Professional Documents

Culture Documents

EMI 400 250 Ton Instalation Guide

Uploaded by

Daniel VillarroelOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EMI 400 250 Ton Instalation Guide

Uploaded by

Daniel VillarroelCopyright:

Available Formats

DOCUMENT NAME: 880044 REV 1

Installation Guide

EMI 400 Top Drive System

250TON EMI 400HP

INSTALLATION GUIDE COPYRIGHT AND DISCLAIMER

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

I

Tesco Corporation (Tesco) has made every effort to ensure that this document contains accurate and

current documentation for the Tesco top drive, however, the document is intended to be used in

conjunction with a complete training program and on-site supervision and Tesco does not warrant

or guarantee that the information contained herein is either complete or accurate in every respect, and

the reader hereby protects, indemnifies and holds harmless Tesco Corporation together with its

directors, officers, employees and agents from and against all liability for personal injury, death or

property damage to any person arising directly or indirectly from the use by the reader of the

information contained in the document.

Tesco Corporation 2007

Contact Information

Corporate Head Office

6204 - 6A St. S.E.

Calgary, AB T2H 2B7

Canada

www.tescocorp.com

Telephone: (403) 692-5700

Fax: (403) 692-5710

REVISION INFORMATION INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

II

Revision Information

Version Date Description of Changes

Rev 0 Jan 2006 Release

Rev 1 March 2007 References to Mechanical Module changed to Auxiliary Hydraulic Power Unit and other

minor updates as per ECN-122-0009

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

III

TABLE OF CONTENTS

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VII

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IX

CHAPTER 1: ABOUT THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CHAPTER 2: PRE-INSTALLATION ACTIVITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rig Installation and Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power/Service Connection Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Main Power Requirements (Rig AC Bus) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Air Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Equipment Inspection (Pre-installation). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHAPTER 3: RIG UP PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Equipment Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Optimal Placement of the Power Module and Auxiliary Hydraulic Power Unit . . . . . . . . . . . . . . . . . 7

How to Place the Power Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Optimal Placement of the Service Loop Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Optimal Placement of the Cable/Hose Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How to Install the Cable Roller Saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to Install the Service Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How to Install the Service Loop: Option 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How to Install the Service Loop: Option 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Torque Arrest System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before You Install the Torque Arrest System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Torque Arrest System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Torque Arrest System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

How to Determine the Torque Track Configuration (where an application drawing is not supplied) . . . . . . . . . . . . 18

Sample Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How to Install the Torque Arrest System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Top Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

How to Install the EMI 400 Top Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Extend Arm Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Counter-Balance System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

How to Set the Counter-Balance Cushion Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Driller's Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

How to Install the Drillers Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

TABLE OF CONTENTS INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

IV

Safety Air Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

How to Install the Drawworks Interlock and Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

About the Mud Pump Interlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

CHAPTER 4: SYSTEM INSPECTION AND START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Inspection-General Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Supply Power and Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

System Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Table of Circuit Breakers and Main Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Support Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

How to Start the Generator (if supplied) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Top Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Preliminary Checks and ESD Shutdown Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

How to Apply 600 VAC Transformer Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Power up the drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

How to Check Phase Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

How to Check the Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

How to Test the ESD on the Drillers Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Final Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

How to Reset the OEMV3000 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

About Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

How to Modify Drive Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

CHAPTER 5: RIG OUT PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Remove the Top Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Remove the Torque Arrest System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Remove the Service Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Disconnect the Power and Auxiliary Hydraulic Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

APPENDIX A: PRE-INSTALLATION CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

APPENDIX B: VISUAL INSPECTION CHECKLISTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

APPENDIX C: SLING LOAD RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

APPENDIX D: HAND SIGNALS FOR BOOM EQUIPMENT OPERATION. . . . . . . . . . . . . . . . .59

APPENDIX E: TRIP AND WARNING CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

APPENDIX F: DRIVE DATA MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

V

Navigating Menus and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Editing Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Monitoring the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

INDEX. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

TABLE OF CONTENTS INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

VI

This page has been left blank intentionally.

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

VII

LIST OF FIGURES

Figure 2-1: Power connection with rig AC bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2-2: Power connection with integrated generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3-1: EMI 400 optimal equipment placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3-2: EMI 400 hose saddle placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 3-3: Service loop installation (option 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3-4: EMI 400roller saddle cable capture clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 3-5: Cable/hose saddle clamping location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 3-6: Front and end views of saddle, hose, and service loop. . . . . . . . . . . . . . . . . . . . . 14

Figure 3-7: EMI 400 cable/hose saddle capture clamp configuration . . . . . . . . . . . . . . . . . . . 14

Figure 3-8: Hoisting the hose saddle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3-9: Positioning the hose saddle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3-10: Torque arrest system configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 3-11: Torque arrest system - permanent installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3-12: Link locks in locked and unlocked position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 3-13: EMI Top Drive capture clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 3-14: Counter-balance system interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3-15: EMI counter-balance cushion height; yoke and split block interface . . . . . . . . . . . 29

Figure 3-16: Drawworks override installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 4-1: Recommended supply power and grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 4-2: Change phase rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 5-1: Setting the swivel link locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 5-2: Spooling the service loop 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figure 5-3: Spooling the service loop 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure F-1: Drive Data Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Figure F-2: Navigating Menus and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure F-3: Entering the Parameter Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure F-4: Editing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

LIST OF FIGURES INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

VIII

This page has been left blank intentionally.

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

IX

LIST OF TABLES

Table 1-1: Where to find more information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table B-1: Top drive inspection list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table B-2: Power module inspection list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table B-3: Auxiliary hydraulic power unit inspection list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table B-4: Cable/hose reel inspection list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table B-5: Drillers panel inspection list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table C-1: Maximum safe working loads (pounds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table C-2: Rope diameter efficiencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table D-1: Hand signals for boom operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table E-1: Trip Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table E-2: View Warnings and Trips. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table E-3: History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table F-1: Parameters in Menu 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

LIST OF TABLES INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

X

This page has been left blank intentionally.

INSTALLATION GUIDE

880044 REV 1250TON EMI 400HP TESCO CORPORATION, 2007

1

CHAPTER 1: ABOUT THIS DOCUMENT

This document contains information on how to install the 250TON EMI 400HP top drive,

power module, auxiliary hydraulic power unit, torque arrest system, and service loop.

You can alter the installation sequence described in this document to accommodate current rig

activity. The procedures described in this document provide instuctions on how to do the fol-

lowing:

perform a pre-installation assessment and equipment check

place equipment

install the service loop and connect services

install the torque arrest system

install the counter-balance system

install the top drive

connect the driller's panel and safety interlocks

perform a system inspection and commission the unit

rig out

Table 1-1: Where to find more information

For information on Refer to

system components System Description

setting torque and speed

driller's panel functions and operating descriptions

making connections

drilling ahead

tripping

freeing stuck pipe

Operations Guide

load path inspections

maintenance/service schedules

component disassembly and reassembly

Maintenance Guide

Tesco manufactured parts and part numbers Parts List

electrical schematics

hydraulic schematics

cooling schematics

gearbox lubrication schematics

System schematics

available options and spares Tesco Representative

ABOUT THIS DOCUMENT INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

2

This page has been left blank intentionally.

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

3

CHAPTER 2: PRE-INSTALLATION ACTIVITIES

RIG INSTALLATION AND MEASUREMENT

To ensure that top drive installation progresses smoothly, complete a detailed rig measurement

package before ordering equipment. Rig measurement packages are available from Tesco.

Accurate rig measurement helps you do the following:

Determine an equipment placement plan

Determine the best method for installing the top drive

Identify specialized equipment requirements, including the following:

torque track hanging pad eye

components and subs (top drive to drill string)

cable lengths and specific accessories

air/electric safety interlocks

torque arrest system components

roller saddle or cable/hose saddle mounting requirements

mud hose connection

standpipe extension

Ask a qualified Tesco representative to help you complete the rig measurement package. This

will help to ensure that the equipment will fit properly within your rigs configuration.

POWER/SERVICE CONNECTION REQUIREMENTS

Discuss the following items with a qualified Tesco representative before you request shipment

of the top drive system:

size and output of all generators

type and model of the distribution/SCR systems

The top drive system requires a 600 VAC, 60 Hz power supply. Where the power supply is 50

Hz, an optional package can be installed during the manufacturing process, upon customer

request. If the top drive unit is equipped with an integrated generator, then the connection

requirements for fuel and air should be considered.

The following figures illustrate the connection considerations to address before the top drive

system arrives on location.

PRE-INSTALLATION ACTIVITIES INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

4

Figure 2-1: Power connection with rig AC bus

Figure 2-2: Power connection with integrated generator

INSTALLATION GUIDE PRE-INSTALLATION ACTIVITIES

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

5

Main Power Requirements (Rig AC Bus)

1. Determine a location for the power and mechanical modules.

Note: If the rig configuration has not been finalized, then select two possible loca-

tions for the power module.

2. Determine where the main disconnect breaker panel will be located.

Note: The best location provides room for service personnel and some shelter

from the weather.

3. Determine the distance from the AC-Bus to the breaker panel.

4. Determine the distance from the breaker to the power module.

5. Determine if any special equipment is required. Examples: penetration or plug

boards.

Note: This equipment is required if the three-phase power cables must pass

through walls on their way from the main breaker to the power module.

6. Determine if cable tray or suitable space is available to accommodate three-phase

power cables (from the breaker to the power module).

Note: If adequate space is not available, determine what materials would be

required to protect the cables from the breaker to the power module.

7. If the customer is providing the main power supply (interconnection package),

consult Tesco.

Fuel Considerations

If the top drive unit is equipped with an integrated generator, then the connection requirements

for fuel and air should be considered.

1. Determine the location and type of the fuel supply.

Note: The fuel connector line should be 1 in. minimum, and it should be able to

supply enough fuel for the power units maximum consumption. The fuel return

line should also be 1 in. minimum.

For the Detroit Diesel 635 hp Genset, maximum consumption is 22.8 gallons per

hour (86 liters per hour).

2. Determine the required length of the fuel line. Determine the route it will take

from the fuel supply to the power unit.

Note: Avoid routing the fuel line where it might become damaged or pinched.

3. Verify the quality of the fuel supply.

Note: Poor fuel quality might require special treatment. For example, fuel line

heaters might be required in areas where diesel fuel contains high levels of paraf-

fin.

Air Considerations

If the top drive unit is equipped with an integrated generator, then the connection requirements

for fuel and air should be considered.

1. Determine if the air supply is adequate.

Note: 100 psi minimum with a 1 in. supply line

PRE-INSTALLATION ACTIVITIES INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

6

2. Verify the quality of the air supply.

Note: If you are in an area with high humidity, then a moisture trap might be

required to remove moisture from the starters air supply.

3. Determine the required length and route of the air supply line.

Note: Avoid routing the line where it might become damaged or pinched. If you

place the air receiver close to the power unit, this might help it start more easily.

EQUIPMENT INSPECTION (PRE-INSTALLATION)

Tesco inspects all top drive equipment before shipping, however, some damage might occur

while equipment is in transit.

It is important to identify any shipping damage as quickly as possible. This allows you to make

necessary repairs, order equipment replacements, and optimize system readiness.

As part of a pre-installation equipment inspection, do the following:

Check all shipping containers for damage. External damage may indicate damage to con-

tents.

Visually inspect all principle components for damage or missing parts.

If the top drive system is shipped with fluid levels at full, check the fluid levels. Low

fluid levels may indicate a leak in the hydraulic, cooling, or lubrication system.

A sample equipment checklist is included in Appendix A: Pre-Installation Checklist.

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

7

CHAPTER 3: RIG UP PROCEDURE

EQUIPMENT PLACEMENT

Optimal Placement of the Power Module and Auxiliary Hydrau-

lic Power Unit

Placement of the power and mechanical modules is similar regardless of whether the power is

supplied by the rig or by an independent generator. The following diagram shows the optimal

placement of the power module and auxiliary hydraulic power unit. This placement is consid-

ered ideal for the following reasons:

The distance from the main disconnect breaker to the power module is short.

The placement allows straight-line access from the cable reel to the cable/hose saddle.

The power module is in the aft position (closest to the generators).

The service loop cable connections are outboard of the rig.

Note: You can easily secure excess service loop cable on the roof of the power module

when it is in this position.

There is easy access to the power module waterfall.

The auxiliary hydraulic power unit is placed close to the power unit and the connections

of the auxiliary hydraulic hose are easily accessible.

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

8

Although the location of the power module depends on the rig configuration, the factors listed

above should be considered when placing equipment.

How to Place the Power Module

1. Ensure the ground surface is level; remove any major obstructions.

2. Install rig matting or another secure material under the equipment location.

Note: Ensure the rig matting extends far enough beyond the equipment to provide

a walkway for outside service activity.

3. Using a crane or loader, place the power module on the rig matting.

4. Move the auxiliary hydraulic power unit to a location within 30 ft of the power

module.

5. Connect the following cords from the auxiliary hydraulic power unit to the incom-

ing cable panel on the power module:

1 x Power cable

6. 1 x Sensor cableConnect the auxiliary hydraulic power module to the hose reel

motor.

Figure 3-1: EMI 400 optimal equipment placement

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

9

Optimal Placement of the Service Loop Reel

The service loop reel acts as a spooling and storage device for electrical cables and auxiliary

hydraulic hoses; it is not required during top drive operations. After the hoses and cables are

moved onto the saddle and connected to the power unit and top drive, then you can move the

hose reel from the installation location to any convenient storage area.

Figure 3-1: EMI 400 optimal equipment placement shows the optimal location for the hose

reel during installation of the service loop. This position is considered optimal for the follow-

ing reasons:

There is a clear view of the cable/hose saddle.

There is straight-line access from the hose reel to the cable/hose saddle.

Although the placement indicated on the illustration is considered optimal, placement of the

reel is determined by the available space on site. Always ensure that the selected path is free of

sharp edges and corners that can damage the service loop.

Optimal Placement of the Cable/Hose Saddle

The following illustration shows the optimal placement of the cable/hose saddle. This place-

ment is considered ideal because the cable/hose saddle is situated as follows:

High enough to prevent cables from landing on the rig floor when top drive is lowered:

If the mast is 100 ft. - 125 ft. (30.5 m-38.1 m), it is 55 ft. - 65 ft. (16.8 m-19.8 m)

above the rig floor.

If the mast height is 130 ft.-145 ft. (39.6 m-44.2 m), it is 75 ft.-85 ft.(22.9 m-25.9 m)

above the rig floor.

Low enough to allow the top drive to reach the rig floor without straining or damaging

cables.

Where there is straight-line cable access from the power unit.

Note: This position is a low activity area for overhead equipment. Accidental damage to

cables is less likely to occur when the roller saddle is placed here.

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

10

Although the arrangement shown here is considered optimal, placement of the cable roller sad-

dle is determined by several factors:

mast height

strongback location and type

length of traveling equipment (drill string, compensator, blocks, and swivel)

available cable length (maximum service loop length is 225 ft. (68.6 m) unless otherwise

requested)

power module location

How to Install the Cable Roller Saddle

1. Use a crane or other available lifting equipment to move the cable roller saddle to

the rig floor.

2. Use a tugger or cat line to hoist the roller saddle to a predetermined location on the

mast.

3. Mount the cable roller saddle to the strongback.

Note: The strongback type determines which mounting hardware you should use.

Discuss mounting requirements during the rig measurement and pre-installation

analysis.

Figure 3-2: EMI 400 hose saddle placement

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

11

HOW TO INSTALL THE SERVICE LOOP

There are typically two options to installing the service loop:

Option 1: The service loop needs to be strung through the mast structure. A roller saddle

should be used as the service loops are typically pulled over the roller saddle and

through the mast structure.

Option 2: The service loop is hung outside the mast structure and does not have to pass

through the mast structure. The service loop is clamped to a cable/hose saddle and

hoisted up beside the mast.

How to Install the Service Loop: Option 1

Use this procedure to string the service loop through the mast structure by using a roller sad-

dle.

1. Use a crane or other available lifting equipment to move the cable roller saddle to

the rig floor.

2. Use a tugger or cat line to hoist the roller saddle to a predetermined location on the

mast.

3. Mount the cable roller saddle to the strongback.

Note: The strongback type determines which mounting hardware you should use.

Discuss mounting requirements during the rig measurement and pre-installation

analysis.

4. Place the reel in a location where you have a clear view of the roller saddle.

Figure 3-3: Service loop installation (option 1)

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

12

5. Connect the auxiliary hydraulic power unit to the storage reel using the 35 ft

extension hoses.

Note: If you need to unreel hoses and the Auxiliary Hydraulic System is not avail-

able, you can manually unreel the hoses by connecting the two quick couplers

closest to the hose reel motor. This allows oil to free-flow through the motor,

hoses, and quick couplers. If you use this technique, the motor free-wheels (no

reel brake is available).

6. Ensure the auxiliary pump is operational.

Note: If the unit is connected to an independent generator, ensure the fuel and air

supply lines are connected.

Note: When connecting to the main electrical power, ensure that 600 VAC power

is established with correct phase rotation and that electrical power is available for

the hydraulic pump at the auxiliary hydraulic power unit.

7. Bundle the ends of all the cables and hoses together in a soft sling.

8. On the rig floor, thread the tugger line through the snatch block.

9. Attach the sling to the tugger line.

Note: Verify that the slings are long enough to pass over the roller saddle and

extend to the service reel. If adequate sling length is not available, see How to

Install the Service Loop: Option 2 on page 13.

10. Thread the slings over the roller saddle.

11. Attach the sling to the soft sling on the service loop.

12. Use the tugger to begin spooling out the service loop.

Note: Use the hydraulic reel controls to hold back or feed the line as required.

13. Spool out the correct length of service loop (enough to reach from the reel side of

the roller saddle to the rig floor plus 2 ft.), then install the mast cable capture

clamp as follows:

a. Use slings to attach the back plate of the capture clamp to the mast.

b. Position the urethane inserts on the back plate.

c. Position the cables and plates as indicated in Figure 3-4 on page 12.

d. Tighten all bolts to prevent cables and hoses from slipping, then install the

cotter pins in the bolts.

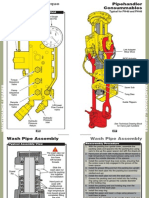

Figure 3-4: EMI 400roller saddle cable capture clamp

1. Power cord

2. Spare

3. Power cord

4. Power cord

5. GND cable

6. Blower motor cable

7. Spare

8. Sensor cable

9. Auxiliary Hydraulic

Return

10.Auxiliary Hydraulic

Pressure

11.Robotics Cable

12.Spare

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

13

14. Pull the remaining portion of the service loop over the roller saddle and down to

the rig floor.

15. Use slings to secure the mast cable capture clamp assembly to the mast approxi-

mately 2 ft. below the roller saddle on the reel side.

16. Connect the service loop cables and hoses at the top drive, the power module, and

the auxiliary hydraulic power unit.

Note: The auxiliary supply/return quick couplers are located on the auxiliary

hydraulic power unit. The power, sensor, robotics and ground cables are con-

nected to the appropriate receptacles in the supply waterfall of the power module.

These cables and hoses cannot be connected until the top drive is mounted to the

torque track. The cable to the drillers panel cannot be connected until the drillers

panel is mounted on the drill floor.

How to Install the Service Loop: Option 2

Use this option when the service loop does not need to be strung through the mast structure.

1. Ensure that the auxiliary hydraulic fluid lines are connected to the hose reel con-

trol.

2. Use a soft sling to bundle the end of the service loop.

3. Attach the bundled end to the cable of the floor tugger or loader.

4. Use the hose reel and tugger to lay out the length the of service loop that will

travel with the top drive.

5. Measure the length of the service loop, starting at the hose or cable ends. Keep the

service loop tidy, and ensure the ends of all hydraulic hoses and cables are as even

with each other as possible.

Note:

Figure 3-5: Cable/hose saddle clamping location

1 - Cable and hose ends

2 - Hose saddle

When the hose saddle is in place, the hoses to the top drive should

reach the rig floor, and approximately 3 ft. of hose should be lying

on the floor.

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

14

6. When the correct length has been spooled off the reel, insert the hoses and cable in

the cable/hose saddle capture clamp.

7. Connect the hose saddle to the cable of the floor tugger or crane.

Figure 3-6: Front and end views of saddle, hose, and service loop

Figure 3-7: EMI 400 cable/hose saddle capture clamp configuration

1. Hydraulic return hose

2. Hydraulic pressure hose

3. Cord T

4. Cord A

5. Phase 1 power cable

6. Phase 2 power cable

7. Phase 3 power cable

8. Ground cable

9. Blower motor power cable

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

15

8. Hoist the saddle and hoses into position below the racking platform.

Note: Hoist the saddle slightly higher than its final position.

9. Install the hanging sling for the hose saddle at the racking platform.

Note: Attach the hanging sling to the pad eye with a shackle, or wrap it around a

suitable beam.

10. Use a shackle to attach the hose saddle to the hanging sling.

Note: The hose saddle sling must be strong enough to hold loads of more than

2,000 lbs (907.2 kg).

Figure 3-8: Hoisting the hose saddle

Figure 3-9: Positioning the hose saddle

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

16

11. Use the floor tugger or crane to lower the saddle until the weight transfers to the

hanging sling.

12. Install a back-up safety sling around the hose saddle.

Caution: This back-up sling is considered critical safety equip-

ment.

13. Lower the crane or floor tugger cable.

14. Attach the crane or floor tugger cable to the sling at the free end of the service

loop.

15. Hoist the free end of the service loop to the rig floor and secure it in place until it

can be connected to the top drive and driller's panel.

TORQUE ARREST SYSTEM

Before You Install the Torque Arrest System

Install a hanging pad eye in the crown before you install the torque arrest system. This pad eye

must be designed and installed to support the hanging weight of the entire torque assembly

(safe working load of 15,000 lb. (6804 kg) plus the recommended safety factor for overhead

equipment).

The pad eye is typically placed 22.5 in. (57.15 cm) back from the crown cluster centre. It is

easiest to install the pad eye when the mast is down. Discuss installation procedures with a

Tesco representative as part of pre-installation activities.

Danger! Design and installation of the pad eye should

meet or exceed all safety specifications for the

operating area and operating conditions.

A variety of stabilization devices can be used to hold the torque arrest system in place during

operations. It is easiest to install the stabilization systems before raising the mast.

Torque Arrest System Components

A standard torque arrest system includes the torque beam, T-bar, and the following torque

track sections (typical). The number of torque track sections depends on the free working

height of the mast and is shown on the application drawing supplied with the top drive system:

one adjustable hanging sling

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

17

one cable clamp mount and cable capture clamp

one 18.5 ft. (5.6m) reversible, bolted, bottom torque track section

five 18.5 ft. (5.6m) standard torque track sections

one 10 ft. (3.1m) torque track section

one 5 ft. (1.5m) torque track section

Obtain additional length by lengthening the top section hanging sling. Purchase additional

torque track sections to accommodate larger masts.

The following two sections of torque track are also included:

one 1.3 ft. (0.4 m) deflector section (bull nose)

one 2 ft. (0.6 m) torque track section

Caution: Never subject these sections to torque. Mount them below

the torque beam only.

The deflector section is always mounted at the bottom. Its tapered design assists in mounting

the torque bushing onto the torque track.

Torque Arrest System Configuration

You must know the following before you can determine the torque track configuration:

height of the hanging pad eye for the torque track, measured from the rig floor (A)

position (height above rig floor) where the torque beam and T-bar will be mounted (B)

length of the hanging assembly for the torque track, including hanging swivel, nut, and

shackles (2.5 ft. minimum (.8 m) to 15 ft. (4.6 m) maximum)

Note: Shorter configurations are safer and more practical.

Note: Correct calculations will help ensure that the torque bushing will not come off of

the torque tube when the blocks are fully hoisted to the crown.

the location of any upper strongback that may interfere with the vertical hanging of the

torque track

Note: If the torque track is to remain in the mast during rig moves, match the torque

track connections to the mast connections wherever possible.

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

18

How to Determine the Torque Track Configuration (where an application drawing is not supplied)

Sketch and calculate the following on paper before you connect sections of torque track.

1. Place the bottom of the deflector section 7 ft.-8 ft. (2.1 m-2.4 m) above the drill

floor (C).

2. Place the bottom bolted section of torque track above the deflector section.

Note: Ensure that a suitable strongback for mounting the torque beam and T-bar is

available somewhere along the length of the bolted section of torque track.

Remember that the bolted section is reversible.

3. Stack the track sections (18.5 ft., 5 ft. and 10 ft. sections) until you reach 5 ft.-15

ft. (1.5 m-4.6 m) from the pad eye.

4. Determine the length of hanging assembly required.

Note: Ensure that the length of hanging assembly is incorporated into the calcula-

tion.

5. Calculate the height of the torque bushing to ensure that it will not come off the

top end of the torque track when it is in the uppermost position.

Sample Calculation

If the mast height is 102 ft. (31.1 m):

1. 102 ft. less 7 ft. (height above the rig floor for the deflector section) = 95 ft.

(29.0 m)

2. 95 ft. less 2.5 ft. (minimum hang sling length) = 92.5 ft. (28.2 m)

3. 92.5 ft divided by 18.5 = five full length tubes; this does not include the deflector

section.

Figure 3-10: Torque arrest system configuration

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

19

Torque beam desired height = 11 ft. (3.4 m)

The rig up would be as follows:

* The bolted track section would be run with the bolt section down, below the

standard track sections and 10 ft. and 5 ft. sections. The deflector track section

would be mounted below the bolted section.

How to Install the Torque Arrest System

Use this procedure to install the torque arrest track system. Refer to Figure 3-11 on page 22.

1. Ensure the hanging pad-eye for the torque track is installed in the crown.

Note: Normal placement for a standard track is 22.5 in. back from the crown clus-

ter centre.

2. Assemble the torque beam, T-bar, and T-bar clamp.

Warning! Assemble the above with the T-bar at mid-length.

This balances the assembly during lifting.The

assembly should not be fully torqued, but it

should hold the T-bar securely in place.

3. Use the tugger to move the torque beam onto the drill floor and up to the lowest,

most practical strongback beam.

Note: Install the torque beam low in the mast. Attach it to a large beam anywhere

between 10 ft. and 16 ft. above the drill floor. If you install it any higher, you

might require additional stabilization below the torque beam. Tesco can supply

additional stabilization, if required.

4. Use four clamps to mount the torque beam to the selected supporting beam.

Note: On a permanent installation, you may weld the anchor beam clamp onto the

mast.

5. Slide the T-bar to the most rearward position.

Note: Always mount the T-bar on top of the torque beam. If possible, mount it so

the T-bar sits approximately 1/8 in. above the T-bar clamp so that the torque hang-

ing assembly carries the total weight of the torque track.

6. Use the calculation method described in How to Determine the Torque Track

Configuration (where an application drawing is not supplied) on page 18 to cal-

culate the required torque track section configuration.

Note: When the torque track is suspended, the bottom of the deflector section

should be 7 ft.-8 ft. off the floor.

Track Part Qty Length (ft.) Total Length (ft.)

Hanging Track 1 18.5 18.5

Standard Tracks 2 37 (18.5 x 2) 55.5

10 ft. section 1 10 65.5

5 ft. section 1 5 70.5

Bolted* section 1 18.5 89

Deflector 1 1.3 90.3

Hanging Assembly 1 Set to 3 feet 90.3

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

20

7. Set and secure the calculated pinned insert location (if used), or adjust the hanging

assembly to the appropriate length.

Hanging Assembly: Thread the cable of the hanging sling assembly through the

hole in the top of the top track section. Fasten the clamp plate to the cable at the

appropriate location so the hanging sling assembly has the required length as

determine in previous calculations.

Caution: Torque sling bolt clamps to 230 ftlbs.

Note: When you tighten the sling clamp bolts, ensure that the sling is compressed

evenly along its length. It will take several repetitions to ensure that the clamping

force is distributed evenly across all of the cable clamps.

Note: Use a soft sling to hold the sling in place so that it will be easily accessible

when the torque track is lifted to the hanging pad eye.

8. Use the rig floor tuggers to hoist the first track section up to the floor.

Note: On most rigs, two full-length sections of torque track can be assembled on

the ground before being lifted to the rig floor. If the rig is very small, you will

have to bring the torque track lengths to the rig floor one at a time.

Note: As the first section is installed, make up additional sections on the ground.

9. Lower the first track section through the rotary table or mousehole.

Note: If the rotary table is too small to permit the torque track to pass through, use

an alternate location on the rig floor. If no alternate location exists, mate the sec-

tions above the rig floor.

10. Lower the blocks and install two handling slings on the torque track.

Note: Thread the slings through the block becket and attach them to the top track

using the handling assembly for the torque track.

Caution: Attach the top section of track such that the top portion of

track extends above the blocks. This allows the hanging assembly

to reach the pad eye without crowning out the blocks.

11. Place a ratchet strap around the top of the blocks and thread it around the torque

track.

12. Use the ratchet strap to pull the blocks and track together.

Note: This immobilizes the track section and keeps it hanging vertically as it trav-

els up the mast.

13. Hoist the blocks until they support the weight of the torque track.

14. Remove the floor tugger.

15. Hoist the blocks until the bottom of the first section is 8 ft. above the drill floor.

16. Connect the floor tugger to the second section of torque track and hoist it to the rig

floor.

17. Lower the second section of track through the rotary table or into the mousehole

until it reaches the appropriate level for connecting to the upper section (which is

currently suspended from the blocks).

18. Install all the studs and lower nuts before you connect the sections.

Note: You cannot install the studs after the track sections are connected.

19. Lower the blocks and upper section of track and connect the two sections. Bolt the

sections together, ensuring a flush connection.

Note: Coat all bolts with an anti-seize compound before installation.

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

21

20. Torque the bolts to 350 ftlbs.

21. Repeat steps 16.20. until all sections are connected and supported by the blocks.

Note: The last section that is installed is typically composed of the reversible

bolted section, the deflector section and, if required, the two-foot track section.

22. Use a ratchet strap to secure the extend arms of the torque bushing in place.

23. Attach a tugger to the torque bushing and move the bushing onto the drill floor.

Note: Ensure that the extend frame is down.

24. Position the torque bushing over hole centre.

25. Use the blocks to lower the assembled torque track and stab it through the torque

bushing.

26. When the torque bushing is in position, pin it in place.

Note: Ensure that the top drive pin ends are at least 8 ft. above the drill floor. If

the torque bushing is too tight to move freely along the torque track, adjust the

torque bushing by adding additional shim packs. To ensure a proper fit, periodi-

cally check the bushing during the first few days of operation.

27. After the torque bushing is installed, raise the blocks to the crown.

28. Connect the hanging assembly of the torque track to the pad eye.

29. When the hanging assembly is connected to the pad eye, lower the blocks until the

weight of the track is transferred to the pad eye.

Note: Do not remove the handling assembly yet. Use the blocks to raise and lower

the torque track while you make the fine adjustments required to connect the T-

bar to the bolted section.

30. Connect the T-bar to the bolted section of the torque track.

Caution: When you connect the bolted section of the torque track,

ensure you suspend the full weight of the torque track from the pad

eye.

Note: If the T-bar and bolted sections are not vertically aligned, then use the

blocks to hoist the track. While the track weight is suspended from the blocks,

adjust the hanging swivel as required. Up to 2 in. of adjustment is available in the

hanging assembly and the lock nut.

31. When all T-bar fastening bolts are tight, move the T-bar to the correct position in

the T-bar seat and tighten the clamp to hold it in position.

Note: Hang the centre of the torque track vertically, 22.5 in. back from the hole

centre.

32. Tighten the lock nut on the hanging assembly.

33. Remove the handling assembly at the crown and lower the blocks.

34. Install stabilization systems.

Note: These are most easily installed when the mast is down, but can also be

installed during rig-up.

35. Attach the stabilization devices to the torque track as shown in the following illus-

trations.

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

22

Figure 3-11: Torque arrest system - permanent installation

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

23

If your rig set-up requires a customized stabilization installation, contact Tesco.

TOP DRIVE

How to Install the EMI 400 Top Drive

Before you move the top drive onto the rig floor, ensure the swivel yoke link with integral

counter-balance is installed in the top drive and is securely supported by the top drive handling

frame.

1. Using blocks or a crane, move the top drive to the rig floor.

Note: If using the block, attach a hold-back line from the handling frame of the

top drive to a loader or cat line tugger. Use the line to prevent the top drive from

swinging when it is lifted off the rig floor.

Caution: Always attach the hoisting line to the top drive handling

frame and not to any part of the top drive when the top drive is

installed in the handling frame.

2. Position the top drive over the hole center.

3. Lower the blocks and remove the lifting sling.

4. Lower the blocks further and install the top drive yoke into the block hook or

beckett.

5. Raise the blocks to support weight of the top drive.

Caution: Do not lift the top drive off the floor.

1 Torque track 7 Extend arms

2 3 way stabilizer 8 T-Bar

3 F clamp 9 T-Bar bolts

4 Nuts, washers, and Redi-rod 10 Torque anchor beam

5 Extend frame 11 Torque track (bolted section)

6 Torque bushing 12 Torque anchor beam clamps

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

24

6. Remove the pins on the handling frame of the top drive (three or four in total,

depending on the unit type).

Caution: Ensure the link locks are set so that the top drive will not

tilt forward. See Figure 3-12.

7. Lift the top drive until it is clear of the handling frame.

8. Use the floor tugger to remove the handling frame from the rig floor.

9. Use the blocks to position the top drive so that it can be joined to the extend

frame.

Note: Align the ears on the top drive with the extend frame and extend arms and

pin them in place.

10. Remove the pin that is holding the torque bushing in place on the torque track.

Note: The weight of the top drive and torque bushing are now suspended from the

blocks.

11. Remove the link locks so that the links can swivel freely.

12. Lower the top drive to the rig floor.

13. Check if the top drive hangs vertical. If not, refer to the Extend Arm Adjustment

Procedure on page 26.

14. Reposition the T-bar so the top drive sits over the hole center, and secure it in

place (if required).

Figure 3-12: Link locks in locked and unlocked position

Link locks in locked position

Link locks in unlocked position

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

25

15. Tighten the T-bar connection to secure it in place.

16. Locate the service loop. It should have been installed before this point. If the ser-

vice loop has not been installed, see How to Install the Service Loop: Option 1

on page 11.

17. Connect the following hoses and cables for the service loop to the top drive:

supply and return hoses for the auxiliary hydraulic system

one sensor cable

one robotics cable

one blower motor and heater cable

one ground cable

3 IC #313 cables

18. When all service loop hoses and cable are attached, check the loop position.

The loop should be off the floor.

There should not be any snagging/interference.

19. Re-check all hose connections.

20. Ensure that all required valves are open.

21. When the top drive and driller's panel are connected, continue with additional set-

up procedures, or begin rig commissioning.

Note: The counter-balance cushion height can be set after all support systems are

running. The cushion height must be set before any drilling operations start. See

How to Set the Counter-Balance Cushion Height on page 27.

Figure 3-13: EMI Top Drive capture clamp

1. Blower Motor Power

2. Ground

3. Power Phase 3

4. Power Phase 2

5. Power Phase 1

6. Cord A (robotics cable)

7. Cord T (sensor cable)

8. Hydraulic Pressure

9. Hydraulic Return

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

26

Extend Arm Adjustment Procedure

The aim of this procedure is to ensure that the top drive hangs vertical and is aligned with the

hole centre. Firstly, adjust the extend arms to ensure the top drive is vertical. Secondly, adjust

the torque track to align the top drive with the hole centre.

1. Start with the extend frame retracted in and a joint in the rotary table.

2. Move the grabber box up to the point where the bottom end of the saver sub is

protruding through the grabber box.

3. Lower the top drive so that it is just above the joint in the rotary table (2~6).

4. Place a level on the top drive upper grabber leg to determine how the extend arms

(extend or retract) will have to be adjusted. The top drive should hang vertically;

if adjustment is required, loosen the jam nuts on the extend arm clevises.

5. Remove the upper extend arm pins and unbolt the split flanges in the extend arms.

Warning! Use a cat line to support the top drive so it does

not tilt forward and to enable easy access and

adjustment.

6. Adjust the arms appropriately by adding or removing shims. This is a trial and

error process that requires guesswork. Ensure the extend arms are equal length by

ensuring the same amount of shims are installed in both extend arms.

7. Tighten the split flange bolts and re-pin the extend arms to the torque bushing.

8. Visually inspect the level. If satisfactory, as judged by the level, continue to the

next step. If the top drive is not satisfactorily level, repeat steps 4. through 8. until

the top drive is vertical (this is a trial and error process and may take 3 to 4 adjust-

ments before the top drive is vertical).

9. Torque the jam nuts appropriately (2300 ft-lbs dry, 1725 ft-lbs lubed) with a

wrench and ensure the retaining cap screws are installed on the lower extend arm

pins.

10. Visually inspect the alignment of the saver sub with the joint in the rotary table. If

they are not aligned, adjust the torque track by adjusting the T-bar in the T-bar

clamp.

Note: The torque track stabilizers must be adjusted accordingly to ensure the

torque track hangs parallel to hole centre.

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

27

COUNTER-BALANCE SYSTEM

How to Set the Counter-Balance Cushion Height

The following conditions must exist before the following portion of the counter-balance instal-

lation can be completed.

The top drive must be installed.

The hydraulic circuit must be connected.

The drillers panel must be operational.

The top drive must be positioned at the racking platform.

1. Connect the hose quick-coupler for the elevator to the charge fitting for the

counter-balance system.

2. Shut off the auxiliary pump.

3. Set the ELEVATOR switch (at the drillers panel) to CLOSE.

4. Open the needle valve on the counter-balance manifold.

Note: This relieves all pressure on the counter-balance system.

5. Check the nitrogen pressure, and adjust if required.

Note: The nitrogen pressure must be 1250 psi.

6. Ensure the counter-balance relief valve is set at 2000 psi.

7. Close the needle valve on the counter-balance manifold.

8. Start the auxiliary pump.

9. Set the ELEVATOR switch (drillers panel) to OPEN, and push and hold the

ELEVATOR SAFTEYOPEN button.

Note: This will send 1500 psi hydraulic pressure to the needle valve on the

counter-balance manifold.

Figure 3-14: Counter-balance system interface

1. Accumulators:

N2-Nitrogen and Oil

2. Counter-balance cylinder

3. Needle Valve

4. Auxiliary system quick-

coupler

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

28

10. Slowly open the needle valve and allow the hydraulic oil to charge the counter-

balance system.

11. Monitor the counter-balance cushion by watching the gap that develops between

the swivel bail and the block hook.

12. Continue to charge the system until the gap is 1-1/2 in. to 2 in.

13. Close the needle valve.

14. Shut off the auxiliary pump.

Note: This will allow the oil pressure in the auxiliary system to decrease.

15. Set the ELEVATOR switch to OPEN, then to CLOSE. This will relieve any pres-

sure in the system.

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

29

16. Remove the elevator hydraulic hose from the counter-balance manifold.

Caution: If you disconnect a quick coupler while there is pressure

in the system, it will be extremely difficult to reconnect the coupler.

DRILLER'S PANEL

How to Install the Drillers Panel

The location you select for the drillers panel should be as follows:

within reach of the driller

where there is an unobstructed view of the rig floor

Figure 3-15: EMI counter-balance cushion height; yoke and split block interface

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

30

in a safe position

The bottom of the driller's panel is equipped with a four-bolt mounting plate. Use this to attach

the control panel to a custom-built pedestal or existing framework. Some on-site fabrication of

a mounting site might be required.

1. Locate the position for the driller's panel.

2. Fabricate a mounting location if required.

3. Drill bolt holes in the mounting location.

Note: A second mounting plate is provided to use as a template.

Caution: To avoid damaging components, avoid mounting the

driller's panel in a location that is exposed to vibration.

4. Install a 4-twisted-pair control cable from the driller's panel to the power module.

5. Mount the brake handle control box to the brake handle.

6. Connect the brake handle control box to the driller's panel.

Note: The driller's panel has three labeled extension cords with military connec-

tors. Use the correct cord (cord F).

SAFETY AIR INTERLOCKS

For detailed information about safety interlocks, refer to the schematics for your unit and/or

contact a qualified Tesco representative.

INSTALLATION GUIDE RIG UP PROCEDURE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

31

How to Install the Drawworks Interlock and Override

The drum clutch interlock stops the air supply to the drum clutch so that the driller cannot

hoist the top drive while the grabber is closed. Use the push button on the brake handle to

override this lockout feature. You cannot install the drawworks interlock override until the

driller's panel is in place.

1. Shut off the air supply from the compressor to the drum clutch control.

Note: Use an isolator valve if necessary.

2. Disconnect the hose for the drum clutch air supply from the control valve.

3. Connect the air supply hose to an air/electric solenoid valve.

Note: If two air supply hoses are present, connect each hose to an air/electric sole-

noid valve (one for low clutch and one for high clutch).

4. Connect the air supply from the air/electric solenoid valve to the drum clutch air

control valve.

5. Connect an electric cable from the air/electric solenoid valve to the extension cord

at the driller's panel. The cord is labeled Cord C.

Note: If two air/electric solenoid valves are required, use a splitter to establish a

connection from both valves to the driller's panel.

6. Ensure the control box for the brake handle is connected to the driller's panel.

Figure 3-16: Drawworks override installation

1. Supply air

2. Air/Electric solenoid valve

3. Air line

4. Drum clutch valve

5. Air line

6. Drawworks

7. Drillers panel

8. Grabber Open/Close switch

9. Elevator button

10.Grabber override button

11.Control box for the brake handle

RIG UP PROCEDURE INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

32

About the Mud Pump Interlock

The mud pump air interlock is designed to disallow operation of the mud pump unless the

mudsaver valve is open.

Before you attempt to install this safety interlock, discuss equipment requirements and opera-

tional considerations with a qualified Tesco representative.

INSTALLATION GUIDE

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

33

CHAPTER 4: SYSTEM INSPECTION AND

START UP

INSPECTION-GENERAL NOTES

When the installation procedures are complete, perform a visual inspection of the complete

system.

Caution: Perform visual inspections before applying power to the

system.

Inspection checklists for the following are included in Appendix B: Visual Inspection Check-

lists.

top drive

power module

auxiliary hydraulic power unit

control cables

power cables

drillers panel

SYSTEM INSPECTION AND START UP INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

34

WARNINGS

Electrical

If client-supplied power is not 600VAC, 60 Hz, discuss necessary system changes with a qual-

ified Tesco representative.

Danger! Electrical voltages of different potentials are used

throughout the Tesco top drive components

(600VAC, 208VAC, 120VAC, 840VDC, 524VDC).

ONLY qualified personnel should install, maintain,

and/or troubleshoot the electrical systems. A

severe safety hazard exists for personnel not

accustomed to, or familiar with, electrical hazards

and procedures.

Danger! There are high voltage capacitors installed in the

OEMV3000 Drive power module. Wait at least five

minutes after disengaging power to the drive

before performing any testing or repairs in the

module. The capacitors require time to drain their

stored electrical energy.

Supply Power and Grounding

Grounding methodology has always been a challenge because of differing interpretations of

the rules and understanding of intent. On-site conditions such as add-on buildings fed from a

common power source or a separate power source and/or power sources not requiring a neutral

conductor all have specific grounding criteria that must be met. Tesco has strived to maintain a

safe standard method of grounding so that its implementation becomes familiar to all per-

sonnel installing these systems.

The following is Tesco's recommended grounding method when a ground fault detection sys-

tem is not incorporated into the service supply.

Tesco incorporates a single point ground system when we provide the power source to Tesco

loads and/or add-on loads. Furthermore, when an isolated system (a power system that is not

conductively connected to the distribution system, as in the case of separate generator but most

commonly a transformer), is incorporated into our system of power supply, it is intended that

all ground paths be connected to the common ground electrode/s.

INSTALLATION GUIDE SYSTEM INSPECTION AND START UP

880044 REV 1 250TON EMI 400HP TESCO CORPORATION, 2007

35

I

t

i

s

i

m

p

e

r

a

t

i

v

e

t

h

a

t

t

h

e

g

r

o

u

n

d

i

n

g

m

e

t

h

o

d

o

l

o

g

y

s

h

o

w

n

a

b

o

v

e

b

e

a

d

h

e

r

e

d

t

o

w

h

e

n

u

s

i

n

g

a

d

e

s

i

g

n

a

t

e

d

g

e

n

e

r

a

t

o

r

a

s

t

h

e

m

a

i

n

p

o

w

e

r

s

e

r

v

i

c

e

s

u

p

p

l

y

f

o

r

t

h

e

T

e

s

c

o

t

o

p

d

r

i

v

e

s

y

s

t

e

m

.

S

i

n

c

e

t

h

e

s

e

p

a

r

a

t

e

g

e

n

e

r

a

t

o

r

s

u

p

p

l

y

i

n

g

p

o

w

e

r

t

o

t

h

e

T

e

s

c

o

e

q

u

i

p

m

e

n

t

d

o

e

s

n

o

t

i

n

c

o

r

p

o

r

a

t

e

a

g

r

o

u

n

d

f

a

u

l

t

d

e

t

e

c

t

i

o

n

s

y

s

t

e

m

(

a

n

d

w

h

e

t

h

e

r

t

h

e

r

i

g

e

m

p

l

o

y

s

a

g

r

o

u

n

d

f

a

u

l

t

d

e

t

e

c

t

i

o

n

s

y

s

t

e

m

o

r

n

o

t

)

i

t

i

s

r

e

q

u

i

r

e

d

t

h

a

t

t

h

e

g

e

n

e

r

a

t

o

r

s

y

s

t

e

m

n

e

u

t

r

a

l

b

e

g

r

o

u

n

d

e

d

a

t

o

n

e

p

o

i

n

t

o

n

l

y

v

i

a

t

h

e

m

a

i

n

g

r

o

u

n

d

b

u

s

a

n

d

g

r

o

u

n

d

r

o

d

s

.

W

h

e

n

t

w

o

o

r

m

o

r

e

p

o

w

e

r

s

y

s

t

e

m

s

a

r

e

e

m

p

l

o

y

e

d

,

a

c

o

m

m

o

n

s

y

s

t

e

m

g

r

o

u

n

d

i

n

g

c

o

n

d

u

c

t

o

r

s

h

a

l

l

b

e

i

n

s

t

a

l

l

e

d

u

n

l

e

s

s

s

e

p

a

r

a

t

e

g

r

o

u

n

d

i

n

g

i

s

s

u

p

p

l

i

e

d

f

o

r

e

a

c

h

s

u

c

h

s

y

s

t

e

m

,

i

n

w

h

i

c

h

c

a

s

e

t

h

e

g

r

o

u

n

d

i

n

g

f

o

r

t

h

e

i

n

d

i

v

i

d

u

a

l

s

y

s

t

e

m

s

s

h

a

l

l

b

e

i

n

t

e

r

c

o

n

n

e

c

t

e

d

.

T

h

e

r

e

f

o

r

e

,

a

s

e

p

a

r

a

t

e

g

r

o

u

n

d

c

a

b

l

e

m

u

s

t

b

e

i

n

s

t

a

l

l

e

d

b

e

t

w

e

e

n

t

h

e

r

i

g

'

s

g

r

o

u

n

d

g

r

i

d

a

n

d

t

h

e

g

e

n

e

r

a

t

o

r

g

r

o

u

n

d

g

r

i

d

.

D

u

e

t

o

t

h

i

s

l

i

n

k

,

t

h

e

g

r

o

u

n

d

r

o

d

s

a

t

t

h

e

g

e

n

e

r

a

t

o

r

m

a

y

b

e

e

l

i

m

i

n

a

t

e

d

,

b

u

t

T

e

s

c

o

r

e

c

o

m

m

e

n

d

s

t

h

a

t

t

h

e

y

r

e

m

a

i

n

.

F

i

g

u

r

e

4

-

1

:

R

e

c

o

m

m

e

n

d

e

d

s

u

p

p

l

y

p

o

w

e

r

a

n

d

g

r

o

u

n

d

i

n

g

SYSTEM INSPECTION AND START UP INSTALLATION GUIDE

TESCO CORPORATION, 2007 250TON EMI 400HP 880044 REV 1

36

Other

Ensure the gearbox breather is installed and the ball valve is opened prior to operating.

Note: The breather may not be installed for shipping purposes and some new units may

have the ball valve handle wired closed.

Close the main breaker MB12 to turn the hydraulic tank heater on. When the tempera-

ture reaches 10C, the heating circuit will be shut off automatically.

Ensure that all electrical components are free of frost and condensation before system

start up. Do this by opening all cabinet doors inside the power module and heating the

building to at least 50

o

Fahrenheit (10 Celsius) for eight hours. 208V power is required

to operate the building HVAC unit.

Install a saver sub in the grabber on the top drive before you test for hydraulic leaks or

operate any robotics function.

Caution: You cannot start the hydraulic pump if the Emergency

Shut Down (E.S.D.) is activated (either of two red buttons: one on

the drillers panel and one on the door of the main panel control

system).

Before you start any pumps, ensure that all appropriate valves on tanks and pumps are

open.

SYSTEM START UP

After you have completed all visual inspections, begin the system start up process.This section

provides instructions on how to do the following:

power up support systems

power up the drive system

test the robotics functions and operations of the top drive

Danger! The information presented in this section is a

guide ONLY. It is not intended to replace complete

training on the use of high voltage equipment.

Note: Refer to the electrical schematics supplied with your unit.

Table of Circuit Breakers and Main Breakers

Refer to the electrical schematics for your unit to confirm breaker details.