Professional Documents

Culture Documents

Conceptual Design of A Commercial Spent Pot Liner Treatment Plant

Uploaded by

inventy0 ratings0% found this document useful (0 votes)

4 views3 pagesAll aluminium smelter plants discharges high volume extremely toxic electrolytic cell waste known as spent pot liner. Scientists have improvised various methods for disposing these toxic wastes either by diluting with inert material or recovering its carbon value. Present paper outlines conceptual design of a commercial treatment plant which allows recovery of its carbon value after decontaminating the toxic waste.

Original Description:

Original Title

b 04600507

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAll aluminium smelter plants discharges high volume extremely toxic electrolytic cell waste known as spent pot liner. Scientists have improvised various methods for disposing these toxic wastes either by diluting with inert material or recovering its carbon value. Present paper outlines conceptual design of a commercial treatment plant which allows recovery of its carbon value after decontaminating the toxic waste.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesConceptual Design of A Commercial Spent Pot Liner Treatment Plant

Uploaded by

inventyAll aluminium smelter plants discharges high volume extremely toxic electrolytic cell waste known as spent pot liner. Scientists have improvised various methods for disposing these toxic wastes either by diluting with inert material or recovering its carbon value. Present paper outlines conceptual design of a commercial treatment plant which allows recovery of its carbon value after decontaminating the toxic waste.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Research Inventy: International Journal of Engineering And Science

Vol.4, Issue 6 (June 2014), PP 05-07

Issn (e): 2278-4721, Issn (p):2319-6483, www.researchinventy.com

5

Conceptual Design of a Commercial Spent Pot Liner Treatment

Plant.

1,

B. Mazumder,

2,

S. Rani Devi

*Former Emeritus Scientist, Council of Scientific & Industrial Research New Delhi 110001, India

**Senior Research Fellow, SPL Project (CSIR).

ABSTRACT: All aluminium smelter plants discharges high volume extremely toxic electrolytic cell waste

known as spent pot liner. Over the years scientists have improvised various methods for disposing these toxic

wastes either by diluting with inert material or recovering its carbon value after decontaminating the toxic

waste. Present paper outlines conceptual design of a commercial treatment plant which allows recovery of its

carbon value. The design is based on long experience of the authors in decontaminating SPL and recovering its

carbon value.

I. INTRODUCTION:

Aluminium smelter plants use age old Hall Heroult electrolysis method for extracting aluminium metal from

molten cryolite in a thickly carbon lined steel vessel where the carbon lining serves as cathode of the cell. The

molten salt containing fluoride which ultimately corrodes these carbon lining(pot liner) and results in failure the

cell when they are rejected as toxic carbon waste known as spent pot liner or SPL in short. The toxic waste

besides being highly voluminous, its disposal is a challenge to plant engineers and scientist for a very long

time. One method currently being pursued in USA involves diluting the waste with inert materials (like sand

and lime) and use them as landfill. But the process is costly and adds to the cost of production of the metal.

Mazumder et al

1-3

at IIMT, Bhubaneswar, India evolved a process whereby the SPL is crushed to about 4-6 mm

size and treated with strong acids resulting in complete removal of the contaminants and recovery its carbon

value.

It may be mentioned here that SPL contains several toxic contaminants (shown in Table 1 below)

and the carbon recovered from such wastes are generally semi crystalline in nature.

Table 1: Contaminants in spent pot liner

Contaminants Typical range (%)

Alkali 11-20

Aluminium 5-10

Fluoride 5-20

Cyanide 0.12-0.20

Pilot plant trial (1 ton SPL/day) for decontaminating SPL by above acid treatment procedure by Mazumder et al.

was highly successful and brought down all above toxic contaminants to its acceptable limits. However, cost of

production of recovered byproduct carbon by this process was still high for making any industrial carbon

products from these recovered carbon economically feasible. Microscopic studies of SPL boulders (as it comes

out from production plant) indicates most of the toxic contaminants remains as a thin layer on surface of SPL

boulders or diffuse into it through its fine cracks. Based on these informations, present authors improvised

experiments for treating large boulders of SPL (first cut only) without powdering them, as was done earlier and

the results are shown below.

II. EXPERIMENTAL:

Boulders for present experiments were handpicked from the piles of first cut SPL from the aluminium

smelter plant. Fluoride in SPL before and after treatment was determined using Ion Selective Electrode . The

procedure involves weighing out a sample of 100 mg into a 10 ml platinum crucible and mixing the same with

0.5 gm of anhydrous sodium-carbonate and 0.1 gm of zinc oxide. The mixture is then heated to 900

0

C for 30

minutes. After cooling the crucible is placed into a 50 ml borosilicate glass beaker, to which 30 ml of water was

added and the beaker was covered and digested overnight at steam bath temperature. The crucible is then

washed, any lump present is broken, and the solution is allowed to cool to room temperature.

Conceptual design of a commercial...

6

The contents are then filtered into a 100 ml volumetric flask using No.42 Whatman filter paper (or its

equivalent), and the residue is washed several times with small portion of a 0.1 % sodium-carbonate solution.

The residue thus obtained is rejected. Then 2 ml of 6N Hydrochloric acid is added slowly to the solution,

shaking vigorously to expel the carbon-dioxide, and diluted to volume with water. Diluted a 45 ml of aliquot of

this solution with 5 ml TISAB solution, and measured the potential of the diluted solution by Ion Selective

Electrode.

Measurement of potential:

a) A series of minimum 3 standards were prepared with the same back ground ionic strength (which can be

done by adding the same volume of TISAB to all the standards i.e 19, 190,1900 ppm) bracketing the sample

fluoride concentration.

b) The Ion Analyser was then calibrated by feeding the standards, starting from dilute to a concentrated

standard.

c) Same volume of TISAB was added to the sample as that of standards and then feed the sample whose

concentration can be directly read with the Ion Analys

Make: ELICO Ion Analyzer. Model No. LI 126.

A strong oxidizing acid was used to remove fluoride from SPL. SPL when comes in contact with strong

oxidizing agent raises temperature of the solution high enough to break down CN

-

present in it. The vessel used

for dipping the boulders in the oxidizing acid was glass lined and enough acid was taken to ensure complete

dipping of boulder into the acid. Boulders were dipped into the acid for 5 minute, 15 minute, 30 minute, 1 hour

and 2 hours. After each specified period, the boulder was taken out of the acid, thoroughly washed with

distilled water and dried before determining their fluoride content. The dried boulder was powdered to -100 BS

mesh size and representative sample was taken out of the heap by quarter and coning method.

Results of the experiments on shown in Table-2 below:

Table 2: Removal of fluoride from SPL boulder with time

Fluoride content after

Size of the SPL boulder

Initial F

-

content 5min 15min 30min 1hr 2hrs

8.5 kg 2.4 % 12 ppm 7 ppm 7 ppm 7ppm 7 ppm

9.66 kg 2.7 % 14 ppm 8 ppm 8 ppm 8ppm 8 ppm

13.65 kg 2.8 % 14 ppm 8 ppm 8 ppm 8ppm 7 ppm

15 kg 2.8 % 15 ppm 10 ppm 9 ppm 9ppm 8 ppm

It is obvious from above table that essentially all fluoride is removed from SPL boulders by such acid treatment

in about 15-20 minutes reaction time. Accordingly design of a commercial plant is envisaged , as elaborated

below, for decontaminating SPL boulders as they come out from aluminium smelter plant.

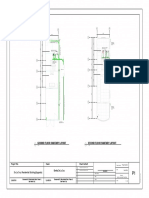

Design of a commercial unit;

Since the strong oxidizing acid used in these experiments react with most common metals and it is

difficult to handle large glass vessels in commercial scale, a SS 317 vessel was found suitable as material of

construction of reaction vessel for the commercial plant. Treatment of SPL boulders by above methods has an

added advantage over powdering and treating the powdered raw material. First the reaction does not emanate

high heat in very short time, gives out less smoke from the treatment tank, and since the treated product is large

in size does not cause high pressure drop in the filter system. Additionally the treated product has less ash in

it.Fig.1 below shows schematic diagram of the entire plant. First the boulders are dipped into acid kept in a

large steel tank which has got arrangement for draining out the reacted acid and empting the reacted boulders on

a conveyer belt (made of glass fiber) which ultimately empties the reacted boulders in a water washing tank.

After washing, the SPL boulders are dried in an oven at about 110

o

C and then powdered in a jaw crusher cum

hammer mill to desired size. Reacted acid can then be taken out of the reaction vessel into a holding tank and

reused for further reaction with next batch of SPL bolders. Spent acid thus can be reused several times until its

strength goes down to a certain level. Preliminary experiments by the present author have indicated that the

spent acid can be re-used 6-7 times before it is being discarded, thus bringing down the acid treatment cost

substantially by this process. By product carbon thus obtained has multiple use in producing useful industrial

carbon products

4-10

.As a measure of safety since the process uses very strong acids, the plant (particularly each

section or unit operation) needs to be covered by transparent acrylic sheets and all the operation needs to be

carried out remotely. Toxic gases from the plant needs to be removed by appropriate exhaust form and bubbled

through caustic lime solution before venting out to atmosphere. Attempts may be made to recover fluoride from

the spent acid and returned to the plant as aluminium fluoride. Similarly washed water from the plant needs to

be recirculated and spent water neutralized with lime before it is discharge to the open drain.

Conceptual design of a commercial...

7

REFERENCES:

[1] B. Mazumder , A process for removal of contaminants from spent pot liners of aluminum industries, Indian Patent No.

0638/DEL/2006 (2006).

[2] B. Mazumder and B. K. Mishra, Managing Wastes from Aluminum Smelter Plants, Woodhead Publishing, U.K. (2010).

[3] B. Mazumder at.el, Decontamination and recovery of carbon value from spent pot lining material- A pilot plant study, Report by

NALCO, India (2008).

[4] B. Mazumder, A process for the removal of sodium from anode butts generated by aluminum smelter plant, Patent filed with CSIR,

Patent Office No. 0226 NF 2003, New Delhi, India (2003).

[5] B. Mazumder, A process for preparation of pencil lead from spent pot liners of aluminum industries. U.S. Patent No. 7,217,378 B2,

European Patent No EP 1664217 B1.

[6] B. Mazumder and S. Rani Devi, Captive utilization of spent pot liner (as anode making) in aluminum smelter plant, Environmental

Sc and Engg., 8, 2 (2010).

[7] B. Mazumder, A process for making dry cell electrodes from spent pot liners of aluminum industries. Indian Patent No.

0395/DEL/2006 (2006).

[8] B. Mazumder and S. Rani Devi, Adsorption of oils, heavy metals, and dyes by recovered carbon powder from SPL of aluminum

smelter plant, J. Env. Science , 50, 3 ( 2008).

[9] B. Mazumder, A process for the preparation of fluffy variety of pyrogenic silica at a relatively lower temperature, Indian Patent No.

006/NF/2002 (2002).

[10] B. Mazumder, A process for making anti-piping compound suitable for steel mold casting and foundry applications, Indian Patent

No.186151 (2002).

You might also like

- Ammonium Sulfate PDFDocument6 pagesAmmonium Sulfate PDFSabhaya Chirag100% (1)

- JIS ChlorideDocument2 pagesJIS ChlorideAndhikaAgraWisesaNo ratings yet

- Pellicer, Eva - Advances in Applications of Industrial Biomaterials-Springer (2017) PDFDocument220 pagesPellicer, Eva - Advances in Applications of Industrial Biomaterials-Springer (2017) PDFEsmael AdemNo ratings yet

- DAO 2010-06 - Guidelines On The Use of Alternative Fuels and Raw Materials in Cement KilnsDocument10 pagesDAO 2010-06 - Guidelines On The Use of Alternative Fuels and Raw Materials in Cement KilnsPacific SpectrumNo ratings yet

- Acid Cleaning of Some Desal UnitsDocument44 pagesAcid Cleaning of Some Desal Unitstata_77100% (2)

- Extraction of Silica From Puddy HuskDocument19 pagesExtraction of Silica From Puddy HuskFauzaan KhanNo ratings yet

- Activated Carbon Synthesised From Bottom Ash From Coal Fired Boilers by Koh Activation For Liquid Phase AdsorptionDocument10 pagesActivated Carbon Synthesised From Bottom Ash From Coal Fired Boilers by Koh Activation For Liquid Phase AdsorptionMuhammad Redzwan Bin IsmailNo ratings yet

- Activated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionDocument8 pagesActivated Carbon From Corn Cobs and Coconut Shell For Heavy Metal Ions AdsorptionS Bharadwaj Reddy100% (1)

- Akira Mikuni Et - Al 2007, Dissolution Properties of Some Fly Ash Fillers Applying To Geopolymeric Materials in Alkali SolutionDocument5 pagesAkira Mikuni Et - Al 2007, Dissolution Properties of Some Fly Ash Fillers Applying To Geopolymeric Materials in Alkali SolutionSatya ChaitanyaNo ratings yet

- AltacusxewDocument23 pagesAltacusxewГаанби Н'ШиефNo ratings yet

- International Journal of Chemical StudiesDocument7 pagesInternational Journal of Chemical StudiessalwaNo ratings yet

- 2016 Wang TsaiDocument6 pages2016 Wang Tsaineetika tiwariNo ratings yet

- Removal of Antimony-124 From PWR Coolant Water - 9111: Ci/mL) - Static Uptake Test Showed A High Uptake ofDocument7 pagesRemoval of Antimony-124 From PWR Coolant Water - 9111: Ci/mL) - Static Uptake Test Showed A High Uptake ofSaeed Ur RahmanNo ratings yet

- Gumus Dan Iyonbe, 2015Document12 pagesGumus Dan Iyonbe, 2015Muhammad Ramadhan SaputraNo ratings yet

- Gregory Dhond 1972Document16 pagesGregory Dhond 1972meeraNo ratings yet

- Preparation and Characterization of Charcoals That Contain Dispersed Aluminum Oxide As Adsorbents For Removal of Fluoride From Drinking WaterDocument11 pagesPreparation and Characterization of Charcoals That Contain Dispersed Aluminum Oxide As Adsorbents For Removal of Fluoride From Drinking WaterCamila NevesNo ratings yet

- 11B-2 Waste Pickle Liquor Utilization As A Coagulant For Water Treatment ProcessDocument8 pages11B-2 Waste Pickle Liquor Utilization As A Coagulant For Water Treatment ProcessArief PrasetyoNo ratings yet

- 1 s2.0 S0043135412001376 Main PDFDocument12 pages1 s2.0 S0043135412001376 Main PDFCarlos AlvarezNo ratings yet

- 00 Adsorption of Copper (II) by Sulfur MicroparticlesDocument29 pages00 Adsorption of Copper (II) by Sulfur MicroparticlesYousef SailiniNo ratings yet

- Yang 2014Document9 pagesYang 2014Alfredo Sebastian Sangurima CedilloNo ratings yet

- Mojtaba Shamsipur, Farhad Raoufi, Hashem SharghiDocument7 pagesMojtaba Shamsipur, Farhad Raoufi, Hashem SharghiangeljosechuquiureNo ratings yet

- 16 Special Waste TreatmentDocument65 pages16 Special Waste TreatmentEgbemuyiwa OlatunjiNo ratings yet

- Ho2016 Enhancement of Hydrogen Generation Using WasteDocument7 pagesHo2016 Enhancement of Hydrogen Generation Using WasteNur FadhilahNo ratings yet

- Zhao 2016Document7 pagesZhao 2016Andre UvillusNo ratings yet

- Zinc BagasseDocument6 pagesZinc BagassePRATYUSH TRIPATHYNo ratings yet

- K2 SO4 Productionviathedoubledecompositionreactionof KClandphosphogypsumDocument12 pagesK2 SO4 Productionviathedoubledecompositionreactionof KClandphosphogypsumGy UiNo ratings yet

- D1757-Standard Test Method For Sulfate Sulfur in Ash From Coal and CokeDocument3 pagesD1757-Standard Test Method For Sulfate Sulfur in Ash From Coal and CokeAyaNo ratings yet

- Prof. Turai Neha SRJISDocument4 pagesProf. Turai Neha SRJISAnonymous CwJeBCAXpNo ratings yet

- Phosphoric Acid PlantDocument56 pagesPhosphoric Acid PlantRohit PrakashNo ratings yet

- % Atom Economy Yield of Potash Alum by Green Chemistry MethodsDocument3 pages% Atom Economy Yield of Potash Alum by Green Chemistry MethodsNeel0% (1)

- Preparation of Shape-Controlled Copper Oxide Powders From Copper-Containing SolutionDocument9 pagesPreparation of Shape-Controlled Copper Oxide Powders From Copper-Containing SolutionAnilú BarreraNo ratings yet

- The Case Study of Isothermal Adsorption of Phenol, O-Cresol On Natural Charcoal's and ApplicationsDocument16 pagesThe Case Study of Isothermal Adsorption of Phenol, O-Cresol On Natural Charcoal's and ApplicationsIJRASETPublicationsNo ratings yet

- Egorov 1Document6 pagesEgorov 1santiNo ratings yet

- Synthesis of Acrolein From Glycerol Using FePO4 CaDocument9 pagesSynthesis of Acrolein From Glycerol Using FePO4 Calu canal do amorNo ratings yet

- WTF PDFDocument6 pagesWTF PDFSenne123No ratings yet

- ICP-MS UdahDocument11 pagesICP-MS UdahAsepSyaefunNazmiNo ratings yet

- Use of SO2 As Reducing Agent in Cobalt Leaching PDFDocument4 pagesUse of SO2 As Reducing Agent in Cobalt Leaching PDFrubcarvNo ratings yet

- Amenability of Au CIP Plant Tails To A Nil Waste ProcessDocument4 pagesAmenability of Au CIP Plant Tails To A Nil Waste ProcessravibelavadiNo ratings yet

- Equillibrium Study On Electroplating Industry Effluent Using ALBIZIA LEBBECKDocument5 pagesEquillibrium Study On Electroplating Industry Effluent Using ALBIZIA LEBBECKDhamodaran ChinnarajNo ratings yet

- Adsorption of Crystal Violet Dye From Aqueous Solution Onto Zeolites From Coal Fly and Bottom AshesDocument13 pagesAdsorption of Crystal Violet Dye From Aqueous Solution Onto Zeolites From Coal Fly and Bottom AshessamsudinhafidNo ratings yet

- SCHAUM Et Al Ny Phosphorus Recovery From Sewage Sludge AshDocument8 pagesSCHAUM Et Al Ny Phosphorus Recovery From Sewage Sludge AshMir Hasib Ul LatifNo ratings yet

- B120432 1279 PDFDocument6 pagesB120432 1279 PDFCarolina PalacioNo ratings yet

- Adsorption of CV PDFDocument13 pagesAdsorption of CV PDFIolanda VeronicaNo ratings yet

- Hydrology 2011 PDFDocument5 pagesHydrology 2011 PDFkapindra prasadNo ratings yet

- Gregory Dhond 1972Document16 pagesGregory Dhond 1972Omar DoskyNo ratings yet

- 16 Deisik PDFDocument9 pages16 Deisik PDFcansuNo ratings yet

- Preparation and Characterization of Waste-Derived Activated CarbonsDocument37 pagesPreparation and Characterization of Waste-Derived Activated CarbonsarulazzikriNo ratings yet

- Extraction and Characterization of Nitrate From Rocks ofDocument10 pagesExtraction and Characterization of Nitrate From Rocks ofم. م. ابراهيم خضرNo ratings yet

- Of Zinc From Wastewater Treatment Sludge: Resources and Conservation, 6 (1981) 203-210Document8 pagesOf Zinc From Wastewater Treatment Sludge: Resources and Conservation, 6 (1981) 203-210Antuanet ToledoNo ratings yet

- Open-Pore Glasses and Glass-Ceramics by Sintering of Modified Pyrogenic Silicic AcidsDocument5 pagesOpen-Pore Glasses and Glass-Ceramics by Sintering of Modified Pyrogenic Silicic AcidsAli AddieNo ratings yet

- Acid Sulfate & Pyrophosphate Copper Plating: Allen C. Hamilton JR., CEF-SEDocument3 pagesAcid Sulfate & Pyrophosphate Copper Plating: Allen C. Hamilton JR., CEF-SEArvin OrayeNo ratings yet

- Acid Sulfate & Pyrophosphate Copper Plating: Allen C. Hamilton JR., CEF-SEDocument3 pagesAcid Sulfate & Pyrophosphate Copper Plating: Allen C. Hamilton JR., CEF-SEAbbey Frosty'Knight Dawn MortaleNo ratings yet

- 1 s2.0 S0011916405002948 MainDocument7 pages1 s2.0 S0011916405002948 MainMeenakshi SamiduraiNo ratings yet

- Co Nano Crystals On AluminaDocument6 pagesCo Nano Crystals On AluminaRamakanta SahuNo ratings yet

- Coloida Silica RemovalDocument9 pagesColoida Silica RemovalAnthony LimNo ratings yet

- Alas Heh 2003Document6 pagesAlas Heh 2003Nila AzizahNo ratings yet

- Ultimate Analysis of Coal and Coke Samples.: Energy Engineering LabDocument3 pagesUltimate Analysis of Coal and Coke Samples.: Energy Engineering LabHafiz hassanNo ratings yet

- Reuse of Spent FCC Catalyst For Removing Trace Olefins From AromaticsDocument5 pagesReuse of Spent FCC Catalyst For Removing Trace Olefins From AromaticsphantanthanhNo ratings yet

- ProjectDocument7 pagesProjectsivaNo ratings yet

- To Prepare Potash Alum From Aluminium ScrapDocument16 pagesTo Prepare Potash Alum From Aluminium ScrapAkshayNo ratings yet

- The Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresFrom EverandThe Chemistry of Fertilisers and Manure - Including Information on the Chemical Constituents and Types of Fertilisers and ManuresRating: 5 out of 5 stars5/5 (1)

- Copper Strip Corrossion Test in Various Aviation FuelsDocument3 pagesCopper Strip Corrossion Test in Various Aviation FuelsinventyNo ratings yet

- A Study of Automated Decision Making SystemsDocument4 pagesA Study of Automated Decision Making Systemsinventy100% (1)

- Choice of Numerical Integration Method For Wind Time History Analysis of Tall BuildingsDocument10 pagesChoice of Numerical Integration Method For Wind Time History Analysis of Tall BuildingsinventyNo ratings yet

- Lean Construction - Approach Capable of Dealing With Complexity and UncertaintyDocument8 pagesLean Construction - Approach Capable of Dealing With Complexity and UncertaintyinventyNo ratings yet

- A Study On Stabilization of Black Cotton Soil by Use of Fly Ash, Ferric Chloride and Stone DustDocument6 pagesA Study On Stabilization of Black Cotton Soil by Use of Fly Ash, Ferric Chloride and Stone DustinventyNo ratings yet

- Water PollutionDocument38 pagesWater PollutionJes GarciaNo ratings yet

- Sludge Bacteria Pellet MSDSDocument2 pagesSludge Bacteria Pellet MSDSBob hamiltonNo ratings yet

- NTPC EOC Noida ReportDocument27 pagesNTPC EOC Noida ReportDhruvKandwalNo ratings yet

- Study Eco-Efficiency of Recovery Scenarios of Plastic Packaging - 2001Document266 pagesStudy Eco-Efficiency of Recovery Scenarios of Plastic Packaging - 2001ademaj08No ratings yet

- Void Generation Method Yields Low-Void Solder Paste - Technical Memo - About Soldering - KOKI Company LTDDocument5 pagesVoid Generation Method Yields Low-Void Solder Paste - Technical Memo - About Soldering - KOKI Company LTDYui PhantomhiveNo ratings yet

- Envt Pollution DoneDocument13 pagesEnvt Pollution DoneJulius MensahNo ratings yet

- Sabp A 060 PDFDocument24 pagesSabp A 060 PDFWalid MegahedNo ratings yet

- Curriculum Integration in Chemical Engineering Education at The Université de SherbrookeDocument8 pagesCurriculum Integration in Chemical Engineering Education at The Université de SherbrookeAri LosNo ratings yet

- Trickling FilterDocument34 pagesTrickling FilterDr. Akepati Sivarami Reddy100% (9)

- Lenovo P90: Quick Start GuideDocument15 pagesLenovo P90: Quick Start Guidesothe1No ratings yet

- NHDC Visit Report by Amit KumarDocument49 pagesNHDC Visit Report by Amit Kumaramit kumar67% (3)

- Concrete Placement Finishing Swms 10064-7Document12 pagesConcrete Placement Finishing Swms 10064-7JamesNo ratings yet

- GM NRB 2015 Score CardDocument28 pagesGM NRB 2015 Score CardAltheaChanNo ratings yet

- Solid Waste Management in SchoolsDocument32 pagesSolid Waste Management in SchoolsRusty TorioNo ratings yet

- Chapter 6 Research Methodology - Report WrittingDocument69 pagesChapter 6 Research Methodology - Report WrittingYared WendaleNo ratings yet

- Annex4 2 8 COMPETE 032448 2ndreport D4.6Document131 pagesAnnex4 2 8 COMPETE 032448 2ndreport D4.6Jawad WaheedNo ratings yet

- Case Study Report Engl Bisc 3Document64 pagesCase Study Report Engl Bisc 3hammy8680% (5)

- DDS Prod Manual PDocument0 pagesDDS Prod Manual Pgarisa1963No ratings yet

- Ficha TecnicaDocument9 pagesFicha TecnicaVictor CamargoNo ratings yet

- Eco Tourism Plan, Pench Tiger Reserve, MPDocument26 pagesEco Tourism Plan, Pench Tiger Reserve, MPRashi KothariNo ratings yet

- Plumbing Plan 1 PDFDocument1 pagePlumbing Plan 1 PDFMildred Peña TolentinoNo ratings yet

- LAB 4 Heat Pump PDFDocument10 pagesLAB 4 Heat Pump PDFMR SASANo ratings yet

- State of Barangay Governance I. PreliminariesDocument57 pagesState of Barangay Governance I. PreliminariesRidzsr DharhaidherNo ratings yet

- Lean Production at Portakabin: HospitalsDocument4 pagesLean Production at Portakabin: HospitalsFLAVIUS222No ratings yet

- Waste Management: Beatriz C. Guerra, Fernanda Leite, Kasey M. FaustDocument12 pagesWaste Management: Beatriz C. Guerra, Fernanda Leite, Kasey M. FaustrpierottNo ratings yet

- Xanthan MSDSDocument5 pagesXanthan MSDShuythai2011No ratings yet

- DM Technical GuidelinesDocument11 pagesDM Technical GuidelinesshyamdameraNo ratings yet

- City Cement SaudiDocument5 pagesCity Cement SaudijagrutNo ratings yet