressure Capability

All pumps designed to operate at two pole running

speeds have casings designed for the full pressure

capability of a 300 RF flange.

Spiral-Wound Casing Gasket

Casing to cover joint sealed with a spiral-wound,

controlled-compression gasket required by API 610.

Provides positive sealing up to the maximum design

pressure and temperature.

4 Goulds 3700

O

I

L

L

E

V

E

L

Optional 3700LF Design for Low-Flow Services

Optional Design for Solids Handling

- Model 3703

For over 19 years, ITT has offered a fully API compliant

optional design (Model 3703) that utilizes a traditional-

style semi-open impeller - useful when you require a pump

with high temperatures or pressures, yet need the

improved solids handling of an semi-open impeller.

Examples of 3703 services are mine dewatering and PTA

chemical plant services. The single stage Model 3703 has

interchangeable parts with Model 3700.

Goulds 3700 5

Optional Features for

Application Flexibility

Goulds offers a range of options to meet specific plant and process

requirements.

High-Temperature Capability

For high-temperature applications, these options

are available:

Heat Flinger

Heat flinger dissipates shaft-

conducted heat and circulates

air to reduce heat buildup.

Lubrication Flexibility

Heat Flinger

Other Options

Extra-Wide Baseplate

Provided for seal systems with auxiliary components to

improve maintenance access.

Heavy-Duty Pedestal

Unique trapezoidal design provides superior resistance to

deflections from flange loads.

Top Suction Nozzle

This option reduces space requirements and installation

costs for unique applications.

Inducer Option

Under certain conditions, reduction in NPHSR can be

provided with an axial flow inducer.

Coke-Crusher Option

Allows coke particles to be easily pumped by crushing coke

with a cutter screw.

Air Cooling

High-capacity fan and shroud

mounted on power end

effectively reduce bearing

frame temperature for

cooler-running bearings

without using cooling water.

Water Cooling

Finned cooler for maintaining

oil/bearing temperature.

Corrosion-resistant material.

Oil Mist Lubrication System

Connections for pure or purge oil mist lubrication can be

provided for immediate use or future requirements.

Sealed Power End

Designed with magnetic end face

seals and expansion chamber to

prevent contaminants from

entering the power end.

Lubricant Sight Glass and

Sampling Bottle

For visual inspection and

sampling of oil.

OIL LEVEL

Inducer Option

Model 3700

API 610 11th Edition / ISO 13709 2nd Edition

API OH2 Overhung, Single Stage, Radially Split

TANGENTIAL DISCHARGE DESIGN

Maximizes hydraulic efficiency.

CONFINED CONTROLLED-COMPRESSION GASKET

Spiral-wound gasket assures positive sealing with

no chance of misalignment.

RENEWABLE WEAR RINGS STANDARD

ON ALL SIZES

Positively locked and set screwed.

Front and rear rings control seal chamber

flows and pressures. Optional non-metallic

rings for improved efficiency. Wear rings not

utilized in 3700LF pumps.

6 Goulds 3700

IMPELLER

Multiple closed impellers for most casings

to meet specific hydraulic requirements.

Balanced to stringent ISO 1940 Grade 1.0

(exceeds API minimum). 3700LF low flow

pumps and 3703 high solids pumps utilize

a semi-open impeller - they do not utilize

impeller or casing wear rings.

NOZZLE LOAD CAPABILITY

Casing/baseplate design optimized to exceed

toughest API/ISO nozzle load criteria.

FABRICATED BASEPLATE

Enlarged drain connection to prevent

buildup of debris. All joints are continuously

welded. Extra-width sizes available to ease

maintenance of seal systems.

DUAL VOLUTE CASING

Standard on 3-inch discharge and larger. Minimizes

radial load and reduces shaft deflection for increased

mechancial seal life.

RIGID, HEAVY-DUTY SHAFT

Minimizes shaft deflection,

maximizes bearing and mechanical

seal life.

LUBRICATION SYSTEM

Proven, engineered ring-oiled

flow-through bearing lubrication

optimizes MTBPM.

LABYRINTH OIL SEALS

Labyrinth seal design prevents oil

from leaking out and contaminants

from intruding. Made from non-

sparking metal.

Goulds 3700 7

HEAVY-DUTY BEARING FRAME

Piloted and metal-to-metal fits assure

runouts and concentricities well within

limits specified in API 610 / ISO 13709.

Large oil sump capacity. Cast fins

enhance cooling.

BEARINGS

Duplex 40 angular contact thrust

bearings and deep-groove (Conrad)

radial bearings sized for minimum

three-year bearing life under most

severe operating conditions. Exceeds

API 610 / ISO 13709 requirements.

3910 INTERCHANGEABILITY

Bearing frame, seal chamber, bearings, shaft,

mechanical seal, impeller and wear rings

completely interchangeable with Goulds

Model 3910 bearing frame in-line process

pumps. Entire back pull-out assembly

interchangeable with Model 3710.

API-682 SEAL CHAMBER

Enlarged seal chamber fully conforms

to API-610 / ISO 13709 standards.

Accepts wide range of API-682 / ISO

21049 cartridge mechanical seals.

Renewable throat bushing standard for

controlled seal chamber environment.

Goulds 3700

Hydraulic Coverage

8 Goulds 3700

T

D

H

-

6

0

H

z

T

D

H

-

5

0

H

z

Flow Rate - 50 Hz

Flow Rate - 60 Hz

Note: Hydraulics above represent 80% to 110% of best efficiency point (BEP).

Typical 3700 Installation

Goulds 3700 9

100

164

202

101

304

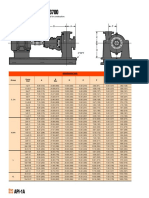

Sectional View

122

356A,

425

Goulds 3700

230 203 125 184

Parts List and Materials of Construction

Item Part Name S-4 S-6 S-8 C-6 A-8 D-1 D-2

100 Casing Carbon Steel 12% Chrome 316L SS Duplex SS S. Duplex SS

101 Impeller Carbon Steel 12% Chrome 316L SS 12% Chrome 316L SS Duplex SS S. Duplex SS

122 Shaft ANSI 4140 * 316L SS 410 SS 316L SS Duplex SS S. Duplex SS

125 Throat Bushing Cast Iron 410 SS 316L SS 410 SS 316L SS Duplex SS S. Duplex SS

164,

230

Wear Ring -

Casing **

Cast Iron 12% Chrome 316L SS 12% Chrome 316L SS Duplex SS S. Duplex SS

202,

203

Wear Ring -

Impeller **

Cast Iron 12% Chrome Nitronic 60 12% Chrome Nitronic 60 Duplex SS S. Duplex SS

184 Seal Chamber

Cover

Carbon Steel 12% Chrome 316 SS Duplex SS S. Duplex SS

304 Impeller Nut Steel 316 SS Duplex SS S. Duplex SS

356A,

425

Casing Studs /

Nuts

ANSI 4140

* 410 SS on S-6 when temperature exceeds 350F (175C)

* Not utilized on 3700LF low flow pumps.

10 Goulds 3700

Upgrade Your Older-Style API

Process Pump

Profit from these exclusive quality services:

Quality rebuilds/repairs ensure maximum reliability

from your rotating equipment.

One-year warranty on all rebuilds/repairs.

Upgrade old designs to latest technology to

maximize reliability.

Your local PRO Services Center offers solutions for lowering

total cost of ownership of your pumping systems. This can

be achieved by upgrading your older-style API process

pumps to todays high-performance API standard.

The question of whether to replace or upgrade existing

equipment is a challenge faced by most end users today.

When casing, piping and foundation are in good shape,

upgrading your existing pump to comply with current API

standards usually is more economical than new pump

installation. By exploring all options, a better decision can

be made.

Upgrades may involve hydraulic modifications, drop-in

replacements and/or power end conversions. PRO Services

Centers are experienced with all pump manufacturers.

Goulds PRO Services Centers are experienced with

reconditioning all types of pumps and rotating equipment,

restoring equipment to original specifications.

Customers rely on PRO Services Centers for economical

repair versus replacement, decreased downtime, reduced

inventory of replacement parts and the advantage of

updated engineering technology.

Benefits:

Years of experience allow PRO Services Centers to easily

handle any rotating equipment, including pumps, drivers,

gear boxes, centrifuges, blowers, fans and compressors.

Model 3700 With Diesel Engine Driver

Goulds 3700 11

PR

services

PRO Services provides an array of services focused on

reducing equipment total cost of ownership (TCO) and

increasing plant output, including predictive monitoring,

maintenance contracts, field service, engineered upgrades,

inventory management, and overhauls for pumps and

other rotating equipment.

Reliability has no quitting time.

Parts & Inventory

PRO Services provides OEM

parts for Goulds Pumps,

Bornemann Pumps, AC,

Morris, Goyne, CB, HVC, UXN

and ROV in a timely manner

to meet end user

requirements. Significant

levels of inventory and quick

response capability provides

the necessary programs to

meet all repair needs.

Operation Performance

PRO Services provides programs of

reliability services, energy

assessments, asset management

and training. These can be deployed

as stand-alone or integrated

solutions, tailored to the needs

of your company.

Repairs & Upgrades

PRO Services provides an array

of repairs and upgrades

services to extend equipment

life. PRO Services helps

customers develop effective

maintenance and asset

management programs to

lower maintenance costs,

improve uptime, reduce

inventory costs and extend

equipment life.

Visit our website at

www.gouldspumps.com

240 Fall Street

Seneca Falls, NY 13148

www.itt.com

2012 Goulds Pumps, Incorporated

A subsidiary of ITT Corporation

Form B3700 04/13

A Leader in API-Engineered Pump Package Solutions

API Family of Pumps

Model 3700

OH-2

Model 3620

3640

BB-2

Model 3910

OH-3

Model 3610

BB-1

Model 3600

BB-3

Model 7200CB

BB-5

You might also like

- Mi Ether CatalogDocument76 pagesMi Ether CatalogcirclelineNo ratings yet

- Technical Specification SwedVent 9851 2931 VENTILADORESDocument4 pagesTechnical Specification SwedVent 9851 2931 VENTILADORESJovanyNo ratings yet

- InstallationOperationMaintenance 3700 en USDocument110 pagesInstallationOperationMaintenance 3700 en USAhmed100% (1)

- Operating Instructions for Vertical Spindle Well PumpsDocument30 pagesOperating Instructions for Vertical Spindle Well PumpsDouglas DuarteNo ratings yet

- 2 - 15B Ah-5vomDocument1 page2 - 15B Ah-5vomMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- +manual HANYOUNG AXseries PDFDocument2 pages+manual HANYOUNG AXseries PDFWilliams MedinaNo ratings yet

- WEB bbb4 Catalog PDFDocument128 pagesWEB bbb4 Catalog PDFDiego PascualNo ratings yet

- Advanced Braking Technologies For Mining Conveyors: Altra Industrial MotionDocument8 pagesAdvanced Braking Technologies For Mining Conveyors: Altra Industrial MotionSathish SutharsanNo ratings yet

- QD bushing specification dimensions chartDocument11 pagesQD bushing specification dimensions charteng_moh04No ratings yet

- To Falk Steel FlexDocument47 pagesTo Falk Steel FlexJose Antonio García RuízNo ratings yet

- Manual Flygt 2201Document24 pagesManual Flygt 2201sion 777No ratings yet

- Estimated compressor performance reportDocument3 pagesEstimated compressor performance reportcondebfNo ratings yet

- 3409 PDFDocument8 pages3409 PDFACNo ratings yet

- Ysly JZDocument2 pagesYsly JZwatep_08No ratings yet

- Bomba Vertical GOULDSDocument84 pagesBomba Vertical GOULDSHéctor RiveraNo ratings yet

- Euroflo Centrifugal Product Flyers 2009Document11 pagesEuroflo Centrifugal Product Flyers 2009Zhang ZhaoyangNo ratings yet

- Acoples CouplingsDocument13 pagesAcoples Couplingspablo coroNo ratings yet

- Atlas VC y VCR Slurry Pump ModelsDocument8 pagesAtlas VC y VCR Slurry Pump ModelsfaundesNo ratings yet

- Un04 t05 enDocument101 pagesUn04 t05 enStephan LewisNo ratings yet

- Aquestia OCV AVIATIONDocument16 pagesAquestia OCV AVIATIONSony Nd AshaNo ratings yet

- FJM10-45 Glass Edging Machine Operation ManualDocument29 pagesFJM10-45 Glass Edging Machine Operation ManualMichael L HerreraNo ratings yet

- CouplingsDocument9 pagesCouplingssam abusiNo ratings yet

- Cerro Verde Production Unit Expansion: Non Destructive Examination Requirements Document No. SN-100462-MD12Document3 pagesCerro Verde Production Unit Expansion: Non Destructive Examination Requirements Document No. SN-100462-MD12jhonNo ratings yet

- Accesorios Csi SensoresDocument7 pagesAccesorios Csi SensoresVILLANUEVA_DANIEL2064No ratings yet

- Eaton AxisPro Servo-Performance Directional Valve User ManualDocument254 pagesEaton AxisPro Servo-Performance Directional Valve User ManualMICKENo ratings yet

- Manual de BombasDocument41 pagesManual de BombasGabriel BecerraNo ratings yet

- Bomba Goulds 3X4 - E213h513 PDFDocument18 pagesBomba Goulds 3X4 - E213h513 PDFRoger ChavezNo ratings yet

- Manual Tension SKFDocument27 pagesManual Tension SKFJaime Juvenal Choque TiconaNo ratings yet

- Cat. Gral MercomarveDocument43 pagesCat. Gral Mercomarvewillys8No ratings yet

- Eei PM1 El02Document61 pagesEei PM1 El02Mohd A IshakNo ratings yet

- Instructions For Use - ELECTROtorque Plus 4893Document65 pagesInstructions For Use - ELECTROtorque Plus 4893sinner86No ratings yet

- Farval Dr45 & Dr460a Reversing ValvesDocument8 pagesFarval Dr45 & Dr460a Reversing ValvesanwarmughalNo ratings yet

- 02 Installation and Operating Manual 100825Document41 pages02 Installation and Operating Manual 100825hectorNo ratings yet

- Brochure Flowserve FRBH Worthington® Heavy Duty Paper Stock and Process PumpDocument8 pagesBrochure Flowserve FRBH Worthington® Heavy Duty Paper Stock and Process PumpCarlos Daniel Michel LeytonNo ratings yet

- Bonfiglioli Seris HDP-HDO Manual de MtoDocument88 pagesBonfiglioli Seris HDP-HDO Manual de MtoAlejandro GarciaNo ratings yet

- Technical Note: Dimension Comparison - DR & DT/DV MotorsDocument1 pageTechnical Note: Dimension Comparison - DR & DT/DV MotorsParmasamy SubramaniNo ratings yet

- CA3000BDocument756 pagesCA3000BAlejandro Hernandez100% (2)

- Mining Industry Gear Units for Conveyor BeltsDocument5 pagesMining Industry Gear Units for Conveyor BeltsZahir KhiraNo ratings yet

- SS. HIDRAULICOS CATALOG WITH PIPE SIZES AND THREAD SPECSDocument1 pageSS. HIDRAULICOS CATALOG WITH PIPE SIZES AND THREAD SPECSJeferson MoraesNo ratings yet

- PC-0088 9A Valve and Coil ChangeDocument3 pagesPC-0088 9A Valve and Coil ChangeMarcelo ArayaNo ratings yet

- Goulds Pump Curves 3175Document3 pagesGoulds Pump Curves 3175RichNo ratings yet

- PivDocument3 pagesPivSameerKulkarniNo ratings yet

- Smart Motion Cheat SheetDocument6 pagesSmart Motion Cheat SheetSerx Armendariz100% (1)

- Golden Dragon XML6125 Plug-in Hybrid City Bus ManualDocument90 pagesGolden Dragon XML6125 Plug-in Hybrid City Bus Manualosama tariqNo ratings yet

- BOSCH Preferred Products CatalogDocument33 pagesBOSCH Preferred Products CatalogJamin SmtpngNo ratings yet

- Installation, Operation and Maintenance of Airflex@ VC Grinding Mill ClutchesDocument28 pagesInstallation, Operation and Maintenance of Airflex@ VC Grinding Mill ClutchesCesar Casachagua DavilaNo ratings yet

- Desalination pump design bookletDocument14 pagesDesalination pump design bookletBenicio Joaquín Ferrero BrebesNo ratings yet

- Camiones para Mineria Cat 785c 2011englishDocument12 pagesCamiones para Mineria Cat 785c 2011englishJuan Manuel Visitacion LavadoNo ratings yet

- TDS - M SeriesDocument8 pagesTDS - M SeriesDevang A Panchal100% (1)

- b9. Instrumentation - Murphy Vs2 Shock-Vibration ControlDocument24 pagesb9. Instrumentation - Murphy Vs2 Shock-Vibration ControlNicolii RamonNo ratings yet

- SKF Microlog Analyzer Accessories CatalogDocument48 pagesSKF Microlog Analyzer Accessories CatalogOlawale John Adeoti100% (1)

- Raise Boring Heads: User ManualDocument40 pagesRaise Boring Heads: User ManualMaykol Ken Hasaki MaselNo ratings yet

- OTE Larox PF Filter Brochure-Lores-Pages PDFDocument8 pagesOTE Larox PF Filter Brochure-Lores-Pages PDFQuinton PaulseNo ratings yet

- 830e Ac PDFDocument4 pages830e Ac PDFManuel Ruiz CayunNo ratings yet

- Goulds 3700: API 610 11th Edition / ISO 13709 2nd Edition API OH2 Overhung, Single Stage, Radially SplitDocument12 pagesGoulds 3700: API 610 11th Edition / ISO 13709 2nd Edition API OH2 Overhung, Single Stage, Radially SplitMarcelo CamposNo ratings yet

- Goulds Pumps 3700Document11 pagesGoulds Pumps 3700Antonio CardosoNo ratings yet

- Goulds 3600 LDocument12 pagesGoulds 3600 LDicky ArdiansyahNo ratings yet

- Goulds 3620i / 3640i: API 610 BB2 1 and 2 Stage, Between-Bearing, Radially Split PumpsDocument12 pagesGoulds 3620i / 3640i: API 610 BB2 1 and 2 Stage, Between-Bearing, Radially Split PumpsSergio Roa PerezNo ratings yet

- 3600 Reader SpreadsDocument12 pages3600 Reader SpreadsfurqanNo ratings yet

- Áreas de La Empresa Y Su Organigrama 1.1. ÁREASDocument7 pagesÁreas de La Empresa Y Su Organigrama 1.1. ÁREASRonald Cuenta MamaniNo ratings yet

- NOELIA PAUCARGrammar Exercise - The Simple Present of The Verb To BeDocument4 pagesNOELIA PAUCARGrammar Exercise - The Simple Present of The Verb To BeRonald Cuenta MamaniNo ratings yet

- Entregable N°1Document1 pageEntregable N°1Ronald Cuenta MamaniNo ratings yet

- Weibull PaperDocument11 pagesWeibull PaperJeff HardyNo ratings yet

- Diseño Y Manufactura Asistida: "Fabrica y Diseñe Un Sistema de Mecanismo" CigueñalDocument9 pagesDiseño Y Manufactura Asistida: "Fabrica y Diseñe Un Sistema de Mecanismo" CigueñalRonald Cuenta MamaniNo ratings yet

- Entregable N°1Document1 pageEntregable N°1Ronald Cuenta MamaniNo ratings yet

- 15 Evaluaciones Laborales-AntesDocument1 page15 Evaluaciones Laborales-AntesRonald Cuenta MamaniNo ratings yet

- EJE PIEZA 2D MACHINING PROGRAMDocument8 pagesEJE PIEZA 2D MACHINING PROGRAMRonald Cuenta MamaniNo ratings yet

- EJE PIEZA 2D MACHINING PROGRAMDocument8 pagesEJE PIEZA 2D MACHINING PROGRAMRonald Cuenta MamaniNo ratings yet

- J8B Hydo PDFDocument2 pagesJ8B Hydo PDFEdwin Julcamoro Aquino100% (1)

- MotoresDocument36 pagesMotoresRonald Cuenta MamaniNo ratings yet

- Goulds 3700 PDFDocument1 pageGoulds 3700 PDFRonald Cuenta MamaniNo ratings yet

- Empowerment Technology Reviewer: First SemesterDocument5 pagesEmpowerment Technology Reviewer: First SemesterNinayD.MatubisNo ratings yet

- Artificial IseminationDocument6 pagesArtificial IseminationHafiz Muhammad Zain-Ul AbedinNo ratings yet

- Ca. Rajani Mathur: 09718286332, EmailDocument2 pagesCa. Rajani Mathur: 09718286332, EmailSanket KohliNo ratings yet

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocument11 pagesRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNo ratings yet

- MORTGAGE Short NotesDocument11 pagesMORTGAGE Short Noteshamzatariq015No ratings yet

- Childrens Ideas Science0Document7 pagesChildrens Ideas Science0Kurtis HarperNo ratings yet

- Second Law of EntrophyDocument22 pagesSecond Law of EntrophyMia Betia BalmacedaNo ratings yet

- 27 MARCH 2020: Assignment 5 Question PaperDocument4 pages27 MARCH 2020: Assignment 5 Question PaperShadreck SandweNo ratings yet

- IP68 Rating ExplainedDocument12 pagesIP68 Rating ExplainedAdhi ErlanggaNo ratings yet

- VL2019201000534 DaDocument2 pagesVL2019201000534 DaEnjoy LifeNo ratings yet

- Waves and Thermodynamics, PDFDocument464 pagesWaves and Thermodynamics, PDFamitNo ratings yet

- Unit 1 - Introduction To BankingDocument17 pagesUnit 1 - Introduction To Bankingc08No ratings yet

- PW CDocument4 pagesPW CAnonymous DduElf20ONo ratings yet

- Reinvestment Allowance (RA) : SCH 7ADocument39 pagesReinvestment Allowance (RA) : SCH 7AchukanchukanchukanNo ratings yet

- Emerson Park Master Plan 2015 DraftDocument93 pagesEmerson Park Master Plan 2015 DraftRyan DeffenbaughNo ratings yet

- SYNOPSIS - Impact of GST On Small Traders!Document21 pagesSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaNo ratings yet

- Reservoir Rock TypingDocument56 pagesReservoir Rock TypingAffan HasanNo ratings yet

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDocument7 pagesOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalNo ratings yet

- Human Resouse Accounting Nature and Its ApplicationsDocument12 pagesHuman Resouse Accounting Nature and Its ApplicationsParas JainNo ratings yet

- Single-Phase Induction Generators PDFDocument11 pagesSingle-Phase Induction Generators PDFalokinxx100% (1)

- Investigatory Project Pesticide From RadishDocument4 pagesInvestigatory Project Pesticide From Radishmax314100% (1)

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Document14 pagesDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiNo ratings yet

- Cianura Pentru Un Suras de Rodica OjogDocument1 pageCianura Pentru Un Suras de Rodica OjogMaier MariaNo ratings yet

- The Singular Mind of Terry Tao - The New York TimesDocument13 pagesThe Singular Mind of Terry Tao - The New York TimesX FlaneurNo ratings yet

- Ryerson EthicsDocument20 pagesRyerson EthicssinghbabaNo ratings yet

- Urodynamics Griffiths ICS 2014Document198 pagesUrodynamics Griffiths ICS 2014nadalNo ratings yet

- SEMICONDUCTORS AssignmentDocument8 pagesSEMICONDUCTORS AssignmentMaryam MuneebNo ratings yet

- Oblicon SampleDocument1 pageOblicon SamplelazylawatudentNo ratings yet

- C Exam13Document4 pagesC Exam13gauravsoni1991No ratings yet

- Robocon 2010 ReportDocument46 pagesRobocon 2010 ReportDebal Saha100% (1)