Professional Documents

Culture Documents

Arcagent 1000

Uploaded by

RamosRamos_2014Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arcagent 1000

Uploaded by

RamosRamos_2014Copyright:

Available Formats

ARCAgent 1000

The ARCAgent 1000 is our entry level system for robotic and automated systems. The 1000

was designed to provide robust, off-the-shelf, real-time monitoring of weld count, weld length

(duration), and process parameters (current, voltage, wire feed, gas flow). Traditional

cut-n-etch and destructive testing alone is ineffective at ensuring process control. The

ARCAgent 1000 offers 2 monitoring modes to assist with quality assurance through 100%

non-destructive testing of every weld on every part.

Part Tracking - Detect Missing/Incomplete Welds

-

Are ALL your welds present and accounted for?

The ARCAgent 1000, when integrated with your welding automation, organizes,

captures and monitors every arc event to ensure that the correct number of welds was

produced on every part. If proper containment procedures are followed, you will not produce

missing welds without them being detected by the ARCAgent.

- Are your welds performed to the proper length?

With upper and lower duration limits, each weld is independently verified to have been

welded for the correct duration. Many, if not all, incomplete welds occur due to automation or

weld equipment faults.

You can control missing and incomplete welds in a manual or automated welding process

through the real-time monitoring and alarming of total welds and arc duration...aka Part

Tracking.

1 / 3

ARCAgent 1000

Set-point Analysis - SPC Limits on Real-time Sensor Averages

- Are my welds within set upper/lower control limits every time?

Do you want to know when your welding process is in or out of control? There are many

factors that affect whether a weld is good or bad. The ARCAgent via Set-Point Analysis

monitors your welding output parameters (average current, voltage, wire feed, gas flow) in

real-time to independently verify that all the 'ingredients' of the weld were accurate and

stable. Poor equipment maintenance is one of the major causes of welding defects. The

ARCAgent will notify your staff when your welding equipment and/or process requires

maintenance.

2 / 3

ARCAgent 1000

Weld Signature Display - For Diagnostic and Troubleshooting

The ARCAgent 1000 allows the acquisition and display of high-speed Weld

Signature data for advanced diagnostic and troubleshooting. The

ARCAgent 1000 does not provide High Speed Weld

Signature Analysis which is available in the ARCAgent 2000, 3000, and 3000P.

3 / 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ICoTA Canada 2010 PresentationDocument33 pagesICoTA Canada 2010 PresentationMahesh sinhaNo ratings yet

- Types & Causes of Welding DefectsDocument9 pagesTypes & Causes of Welding DefectsshankarNo ratings yet

- АК туториалDocument63 pagesАК туториалLucas Gabriel100% (2)

- Pipeline Design and ConstructionDocument47 pagesPipeline Design and ConstructionSaber Abdel Moreid100% (5)

- Final Int RPT RVDocument58 pagesFinal Int RPT RVRudhra veena100% (1)

- Consumable and Welding of Modified 9 Cr-1M0 Steel PDFDocument4 pagesConsumable and Welding of Modified 9 Cr-1M0 Steel PDFmahmoud_allam3No ratings yet

- Chemical Engineering Basics MCQ Practice TestDocument10 pagesChemical Engineering Basics MCQ Practice TestAmir RajputtNo ratings yet

- Nippon Tube dp28wDocument3 pagesNippon Tube dp28wyoi sigit70No ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Document15 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Mohamed Atef100% (1)

- Fate of Manganese Associated With The Inhalation of Welding Fumes: Potential Neurological EffectsDocument7 pagesFate of Manganese Associated With The Inhalation of Welding Fumes: Potential Neurological EffectsAndrea Carolina Salas LalindeNo ratings yet

- WRC452Document76 pagesWRC452Mayank Singla100% (3)

- Wa380-5 Sebm024710Document1,173 pagesWa380-5 Sebm024710ary fauzi rahmanNo ratings yet

- Partially Melted Zone in Aluminum Welds - Liquation Mechanism and Directional SolidificationDocument8 pagesPartially Melted Zone in Aluminum Welds - Liquation Mechanism and Directional SolidificationtazzorroNo ratings yet

- Drawing of Weld SymbolsDocument17 pagesDrawing of Weld SymbolsSteranskoNo ratings yet

- Full Report On Friction Stirr WeldDocument66 pagesFull Report On Friction Stirr WeldVenkat SaiNo ratings yet

- Manual Millermatic 211Document4 pagesManual Millermatic 211Густаво Аранда Мендоса0% (1)

- ASWP Manual - Section 3 - Joints (10!6!12)Document12 pagesASWP Manual - Section 3 - Joints (10!6!12)shah1980No ratings yet

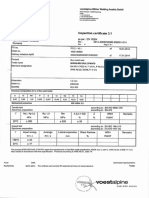

- Product Certification FabCo 811N1 Lot 01873Document1 pageProduct Certification FabCo 811N1 Lot 01873Sleyda MunozNo ratings yet

- Large Web Openings For Service Integration in Composite FloorsDocument121 pagesLarge Web Openings For Service Integration in Composite FloorsStephen HicksNo ratings yet

- API 653 Calculation TestsDocument20 pagesAPI 653 Calculation TestsAnuradha Sivakumar100% (4)

- Data Rates Gate Works 6Document21 pagesData Rates Gate Works 6vpmohammedNo ratings yet

- Catalog Hydraulic Excavator 365cl CaterpillarDocument28 pagesCatalog Hydraulic Excavator 365cl CaterpillarHossam Mohi EldinNo ratings yet

- Sarma Tub Inox Certificat PDFDocument1 pageSarma Tub Inox Certificat PDFJacob HarrisNo ratings yet

- P280 ManualDocument14 pagesP280 ManualzlatkozdihanNo ratings yet

- Welding Lincon CatalogDocument72 pagesWelding Lincon CatalogbarukomkssNo ratings yet

- Pipe Thickness Calculator As Per ASME B31.3Document3 pagesPipe Thickness Calculator As Per ASME B31.3anh thoNo ratings yet

- Information About WeldingDocument16 pagesInformation About Weldingdav.id.stNo ratings yet

- Ultrasonic Testing of Welds Report: Wisconsin Department of Transportation DT2104 2004 (Replaces EM771)Document2 pagesUltrasonic Testing of Welds Report: Wisconsin Department of Transportation DT2104 2004 (Replaces EM771)Abdul GhafoorNo ratings yet

- Welding Filler MetalsDocument1 pageWelding Filler Metalsamir moniriNo ratings yet