Professional Documents

Culture Documents

Pulsation Dampener Removes Pulsations for Smooth Flow

Uploaded by

Cristian Jhair Perez0 ratings0% found this document useful (0 votes)

73 views2 pagesPulsafeeder's pulsation Dampeners improve pump system efficiency by removing pulsating flows from positive displacement pumps. Compressed air or gas is introduced into the air chamber to a specified pressure. During pump discharge, fluid enters the wetted chamber of the pulsation dampener, displacing the bladder, compressing the gas and absorbing the shock.

Original Description:

Original Title

Pulsation Dampener Tech Sheet

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPulsafeeder's pulsation Dampeners improve pump system efficiency by removing pulsating flows from positive displacement pumps. Compressed air or gas is introduced into the air chamber to a specified pressure. During pump discharge, fluid enters the wetted chamber of the pulsation dampener, displacing the bladder, compressing the gas and absorbing the shock.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

73 views2 pagesPulsation Dampener Removes Pulsations for Smooth Flow

Uploaded by

Cristian Jhair PerezPulsafeeder's pulsation Dampeners improve pump system efficiency by removing pulsating flows from positive displacement pumps. Compressed air or gas is introduced into the air chamber to a specified pressure. During pump discharge, fluid enters the wetted chamber of the pulsation dampener, displacing the bladder, compressing the gas and absorbing the shock.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Pulsation Dampener

Pulsafeeders Pulsation Dampeners improve pump

system efficiency by removing pulsating flows from

positive displacement pumps. Insuring a smooth and

continuous fluid flow and metering accuracy,

eliminating pipe vibration and protecting gaskets and

seals. The result is a longer lasting safer system.

Compressed air or gas is introduced into the air

chamber of the Pulsation Dampener to a specified

pressure. The gas is entrapped by the elastomeric

bladder, which prevents contact between the

process fluid and compressed gas. During pump

discharge, fluid enters the wetted chamber of the

Pulsafeeder Pulsation Dampener, displacing the

bladder, compressing the gas and absorbing the

shock. During pump shift, liquid pressure decreases,

the dampener gas expands, pushing fluid back into

the process line.

Whether a piston, plunger, air diaphragm, peristaltic,

gear, or diaphragm metering pump, a Pulsafeeder

Pulsation Dampener placed at the pumps discharge

will produce a steady fluid flow up to 99% pulsation

free; protecting the entire pumping system from the

damaging effects of shock.

Features

Quick Installation

In-line Maintenance

Bodies in a full range of Chemical Resistant

materials

Bladders for even the most corrosive

applications

Operating Benefits

Produces near steady fluid flow

99% pulsation and vibration free

Protects pumping system from pulsation, water

hammer, vibrations, and more

Aftermarket

Double Wall Containment Tanks from 15

to 500 gallons.

1, 2, or 4 Drum Spill Containment Pallets.

Loading Ramp and Pallet with or without

Cover.

Pulsation Dampener

Series CW

Custom Engineered Designs

Pre-Engineered Systems

Pre-Engineered Systems

Pulsafeeders Pre-Engineered Systems

are designed to provide complete

chemical feed solutions for all electronic

metering applications. From stand alone

simplex pH control applications to full-

featured, redundant sodium hypochlorite

disinfection metering, these rugged

fabricated assemblies offer turn-key

simplicity and industrial-grade durability.

The UV-stabilized, high-grade HDPE

frame offers maximum chemical

compatibility and structural rigidity. Each

system is factory assembled and

hydrostatically tested prior to shipment.

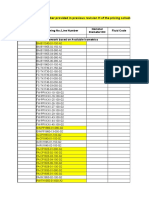

Specifications and Model Selection

Engineering Data

Body Materials:

Polypropylene

PVC

PVC

PVDF

Pressure Rating at Ambient Temp: Up to 150 PSI (10 BAR)

Temperature Range: -20F to +250F

(-29C to + 121C)

Body Materials:

316 SS

Pressure Rating at Ambient Temp: Up to 4000 PSI (276 BAR)

Temperature Range: -60F to + 400 F

(-51C to +204C)

Bladder Compound: Temperature Limits:

EPDM -60F to +280F (-51C to +137C)

CSPE -20F to +275F (-29C to +135C)

Viton -10F to +350F (-23C to +176C)

PTFE +40F to +220F (+4C to +104C)

Applications:

EPDM -Use in extreme cold; good chemical resistance with ketones, caustics

CSPE -Excellent abrasion resistance; good in aggressive acid applications.

Viton - Use in hot & aggressive fluids; good with aromatics, solvents, acids

and oils.

PTFE - Bellows design; excellent flex life; use with highly aggressive fluids.

Viton is a registered trademark of E.I. DuPont Company.

DMP001 B12

You might also like

- Pump Sealing Systems Scott 060712 PDFDocument50 pagesPump Sealing Systems Scott 060712 PDFmishraenggNo ratings yet

- FM Data Sheet CompressorsDocument14 pagesFM Data Sheet Compressorsralph1949No ratings yet

- LJ Pulsation Dampener PDS en BWDocument2 pagesLJ Pulsation Dampener PDS en BWmasimaha1379No ratings yet

- Classes and Comparisons Between CompressorsDocument48 pagesClasses and Comparisons Between CompressorsVijay MeenaNo ratings yet

- Dry Gas Seal System ManualDocument44 pagesDry Gas Seal System ManualGeorge J AlukkalNo ratings yet

- CWA Piping Design, Layout & AnalysisDocument2 pagesCWA Piping Design, Layout & AnalysisIan LiuNo ratings yet

- Best Practices in Compressor MountingDocument9 pagesBest Practices in Compressor MountingDaniel Puello RodeloNo ratings yet

- Mitsubishi Centrifugal Compressor: MCO Web SiteDocument3 pagesMitsubishi Centrifugal Compressor: MCO Web SitePoliana PolyNo ratings yet

- ValvTechnologies 01 - Zero Leakage Valve Solution PDFDocument20 pagesValvTechnologies 01 - Zero Leakage Valve Solution PDFNanangdp48No ratings yet

- Types of Refrigeration Compressors: OCT. 2006 D.RavindraDocument31 pagesTypes of Refrigeration Compressors: OCT. 2006 D.RavindraDnyanesh BodreNo ratings yet

- Kranji MYSEP Jan2011 WebDocument9 pagesKranji MYSEP Jan2011 Webdhl_tuNo ratings yet

- Process Recip PDFDocument8 pagesProcess Recip PDFGanesh KumarNo ratings yet

- High Speed Direct Drive Motor CompressorsDocument9 pagesHigh Speed Direct Drive Motor CompressorsGeorge V ThomasNo ratings yet

- Compressor Anti-Surge ValveDocument2 pagesCompressor Anti-Surge ValveMoralba SeijasNo ratings yet

- FRP PresentationDocument21 pagesFRP PresentationKhairul AnwarNo ratings yet

- DuctIsolationSystems DiverterDampersDocument12 pagesDuctIsolationSystems DiverterDampersefte_14100% (1)

- MySep White Paper - Troubleshooting Liquid Carryover in Gas CompressionDocument11 pagesMySep White Paper - Troubleshooting Liquid Carryover in Gas Compressionbederinadml100% (1)

- 8510-1447 Zero-Maintenance Pulsation DampenersDocument2 pages8510-1447 Zero-Maintenance Pulsation DampenersdharmeswarNo ratings yet

- Parker Industrial Hose Catalog 4800Document258 pagesParker Industrial Hose Catalog 4800MROstop.comNo ratings yet

- Fuji Ring BlowerDocument55 pagesFuji Ring BlowerCarlos Davalos100% (1)

- Prinsip Dasar M-RSDocument45 pagesPrinsip Dasar M-RSIkhsan ArifNo ratings yet

- Plastic Vessel Pressure DesignDocument12 pagesPlastic Vessel Pressure Designr1p2100% (1)

- IntroDocument52 pagesIntrosaranyabhuvanaNo ratings yet

- High-Tech Block & Bleed ValvesDocument20 pagesHigh-Tech Block & Bleed ValvesMayur PatelNo ratings yet

- Ar166 208 260Document82 pagesAr166 208 260michaelxiaoNo ratings yet

- Field Instrument List V1 R1Document12 pagesField Instrument List V1 R1sudhansu8beheraNo ratings yet

- Efficient slug catcher separates two-phase flow under 40 charsDocument3 pagesEfficient slug catcher separates two-phase flow under 40 charswkhan_55No ratings yet

- GEA Grasso Company ProfileDocument28 pagesGEA Grasso Company ProfileLuis Fernando Lopez PalaciosNo ratings yet

- Winston Engineering CompanyDocument10 pagesWinston Engineering Companylimcsiang99No ratings yet

- Report Vortex TubeDocument68 pagesReport Vortex TubePravinSharmaNo ratings yet

- Product Reference Guide - Oil and GasDocument9 pagesProduct Reference Guide - Oil and GasDavid RodriguesNo ratings yet

- A Brief Overview of Centrifugal Compressor System Process DesignDocument6 pagesA Brief Overview of Centrifugal Compressor System Process DesignkrvishwaNo ratings yet

- Reciprocating Compressor FeaturesDocument3 pagesReciprocating Compressor Featuresjk_iitkNo ratings yet

- Noruegan StandardDocument152 pagesNoruegan StandarderikohNo ratings yet

- Rolon Seals Catalogue NewDocument12 pagesRolon Seals Catalogue NewSri Lalitha ParabhattarikaNo ratings yet

- Article Surge Control Analysis For Centrifugal CompressorsDocument3 pagesArticle Surge Control Analysis For Centrifugal CompressorsHatem Ali100% (1)

- Top Performance under Pressure: SEMPERIT Hydraulic and Pressure Washer HosesDocument24 pagesTop Performance under Pressure: SEMPERIT Hydraulic and Pressure Washer Hosesado_22No ratings yet

- For Non-Account Holder BeneficiaryDocument2 pagesFor Non-Account Holder BeneficiarySP CONTRACTORNo ratings yet

- Centrifugal Compressor HorsepowerDocument9 pagesCentrifugal Compressor HorsepowerCurtis DookieNo ratings yet

- Blowers and Vacuum BoostersDocument6 pagesBlowers and Vacuum BoostersMara RusyadiNo ratings yet

- 2080 BOG CompressorDocument2 pages2080 BOG CompressordimythreeNo ratings yet

- Asme PTC 10 (1997)Document191 pagesAsme PTC 10 (1997)Luigi RondonNo ratings yet

- 081201X V3533 PDFDocument59 pages081201X V3533 PDFClemente Rafael Marval Escalona50% (2)

- LPG Leakage & DetectionDocument3 pagesLPG Leakage & DetectionSravan GopuNo ratings yet

- Therminol 55Document2 pagesTherminol 55Christian Joel CarriónNo ratings yet

- Control Valve Common Interview QuestionsDocument10 pagesControl Valve Common Interview QuestionsMustafa MehdiNo ratings yet

- Shutdown ValvesDocument2 pagesShutdown Valvesnazury2kNo ratings yet

- GESTRA Condensate ManualDocument172 pagesGESTRA Condensate ManualChirag ShahNo ratings yet

- CSWIPDocument9 pagesCSWIPAbdul KhaliqNo ratings yet

- Centrifugal Compressor Inspection GuideDocument7 pagesCentrifugal Compressor Inspection GuideEnergy 2GreenNo ratings yet

- Dyneon PTFE All GradesDocument3 pagesDyneon PTFE All GradesRajanSharmaNo ratings yet

- Planning Information: Börger Rotary Lobe Pumps Börger Chopping TechnologyDocument137 pagesPlanning Information: Börger Rotary Lobe Pumps Börger Chopping TechnologyMilena Lemus FonsecaNo ratings yet

- Real Gas vs. Ideal Gas - Tan Chun WeiDocument5 pagesReal Gas vs. Ideal Gas - Tan Chun WeiConradodaMattaNo ratings yet

- Pulsation Dampener - Tech - SheetDocument2 pagesPulsation Dampener - Tech - SheetJuan Dela CruzNo ratings yet

- Chemical Resistance GuideDocument36 pagesChemical Resistance GuideHeiner PalaciosNo ratings yet

- Technical Specifications With SaddlesDocument6 pagesTechnical Specifications With Saddlesmihaidanpan791No ratings yet

- TPR22 Pressure and Temperature Relief Valve 7.0bar 3-4inch MBSP X 22mmDocument1 pageTPR22 Pressure and Temperature Relief Valve 7.0bar 3-4inch MBSP X 22mmAdvancedWaterCoNo ratings yet

- BGD 886-S Cyclic Corrosion Test CCT CabinetsDocument5 pagesBGD 886-S Cyclic Corrosion Test CCT CabinetsAbhinandan AdmutheNo ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Biscuits fortified with haem iron may improve intellectual performance in preschool childrenDocument6 pagesBiscuits fortified with haem iron may improve intellectual performance in preschool childrenCristian Jhair PerezNo ratings yet

- CookbookDocument16 pagesCookbookPrince Israel EboigbeNo ratings yet

- Notepad++ - Tutorial Compile and Run Java ProgramDocument13 pagesNotepad++ - Tutorial Compile and Run Java ProgramJorge Junior.0% (1)

- ADGPIPDocument2 pagesADGPIPTarek MustafaNo ratings yet

- Ars 08111Document10 pagesArs 08111Sergio SmithNo ratings yet

- 3Dx Brochure Range ENUS Letter v1 1 HiresscreenDocument3 pages3Dx Brochure Range ENUS Letter v1 1 HiresscreenCristian Jhair PerezNo ratings yet

- Process Industry Practices Electrical: Pip Elsap01D Data Sheet For Battery Chargers For Station BatteriesDocument3 pagesProcess Industry Practices Electrical: Pip Elsap01D Data Sheet For Battery Chargers For Station BatteriesCristian Jhair PerezNo ratings yet

- ADG008Document29 pagesADG008halder_kalyan9216No ratings yet

- Process Industry Practices Electrical: Pip Elimt000 Motor Installation DetailsDocument6 pagesProcess Industry Practices Electrical: Pip Elimt000 Motor Installation DetailsMunir BaigNo ratings yet

- Process Industry Practices Electrical: Pip Elimt000 Motor Installation DetailsDocument6 pagesProcess Industry Practices Electrical: Pip Elimt000 Motor Installation DetailsMunir BaigNo ratings yet

- ADG002Document8 pagesADG002prufino2No ratings yet

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDocument7 pagesProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezNo ratings yet

- Product CatalogDocument9 pagesProduct Catalogjkhgvdj mnhsnjkhgNo ratings yet

- Asme B31e (2008) PDFDocument18 pagesAsme B31e (2008) PDFCristian Jhair Perez100% (3)

- Ctce1013 EedsDocument2 pagesCtce1013 EedsCristian Jhair PerezNo ratings yet

- Ebooks Chemical Engineering PDFDocument1 pageEbooks Chemical Engineering PDFCristian Jhair PerezNo ratings yet

- Ars 08710Document14 pagesArs 08710zblakNo ratings yet

- Segment 1 - CSWP-CORE ExamDocument9 pagesSegment 1 - CSWP-CORE ExammengodNo ratings yet

- W 1 AsDocument3 pagesW 1 AsCristian Jhair PerezNo ratings yet

- Intense Heat. Extreme Cold. Aggressive Chemicals. InnovativeDocument2 pagesIntense Heat. Extreme Cold. Aggressive Chemicals. InnovativeCristian Jhair PerezNo ratings yet

- Glass Manufacture BrochureDocument4 pagesGlass Manufacture BrochureCristian Jhair PerezNo ratings yet

- Earphone Headphone Brochure EnglishDocument24 pagesEarphone Headphone Brochure EnglishCristian Jhair PerezNo ratings yet

- Glass Manufacture BrochureDocument4 pagesGlass Manufacture BrochureCristian Jhair PerezNo ratings yet

- Rectangular Tank SizingDocument8 pagesRectangular Tank Sizingvofaith100% (16)

- W 1 AsDocument3 pagesW 1 AsCristian Jhair PerezNo ratings yet

- Recording Media Batteries 2009 BrochureDocument13 pagesRecording Media Batteries 2009 BrochureCristian Jhair PerezNo ratings yet

- Diseño Por Presion ExternaDocument29 pagesDiseño Por Presion ExternaAndres PozoNo ratings yet

- Solidworks: Part ModelingDocument10 pagesSolidworks: Part ModelingBhavesh PanchalNo ratings yet

- Lodgy Brochure PDFDocument17 pagesLodgy Brochure PDFcanraoNo ratings yet

- EDU Detailed DWG Exercises 2010 ENGDocument51 pagesEDU Detailed DWG Exercises 2010 ENGHG GabyNo ratings yet

- Atmos c451Document8 pagesAtmos c451Ștefan BulgaruNo ratings yet

- Pesco Catalog 1960'sDocument34 pagesPesco Catalog 1960'sgrcatu100% (1)

- Rod Pump - Failure.analysisDocument109 pagesRod Pump - Failure.analysisvibhutiNo ratings yet

- URS For Water For Injection Storage and Distribution SystemDocument19 pagesURS For Water For Injection Storage and Distribution Systemyogendra100% (2)

- AEClass4 20140821Document31 pagesAEClass4 20140821Sergio Sebastian Ramirez GamiñoNo ratings yet

- Hydraulic System ComponentsDocument58 pagesHydraulic System ComponentsMaz Ariez EkaNo ratings yet

- OEM ManualDocument784 pagesOEM ManualJ BrockNo ratings yet

- NRDC Report: Synergies in Swimming Pool EfficiencyDocument34 pagesNRDC Report: Synergies in Swimming Pool EfficiencyGreenSafePool100% (3)

- CO2 Flooding System ExplainedDocument15 pagesCO2 Flooding System ExplainedSuresh JangidNo ratings yet

- QSB6.7 General Data SheetDocument3 pagesQSB6.7 General Data SheetBac NguyenNo ratings yet

- HVAC - BOQ, Cost Estimate & ProcurementDocument6 pagesHVAC - BOQ, Cost Estimate & Procurementsunkk0369No ratings yet

- 5012HP Spec 2008Document2 pages5012HP Spec 2008Mohamed ZaghloulNo ratings yet

- Oil Centrifuge Operation and MaintenanceDocument65 pagesOil Centrifuge Operation and Maintenancesayed2allNo ratings yet

- SP25Y English PDFDocument2 pagesSP25Y English PDFGarcia CruzNo ratings yet

- Eurostream OM ManualDocument19 pagesEurostream OM ManualGede SantosaNo ratings yet

- Undercowl Pocket Guide RRDocument32 pagesUndercowl Pocket Guide RRbnmmauricio100% (3)

- RR 20-Weatherford Model T425Document2 pagesRR 20-Weatherford Model T425soroush niliNo ratings yet

- Van Ruth - Cementing Wedging PlugsDocument1 pageVan Ruth - Cementing Wedging PlugsSergei Sarmiento DuránNo ratings yet

- PIPING IdentificationDocument49 pagesPIPING IdentificationSiji OktoberNo ratings yet

- Item Inspected: CBLT-TPI-00F-186-12623Document16 pagesItem Inspected: CBLT-TPI-00F-186-12623Zulfadli RaniNo ratings yet

- Stanadyne de Pump Timing InstructionsDocument1 pageStanadyne de Pump Timing Instructionskonstantin chekan100% (1)

- Pulsatron Series C Metering Pump DatasheetDocument2 pagesPulsatron Series C Metering Pump DatasheetReady EpinoNo ratings yet

- Manufacturing RangeDocument38 pagesManufacturing RangeAhmad HafizNo ratings yet

- Identification CardDocument11 pagesIdentification Cardangel alvarezNo ratings yet

- L&T Power Training Circular - 752440Document11 pagesL&T Power Training Circular - 752440Kamalnath GNo ratings yet

- Yanmar Diesel Engine PDFDocument240 pagesYanmar Diesel Engine PDFNam Anh Trần75% (8)

- Booster Pump and Ejector GuideDocument8 pagesBooster Pump and Ejector Guidegmurali2kNo ratings yet

- B Bredel SPX Us 04Document20 pagesB Bredel SPX Us 04Luis Gutiérrez AlvarezNo ratings yet

- Etp - 30 KLDDocument18 pagesEtp - 30 KLDsubramanyam kumarNo ratings yet

- Vietnamese Standard: Fire Protection, Detection and ExtincitionDocument25 pagesVietnamese Standard: Fire Protection, Detection and ExtincitionThinh NguyenNo ratings yet