Professional Documents

Culture Documents

Friction Stir Welding-Process Developmentannd Variant

Uploaded by

robertalha0 ratings0% found this document useful (0 votes)

46 views21 pagesFriction Stir Welding Friction Stir Welding Friction Stir Welding

Original Title

Friction Stir Welding-process Developmentannd Variant

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFriction Stir Welding Friction Stir Welding Friction Stir Welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views21 pagesFriction Stir Welding-Process Developmentannd Variant

Uploaded by

robertalhaFriction Stir Welding Friction Stir Welding Friction Stir Welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 21

1

The SME Summit 2005

Oconomowoc, Milwaukee, USA

August 3-4

th

2005

Friction Stir Welding Process Developments and Variant Techniques

By W M Thomas, I M Norris, D G Staines, and E R Watts

wayne.thomas@twi.co.uk

ian.norris@twi.co.uk

Staines@twi.co.uk

Ed.watts@twi.co.uk

TWI Ltd

Granta Park,

Great Abington,

Cambridge,

CB1 6AL

United Kingdom

Abstract

Friction stir welding (FSW) is now extensively used in aluminium industries for

joining and material processing applications. The (FSW) technology has gained

increasing interest and importance since its invention at TWI almost 14 years ago.

The basic principle and the continuing development of the FSW technology are

described and recent applications are reviewed. The paper will introduce some of the

variants of FSW, such as Twin-stir Skew-stir, Re-stir, Dual-rotation stir and

the Pro-stir near-net shape processing technique. Particular attention will also be

paid to tool probe/shoulder features, in relation to the joint geometry being welded.

In addition, this paper makes special reference to the mechanical and structural

integrity that can be expected from FSW technology.

Keywords: Friction Stir Welding and Processing, Fatigue and variant techniques.

Introduction

The basic principle of conventional rotary friction stir welding (FSW) is shown in Fig.1.

2

Fig.1 Basic principle of conventional rotary friction stir welding

The systematic development of Friction stir welding (FSW) has led to a number of variants

of the technology. The following describes preliminary studies being carried out on Twin-

stir, Skew-stir, Re-stir, Dual-rotation stir, and Pro-stir a three-dimensional material

processing technique (1-4).

Currently, FSW is used particularly for joining aluminium alloys in shipbuilding and marine

industries, aerospace, automotive and the rail industry. Furthermore, the technology

provides significant advantage to the aluminium extrusion industry. Automotive suppliers

are already using the technique for wheel rims and suspension arms. Fuel tanks joined by

FSW have already been launched in spacecraft, and many other space advances are under

development; commercial jets welded by FSW have successfully completed flying trials,

with high volume commercial production forthcoming. Aluminium panels for high speed

ferries and panels for rail vehicles are also produced. Moreover, the friction stir welding of

50 mm thick copper material has provided a potential solution for nuclear encapsulation of

radioactive waste. Friction stir welding is making an impact as a material processing

technique and the prognosis for the successful welding of steel products by FSW looks

promising.

Twin-stir technique

The simultaneous use of two or more friction stir welding tools acting on a common

workpiece was first described in 1991 (5). The concept involved a pair of tools applied on

opposite sides of the workpiece slightly displaced in the direction of travel. The contra-

rotating simultaneous double-sided operation with combined weld passes has certain

advantages such as a reduction in reactive torque and a more symmetrical weld and heat

input through the thickness (6). In addition, for certain applications, the use of purpose

designed multi-headed friction stir welding machines can increase productivity, reduce side

force asymmetry and reduce or minimise reactive torque (7).

The use of a preceding friction pre-heating tool followed in line by a friction stir welding

tool for welding steel is reported in the literature 1999 (8). More recently a similar

arrangement has been reported with two rotating tools one used to pre-heat and one used to

weld (9). This disclosure (9), however, shows a tandem technique with the tools rotating in

the same direction. A further reference is made to tandem arrangements with tools rotating

in the same direction (10). The use of tandem contra-rotating tools in-line with the welding

direction and parallel (Side-by-side across the welding direction) is also disclosed (11).

Figure 2 shows the three versions of Twin-stir welding techniques that are being

investigated and developed at TWI.

3

Fig. 2 Twin-stir variants

a) Parallel side-by-side transverse to the welding direction

b) Tandem in-line with the welding direction

c) Staggered to ensure the edges of the weld regions partially overlap.

Parallel twin-stir

The Twin-stir parallel contra-rotating variant (Fig. 2a) enables defects associated with lap

welding to be positioned on the inside between the two welds. For low dynamic volume to

static volume ratio probes using conventional rotary motion, the most significant defect will

be plate thinning on the retreating side. With tool designs and motions designed to

minimise plate thinning, hooks may be the most significant defect type. The Twin-stir

method may allow a reduction in welding time for parallel overlap welding. Owing to the

additional heat available, increased travel speed or lower rotation process parameters will be

possible.

Tandem twin-stir

The Twin-stir tandem contra-rotating variant (Fig. 2b) can be applied to all conventional

FSW joints and will reduce reactive torque. More importantly, the tandem technique will

help improve the weld integrity by disruption and fragmentation of any residual oxide layer

remaining within the first weld region by the following tool. Welds have already been

produced by conventional rotary FSW, whereby a second weld is made over a previous

weld in the reverse direction with no mechanical property loss. The preliminary evidence

suggests that further break-up and dispersal of oxides is achieved within the weld region.

The Twin-stir tandem variant will provide a similar effect during the welding operation.

Furthermore, because the tool orientation means that one tool follows the other, the second

tool travels through already softened material. This means that the second tool need not be

as robust.

a)

b)

c)

4

Staggered twin-stir

The staggered arrangement for Twin-stir (Fig 2c) means that an exceptionally wide

common weld region can be created. Essentially, the tools are positioned with one in front

and slightly to the side of the other so that the second probe partially overlaps the previous

weld region. This arrangement will be especially useful for lap welds, as the wide weld

region produced will provide greater strength than a single pass weld, given that the

geometry details at the extremes of the weld region are similar. Residual oxides within the

overlapping region of the two welds will be further fragmented, broken up and dispersed.

One particularly important advantage of the staggered variant is that the second tool can be

set to overlap the previous weld region and eliminate any plate thinning that may have

occurred in the first weld. This will be achieved by locating the retreating side of both welds

on the inside (see Fig. 3).

For material processing, the increased amount of material processed will also prove

advantageous. In addition, for welding it would enable much wider gaps and poor fit up to

be tolerated.

Fig. 3 Arrangement of Staggered twin-stir contra-rotating tools with respect to rotation

and direction

a) Advancing sides of the common weld region are positioned outwards with left-hand

tool leading.

b) Retreating sides of the common weld region are positioned outwards with left-hand

tool leading

c) Retreating sides of the common weld region are positioned outwards with right-hand

tool leading

d) Advancing sides of the common weld region are positioned outwards with right-hand

tool leading

Welding trials

A Series of preliminary welding trials has been carried out using an experimental Twin-

stir head at TWI in order to investigate the characteristics of welds made in a variety of

a)

b)

c)

d)

5

configurations. The welding trials were carried out with the prototype Twin-stir head as

shown in Fig. 4.

Fig. 4 Twin-stir prototype head assembly

The welding trial demonstrated the feasibility of Twin-stir and showed that welds of good

appearance were produced as shown in Fig. 5.

Fig. 5 Surface appearance of a typical Tandem twin-stir weld made in 6083-T6

aluminium alloy

The two exit holes produced in a tandem weld showed that a similar footprint was achieved

for both the lead and following tool (see Fig. 6).

Fig. 6 Tandem twin-stir lead and follow exit holes

Metallographic observations revealed a marked refinement of grain size in the weld region

and comminution of oxide remnants and particles. This is consistent with the

microstructural features previously observed in conventional rotary stir welds in aluminium

6

alloys. In lap welds, an upturn on both sides of the weld region is also shown (Fig. 7). All

sections were prepared in the direction looking towards the start of the weld.

Advancing side follower tool Retreating side follower tool

Fig. 7 Macrosection of Tandem twin-stir lap weld in 6 mm thick 6082-T6 aluminium

alloy

Metallographic examination of Staggered twin-stir lap welds revealed a common weld

region that measures 430% of the sheet thickness as shown in Fig 8.

Advancing side of follower tool Advancing side of leading tool

Fig. 8 Macrosection taken from the common weld region of a Staggered twin-stir lap

weld in 3mm thick 5083 H111 aluminium sheets.

The tool arrangement used to produce this Staggered twin-stir weld is that illustrated in

Fig. 3a; whereby the advancing sides of the common weld region are positioned outwards.

Consequently, both retreating sides face inwards with the lead weld retreating side receiving

further friction stirring treatment from the retreating side of the follower tool.

7

Skew-Stir

The skew-stir variant of FSW differs from the conventional method in that the axis of the

tool is given a slight inclination (skew) to that of the machine spindle (3), as shown in Fig.

9a, b and c.

The skew-stir technique enables the ratio between the dynamic (swept) volume and the

static volume to be increased by the skew motion of the tool. This can be additional to that

provided by the use of re-entrant features machined into the probe. It is this ratio that is a

significant factor in enabling a reduction or elimination of void formation and improving

process efficiency.

The arrangement shown in Fig.9a, results in the shoulder face being oblique to the axis of

the skew tool and square to the axis of the machine spindle. This shoulder face remains in a

fixed relationship with respect to the plate top surface. Tilting the plate or the machine

spindle will produce a plate to tool tilt that can be varied to suit conditions.

The focal point of a skewed tool affects the amplitude of the orbit of the tool shoulder and

probe. With the focal point at the shoulder position, i.e. at the top of the workpiece, the

shoulder essentially has a rotary motion with no off-axis orbit. When the focal point is

positioned slightly above the top surface of the work piece, or at any position through the

thickness of the workpiece, the shoulder contact face has an off-axis orbital movement. In

addition, the off-axis orbital motion of the shoulder is dependent on the angle of skew and

the distance that the intersection (focal point) is away from the top of the plate. The greater

the skew angle and the greater the distance that the focal point is away from the workpiece

surface, the greater is the amplitude of the shoulder off-axis movement.

The skew action results in only the outer surface of the probe making contact with the

extremities of the weld region. The FSW tool does not rotate on its own axis, and therefore

only a specific part of the face of the probe surface is directly involved in working the

substrate material. Consequently, the inner part of the tool can be cut away to improve the

flow path of material during welding, (see Fig.9a). This probe type is termed A-Skew.

Fig. 9 Details of Prototype A-Skew Probe.

a) Side view

b) Front view, showing tip profile

c) Swept region encompassed by skew action

The skew-stir technique provides an easier material flow path than conventional FSW and

a weld nugget region of width greater than the diameter of the probe. In addition the skew

8

action provides an orbital forging action at the root of the weld, which improves weld

quality in this region.

Work has been undertaken to establish the fatigue performance of welds made using the

skew-stir technique and a fatigue-tested sample is shown in Fig. 10.

Retreating side Advancing side

a) b)

c) d)

Fig. 10 Lap weld made with the retreating side near the top sheet edge (RNE configuration)

using Skew-stir with an A-skew probe (8.25mm in length) in 6mm thick 5083-H111

aluminium alloy at a welding speed of 3mm/sec (180mm/min).

a) Macrosection

b) Detail of fracture, bottom sheet retreating side

c) Detail of fracture top sheet advancing side

d) Detail of the form of the notch at the edge of the weld advancing side

Typically these Skew-stir lap welds gave good fatigue performance when compared with

an artificial weld made from parent material of similar geometry as shown in Fig. 11.

9

Fig. 11 Fatigue results of welds carried out with different lap configurations with a 8.25mm

long probe

Reversal Stir Welding - Re-stir

The following describes preliminary studies being carried out on Re-stir welding at TWI.

The salient features of the Re-stir welding technique are illustrated in Fig.12. This

illustration applies to both angular reciprocating, where reversal is imposed within one

revolution, and rotary reversal, where reversal is imposed after one or more revolutions.

Fig. 12 The basic principle of Re-stir, showing the reversal technique.

The use of the Re-stir welding technique provides a cyclic and essentially symmetrical

welding and processing treatment. Most problems associated with the inherent asymmetry

of conventional rotary FSW are avoided.

Figure 13 shows the detail of the surface of a weld made at 4 mm/sec (240 mm/min) travel

speed, using 10 revolutions per interval. The fine surface ripples reveal the number of

Lap weld configuration (A-Skew

TM

, 584revs, 3mm/sec, 8.25mm probe)

1

10

100

10,000 100,000 1,000,000 10,000,000

Number of cycles

S

t

r

e

s

s

r

a

n

g

e

,

N

/

m

m

2

Artificial lap weld

W231 configuration RNE

W232 configuration RNE

W233 configuration RNE

W234 configuration RNE

W237 configuration ANE

W238 configuration ANE

W239 configuration ANE

Run-out

R=0.5

10

rotations and the extent of the interval, while the less frequent, coarser and wider surface

ripples reveal the position of the change in rotation direction. For Re-stir, the distance and

time between each interval depends on the combination of rotational speed and the travel

speed used.

Fig. 13 Close up of Re-stir weld surface formed beneath the tool shoulder showing

surface rippling and reversal interval. Produced at 4 mm/sec (240 mm/min) welding travel

speed, using 10 revolutions per interval.

Macrosections of a lap weld made by Re-stir are shown in Fig. 14 a, b & c. This weld was

made in 5083-H111 condition aluminium alloy, using a Flared-Triflute type probe

designed for rotary stir, at a travel speed of 3.3 mm/sec (198 mm/min) using 10 revolutions

per interval. The plan view in Fig. 4c reveals a patterned weld region surrounded by a HAZ.

There is some evidence that during the reversal stage some of the Third-body plasticised

material close to the probe is re-stirred back in the opposite direction.

a) b)

Fig. 14 Metallurgical sections showing the effect of the Re-stir technique on the weld

shape, produced at a welding speed of 3.3 mm/sec (198 mm/min), using 10 revolutions per

interval.

a) Longitudinal macrosection showing regular patterns caused by rotation reversal.

b) Plan macrosection taken mid thickness showing the effect of reversal motion.

The Re-stir process requires further optimisation to achieve welds of reproducibly high

quality and freedom from defects but early trials suggest benefits in terms of weld

symmetry. Initial work using an A-skew probe also suggests that it may be possible to

11

achieve a slight down turn in the overlapping plate/weld interface at the outer regions of the

weld which may be beneficial in particular structures and loading situations. Figure 15 a, b

& c, illustrates this effect in an overlap weld in 5083-H111 condition aluminium alloy.

a) b)

c)

Fig. 15 Detail of the outer regions of a Re-stir weld made with an A-skew probe in

combination with a skew motion, at a travel speed of 1.6 mm/sec (96 mm/min), using 8

revolutions per reversal interval.

a) Macrosection

b) Detail of notch (that would formerly have been at the retreating side with conventional

rotary FSW)

c) Detail of notch (that would formerly have been at the advancing side with conventional

rotary FSW)

Typically these Re-stir lap welds gave very good fatigue performance when compared

with an artificial weld made from parent material of similar geometry as shown in Fig. 16.

12

Re-Stir

TM

with skew action (900 rev, 8 revs per reversal interval, 1.7mm/sec, 7mm long

probe)

1.0

10.0

100.0

10,000 100,000 1,000,000 10,000,000

Number of cycles

S

t

r

e

s

s

r

a

n

g

e

(

N

/

m

m

2

)

R69 Re-Stir

R70 Re-Stir

Artificial lap weld

Artificial lap weld mean curve

R=0.5

Fig. 16 Fatigue results of welds carried out with reversal motion Skew-stir

Dual-rotation friction stir welding

A dual-rotation FSW variant is being investigated at TWI, whereby, the probe and shoulder

rotate separately. The dual-rotation FSW variant provides for a differential in speed and/or

direction between the independently rotating probe and the rotating surrounding shoulder as

shown in figure 17.

Fig. 17 Principle of dual-rotation friction stir welding with rotation of the probe and

shoulder in the same direction.

The apparatus used for this investigation is shown sequentially in Figures 18 a & b.

13

a) b)

Fig. 18 Dual-rotation apparatus complete with white marks on the shoulder and probe to

indicate relative rotational movement.

a) White marks on shoulder and probe almost in line.

b) White marks on shoulder and probe moving apart

The apparatus can enable a range of different rotational speeds to be pre-selected or varied

automatically by in-process control to achieve the desired welding conditions.

In conventional rotary FSW, the relative velocity of the tool increases from zero at the probe

centre to maximum velocity at the outer diameter of the shoulder. The dual-rotation

technique can significantly modify the velocity gradient between the probe centre and the

shoulder diameter. This technique provides a differential in rotation speed and the option for

rotation in opposite directions. This dual-rotation technique effectively allows for a high

probe rotational speed without a corresponding increase in shoulder peripheral velocity.

This technique can provide for a more optimised rotational speed for both probe and

shoulder.

Dependent on the material and process conditions used, over-heating or incipient melting

along the 'near shoulder side' of the weld surface of certain friction stir welds can occur.

Melting can lead to fusion related defects along the 'near shoulder side' weld surface. The

dual-rotation technique can be used to reduce the shoulder rotational speed as appropriate

and, therefore, help reduce any tendency towards over-heating or melting, while

maintaining a higher rotational speed for the probe.

A double sided butt weld using non-optimised conditions was made to demonstrate that

dual-rotation stir welding is practicable for certain applications. Figure 19 shows the

macrostructural features produced by dual-rotation stir welding using a Flared-Triflute

type probe.

14

Advancing side Retreating side

Advancing side Retreating side

Fig. 19 Macrosection of a dual-rotation stir double-sided butt weld in 16 mm thick 5083-

H111 aluminium alloy, produced at a welding speed of 3 mm/sec (180mm/min), using 584

rev/min for the probe and 219 rev/min for the shoulder. The two weld passes were made in

opposite directions, with the first pass shown on top.

Guided bend testing demonstrated freedom from gross defects as shown in Fig. 20.

Fig. 20 Guided side bend test, carried out on a double-sided butt weld, in 16 mm thick

5083-H111 aluminium alloy, achieved 180.

Figure 21, shows the appearance of the weld surface that is formed beneath the tool

shoulder after dual-rotation stir welding.

15

Fig. 21 Surface appearance of dual-rotation stir weld made in 16 mm thick 5083-H111

aluminium alloy at a welding speed of 3 mm/sec (180 mm/min), using 584 rev/min for the

probe and 219 rev/min for the shoulder.

Owing to the relatively low temperature reached, with solid-phase welding techniques such

as FSW, the problems of solidification and liquation cracking when fusion welding certain

materials, can be significantly reduced. However, the thermal cycle produced in FSW is

sufficient to modify the original alloy temper in certain heat-treatable materials (e.g. 2xxx

and 7xxx series aluminium alloys) producing a reduction in both the mechanical and

corrosion properties across the weld (12&13).

One advantage of dual-rotation FSW is that it reduces the peak temperature reached during

the weld thermal cycle. Figure 22, shows a comparison of thermal profiles produced by

conventional rotary and dual-rotation friction stir welds made in AA7050-T7451 using

similar probes and process conditions. For a given travel speed, 5.25 mm/sec (315 mm/min),

a difference of approximately 66 C in the maximum temperature of the HAZ region close

to the probe (5 mm from the weld centre line) is shown.

Fig. 22 Thermal profiles of conventional rotary friction stir welds and dual-rotation friction

stir welds made in 6.35 mm AA7050-T7451, using the same probe geometry and a travel

speed of 5.25 mm/secs (315 mm/min). The probe rotation speed was 394 rev/min and 388

rev/min for conventional rotary and dual-rotation stir welding techniques respectively.

0

50

100

150

200

250

300

350

400

450

Time (increments of 50 seconds)

Te

mp

era

tur

e

(D

eg

C)

Conventional FSW

5mm

10mm

20mm

30mm

Dual-rotation FSW

50secs

16

The lower temperatures reached in the dual rotary weld reduce the change in mechanical

properties produced during friction stir welding. After two months natural ageing (figures

23 & 24), the dual-rotation friction stir weld shows higher hardness values in the stirred

zone, TMAZ and HAZ compared to the conventional friction stir weld. This indicates that

the lower temperatures produced by the dual-rotation technique reduced thermal softening

resulting in an increase in weld hardness.

Fig. 23 Hardness traverses as a function of depth through the cross section of a conventional

friction stir weld made in 6.35 mm AA7050-T7451, using a travel speed of 5.25 mm/sec

(315 mm/min) and a probe rotation speed of 394 rev/min

Fig. 24 Hardness traverses as a function of depth through the cross section of a dual-rotary

friction stir weld made in 6.35 mm AA7050-T7451, using the same probe geometry used in

100

110

120

130

140

150

160

170

-20 -15 -10 -5 0 5 10 15 20

Distance from weld centre line (mm)

H

a

r

d

n

e

s

s

(

2

.

5

H

v

)

1mm from top surface

3mm from top surface

5mm from top surface

RETREATING SIDE ADVANCING SIDE

100

110

120

130

140

150

160

170

-20 -15 -10 -5 0 5 10 15 20

Distance from weld centre line (mm)

H

a

r

d

n

e

s

s

(

2

.

5

H

v

)

1mm from top surface

3mm from top surface

5mm from top surface

RETREATING SIDE ADVANCING SIDE

17

the conventional friction stir weld (see fig. 23), a travel speed of 5.25 mm/sec (315

mm/min), and a probe rotation speed of 388 rev/min and a shoulder rotational speed of 145

rev/min.

The heat affected zone (HAZ) of conventional friction stir welds in both 2xxx and 7xxx

series aluminium alloys has been shown to be the region most susceptible to localised

corrosive attack (14). Figure 25, shows a comparison of the extent of corrosion in specimens

from conventional and dual-rotation friction stir welds that were exposed to the same test.

These tests were carried out after two months natural ageing the near shoulder side of the

weld surface was removed and the surface prepared to a micron finish before being

immersed in a 0.1M NaCi aerated solution at ambient temperature for 7 days. Both welds

were made in 6.35mm AA7050-T7451 using the same probe geometry and a travel speed of

9.2mm/secs (522 mm/min).

Advancing side Retreating side

Fig.25 Photomacrograph of the top surface of (a) conventional friction stir weld and (b)

Dual rotation friction stir weld.

The probe rotation speed was 394 rev/min and 388 rev/min for conventional rotary and

Dual-rotation stir welding techniques respectively. A shoulder rotational speed of 145

rev/min was used for dual-rotation.

In the conventional friction stir weld the high temperature HAZ is shiny due to severe

localised attack that has occurred in this region, therefore cathodically protecting the

surrounding areas in the HAZ. In the dual-rotation friction stir weld there is no shiny region

evident in the HAZ suggesting the degree of localised attack occurring in this region to be

lower than in conventional friction stir welding.

Additive FSW technology - Pro-stir

A novel near-net shape prototyping technique is under development at TWI. Rapid

prototyping is the most widespread name given to a host of related additive technologies

that are used to fabricate physical objects directly from sheet, or powder material. These

methods are unique in that they add and bond materials in layers to form objects. Near net

shape additive technologies offer advantages in many applications compared to classical

subtractive fabrication methods such as milling or turning:

HAZ

(a)

Weld TMAZ

HAZ

HAZ

(b)

Weld TMAZ

HAZ

HAZ

18

Near-net shape manufacturing systems reduce the construction of complex objects to

a manageable, clear-cut, and relatively fast process.

Objects can be fashioned that have geometric complexity or sophistication without

the need for elaborate machine set up.

Environmental benefits include reduced machined waste, energy, and waste

disposal.

Many welding techniques have been adapted and developed for rapid prototyping and near-

net shape manufacture. Figure 26, shows the notion of using the Pro-stir method with the

Twin-stir technique to manufacture near-net shape components.

Fig. 26 Principle of Near-net shape manufacture by Pro-stir

Figure 27, shows a small test trial using 6 mm thick 5083 aluminium alloy. The same

principle would apply for much thicker plate material.

Fig. 27 Near-net shape test sample, 6x6 mm thick sheets welded on top of each other

19

The advantages of FSW near net shape, prototype-processing techniques can be summarised

as follows:

High deposition rate is possible when used with comparatively thick plate.

Able to use comparatively thin sheet as well as thick plate.

Low distortion

Three-dimensional processing technique

Strategic regions of the component can be tailored with material to provide different

properties.

The product comprises processed, hot forged material.

It is solid-phase technique not subject to gravity (most rapid prototyping systems are

gravity restricted) This means that it is potentially possible to grow additional parts

in situ on large, complex structures if required

Discussion and Concluding Remarks

The basic principles and the continuing development of the FSW technology such as Twin-

stir, Skew-stir, Re-stir, Dual-rotation stir and the Pro-stir near-net shape processing

techniques, have been described in the paper and the following concluding remarks are

made:

It is to be expected that the tandem and staggered Twin-stir variants will further fragment

and disperse tenacious residual oxides within the weld region or part of the weld region

respectively. This will lead to improved weld integrity and performance. Moreover, the

staggered Twin-stir method is likely to provide advantage and in some instances be

preferred for safety critical applications for both butt and lap joints.

All contra-rotating systems help to reduce the reactive torque necessary to secure plates to

the machine during welding. The use of twin-stir techniques is expected to prove

advantageous for material processing, lap welding, spot welding and it would enable much

wider gaps on butt welds to be tolerated.

Rotary motion Skew-stir lap welds and reversal motion Skew-stir lap welds provided

good fatigue performance when compared with artificial lap welds made from parent

material.

The initial investigation of dual rotation stir welding has demonstrated the feasibility of the

technique for butt welding 5083-H111 and 7050-T7451 aluminium alloys. The dual-

rotation technique is capable of minimising any tendency towards over-heating or incipient

melting associated with the 'shoulder near side' weld surface. The results confirm that the

dual-rotation technique can significantly modify the velocity gradient between the probe

centre and the shoulder diameter. These trials confirm that use of slower shoulder rotational

speed lowers the HAZ temperature during the welding operation. This effectively reduces

thermal softening in the HAZ region. The results shows that dual-rotation technique reduces

the susceptibility to corrosion in 7xxx series aluminium alloys HAZs. Work will continue at

TWI to investigate the use of dual-rotation on spot, butt, and lap welds.

Preliminary trials using a FSW method of near-net shape manufacture and three-

dimensional material processing show promise, but much more work will be required to

develop and perfect the technique.

20

Development work will continue at TWI to ensure these techniques can be used

commercially.

Acknowledgements

The Authors wish to thank C S Wiesner, P J Oakley, P Evans, M J Russell, A Duncan, D

Saul and N L Horrex for their support and contributions.

References

1. Thomas W M, Wiesner C S, Staines D G & Watts E R: Friction stir welding Process

developments for aluminium applications. International Conference & Exhibition,

Aluminium in Transport, Moscow, Russia, April 24-29, 2005.

2. Catin G M D, David S A, Thomas W M, Lara-Curzio E, and Babu S S: Friction Skew-

stir welding of lap joints in 5083-0 aluminium Science and Technology of Welding and

Joining, Vol. 10, No. 1, 2005

3. Thomas W M, Braithwaite A B M and R John: Skew-Stir technology. TWI 3

rd

International Symposium on Friction Stir Welding, Kobe, Japan, 27-28 September 2001.

4. Thomas W M, Norris I M, Smith I J, and Staines D G: Reversal sir welding Re-Stir

- Feasibility Study. Fourth International Symposium on Friction Stir Welding, Park

City, Utah, USA, 14-16 may 2003.

5. Thomas W M, Nicholas E D, Needham J C, Murch M G, Temple-Smith P and Dawes C

J: 'Improvements relating to friction welding'. European Patent Specification 0 615 480

B1.

6. Thomas W M, Friction Stir Welding and Related Friction process Characteristics,

Inalco 98 7

th

International Conference, joints in Aluminium, Cambridge, UK. April

1998.

7. Thomas W M, Nicholas E D, Watts E R, and Staines D G: Friction Based Welding

Technology for Aluminium, The 8

th

International Conference on Aluminium Alloys 2

nd

to 5

th

July 2002, Cambridge, UK

8. Thomas W M, Friction Stir welding of Ferrous materials; A Feasibility Study, 1st

Symposium on Friction stir Welding, 14-16 June 1999, Rockwell Science Center,

Thousand Oaks, California, USA.

9. H Mitsuo; Friction agitation joining method and Frictional Agitation joining device

Patent Abstracts of Japan, Publication number 2000-094156, Date of publication of

application 04.04.2000.

10. K Atsuo, O Yoshinori, and Y Mutsumi: Friction Stir welding Method Patents

Abstracts of Japan, Publication number 2003-112272, Date of publication of application

15.04.2003.

11. K Atsuo, O Yoshinori, and Y Mutsumi: Friction stir welding method Patents abstracts

of Japan, Publication number 2003-112271, Date of publication of application

15.04.2003.

12. Mahoney M W, Rhodes C G, Flintoff J G, Spurling R A and Bingel W H: Properties of

friction stir welded 7075-T651 aluminium. Metallurgical and Materials Transactions,

Vol. 29A, pp1955-1964, 1998.

13. Biallas G, Braun R, Dalle Donne C, Staniek G and Kaysser W A: Mechanical

properties and corrosion behaviour of friction stir welded 2024-T3. 1

st

International

Friction Stir Welding Symposium, Thousand Oaks, California, USA, 1999.

21

14. Hannour F, Davenport A J and Strangwood M: Corrosion of friction stir welds in high

strength aluminium alloys. 2

nd

International Symposium on Friction Stir Welding,

Gothenberg, Sweden, 2000.

You might also like

- The Simultaneous Use of Two or More Friction Stir Welding ToolsDocument6 pagesThe Simultaneous Use of Two or More Friction Stir Welding ToolsrobertalhaNo ratings yet

- 1082 DDocument21 pages1082 DbilsaitNo ratings yet

- Friction Based Welding Technology For Aluminium (July 2002) - TWI (BACKING NEEDED)Document11 pagesFriction Based Welding Technology For Aluminium (July 2002) - TWI (BACKING NEEDED)Amar DJEDIDNo ratings yet

- Li, Shen - 2012 - A Feasibility Research On Friction Stir Welding of A New-Typed Lap-Butt Joint of Dissimilar Al AlloysDocument7 pagesLi, Shen - 2012 - A Feasibility Research On Friction Stir Welding of A New-Typed Lap-Butt Joint of Dissimilar Al AlloysJose Anand ANo ratings yet

- Study of Tool Geometry On Friction Stir Welding of Aa 6061 and Az61Document7 pagesStudy of Tool Geometry On Friction Stir Welding of Aa 6061 and Az61Osama MohammedNo ratings yet

- The Effect of Rotational Speed On Flow BDocument8 pagesThe Effect of Rotational Speed On Flow Bالسيد ابراهيم عبدالعزيز عبداللهNo ratings yet

- Hemming Aluminum em FormingDocument9 pagesHemming Aluminum em FormingAaron AzmiNo ratings yet

- Experimental Analysis of Friction Stir Welding of Dissimilar Alloys Aa7075 and MG Ze42 Using Butt Joint GeometryDocument8 pagesExperimental Analysis of Friction Stir Welding of Dissimilar Alloys Aa7075 and MG Ze42 Using Butt Joint GeometryTJPRC PublicationsNo ratings yet

- Research Paper FSWDocument10 pagesResearch Paper FSWsahith palikaNo ratings yet

- 2019 June IJRARDocument8 pages2019 June IJRARtarasasankaNo ratings yet

- Eurocode 9 To Estimate The Fatigue Life of Friction Stir Welded Aluminium Panels PDFDocument7 pagesEurocode 9 To Estimate The Fatigue Life of Friction Stir Welded Aluminium Panels PDFdjordjeueNo ratings yet

- Microstructures and Failure Mechanisms of Friction Stir Spot Welds of Aluminum 6061-T6 SheetsDocument24 pagesMicrostructures and Failure Mechanisms of Friction Stir Spot Welds of Aluminum 6061-T6 SheetsAnand Kumar MandalNo ratings yet

- An Experimental Study On The Examination of Springback of Sheet Metals With Several Thicknesses and Properties in Bending DiesDocument9 pagesAn Experimental Study On The Examination of Springback of Sheet Metals With Several Thicknesses and Properties in Bending Dieskhudhayer1970No ratings yet

- 1.1.1. Joining Parameters: Figure 1.3 Classification of ParametersDocument4 pages1.1.1. Joining Parameters: Figure 1.3 Classification of ParametersdeepanshuNo ratings yet

- Study of The Potentiality To Manufacture Forming Tools Via Waam (Wire + Arc Additive Manufacturing)Document10 pagesStudy of The Potentiality To Manufacture Forming Tools Via Waam (Wire + Arc Additive Manufacturing)jefferson segundoNo ratings yet

- Evaluation of Carbide Grades and A New Cu!Pi'Ing Geometry For Machining Titanium AlloysDocument11 pagesEvaluation of Carbide Grades and A New Cu!Pi'Ing Geometry For Machining Titanium AlloysBharat HPNo ratings yet

- 2004 Int Ansys Conf 201Document9 pages2004 Int Ansys Conf 201Vigneshwar ManokaranNo ratings yet

- Joining of Aa1050 Sheets Via Two Stages of Friction Spot TechniqueDocument13 pagesJoining of Aa1050 Sheets Via Two Stages of Friction Spot Techniquemunaf.h.ridhaNo ratings yet

- Effect of SiC on Friction WeldingDocument9 pagesEffect of SiC on Friction WeldingGaddipati MohankrishnaNo ratings yet

- Friction Stir Welding (FSW) Final ReportDocument28 pagesFriction Stir Welding (FSW) Final ReportRahul Tripathi88% (33)

- Effects of FSW Parameters On Joint Properties of Almg3 AlloyDocument7 pagesEffects of FSW Parameters On Joint Properties of Almg3 AlloyWaldo AtNo ratings yet

- VideoDocument27 pagesVideoAsk ArtNo ratings yet

- Mechanical and Microstructural Behaviour of 2024-7075 Aluminium Alloy Sheets Joined by Friction Stir Welding PDFDocument7 pagesMechanical and Microstructural Behaviour of 2024-7075 Aluminium Alloy Sheets Joined by Friction Stir Welding PDFSabry S. YoussefNo ratings yet

- Friction Processing TechnologiesDocument11 pagesFriction Processing TechnologiesjunevessteinNo ratings yet

- A Novel Forming Technology For Tailor-Welded BlanksDocument9 pagesA Novel Forming Technology For Tailor-Welded BlanksGabipmNo ratings yet

- Seminar ReportDocument15 pagesSeminar Reportchitran duttaNo ratings yet

- 10 11648 J Ajmie 20230801 12Document11 pages10 11648 J Ajmie 20230801 12Elina EsfandiariNo ratings yet

- Friction Stir Welding: A Solid State Joining ProcessDocument23 pagesFriction Stir Welding: A Solid State Joining ProcessMahaManthraNo ratings yet

- Rotational Tool Without PinDocument6 pagesRotational Tool Without PinBilal GhazanfarNo ratings yet

- HWDP HardfacingDocument6 pagesHWDP HardfacingHatem RagabNo ratings yet

- Design and Experimental Analysis of Composite GratingDocument6 pagesDesign and Experimental Analysis of Composite GratingIJSTENo ratings yet

- Roll Pass Design For Ribbed BarsDocument8 pagesRoll Pass Design For Ribbed BarsDiaa KassemNo ratings yet

- Friction Stir Welding Thesis PDFDocument8 pagesFriction Stir Welding Thesis PDFcarolinalewiswashington100% (2)

- Elimination of Bowing Distortion in Welded StiffenersDocument8 pagesElimination of Bowing Distortion in Welded StiffenersHaris HartantoNo ratings yet

- Rapid Prototyping Using 3-D WeldingDocument11 pagesRapid Prototyping Using 3-D WeldingSundar SivamNo ratings yet

- AISC - Experience With Use of Heavy W Shapes in TensionDocument15 pagesAISC - Experience With Use of Heavy W Shapes in TensionChris ScheinerNo ratings yet

- FSW Welding PresentationDocument56 pagesFSW Welding PresentationMazharNo ratings yet

- Mechanical Metallurgical Characteristics and CorroDocument8 pagesMechanical Metallurgical Characteristics and CorroNikhil KanojiNo ratings yet

- Thesis Pp1 40Document40 pagesThesis Pp1 4016562306No ratings yet

- MATS214 Jan 2020 Exam Paper (Moderator Version With Indicative Answers)Document9 pagesMATS214 Jan 2020 Exam Paper (Moderator Version With Indicative Answers)Quỳnh Quốc Thắng VõNo ratings yet

- WeldingDocument27 pagesWeldingCleo Elveña100% (1)

- Failure Analysis of Coal Pulverizer Mill PDFDocument12 pagesFailure Analysis of Coal Pulverizer Mill PDFHendraNo ratings yet

- Effect of Tool Pin Profile On Microstructure and Tensile Properties of Friction Stir Welded Dissimilar AA 6061 eAA 5086 Aluminium Alloy JointsDocument11 pagesEffect of Tool Pin Profile On Microstructure and Tensile Properties of Friction Stir Welded Dissimilar AA 6061 eAA 5086 Aluminium Alloy JointsRaul VelascoNo ratings yet

- AC4CDocument6 pagesAC4CTay Chu YenNo ratings yet

- Mechanical and Microstructural Characterization of Friction Stir Welded Al-Si-Mg AlloyDocument6 pagesMechanical and Microstructural Characterization of Friction Stir Welded Al-Si-Mg AlloySayyid RidhoNo ratings yet

- Friction Stir Welding of Three Dissimilar AluminiuDocument9 pagesFriction Stir Welding of Three Dissimilar AluminiuHüsam NaylonNo ratings yet

- Friction Welding of Combat Vehicles at TWI: by Stephan Kallee and Dave NicholasDocument10 pagesFriction Welding of Combat Vehicles at TWI: by Stephan Kallee and Dave NicholasB Vijaya KumarNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Analysis of Cracks Generated in The Spin 2014 Case Studies in Engineering FaDocument9 pagesAnalysis of Cracks Generated in The Spin 2014 Case Studies in Engineering FaMeccbellNo ratings yet

- Taguchi Optimization of Process Parameters in Friction Stir Welding of 6061 Aluminum Alloy: A Review and Case StudyDocument12 pagesTaguchi Optimization of Process Parameters in Friction Stir Welding of 6061 Aluminum Alloy: A Review and Case StudyVijay GadakhNo ratings yet

- Failure Analysis of A Helical GearDocument7 pagesFailure Analysis of A Helical Geartheerapat patkaewNo ratings yet

- Friction Stir WeldingDocument12 pagesFriction Stir WeldingelmardaNo ratings yet

- FEM_Modelling_of_Weld_Damage_in_Continuous_Cold_RoDocument11 pagesFEM_Modelling_of_Weld_Damage_in_Continuous_Cold_RoAimen AouniNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- HardeningDocument6 pagesHardeningRichardo AdhitamaNo ratings yet

- Failure Analysis of A Bridge Crane Shaft-Version Online FinalDocument8 pagesFailure Analysis of A Bridge Crane Shaft-Version Online FinaloazzambranoNo ratings yet

- Q.1 Which Welding Technique You Would Adopt To Weld The Vertical Seams of TwoDocument38 pagesQ.1 Which Welding Technique You Would Adopt To Weld The Vertical Seams of Twoquiron2010No ratings yet

- Functions, Designs and Materials of Friction Stir Welding Tools - TWIDocument14 pagesFunctions, Designs and Materials of Friction Stir Welding Tools - TWIPhong TrầnNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Friction Stir WeldingDocument43 pagesFriction Stir WeldingrobertalhaNo ratings yet

- Friction Stir Welding ThesisDocument63 pagesFriction Stir Welding Thesisrobertalha80% (5)

- Friction Stir Welding-Process Developmentannd VariantDocument21 pagesFriction Stir Welding-Process Developmentannd VariantrobertalhaNo ratings yet

- Friction Stir WeldingDocument43 pagesFriction Stir WeldingrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool FlywheelDocument1 pageFriction Stir Welding Twin Tool FlywheelrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool SideaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool SideaxlerobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ViewsDocument1 pageFriction Stir Welding Twin Tool Twin Tool ViewsrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ToolDocument1 pageFriction Stir Welding Twin Tool Twin Tool ToolrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool ColletDocument1 pageFriction Stir Welding Twin Tool ColletrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool MainaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool MainaxlerobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ViewsDocument1 pageFriction Stir Welding Twin Tool Twin Tool ViewsrobertalhaNo ratings yet

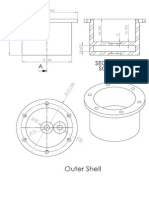

- Friction Stir Welding Twin Tool Twin Tool Outer ShellDocument1 pageFriction Stir Welding Twin Tool Twin Tool Outer ShellrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool GearDocument1 pageFriction Stir Welding Twin Tool GearrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool 1020ball BearingDocument1 pageFriction Stir Welding Twin Tool 1020ball BearingrobertalhaNo ratings yet

- Friction Stir Welding Shridhar Rev-1Document26 pagesFriction Stir Welding Shridhar Rev-1robertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool MainaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool MainaxlerobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ToolDocument1 pageFriction Stir Welding Twin Tool Twin Tool ToolrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool Outer ShellDocument1 pageFriction Stir Welding Twin Tool Twin Tool Outer ShellrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool GearDocument1 pageFriction Stir Welding Twin Tool GearrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool SideaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool SideaxlerobertalhaNo ratings yet

- Friction Stir Welding Twin Tool FlywheelDocument1 pageFriction Stir Welding Twin Tool FlywheelrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool ColletDocument1 pageFriction Stir Welding Twin Tool ColletrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool 1020ball BearingDocument1 pageFriction Stir Welding Twin Tool 1020ball BearingrobertalhaNo ratings yet

- Friction Stir Welding Shridhar Rev-1Document26 pagesFriction Stir Welding Shridhar Rev-1robertalhaNo ratings yet

- Friction Stir Welding RS REPORT-1 (17th April 13)Document52 pagesFriction Stir Welding RS REPORT-1 (17th April 13)robertalha100% (1)

- Friction Stir Welding ThesisDocument63 pagesFriction Stir Welding Thesisrobertalha80% (5)

- Friction Stir Welding Report Ent111Document45 pagesFriction Stir Welding Report Ent111robertalhaNo ratings yet