Professional Documents

Culture Documents

App Note Wet Scrubber

Uploaded by

Özer YildirimOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

App Note Wet Scrubber

Uploaded by

Özer YildirimCopyright:

Available Formats

pH

.JJ.J

`

J.JJ

.J

`

APPLICATION NOTES

pH and Conductivity Measurement for

Wet Scrubbers

Application # APPNOTE-003

Rev# 2006-04-24

Page 1 of 3

Introduction

Industrial scrubbers are used for the removal of potentially

harmful and polluting gas emissions. Gases that must be

removed include sulfur dioxide (SO2) from combustion by

utilities and industries and a wide variety of by-product and

waste gases such as chlorine (Cl2), hydrogen chloride (HCl) and

hydrogen sulde (H2S).

Application

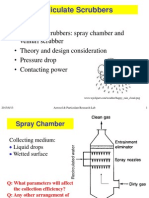

Wet scrubbers operate by spraying the incoming gas stream

with a scrubbing solution containing a scrubbing chemical,

which destroys the harmful gas. This process is illustrated in

Fig. 1.

The effectiveness of the scrubbing solution in removal of

harmful gases depends on the concentration of the scrubbing

chemical, which is continuously being depleted during the pro-

cess. Scrubbing chemical concentration must be maintained to

ensure effectiveness of the scrubber. Conductivity and pH can

be used to monitor scrubber solution strength/concentration.

Control of the solution strength (concentration) can be

achieved by either of the following methods:

1) Batch Scrubbing: Starts with an initially high con-

centration of scrubbing

Chemical, that is allowed to reach near depletion,

followed by

blowdown and replenishment by fresh, full strength

scrubber solution.

2) Continual Scrubbing: Continual replenishment and

blowdown

Scrubber solution composition at any time will depend upon

how it is being controlled and, the scrubbing chemical and

gases being scrubbed.

Gas to be scrubbed

scrubbed gas

Recirculating pump

pH Control

Conductivity

Control

Scrubbing

Solution

Fig. 1

Scrubber Soln

Make-up

Blowdown

valve

To disposal

APPLICATION NOTES (CONT.)

Page 2 of 3

The choice whether to control with pH or conductivity will

depend on the scrubber solution composition and how it

changes during the scrubber operation. While each applica-

tion should be evaluated individually, the applications best

suited for conductivity and pH are as follows:

Conductivity Control

Conductivity is best suited to measure scrubber solution con-

centration of scrubber chemical in batch scrubbers.

Conductivity is non-specic and will respond to both conduc-

tive scrubbing chemicals and by-products. As the scrubbing

chemical is depleted, its contribution to the scrubber solution

conductivity will decrease. At the same time, the concentra-

tion of the by-products is building up and their contribution to

the total conductivity is increasing.

If a measurable decrease in conductivity is detected as the

scrubbing solution is depleted, then the scrubbing chemical

concentration can be measured. One example of this is batch

scrubbing of chlorine gas (Cl2), using strong caustic (10-15%

NaOH).

If more than one gas is being scrubbed, difculties can arise.

Depending upon the relative proportions of the gases, the

by-products formed will differ, leading to variations in the

conductivity background. Deriving concentration from con-

ductivity can be difcult or impossible, although a conductiv-

ity measurement may still provide an alarm point to alert the

operator to check a grab sample.

In continual replacement scrubbers, conductivity can be used

to initiate blowdown to prevent high dissolved solids build up.

pH Control

pH control is often the choice for scrubbers using continuous

blowdown and replenishment. Acidic gas scrubbing, such as

sulfur dioxide (SO2 ), is controlled by maintaining an excess

concentration of a basic scrubbing chemical, such as caustic

(NaOH) or lime (Ca(OH)2). Since pH is specic to hydrogen ion

concentration (H+), which is related to the concentration of

the basic scrubbing chemical (high pH means low H

+

con-

centration), it can be used to control scrubbing with minimal

effects from scrubber by-products. If the scrubber uses strong

caustic (10-15% NaOH), pH control is not suggested since

the exposure of the pH glass to high concentration of caustic

will cause dissolution of the pH glass, thus destroying the

electrode. The pH response curve follows a strong acid/base

titration curve, which results in a reading that only drops back

on-scale near a point of complete exhaustion of the caustic,

followed by a sudden drop at the exhaustion point.

ORP (Oxidation Reduction Potential) measurement may also

be used in addition to pH measurement if the scrubbing reac-

tion involves an oxidation or reduction change. It can only be

used to determine the complete exhaustion of a particular

chemical and is not recommended as a means to determine

concentration of scrubbing solution or by-products.

The scrubbing chemical in spent scrubber solution is some-

times regenerated on-site for reuse in the scrubber. An

example is the regeneration of caustic (NaOH) in spent sulfur

dioxide scrubbing solution from sodium sulfate

(Na

2

SO

4

) using lime (Ca(OH)2). Conductivity can be used to

measure the concentration of the caustic produced in this

reaction. Scrubbing reaction by-products can also be used in

the plant or sold. These include sodium hypochlorite (NaOCl)

from chlorine gas scrubbed with caustic; Ammonium sulfate

(NH

4

HSO

4

) for use as fertilizer from Sulfur dioxide (SO

2

) scrub-

bing with ammonium hydroxide (NH

4

OH).

SCRUBBER INFORMATION TO KNOW

BEFORE CHOOSING A SENSOR:

1) Gas or gases being scrubbed (chemical name and formula)

2) Scrubbing chemical and concentration range

3) Scrubbing chemical concentration maintained by:

a) continual blowdown

b) deplete down to certain range

Sensors and Instruments

Toroidal conductivity sensors and instruments should be used

for scrubber control since the sensors are highly resistant to

fouling. They are also recommended due to the high conduc-

tance of many of these scrubbing solutions and by-products.

pH sensors will tend to coat in scrubbing applications, espe-

cially in applications that use lime (Ca(OH)2) as the scrubbing

chemical. To minimize coating effects, make sure that the

sensor is mounted in a high ow area (in-line >3ft/sec velocity

is suggested). The use of at-surface, seld-cleaning pH & ORP

electrodes are recommended. Cleaning frequency is reduced

and much time can be saved. Do not use pH for scrubbers

using strong caustic 10-15%). This will damage the pH glass.

Choose materials of construction of pH electrodes based on

the chemicals being scrubbed and any possible by-products

(CPVC or PVDF).

Application # APPNOTE-003

Rev# 2006-04-24

APPLICATION NOTES (CONT.)

Page 3 of 3

Typical Scrubber Applications

Gas Scrubber Solution Measurement

Chlorine Caustic (10-15%) Conductivity

White Liquor pH,ORP

Sulfur Dioxide (SO

2

) Lime (CaO) pH

Magnesium Oxide (MgO) pH

Caustic (weak) pH

Caustic (strong) Conductivity

Hydrogen Chloride Caustic (10-15%) Conductivity

Hydrogen Sulfide Caustic (10-15%) Conductivity

Sodium Hypochlorite

(NaOCl)

Conductivity, ORP

Electrode installation

Electrode instatllation depends on piping sytem dimensions.

Piping up to 2 diameter can use in-line electrode mounting.

It is suggested to install a by-pass line with isolation valves

so that the scrubber does not need to be stopped to remove

or maintain the electrode. For piping with >2 diameter a

wet-tap installation is offered. This allows the customer to

directly insert and retract the electrode into the line to take

advantage of the turbulent ow or postiion the electrode

near the pipe wall. A saddle and 1 or larger full-port ball

valve are required for installation. No tools are required for

electrode maintenance.

11751 Markon Dr.

Garden Grove, CA 92841 USA

Tel: 714-895-4344

Fax: 714-894-4839

E-mail: info@sensorex.com

www.sensorex.com

Application # APPNOTE-003

Rev# 2006-04-24

Products for Wet Scrubber Monitoring

Toroidal Conductivity Sensor:

Model TCS-1000 offers no maintenance

control of scrubber chemical concentration via

conductivity.

In-line pH and ORP Sensors:

Models are available for 3/4, 1 or 2 in-line

mounting. Sensors require no tools to install

and can be changed in seconds. Mounting

hardware with integral temperature sensor for

ATC saves money!

Insertion mount pH and ORP Sensors:

Models are available with 12, 18 or 24 maxi-

mum insertion depth. No need to stop ow to

change sensor. No tools are required to install

sensors and they can be changed in seconds.

Mounting hardware with integral temperature

sensor for ATC saves money!

You might also like

- Crane Tp410 Fluid FlowDocument133 pagesCrane Tp410 Fluid FlowLucia Lorenzini100% (8)

- Chemical Analysis Procedures For Galvanizing PlantsDocument32 pagesChemical Analysis Procedures For Galvanizing PlantsSreedhar Patnaik.M100% (2)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsFrom EverandModeling, Control, and Optimization of Natural Gas Processing PlantsRating: 5 out of 5 stars5/5 (1)

- TOC Application HandbookDocument79 pagesTOC Application Handbookmregalopez3647100% (1)

- Reactive Exhaust DyeingDocument12 pagesReactive Exhaust DyeingKhandaker Sakib Farhad67% (3)

- Chapter 10 - Cement Production - Calculation of Raw Mix Composition PDFDocument57 pagesChapter 10 - Cement Production - Calculation of Raw Mix Composition PDFSamnang HangNo ratings yet

- Complex Formation Titrations PDFDocument15 pagesComplex Formation Titrations PDFMich TolentinoNo ratings yet

- PH and Conductivity Measurements For ScrubbersDocument4 pagesPH and Conductivity Measurements For ScrubbersAlberto GutierrezNo ratings yet

- Application Note PH Conductivity Measurements For Scrubbers en 71958Document4 pagesApplication Note PH Conductivity Measurements For Scrubbers en 71958Samy khanNo ratings yet

- Paper presentedtoWEFConferenceDec2005Document15 pagesPaper presentedtoWEFConferenceDec2005Nikhil MalhotraNo ratings yet

- C10743Document16 pagesC10743Victor YepezNo ratings yet

- Hexavalent Chromium Waste TreatmentDocument2 pagesHexavalent Chromium Waste TreatmentEstiNo ratings yet

- TSB 120Document7 pagesTSB 120patelpiyushbNo ratings yet

- Technical Service Bulletin: RO Membrane Foulants and Their Removal From Polyvinyl Derivative (PVD) RO Membrane ElementsDocument6 pagesTechnical Service Bulletin: RO Membrane Foulants and Their Removal From Polyvinyl Derivative (PVD) RO Membrane ElementspatelpiyushbNo ratings yet

- Procedure For ChemicallyDocument6 pagesProcedure For ChemicallyArunkumar ChandaranNo ratings yet

- HydraunauticsDocument6 pagesHydraunauticshassan zakwanNo ratings yet

- Feedwater Quality Requirements for OTSGDocument13 pagesFeedwater Quality Requirements for OTSGger80100% (1)

- Asta E-13-20Document8 pagesAsta E-13-20galin8575No ratings yet

- Odour Control in Waste Water PlantsDocument10 pagesOdour Control in Waste Water PlantsMadhavan DurairajNo ratings yet

- Measure Organic Carbon in Water SamplesDocument3 pagesMeasure Organic Carbon in Water SamplesspmoralesaNo ratings yet

- Wash Water Injection in Hydroprocessing UnitsDocument13 pagesWash Water Injection in Hydroprocessing Unitscüneyt şanNo ratings yet

- 03-Pre-treatment-Neutralization, Nov. 23, 2017Document32 pages03-Pre-treatment-Neutralization, Nov. 23, 2017jantskieNo ratings yet

- Improve Scrubbing DesignDocument5 pagesImprove Scrubbing Designtrong40No ratings yet

- LdoDocument4 pagesLdoprannoyNo ratings yet

- Chemical Pretreatment for RO and NF SystemsDocument16 pagesChemical Pretreatment for RO and NF SystemsBerliana Cahya NingtiasNo ratings yet

- Steam and Water Analysis System (Swas) : Submitted byDocument101 pagesSteam and Water Analysis System (Swas) : Submitted bySrinivasarao YenigallaNo ratings yet

- Removal of Hydrogen Sulfide (H S) From Wastewater Using Chemical Oxidation and Red Mud-A Comparative StudyDocument4 pagesRemoval of Hydrogen Sulfide (H S) From Wastewater Using Chemical Oxidation and Red Mud-A Comparative StudyVenkatesh VenkyNo ratings yet

- Osec B-Pak - Frequently Asked QuestionsDocument8 pagesOsec B-Pak - Frequently Asked Questionsalassy juyNo ratings yet

- Chemical Treatment Options For Tannery Wastewater: Shaikh Obaidullah Al MahmoodDocument6 pagesChemical Treatment Options For Tannery Wastewater: Shaikh Obaidullah Al MahmoodShaikh Obaidullah Al MahmoodNo ratings yet

- TocDocument5 pagesTocReza Hafidz SukamtoNo ratings yet

- H2S Gas Analyzer Detects Corrosive Hydrogen SulfideDocument2 pagesH2S Gas Analyzer Detects Corrosive Hydrogen SulfideiptNo ratings yet

- Exp4 CodDocument9 pagesExp4 CodsajidahdsNo ratings yet

- Organic Odor Control With Chlorine DioxideDocument3 pagesOrganic Odor Control With Chlorine DioxideCostas AggelidisNo ratings yet

- US EPA Method 26ADocument13 pagesUS EPA Method 26AputtipongtanNo ratings yet

- AstroUV Turbo - HACH New ProductDocument4 pagesAstroUV Turbo - HACH New ProductprannoyNo ratings yet

- Test Method To Check The Concentration of CausticDocument23 pagesTest Method To Check The Concentration of CausticGaurav DhawanNo ratings yet

- Wet scrubbing of acidic gasesDocument4 pagesWet scrubbing of acidic gasesnikhaarj100% (1)

- H2S Measurement MethodsDocument3 pagesH2S Measurement Methodssummiullah-zafar-1773No ratings yet

- sjac.20200802.17Document8 pagessjac.20200802.17GauravNo ratings yet

- FGD Scrubber An RevADocument2 pagesFGD Scrubber An RevAgaol_bird009No ratings yet

- Chrome WasteDocument2 pagesChrome WastesambitNo ratings yet

- What is COD and how to measure itDocument4 pagesWhat is COD and how to measure itgurubakkiamjai100% (1)

- TOC Chapter2Document18 pagesTOC Chapter2NowsathAliNo ratings yet

- Anaerobic Sulphide Inhibition Control Using Air StrippingDocument3 pagesAnaerobic Sulphide Inhibition Control Using Air StrippingAjit HaridasNo ratings yet

- Detackifier d2430s ProgrameDocument21 pagesDetackifier d2430s ProgrameHuong ToNo ratings yet

- Appendix V P. Total Organic Carbon in Water For Pharmaceutical UseDocument2 pagesAppendix V P. Total Organic Carbon in Water For Pharmaceutical UseNam ĐoànNo ratings yet

- 1.0 Scope and Application: Analytes Cas NoDocument13 pages1.0 Scope and Application: Analytes Cas NowalaaiNo ratings yet

- Disinfection of Treated SewageDocument23 pagesDisinfection of Treated SewagemathitwadNo ratings yet

- RODocument60 pagesROVel Murugan100% (1)

- PH Measurement in Wet Scrubbers: Product Application DataDocument2 pagesPH Measurement in Wet Scrubbers: Product Application DataVanessa VanegasNo ratings yet

- Caustic Scrubber Designs for H2SDocument26 pagesCaustic Scrubber Designs for H2SWidya Isti AriantiNo ratings yet

- Artigo - An Advancement in Steam Turbine Chemistry Monitoring (IMPRESSO)Document10 pagesArtigo - An Advancement in Steam Turbine Chemistry Monitoring (IMPRESSO)Mateus PinheiroNo ratings yet

- UOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFDocument9 pagesUOP-Mercury-Removal-From-Natural-Gas-and-Liquid-Streams-Tech-Paper 2 PDFPedraza Velandia JhonNo ratings yet

- NHT OperationsDocument61 pagesNHT OperationsIrfan Shahzad75% (4)

- Biogas Production Fromuasb Technology: A Review Onfunctioning and Suitability Ofuasb Based Sewage Treatment Plant Atraipur Kalan, ChandigarhDocument7 pagesBiogas Production Fromuasb Technology: A Review Onfunctioning and Suitability Ofuasb Based Sewage Treatment Plant Atraipur Kalan, ChandigarhIOSRjournalNo ratings yet

- Shimadzu TOC Analyzer GuideDocument20 pagesShimadzu TOC Analyzer GuideAravindavindana VindanaNo ratings yet

- Analytical Products: Sales Engineering Supercritical Fluid Chromatography For Process ControlDocument11 pagesAnalytical Products: Sales Engineering Supercritical Fluid Chromatography For Process Controltejasmodi21No ratings yet

- 00-Studio ScaleChem CIBPDocument13 pages00-Studio ScaleChem CIBPthangNo ratings yet

- Section2 CODDocument14 pagesSection2 CODfabian_granoblesNo ratings yet

- Coagulation Control Using The Streaming Current Detector: Problems and A Possible SolutionDocument4 pagesCoagulation Control Using The Streaming Current Detector: Problems and A Possible SolutionMohammad Ali ZamanNo ratings yet

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Case Study Autoclave AutomationDocument8 pagesCase Study Autoclave AutomationÖZER YILDIRIMNo ratings yet

- Product Guide - Rosco - Rev 02 12Document2 pagesProduct Guide - Rosco - Rev 02 12Özer YildirimNo ratings yet

- 66 User Manual 2Document74 pages66 User Manual 2Özer YildirimNo ratings yet

- 66 User Manual 2Document74 pages66 User Manual 2Özer YildirimNo ratings yet

- Firearm Technology and VocabularyDocument6 pagesFirearm Technology and VocabularyÖzer Yildirim100% (1)

- Displacement App Guide - 2013Document14 pagesDisplacement App Guide - 2013Özer YildirimNo ratings yet

- SAAMI ITEM 202-Sporting AmmunitionDocument7 pagesSAAMI ITEM 202-Sporting AmmunitionÖzer YildirimNo ratings yet

- SAAMI ITEM 211-Unsafe Arms and Ammunition Combinations 2Document13 pagesSAAMI ITEM 211-Unsafe Arms and Ammunition Combinations 2Özer YildirimNo ratings yet

- Soda Blasting Cabinet GloveBoxDocument2 pagesSoda Blasting Cabinet GloveBoxÖzer YildirimNo ratings yet

- H2S DesignExampleDocument2 pagesH2S DesignExampleÖzer YildirimNo ratings yet

- Literature - Scrubbing Pollutants From Vent StreamsDocument15 pagesLiterature - Scrubbing Pollutants From Vent StreamsFrancisco RenteriaNo ratings yet

- Particulate Scrubber Design and PerformanceDocument17 pagesParticulate Scrubber Design and PerformanceÖzer YildirimNo ratings yet

- Particulate Scrubber Design and PerformanceDocument17 pagesParticulate Scrubber Design and PerformanceÖzer YildirimNo ratings yet

- Enzyme Performance Affected by TemperatureDocument5 pagesEnzyme Performance Affected by TemperatureJeannete Claudia Wulandari100% (1)

- DMFCDocument12 pagesDMFCSilmi Rahma AmeliaNo ratings yet

- Flashcards - CP14 Preparation of A Transition Metal Complex - Edexcel IAL Chemistry A-LevelDocument31 pagesFlashcards - CP14 Preparation of A Transition Metal Complex - Edexcel IAL Chemistry A-LevelHussain NvNo ratings yet

- Stree Vyadhihari RasaDocument2 pagesStree Vyadhihari RasaRupendra sainiNo ratings yet

- Aluminum Analysis ReportGlient: Here is a concise, SEO-optimized title for the document:TITLE IGAS Research Reports Aluminum Alloy Purity and PropertiesDocument3 pagesAluminum Analysis ReportGlient: Here is a concise, SEO-optimized title for the document:TITLE IGAS Research Reports Aluminum Alloy Purity and PropertiessalmanNo ratings yet

- Phytochemicals and Antioxidant Activities of Aloe Vera (Aloe Barbadensis)Document12 pagesPhytochemicals and Antioxidant Activities of Aloe Vera (Aloe Barbadensis)Journal of Nutritional Science and Healthy DietNo ratings yet

- Chemistry Past PapersDocument372 pagesChemistry Past Papersmahima100% (1)

- Chloride VolhardDocument3 pagesChloride Volhardkabilan_111100% (1)

- MLS 5a - BSMLS2-E - Module4 - Group9Document8 pagesMLS 5a - BSMLS2-E - Module4 - Group9Lexi Evonne NacionalesNo ratings yet

- Purolite MB400 LDocument1 pagePurolite MB400 LjoaoNo ratings yet

- Potassium ChlorideDocument2 pagesPotassium ChlorideRajesh RaviNo ratings yet

- Pyrometallurgy Lecture 4 Chlorination RoastingDocument16 pagesPyrometallurgy Lecture 4 Chlorination RoastingNhut NguyenNo ratings yet

- Ex6 Peroxide ValueDocument2 pagesEx6 Peroxide ValueFederico Kikut100% (1)

- Castor Oil Derivatives Guide for EntrepreneursDocument11 pagesCastor Oil Derivatives Guide for EntrepreneursMohammad Kamal HabbabaNo ratings yet

- Daftar Nama Obat ExcelDocument11 pagesDaftar Nama Obat ExcelEja NugrohoNo ratings yet

- Stern WEX Product Range and Comparison Test ResultsDocument9 pagesStern WEX Product Range and Comparison Test Resultssimbua72No ratings yet

- AcetaldehydeDocument10 pagesAcetaldehydeDinesh guhanNo ratings yet

- Chapter 1 Organic CompoundsDocument7 pagesChapter 1 Organic CompoundsMark DiezNo ratings yet

- Earth Science 11 - q1 - m3Document16 pagesEarth Science 11 - q1 - m3Dog GodNo ratings yet

- 0620 - s05 - QP - 1.chemistry O LevelDocument16 pages0620 - s05 - QP - 1.chemistry O LeveltiffaNo ratings yet

- Acid-base equilibria conceptsDocument2 pagesAcid-base equilibria conceptsNkemzi Elias NzetengenleNo ratings yet

- Hydrometallurgy: M.S. Sonmez, R.V. KumarDocument5 pagesHydrometallurgy: M.S. Sonmez, R.V. KumarAndres MorenoNo ratings yet

- Yoan de Nanda Herru, Adlis Santoni, Mai Efdi : Maiefdi@sci - Unand.ac - IdDocument12 pagesYoan de Nanda Herru, Adlis Santoni, Mai Efdi : Maiefdi@sci - Unand.ac - IdYoan D' NandaNo ratings yet

- CLS - ENG 22 23 XI - Che - Target 5 - Level 1 - Chapter 10 PDFDocument38 pagesCLS - ENG 22 23 XI - Che - Target 5 - Level 1 - Chapter 10 PDFSaksham Chamoli 10 G , 27No ratings yet

- Sample Questions - Chapter 3Document8 pagesSample Questions - Chapter 3Rasel IslamNo ratings yet

- Kami Export - POGIL Acids and Bases-S-1Document5 pagesKami Export - POGIL Acids and Bases-S-1demyeets64No ratings yet

- YouTube: Salt Analysis Scheme & Cation/Anion TestsDocument2 pagesYouTube: Salt Analysis Scheme & Cation/Anion TestsNived Narayan PNo ratings yet