Professional Documents

Culture Documents

Retrofit - Propulsion Improvement

Uploaded by

Ramon Velasco Stoll0 ratings0% found this document useful (0 votes)

45 views4 pagesThe total propulsion efficiency of a propeller varies between 50% and 70%. Axial LOSSES A propeller generates thrust, due to the acceleration of the incoming water. A reduction in frictional losses can result in efficiency improvements UP TO 15%.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe total propulsion efficiency of a propeller varies between 50% and 70%. Axial LOSSES A propeller generates thrust, due to the acceleration of the incoming water. A reduction in frictional losses can result in efficiency improvements UP TO 15%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

45 views4 pagesRetrofit - Propulsion Improvement

Uploaded by

Ramon Velasco StollThe total propulsion efficiency of a propeller varies between 50% and 70%. Axial LOSSES A propeller generates thrust, due to the acceleration of the incoming water. A reduction in frictional losses can result in efficiency improvements UP TO 15%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

HYDRODYNAMICS

The total propulsion efciency of a propeller

varies between 50% and 70%. The losses

for an average propeller can be traced to 3

physical phenomena:

AXIAL LOSSES

A propeller generates thrust, due to the

acceleration of the incoming water. Behind

the vessel, the out coming ow mixes with the

environmental ow. Due to turbulence, energy

will be lost.

FRICTIONAL LOSSES

Water in contact with the propeller blade

surface causes friction, and thus losses. The

total blade surface, speed of rotation and

surface roughness are the dominating factors

concerning frictional losses.

ROTATIONAL LOSSES

Rotation of the blade causes a rotation in the

wake too; consequently this energy is lost to

Visualization of axial losses.

SAVE UP TO 15%

ON FUEL COSTS

The fuel prices have risen considerably the

last years, resulting in an increase of ship

operating costs. To maintain the economic

protability of the vessel, a large focus is

nowadays on fuel saving devices in the

broadest sense of the word.

A number of options is available to

improve the efciency of the propulsion

system, depending on the type of propeller

and vessel. In this leaet we explain the

propulsion improvements through retrots

and the economic effects by means of the

Return On Investment (ROI).

efficiency 60%

axial losses 20%

frictional

losses 15%

rotational

losses 5%

Example of type of losses general ship propeller.

Increase in fuel prices.

BEFORE AFTER

RETROFIT PROPULSION IMPROVEMENT

Internal profile

External profile

Flow pattern HR nozzle

Flow pattern 19A or 37 nozzle

Better flow around nozzle

- Curved exterior

- Curved interior

HR-nozzle: No flow separation at the outside

of the nozzle.

Conventional nozzle: Flow separation.

Advantage of Wrtsil high efciency (HR) nozzle.

Conventional propeller

design.

Wrtsil tip rake

propeller design.

positive effect can be up to 3%. The ROI is

4-5 years, since a new propeller is required.

With the help of modern hydrodynamic

software, more reliable cavitation predictions

are made. This way higher power densities can

be allowed, and thus a lower blade area can

be applied. A reduction in frictional losses can

result in efciency improvements up to 3%.

With the combination of tip rake and a

lower blade area it is possible to realize fuel

savings up to 5%. Payback period is 3 years.

UP TO 10% IMPROVEMENT

MODERN DESIGN PROPELLER WITH

INCREASED DIAMETER AND LOW SPEED

In general a larger propeller diameter in

combination with a low rotational speed leads

to an improvement in efciency. The axial

losses will be reduced. Basically we can apply

this for all ship/propeller types.

In case the diameter can not be increased,

sometimes a larger number of blades (5 or

6) provides a solution for further optimization.

Payback period is 1.5 to 2.5 years.

EFFICIENCY RUDDER

The efciency rudder is a successful new

development. Axial and rotational losses in the

slip stream of the hub are eliminated by the

torpedo, which is tted in between the propeller

and the rudder. Highly loaded propellers and

ships with speeds exceeding 15-20 knots,

can benet from an efciency rudder. For new

building vessels it can be attractive since a

rudder and propeller is needed anyway. For

the retrot market the investment is quite

large, and therefore the Return On Investment

exceeds a period of 5 years.

PROPELLER - ENGINE INTERACTION

Vessels equipped with a xed pitch propeller

can suffer from a so called heavy running

propeller. The terminology is somewhat

misleading; the propeller loading and

engine characteristics are not matching.

The propeller curve crosses the load limit

of the engine before full power is reached.

As a consequence the engine is overloaded,

leading to increased fuel consumption as well

as increased wear of internal engine parts.

A pitch modication of the propeller can

be conducted. This way the same power is

absorbed at a higher rpm, and the engine

operation is shifted out of the red area.

Fuel savings, after trailing edge cutting,

of 6% to 8% are reported. Payback period is

2 months.

UP TO 15% IMPROVEMENT

By conversion of an open propeller to a ducted

propeller, efciency gains up to 15% are

established.

The idea of surrounding a propeller by a

nozzle is already very old. Today about 25%

of all Wrtsil controllable pitch propellers are

running in a nozzle.

In an accelerating nozzle the water speed

at the propeller is higher then that of the

open propeller. The increase in axial velocity

reduces the propeller load especially for

heavily loaded propellers. This then leads

to an increase in overall performance of

the propeller and nozzle compared to that

of a propeller alone. Additionally, the nozzle

generate a thrust in axial direction.

Fuel saving devices are categorized on

percentage of efciency improvement: up to

5%, up to 10% and up to 15%.

UP TO 5% IMPROVEMENT

PROPELLER POLISHING AND/OR REPAIR OF

EDGE DAMAGE

Propeller polishing in combination with

repair of edge damage easily increases the

propellers operating efciency with 2% to

4%. The Return On Investment (ROI) period

is quite short. After 1 to 3 months, the

maintenance costs are already paid back.

MODERN DESIGN PROPELLER

A redesign of the current propeller, based

on the state-of-the-art, without optimizing

the boundary conditions like propeller speed

and diameter, can lead to an improvement of

approximately 5%.

Tip rake reduces the local rotation around

the tip. For large xed pitch propellers the

0

1

2

3

4

5

6

0 5 10 15

Efficiency improvement [%]

R

e

t

u

r

n

o

n

i

n

v

e

s

t

m

e

n

t

[

y

e

a

r

]

Grinding and repair

Modern

design

propeller

Efficiency rudder

Modern design

propeller diameter

and rpm adapted

Propeller-engine interaction

Ducted propellers

More interesting

Less interesting

Return On Investments of propulsion improvement devices.

generates forward thrust caused by the

pressure distribution round the nozzle,

resulting in a force in the forward direction.

To extend the application of ducted

propellers towards higher ship speeds in

combination with a larger bollard pull, Wrtsil

has introduced the high efciency nozzle

(HR-nozzle). The HR-nozzle has a curved

exterior and interior, leading to absence of

ow separation and consequently a higher

efciency.

Replacing an open propeller with an

HR ducted propeller, the bollard pull can be

increased with about 25%, while the free

running efciency can be increased with 10%

to 15%. This mainly depends on the power

density of the propeller and the sailing speed

of the vessel.

ECONOMICS OF RETROFITS

To judge the protability of a propulsion

improvement, the increase in hydrodynamic

efciency needs to be known in relation with

investment or total costs.

A number of conducted retrots were

reviewed with respect to investment and fuel

savings. Data for the fuel consumption were

supplied by the ship operator, or otherwise

estimated based on the mission prole.

Figure below shows the estimated Return

On Investment of each discussed propulsion

improvement device. Each type of device

has a wide eld of application, depending

on ship type, size, engine, type of fuel etc.

Therefore an envelope is sketched in the

chart, identifying a range of hydrodynamic

improvements and pay back time.

WARTSILA.COM

WRTSIL

is a registered trademark. Copyright 2008 Wrtsil Corporation.

Wrtsil Propulsion Netherlands B.V.

Lipsstraat 52, P.O. Box 6, 5150 BB Drunen, The Netherlands

Tel. +31 416 388115 Fax +31 416 373162 www.wartsila.com

SUMMARY AND CONCLUSION

Due to the focus on environmental issues and the increasing fuel

prices, ship owners are more and more interested in solutions

to save fuel. Wrtsil can offer several different options for fuel

savings.

With modern design propellers, grinding and repair

and modication of heavy running propellers considerable

hydrodynamic improvement can be established, with attractive

Return On Investments.

By the application of ducted propellers however, and especially

the Lips high efciency nozzle, an increase of free running

propeller efciency of 15% can be reached, with a payback period

of 1 to 1.5 years.

You might also like

- 2004.12 Mitsubishi (MHI) Stator-Fin Ship Energy Saving Device DesignDocument4 pages2004.12 Mitsubishi (MHI) Stator-Fin Ship Energy Saving Device Designgnd100No ratings yet

- B19103-R1E - Ylinder Lrication Guideline On 0.1% ULSFO and 0.5% VLSFODocument6 pagesB19103-R1E - Ylinder Lrication Guideline On 0.1% ULSFO and 0.5% VLSFOS.K.SEONo ratings yet

- ANGARA - Invest - Deck - April 2022Document47 pagesANGARA - Invest - Deck - April 2022vonyyudhaNo ratings yet

- Energy Saving Basics - EsdsDocument40 pagesEnergy Saving Basics - Esdsapi-238581599No ratings yet

- Cylinder Lube Oil Feed Rate Calculation From HMI R-ValueDocument4 pagesCylinder Lube Oil Feed Rate Calculation From HMI R-ValueАндрей АндреевичNo ratings yet

- Performance Measurement IndicatorDocument9 pagesPerformance Measurement IndicatorDanut TatuNo ratings yet

- Performance CurvesDocument4 pagesPerformance Curvessevero97No ratings yet

- A Study On Torque Rich Phenomena in Ship OperationDocument11 pagesA Study On Torque Rich Phenomena in Ship OperationAnonymous XtvvG80zuNo ratings yet

- Ship Performance IndicatorDocument10 pagesShip Performance Indicatorc rkNo ratings yet

- 5510 0101 01ppr - LowDocument30 pages5510 0101 01ppr - LowFuchsbauNo ratings yet

- Emission Factors From Cross Sector Tools March 2017Document91 pagesEmission Factors From Cross Sector Tools March 2017GeraldinneNo ratings yet

- Ship Energy Saving DeviceDocument43 pagesShip Energy Saving DeviceMax VerardiNo ratings yet

- Nox Technical Code Mepc.291Document15 pagesNox Technical Code Mepc.291Arvind Agarwal (Faculty)No ratings yet

- ME-C Introduction: Total Solution ProviderDocument6 pagesME-C Introduction: Total Solution ProviderАндрейNo ratings yet

- 706 - Performance Evaluation and General Operation - 007 PDFDocument72 pages706 - Performance Evaluation and General Operation - 007 PDFVignesh SivaNo ratings yet

- 1 Eng Performance 2Document17 pages1 Eng Performance 2Virdhaval JadhavNo ratings yet

- 14-Ship Efficiency Seminar - CMA CGM - HydrOcean 1. CMADocument30 pages14-Ship Efficiency Seminar - CMA CGM - HydrOcean 1. CMAJai FrinzNo ratings yet

- Computerised Engine Application System (CEAS)Document13 pagesComputerised Engine Application System (CEAS)Kamal WanniarachchiNo ratings yet

- Propulsion Trends in Container VesselsDocument28 pagesPropulsion Trends in Container VesselsFuchsbauNo ratings yet

- E-Ship 1Document47 pagesE-Ship 1ozan sancakNo ratings yet

- Marine Diesel Engines by Davan Arenha PDFDocument202 pagesMarine Diesel Engines by Davan Arenha PDFTowfiqNo ratings yet

- Brave Royal Ship Management (BD) Limited: Bunkering PlanDocument6 pagesBrave Royal Ship Management (BD) Limited: Bunkering PlanTowfiqNo ratings yet

- Wartsila Nozzle Improves Fishing EfficiencyDocument2 pagesWartsila Nozzle Improves Fishing EfficiencyRamon Velasco StollNo ratings yet

- 01 M00001720 Introduction To ME-GIDocument31 pages01 M00001720 Introduction To ME-GISajeev NerurkarNo ratings yet

- Man Diesel - Sl2013-571Document17 pagesMan Diesel - Sl2013-571stopless_dalian685No ratings yet

- Large Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009Document26 pagesLarge Marine Diesels in Challenging Times CIMAC Circle, Marintec 2009leo_ombinkNo ratings yet

- Hellenic Eng Soc Uk Nov2011Document79 pagesHellenic Eng Soc Uk Nov2011AmmarNo ratings yet

- 2 Stroke Diesel EngineDocument5 pages2 Stroke Diesel EngineJims Cudinyerah100% (1)

- DF 2005 2 PDFDocument16 pagesDF 2005 2 PDFAnonymous yRpebGJGaNo ratings yet

- Clean Cargo Working Group Carbon Emissions Accounting MethodologyDocument21 pagesClean Cargo Working Group Carbon Emissions Accounting Methodologyjean pNo ratings yet

- Cylinder LubricationDocument8 pagesCylinder LubricationVinay Kumar Neelam100% (1)

- Monitoring of Hull Condition of ShipsDocument137 pagesMonitoring of Hull Condition of ShipsFotis StefanidisNo ratings yet

- ABS Guide For Ballast Water Treatment: Bill LindDocument13 pagesABS Guide For Ballast Water Treatment: Bill LindjerylsNo ratings yet

- Diesel Engines and Gas Turbines in Cruise Vessel PropulsionDocument13 pagesDiesel Engines and Gas Turbines in Cruise Vessel PropulsionFuchsbauNo ratings yet

- DK Sanyal Principlespractice of Marine Diesel Engines: Book Read / Download OnlineDocument10 pagesDK Sanyal Principlespractice of Marine Diesel Engines: Book Read / Download OnlineLibin RajaNo ratings yet

- Controllable Pitch PropellerDocument4 pagesControllable Pitch PropellerRamonValdezNo ratings yet

- 213 34172 Global Marine Fuel Trends 2030Document60 pages213 34172 Global Marine Fuel Trends 2030Luis AlcalaNo ratings yet

- CIMAC Paper 008Document12 pagesCIMAC Paper 008김민욱No ratings yet

- HIMSEN Engine Operation With Low Sulphur FuelDocument18 pagesHIMSEN Engine Operation With Low Sulphur FuelPipis FakidomitisNo ratings yet

- MAN Diesel and Turbo SL2014-571 PDFDocument20 pagesMAN Diesel and Turbo SL2014-571 PDFhiiiNo ratings yet

- Vit and Super VitDocument6 pagesVit and Super VitRavindar Anandan0% (1)

- Gioi Thieu Dong Co MANBW ME-CDocument26 pagesGioi Thieu Dong Co MANBW ME-CMitdac HP0% (1)

- DieselFacts 2008-1 PDFDocument16 pagesDieselFacts 2008-1 PDFAsh Kai100% (1)

- Oros PistonDocument6 pagesOros Pistonbrigolmustihotmail.com100% (1)

- Guidelines For Operation On Fuels With Less Than 0 1 SulphurDocument24 pagesGuidelines For Operation On Fuels With Less Than 0 1 SulphurFuchsbauNo ratings yet

- CCAIDocument0 pagesCCAIshishir4870No ratings yet

- MANDocument141 pagesMANFirman Maulana Erawan HakamNo ratings yet

- ABB Optimization of Engine Performance 2009Document40 pagesABB Optimization of Engine Performance 2009Napoleon MpNo ratings yet

- Full Scale Wake Prediction of An Energy Saving Device by Using Computational Fluid DynamicsDocument10 pagesFull Scale Wake Prediction of An Energy Saving Device by Using Computational Fluid DynamicsChristoper MochengoNo ratings yet

- MARPOL 12aDocument12 pagesMARPOL 12agmarinovNo ratings yet

- Master Air Starting Valve ExploredDocument13 pagesMaster Air Starting Valve Exploredavm4343100% (1)

- GG 05 09 2012 200 PDFDocument4 pagesGG 05 09 2012 200 PDFpapaki2100% (1)

- Engine Retrofit Guide v8Document70 pagesEngine Retrofit Guide v8Romulo AlvarezNo ratings yet

- 01 Fir TheoryDocument2 pages01 Fir TheoryTrịnh Minh KhoaNo ratings yet

- DF 2012-1Document12 pagesDF 2012-1stopless_dalian685No ratings yet

- Certificates BASHA1Document7 pagesCertificates BASHA1Ravi AnuNo ratings yet

- Marine Sources of Energy: Pergamon Policy Studies on Energy and EnvironmentFrom EverandMarine Sources of Energy: Pergamon Policy Studies on Energy and EnvironmentNo ratings yet

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- 2018 RTTN On Occupational Fraud y AbuseDocument80 pages2018 RTTN On Occupational Fraud y AbuseDaniel GarciaNo ratings yet

- 2018 RTTN On Occupational Fraud y AbuseDocument80 pages2018 RTTN On Occupational Fraud y AbuseDaniel GarciaNo ratings yet

- Construction Vessel Keh 09015Document1 pageConstruction Vessel Keh 09015Ramon Velasco StollNo ratings yet

- 24 M Explorer Yachts 13144Document1 page24 M Explorer Yachts 13144Ramon Velasco StollNo ratings yet

- 24 M Patrol Emergency Response Vessel 09047Document1 page24 M Patrol Emergency Response Vessel 09047Ramon Velasco StollNo ratings yet

- Fishing Vessel Factory Trawler 1288Document1 pageFishing Vessel Factory Trawler 1288Ramon Velasco StollNo ratings yet

- LNG Comes of AgeDocument3 pagesLNG Comes of AgeRamon Velasco StollNo ratings yet

- Anodos de Zinc EstandaresDocument20 pagesAnodos de Zinc EstandaresRamon Velasco StollNo ratings yet

- DS DeltamarinDocument4 pagesDS DeltamarinRamon Velasco StollNo ratings yet

- Wartsila Ship TechnologyDocument20 pagesWartsila Ship Technologyalberto_rd100% (2)

- Wartsila Nozzle Improves Fishing EfficiencyDocument2 pagesWartsila Nozzle Improves Fishing EfficiencyRamon Velasco StollNo ratings yet

- Introducing PolyCAD 9Document11 pagesIntroducing PolyCAD 9Ramon Velasco StollNo ratings yet

- NURBS Recomendations EngDocument10 pagesNURBS Recomendations Engben_vkNo ratings yet

- 2 - Irving - Why AVEVA - v2 Less Images For Size ReductionDocument51 pages2 - Irving - Why AVEVA - v2 Less Images For Size ReductionRamon Velasco StollNo ratings yet

- Index: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsDocument5 pagesIndex: © Christopher Pitt 2018 C. Pitt, The Definitive Guide To AdonisjsZidi BoyNo ratings yet

- Saudi Methanol Company (Ar-Razi) : Job Safety AnalysisDocument7 pagesSaudi Methanol Company (Ar-Razi) : Job Safety AnalysisAnonymous voA5Tb0No ratings yet

- Pyromet Examples Self StudyDocument2 pagesPyromet Examples Self StudyTessa BeeNo ratings yet

- Peanut AllergyDocument4 pagesPeanut AllergyLNICCOLAIONo ratings yet

- 15 Miscellaneous Bacteria PDFDocument2 pages15 Miscellaneous Bacteria PDFAnne MorenoNo ratings yet

- 1KHW001492de Tuning of ETL600 TX RF Filter E5TXDocument7 pages1KHW001492de Tuning of ETL600 TX RF Filter E5TXSalvador FayssalNo ratings yet

- The Original Lists of Persons of Quality Emigrants Religious Exiles Political Rebels Serving Men Sold For A Term of Years Apprentices Children Stolen Maidens Pressed and OthersDocument609 pagesThe Original Lists of Persons of Quality Emigrants Religious Exiles Political Rebels Serving Men Sold For A Term of Years Apprentices Children Stolen Maidens Pressed and OthersShakir Daddy-Phatstacks Cannon100% (1)

- 1Document2 pages1TrầnLanNo ratings yet

- OB and Attendance PolicyDocument2 pagesOB and Attendance PolicyAshna MeiNo ratings yet

- Ppap - 2556 PDFDocument7 pagesPpap - 2556 PDFMohamed ElmakkyNo ratings yet

- Coke Drum Repair Welch Aquilex WSI DCU Calgary 2009Document37 pagesCoke Drum Repair Welch Aquilex WSI DCU Calgary 2009Oscar DorantesNo ratings yet

- Pediatric Fever of Unknown Origin: Educational GapDocument14 pagesPediatric Fever of Unknown Origin: Educational GapPiegl-Gulácsy VeraNo ratings yet

- Session 10. Value Proposition.Document69 pagesSession 10. Value Proposition.Bibhu R. TuladharNo ratings yet

- 5045.CHUYÊN ĐỀDocument8 pages5045.CHUYÊN ĐỀThanh HuyềnNo ratings yet

- 5 Ways To Foster A Global Mindset in Your CompanyDocument5 pages5 Ways To Foster A Global Mindset in Your CompanyGurmeet Singh KapoorNo ratings yet

- ARIIX - Clean - Eating - Easy - Ecipes - For - A - Healthy - Life - Narx PDFDocument48 pagesARIIX - Clean - Eating - Easy - Ecipes - For - A - Healthy - Life - Narx PDFAnte BaškovićNo ratings yet

- Fin Accounting IFRS 2e Ch13Document62 pagesFin Accounting IFRS 2e Ch13Nguyễn Vinh QuangNo ratings yet

- Acceptable Use Policy 08 19 13 Tia HadleyDocument2 pagesAcceptable Use Policy 08 19 13 Tia Hadleyapi-238178689No ratings yet

- DBM Uv W ChartDocument2 pagesDBM Uv W ChartEddie FastNo ratings yet

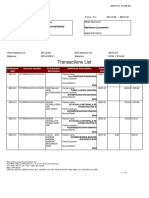

- Transactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinDocument12 pagesTransactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinConstantin MarilenaNo ratings yet

- Outlook of PonDocument12 pagesOutlook of Ponty nguyenNo ratings yet

- National Insurance Mediclaim Claim FormDocument4 pagesNational Insurance Mediclaim Claim FormIhjaz VarikkodanNo ratings yet

- MEMORANDUM OF AGREEMENT DraftsDocument3 pagesMEMORANDUM OF AGREEMENT DraftsRichard Colunga80% (5)

- Guidelines For Doing Business in Grenada & OECSDocument14 pagesGuidelines For Doing Business in Grenada & OECSCharcoals Caribbean GrillNo ratings yet

- Pantone PDFDocument53 pagesPantone PDF2dlmediaNo ratings yet

- Institutions and StrategyDocument28 pagesInstitutions and StrategyFatin Fatin Atiqah100% (1)

- Canon I-SENSYS MF411dw Parts CatalogDocument79 pagesCanon I-SENSYS MF411dw Parts Catalogmarian100% (1)

- Chapter 5 - Principle of Marketing UpdateDocument58 pagesChapter 5 - Principle of Marketing UpdateKhaing HtooNo ratings yet

- SHS G11 Reading and Writing Q3 Week 1 2 V1Document15 pagesSHS G11 Reading and Writing Q3 Week 1 2 V1Romeo Espinosa Carmona JrNo ratings yet

- BV DoshiDocument6 pagesBV DoshiNimNo ratings yet